Production method of high-sulfur phosphorus high-strength steel continuous casting slab for expanding connecting rod

A technology for expanding and breaking connecting rods and high-strength steels is applied in the field of metallurgy, which can solve the problems of corrosion of basic furnace lining ladle, low phosphorus content at the end of smelting, and difficulty in controlling the composition of steel grades, so as to achieve low production cost, excellent surface quality, Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

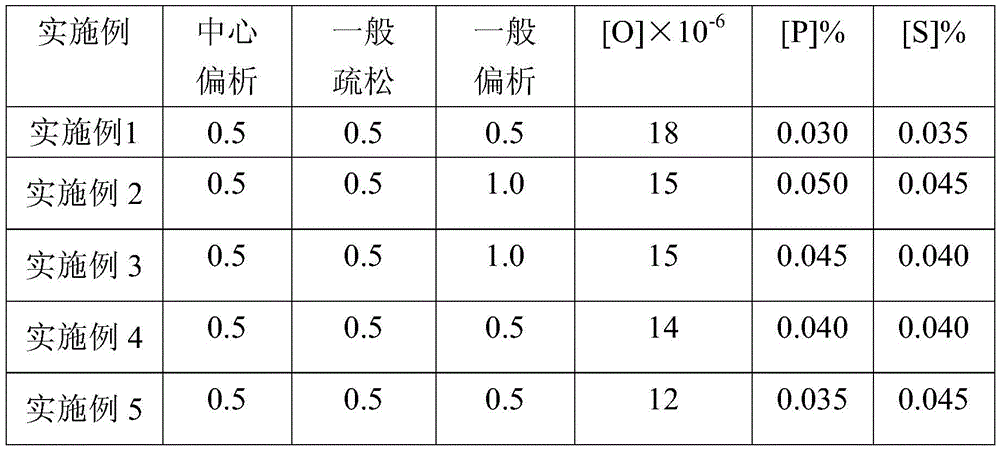

Examples

Embodiment 1

[0026] Produce a kind of continuous casting slab of high-sulfur phosphorus high-strength steel for the expansion and breaking of connecting rods of automobile engines, the production method steps of the continuous casting slab are as follows:

[0027] 1) Electric furnace smelting: use molten iron and steel scrap as raw materials, and the weight ratio of molten iron and steel scrap is 6:1; in the early stage of smelting, the temperature rises rapidly for decarburization and less slag flow, and the final oxidation temperature is controlled to 1630°C, and the final carbon content is 0.30% , the final phosphorus content is 0.030%;

[0028] 2) Tapping at the center of the bottom of the electric furnace: Tapping adopts the operation of leaving steel and slag, and adding 4.0kg / t of active lime, 2.0kg / t of ferrous sulfide, and 1.5kg / t of aluminum block to the ladle when tapping 1 / 3 of the steel, Silicon calcium barium 2.5kg / t, control the oxygen content in the subsequent LF refining f...

Embodiment 2

[0033] Produce a kind of continuous casting slab of high-sulfur phosphorus high-strength steel for the expansion and breaking of connecting rods of automobile engines, the production method steps of the continuous casting slab are as follows:

[0034] 1) Electric furnace smelting: use molten iron and steel scrap as raw materials, the weight ratio of molten iron and steel scrap is 8:1; in the early stage of smelting, the temperature rises rapidly for decarburization and less slag flow, and the final oxidation temperature is controlled to 1645°C, and the final carbon content is 0.35% , the final phosphorus content is 0.045%;

[0035] 2) Tapping at the partial bottom center of the electric furnace: tapping adopts the operation of leaving steel and slag, adding 3.0kg / t of active lime, 2.5kg / t of ferrous sulfide, and 1.2kg / t of aluminum block to the ladle when tapping 1 / 3 of the steel, Silicon calcium barium 2.3kg / t, control the oxygen content in the subsequent LF refining furnace ...

Embodiment 3

[0040] Produce a kind of continuous casting slab of high-sulfur phosphorus high-strength steel for the expansion and breaking of connecting rods of automobile engines, the production method steps of the continuous casting slab are as follows:

[0041] 1) Electric furnace smelting: use molten iron and steel scrap as raw materials, the weight ratio of molten iron and steel scrap is 8:1; in the early stage of smelting, the temperature rises rapidly for decarburization and less slag flow, and the final oxidation temperature is controlled to 1630°C, and the final carbon content is 0.40% , the final phosphorus content is 0.042%;

[0042] 2) Tapping at the center of the bottom of the electric furnace: Tapping adopts the operation of leaving steel and slag. When tapping 1 / 3, add 3.5kg / t of active lime, 2.2kg / t of ferrous sulfide, and 1.2kg / t of aluminum block to the ladle, Silicon calcium barium 2.2kg / t, control the oxygen content in the subsequent LF refining furnace to be 70ppm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com