Patents

Literature

36results about How to "The process line is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

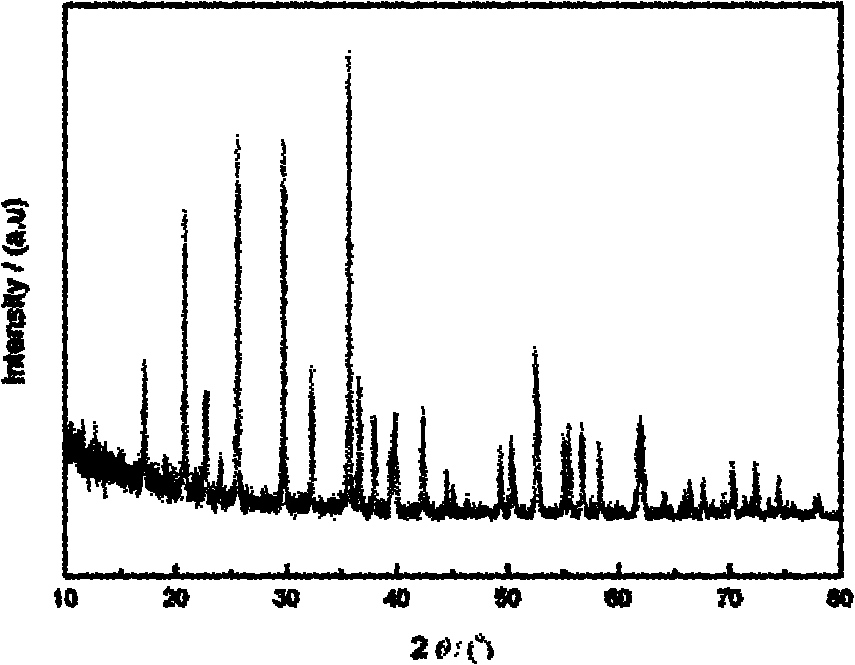

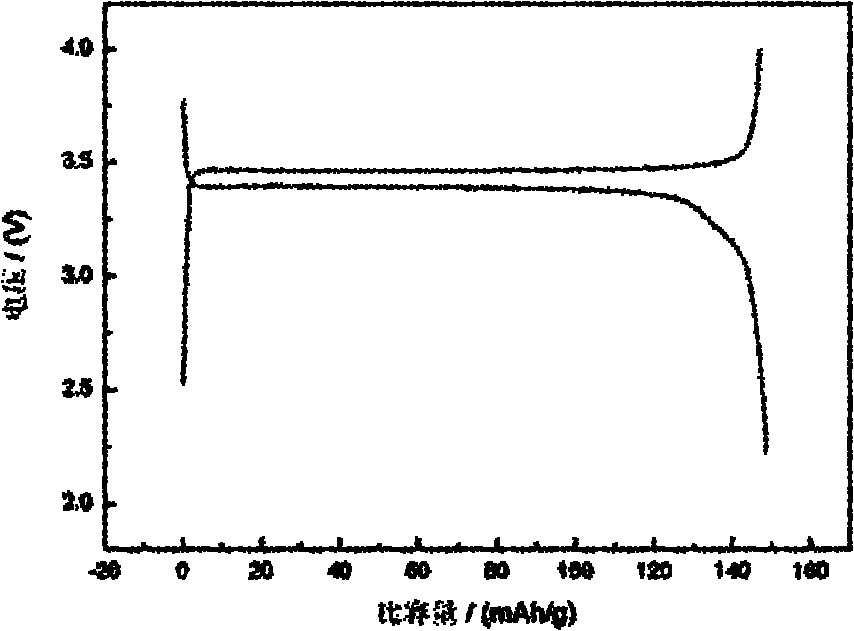

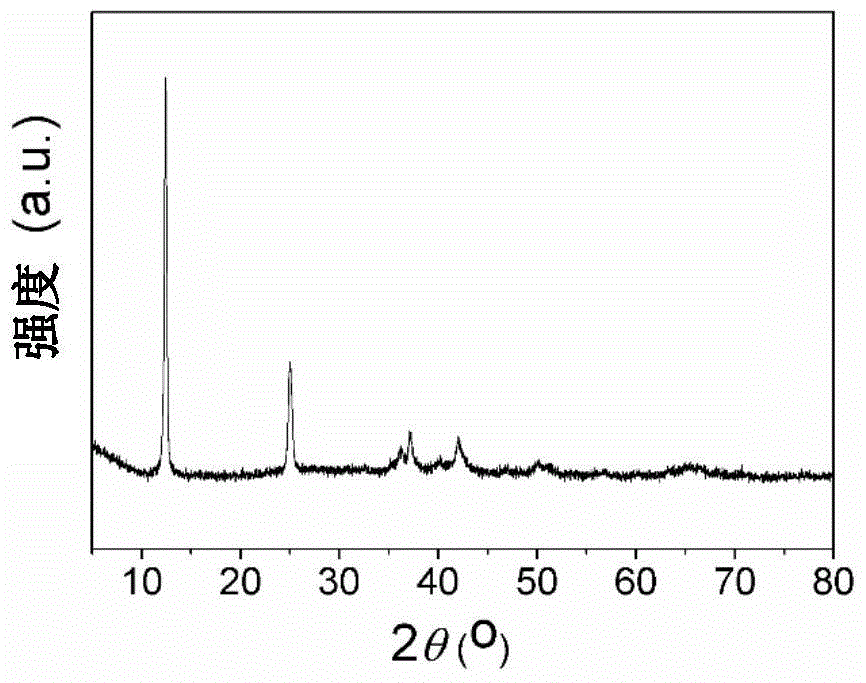

Anode material of high-magnification aqueous alkali metal electrochemical battery and preparation method of anode material

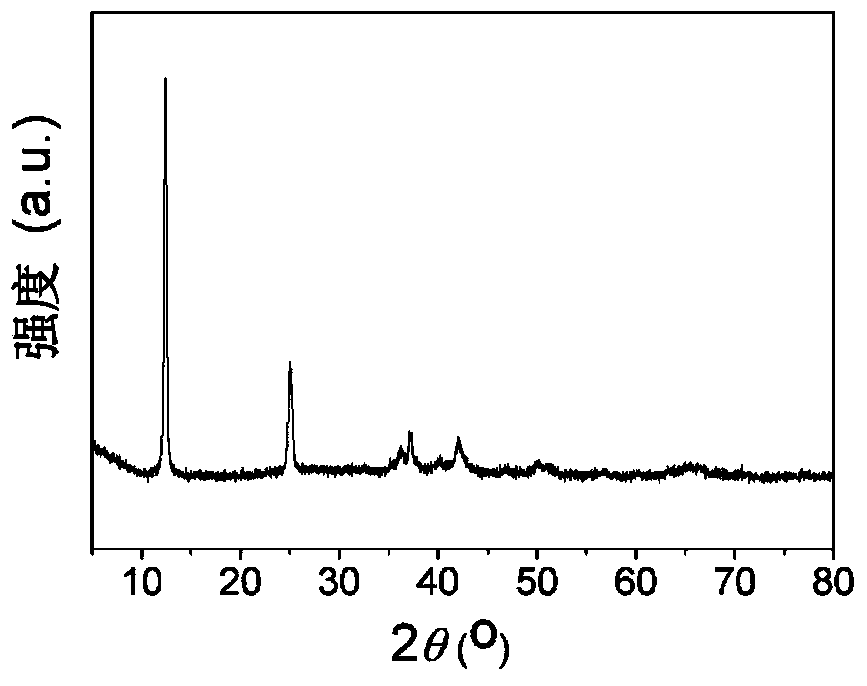

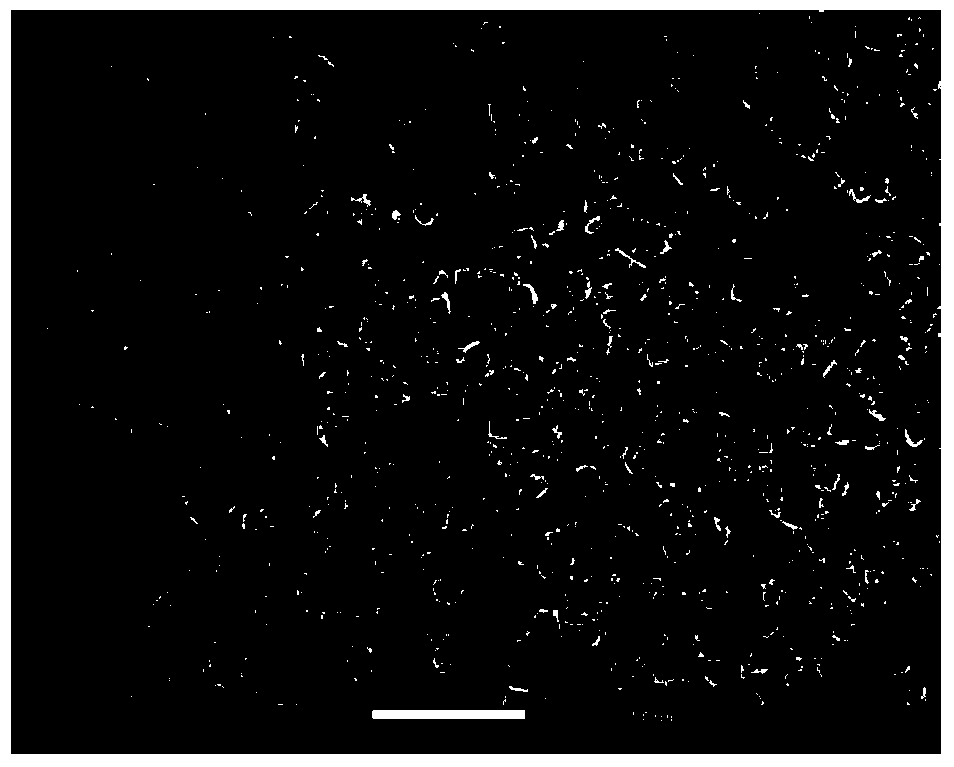

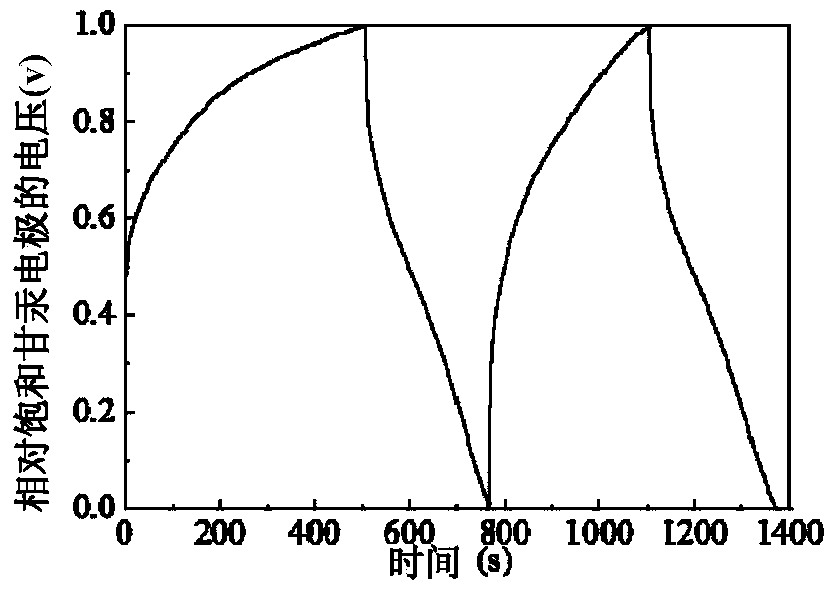

ActiveCN103441259APromote prolapseImprove electrochemical performanceAlkaline accumulatorsCell electrodesManganateCrystal structure

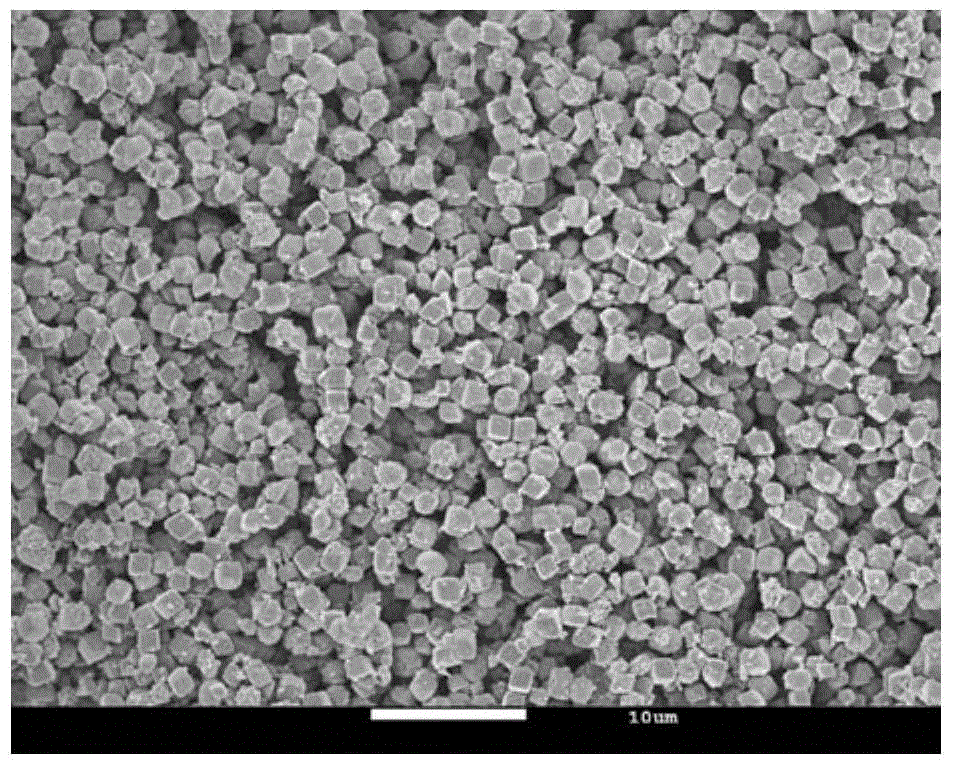

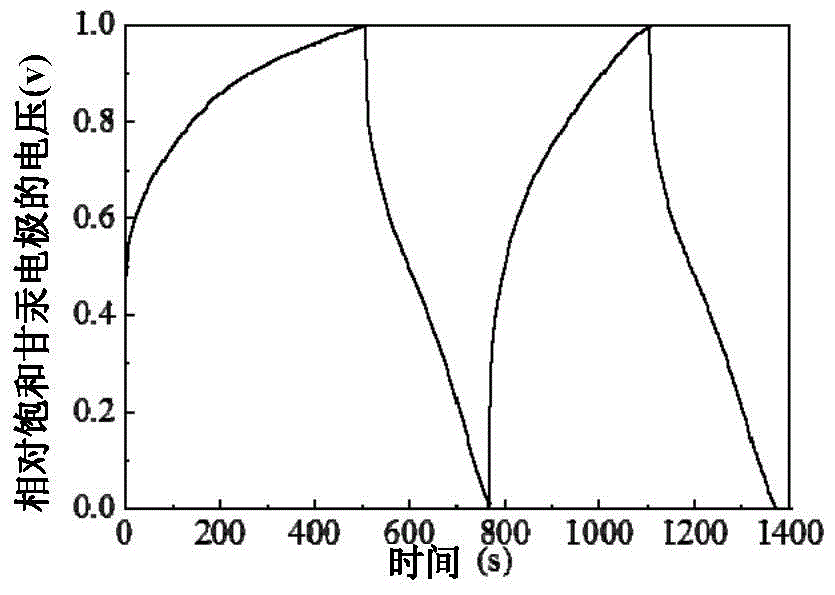

The invention relates to an anode material of a high-magnification aqueous alkali metal electrochemical battery and a preparation method of the anode material. The anode material is characterized is that the anode material is manganate with alkali metal of which the formula is AxMnO2, wherein A is one or two selected from Na and K; x is greater than 0 and less than 1; the crystal structure of the manganate with the alkali metal is of a layer-shaped structure. The anode material is of a nano-crystallized three-dimensional shape, the specific surface area of the material is increased, a conduction route for ions and electrons in an aqueous electrolyte is reduced, and the magnification property of an electrode material can be effectively improved.

Owner:ENPOWER ENERGY TECH ANHUI CO LTD +1

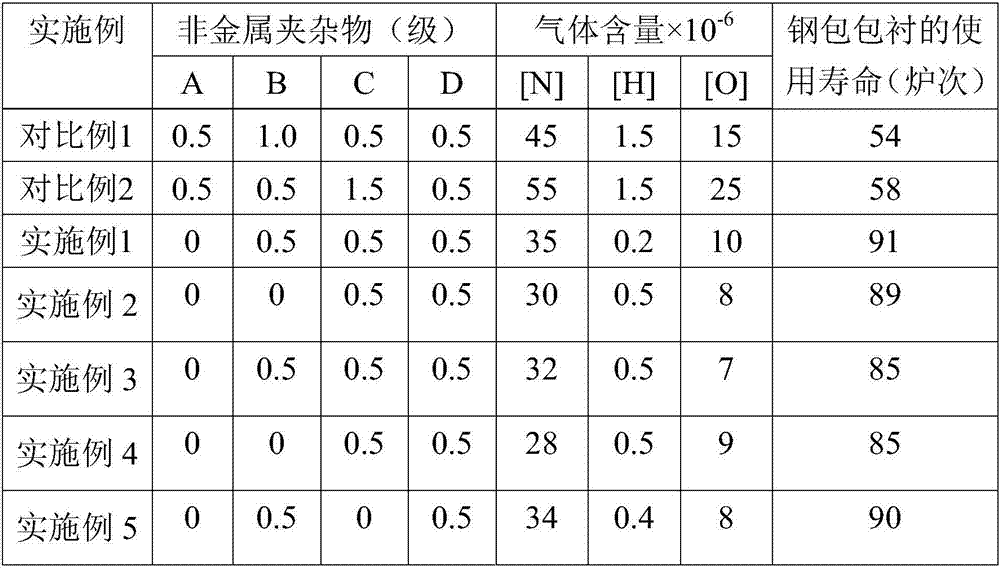

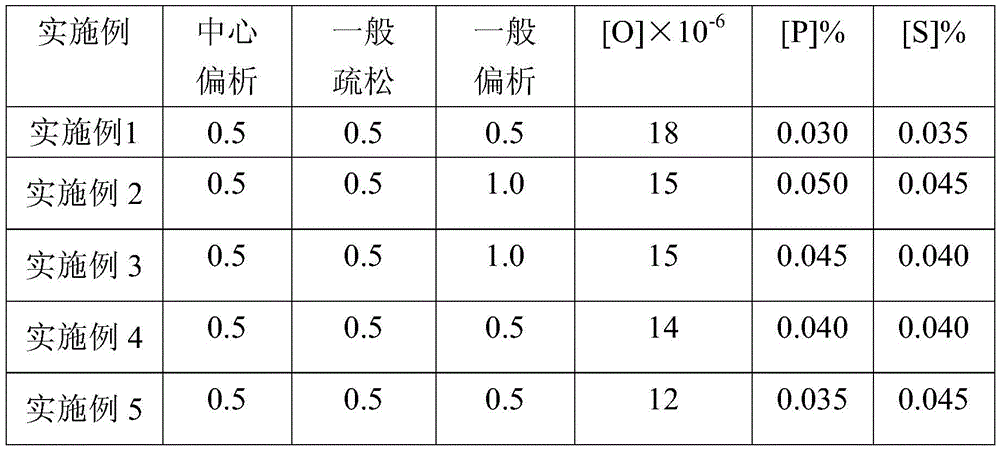

High-cleanliness low-carbon and low-silicon welding steel wire and preparation method of same

ActiveCN103243263AReduce manufacturing costSave energyWelding/cutting media/materialsSoldering mediaChemical compositionSlag

The invention discloses a high-cleanliness low-carbon and low-silicon welding steel wire and a preparation method of the same. The welding steel wire comprises the following chemical components by weight percent: 0.002-0.10% of C, 0.005-0.04% of Si, 0.35-0.60% of Mn, 0.001-0.006% of P, 0.001-0.003% of S, 0.001-0.007% of As, 0.001-0.015% of Al, 0.005-0.015% of Sn, 0.005-0.01% of N, 0.05-0.20% of Ti, 0.0005-0.002% of O and the balance of Fe. The preparation method comprises the following steps of: discharging steel from a primary smelting electric furnace, measuring the temperature of the molten steel after the molten steel enters a ladle furnace, sequentially adding a first batch of slag charge and a second batch of slag charge, and then, continuously casting while performing electromagnetic stirring. The preparation method is low in production cost and energy-saving; and the technology provided by the invention is simple in route and strong in operability.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

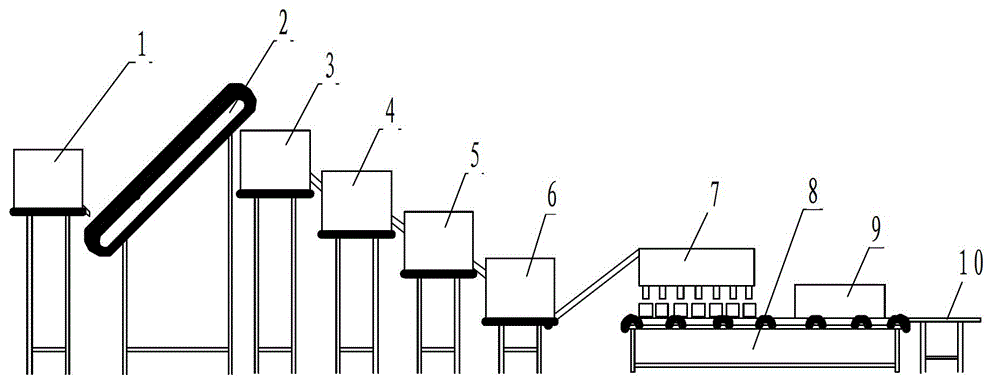

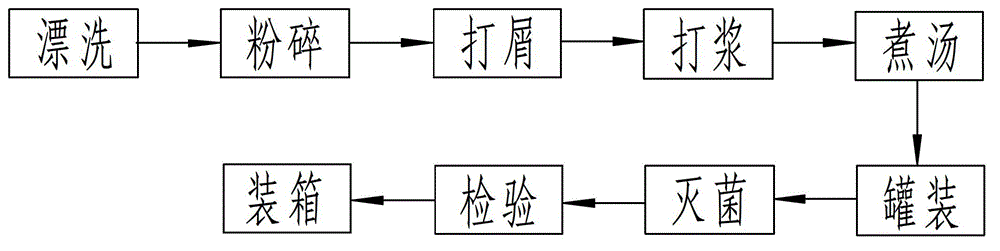

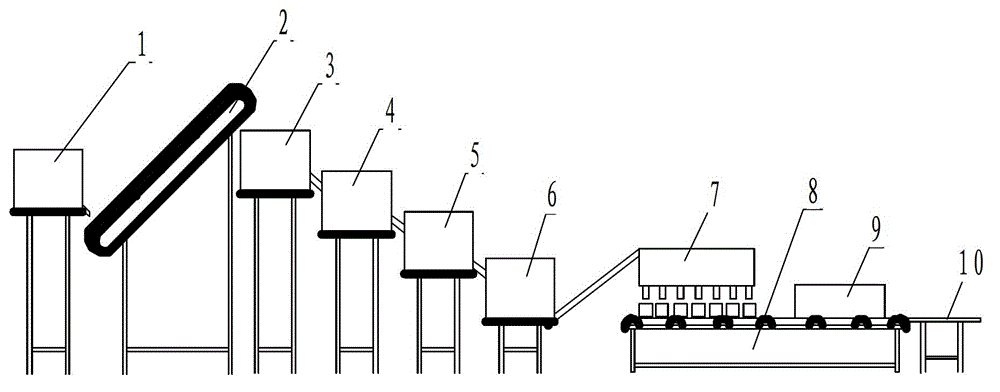

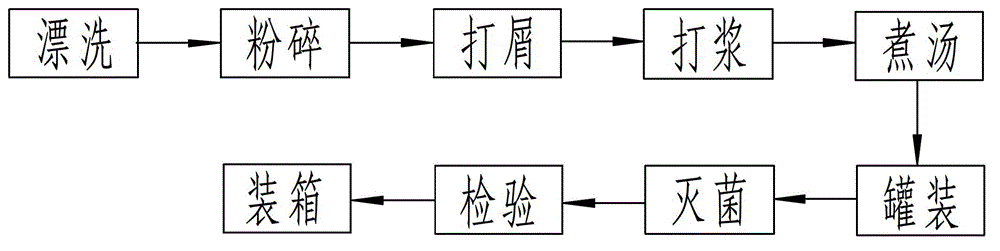

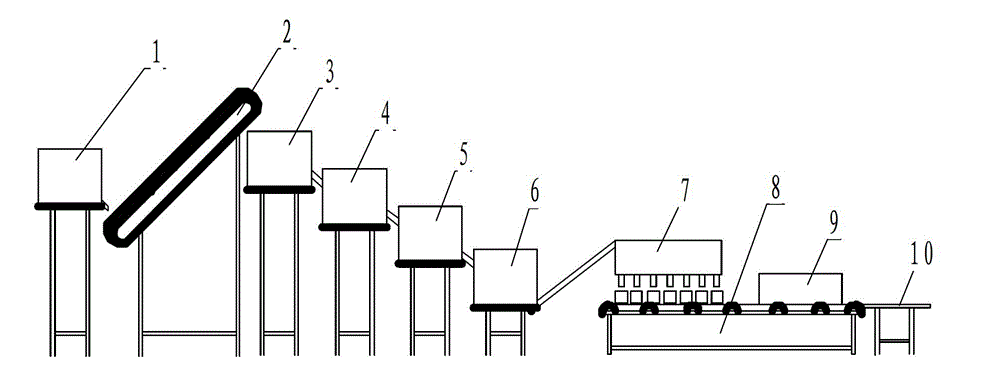

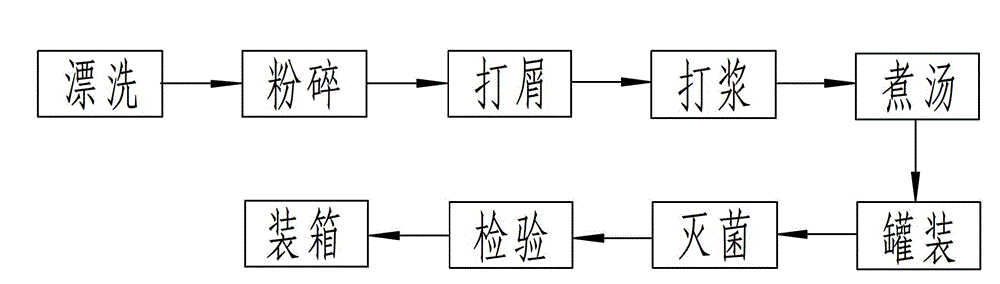

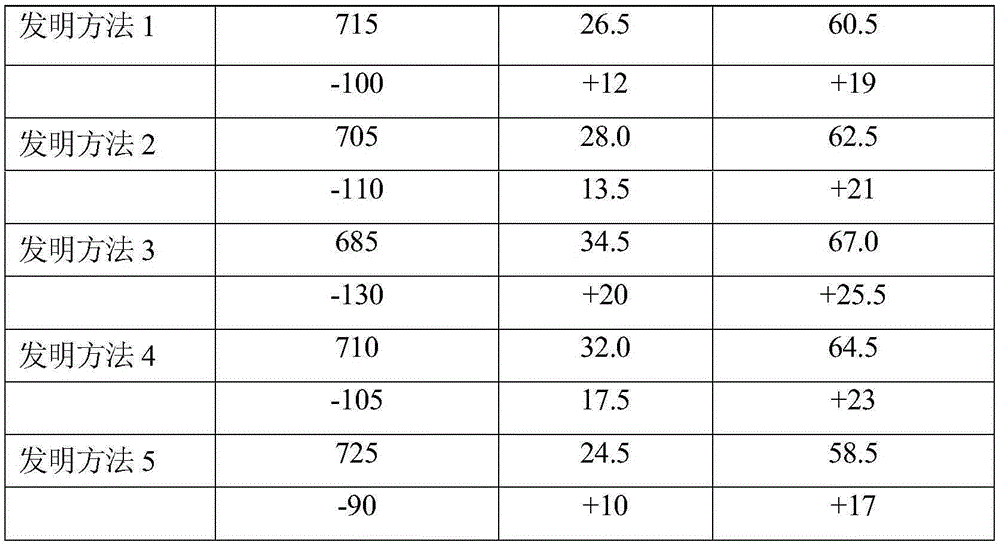

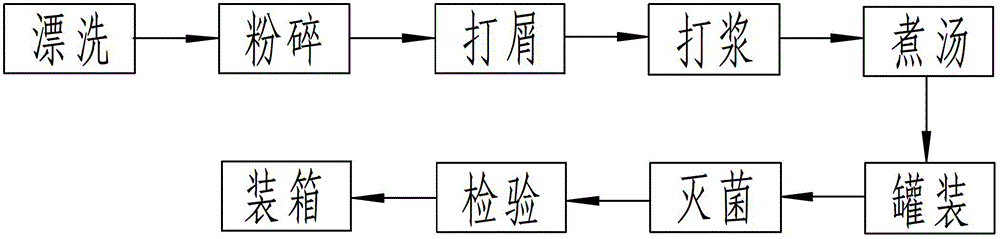

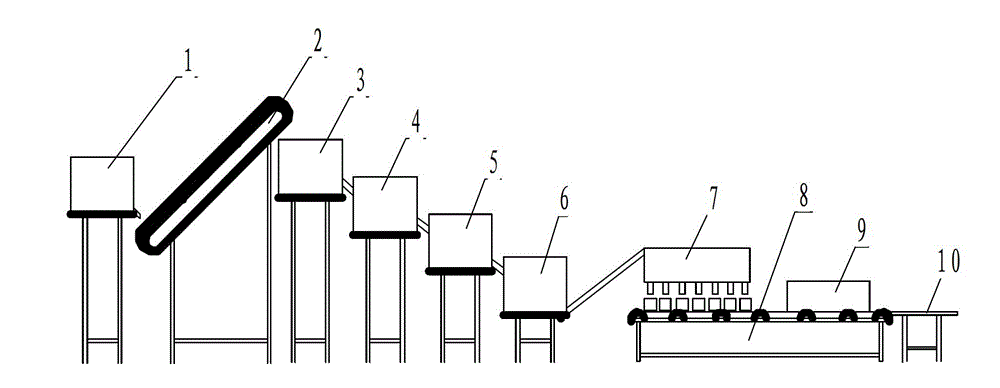

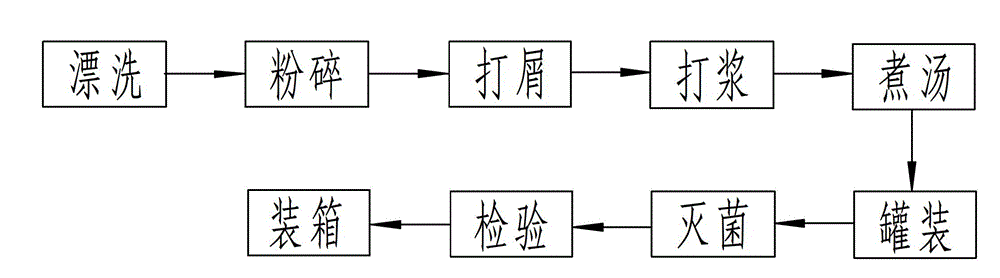

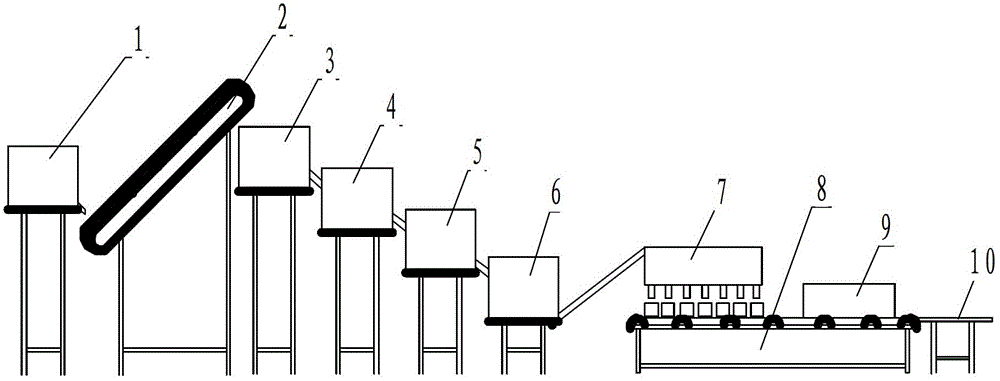

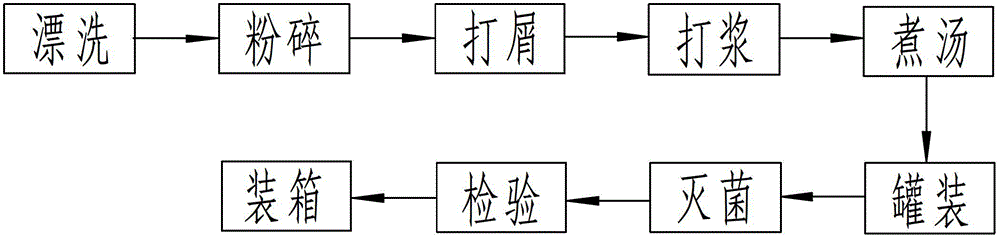

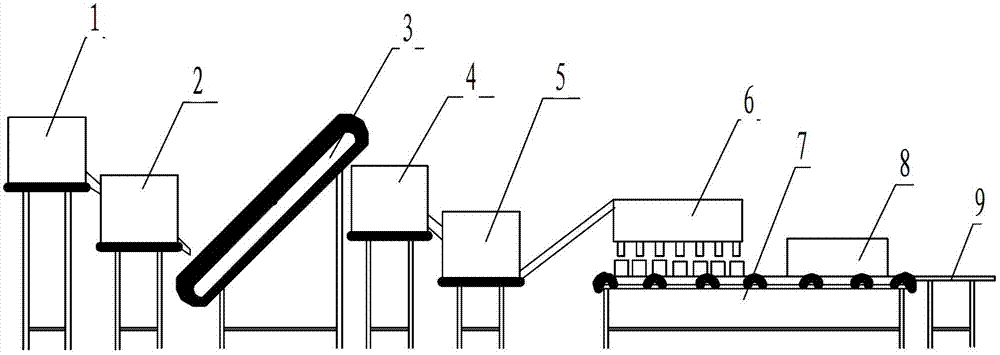

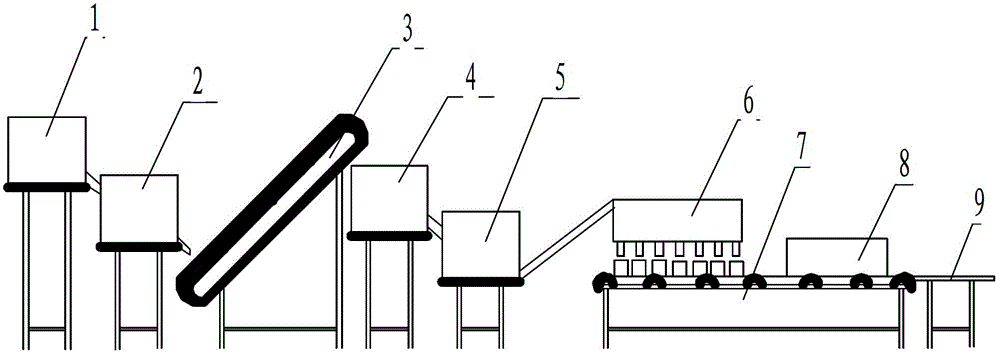

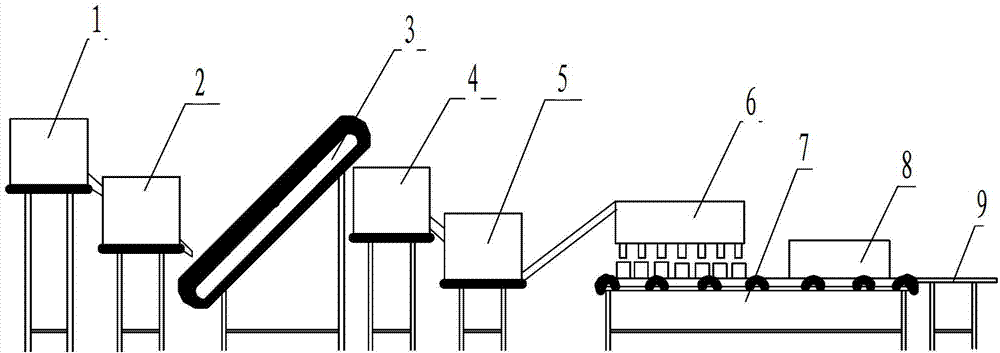

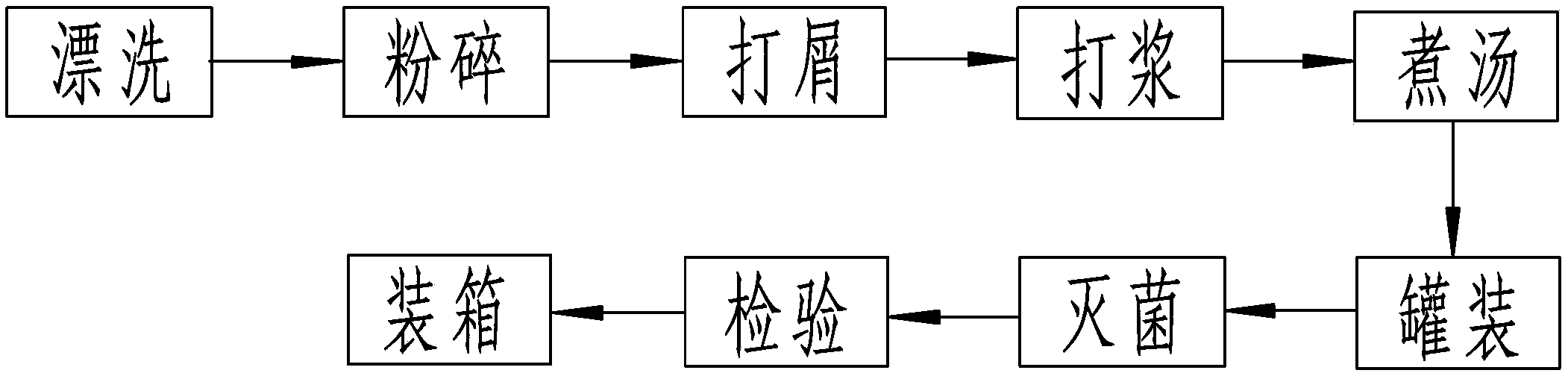

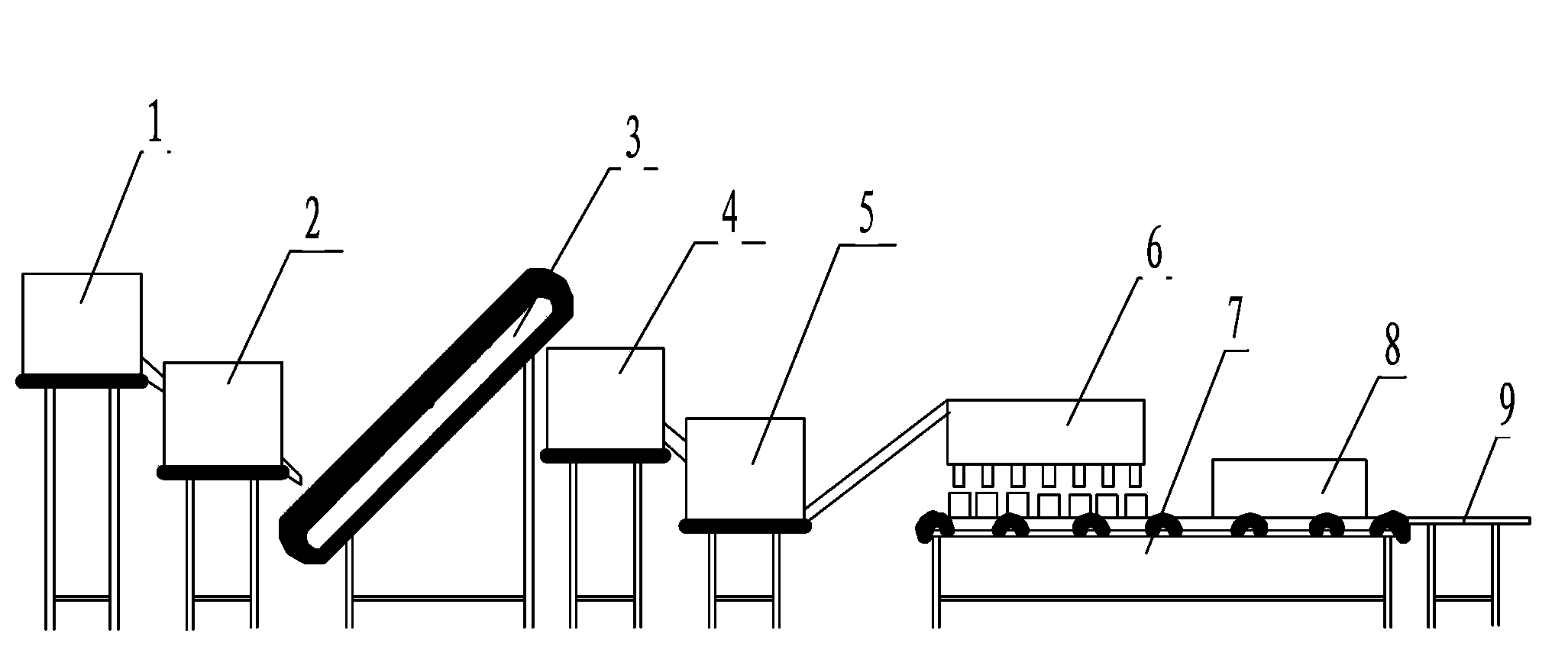

Preparation method of Pleurotus eryngii soup

InactiveCN103141886AChange the way you eatFull use of nutritional valueFood preparationProduction lineNutritive values

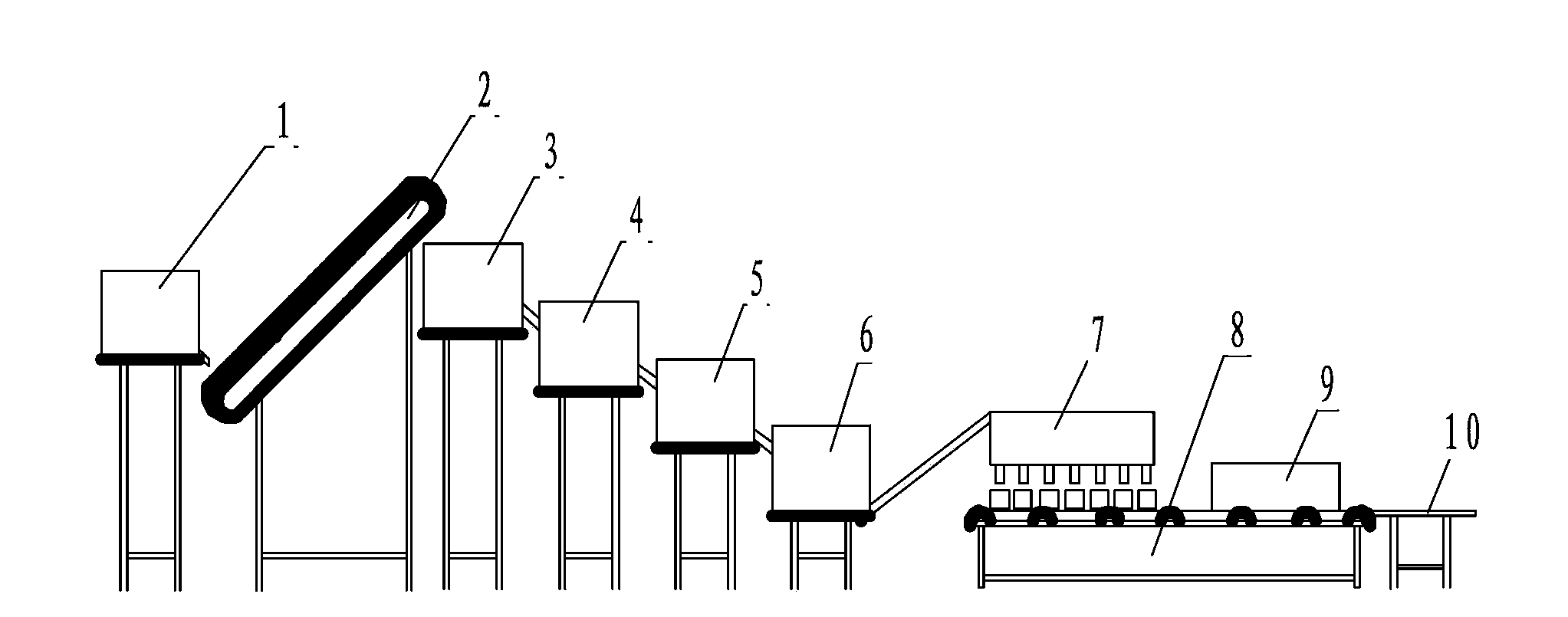

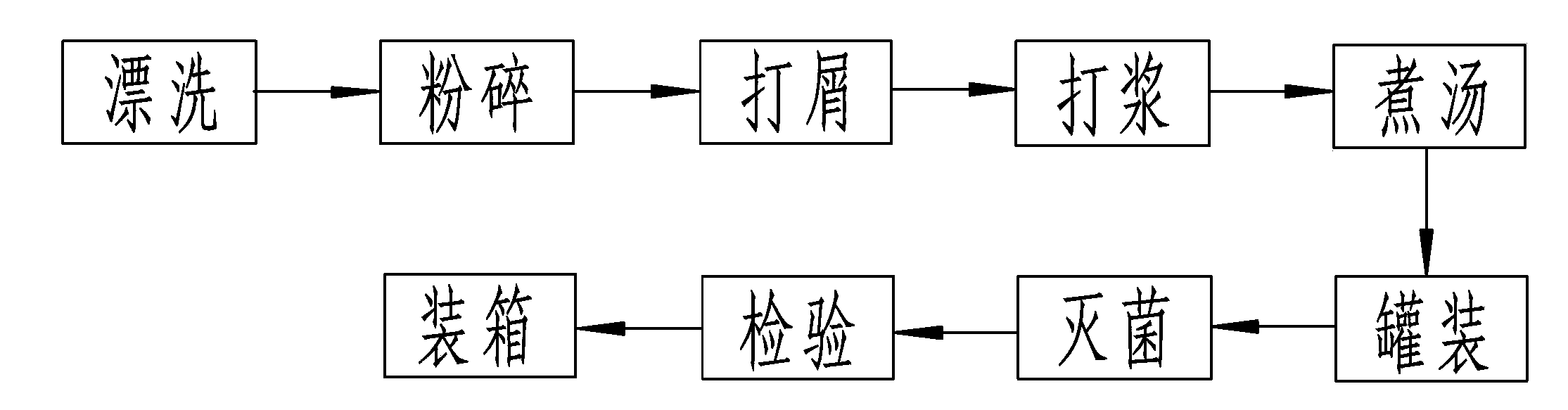

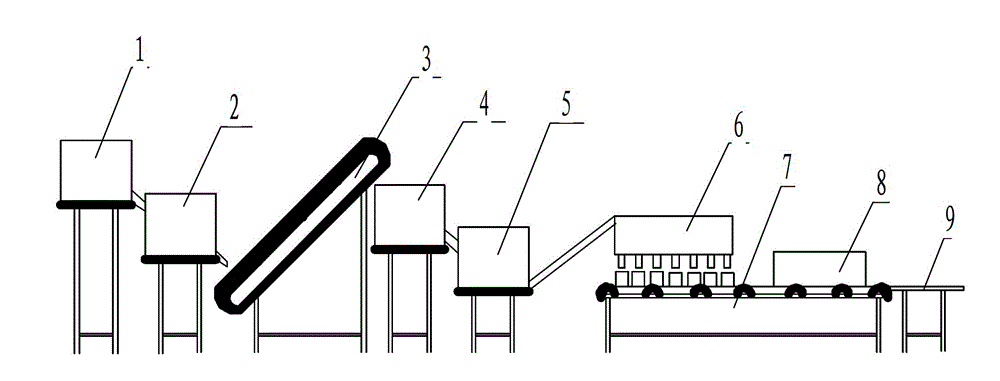

The invention relates to a preparation method of Pleurotus eryngii soup, which comprises the following steps: rinsing raw material Pleurotus eryngii in a rinser, pulverizing in a pulverizer, granulating in a granulator, making Pleurotus eryngii pulp in a pulping machine, decocting in a soup decocting machine for 3-6 hours to obtain Pleurotus eryngii soup, canning, sterilizing, inspecting on an inspection platform to obtain qualified products, and boxing. The invention solves the problems of low income in spite of high yield of Pleurotus eryngii, unnecessary economic loss for people due to rotting of the Pleurotus eryngii which is hard to store, and severe waste of Pleurotus eryngii leftover resources, and enhances the utilization ratio of the Pleurotus eryngii Pleurotus eryngii and the added value of the Pleurotus eryngii; and the Pleurotus eryngii soup is convenient to carry and eat, fully utilizes the pure natural nutritive value of the Pleurotus eryngii, can be absorbed by the human body more easily, and enhances the immunological competence of the human body. The invention has the advantages of simple technical production line, high production efficiency, low investment and high income, is economical and practical, has an active action on environmental protection, has wide market prospects, and is suitable for popularization.

Owner:LUOYANG CHUNKUI AGRI DEV

Preparation method of pine mushroom soup

The invention relates to a preparation method of pine mushroom soup, which comprises the following steps: rinsing raw material pine mushroom in a rinser, pulverizing in a pulverizer, granulating in a granulator, making pine mushroom pulp in a pulping machine, decocting in a soup decocting machine for 3-6 hours to obtain pine mushroom soup, canning, sterilizing, inspecting on an inspection platform to obtain qualified products, and boxing. The invention solves the problems of low income in spite of high yield of pine mushroom, unnecessary economic loss for people due to rotting of the pine mushroom which is hard to store, and severe waste of pine mushroom leftover resources, and enhances the utilization ratio of the pine mushroom leftovers and the added value of the pine mushroom; and the pine mushroom soup is convenient to carry and eat, fully utilizes the pure natural nutritive value of the pine mushroom, can be absorbed by the human body more easily, and enhances the immunological competence of the human body. The invention has the advantages of simple technical production line, high production efficiency, low investment and high income, is economical and practical, has an active action on environmental protection, has wide market prospects, and is suitable for popularization.

Owner:LUOYANG CHUNKUI AGRI DEV

Preparation method of straw mushroom soup

InactiveCN103141819AChange the way you eatFull use of nutritional valueFood preparationProduction lineNutritive values

The invention relates to a preparation method of straw mushroom soup, which comprises the following steps: rinsing raw material straw mushroom in a rinser, pulverizing in a pulverizer, granulating in a granulator, making straw mushroom pulp in a pulping machine, decocting in a soup decocting machine for 3-6 hours to obtain straw mushroom soup, canning, sterilizing, inspecting on an inspection platform to obtain qualified products, and boxing. The invention solves the problems of low income in spite of high yield of straw mushroom, unnecessary economic loss for people due to rotting of the straw mushroom which is hard to store, and severe waste of straw mushroom leftover resources, and enhances the utilization ratio of the straw mushroom leftovers and the added value of the straw mushroom; and the straw mushroom soup is convenient to carry and eat, fully utilizes the pure natural nutritive value of the straw mushroom, can be absorbed by the human body more easily, and enhances the immunological competence of the human body. The invention has the advantages of simple technical production line, high production efficiency, low investment and high income, is economical and practical, has an active action on environmental protection, has wide market prospects, and is suitable for popularization.

Owner:LUOYANG CHUNKUI AGRI DEV

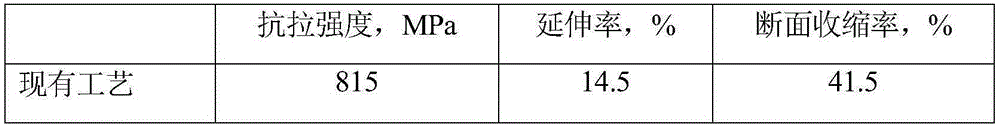

Production method of high-plasticity steel wire rod for welding

The invention relates to a production method of a high-plasticity steel wire rod for welding, comprising the steps of heating, descaling, rough rolling, pre-finish rolling, finish rolling, spinning, cold control, cooling and transportation. The strength of steel for welding is reduced and the plasticity is improved through such methods as rolling temperature control, rolling mill cooling water control, air volume control and insulation measure; and the generation of bad phenomenon in the drawing machining process is effectively improved.

Owner:武钢集团有限公司

Preparation method of phoenix mushroom soup

InactiveCN103141881AChange the way you eatFull use of nutritional valueFood preparationProduction lineNutritive values

The invention relates to a preparation method of phoenix mushroom soup, which comprises the following steps: rinsing raw material phoenix mushroom in a rinser, pulverizing in a pulverizer, granulating in a granulator, making phoenix mushroom pulp in a pulping machine, decocting in a soup decocting machine for 3-6 hours to obtain phoenix mushroom soup, canning, sterilizing, inspecting on an inspection platform to obtain qualified products, and boxing. The invention solves the problems of low income in spite of high yield of phoenix mushroom, unnecessary economic loss for people due to rotting of the phoenix mushroom which is hard to store, and severe waste of phoenix mushroom leftover resources, and enhances the utilization ratio of the phoenix mushroom leftovers and the added value of the phoenix mushroom; and the phoenix mushroom soup is convenient to carry and eat, fully utilizes the pure natural nutritive value of the phoenix mushroom, can be absorbed by the human body more easily, and enhances the immunological competence of the human body. The invention has the advantages of simple technical production line, high production efficiency, low investment and high income, is economical and practical, has an active action on environmental protection, has wide market prospects, and is suitable for popularization.

Owner:LUOYANG CHUNKUI AGRI DEV

Preparation method of Calocybe gambosa soup

The invention relates to a preparation method of Calocybe gambosa soup, which comprises the following steps: rinsing raw material Calocybe gambosa in a rinser, pulverizing in a pulverizer, granulating in a granulator, making Calocybe gambosa pulp in a pulping machine, decocting in a soup decocting machine for 3-6 hours to obtain Calocybe gambosa soup, canning, sterilizing, inspecting on an inspection platform to obtain qualified products, and boxing. The invention solves the problems of low income in spite of high yield of Calocybe gambosa, unnecessary economic loss for people due to rotting of the Calocybe gambosa which is hard to store, and severe waste of Calocybe gambosa leftover resources, and enhances the utilization ratio of the Calocybe gambosa leftovers and the added value of the Calocybe gambosa; and the Calocybe gambosa soup is convenient to carry and eat, fully utilizes the pure natural nutritive value of the Calocybe gambosa, can be absorbed by the human body more easily, and enhances the immunological competence of the human body. The invention has the advantages of simple technical production line, high production efficiency, low investment and high income, is economical and practical, has an active action on environmental protection, has wide market prospects, and is suitable for popularization.

Owner:LUOYANG CHUNKUI AGRI DEV

Preparation method of oyster mushroom soup

InactiveCN103141880AChange the way you eatPromote absorptionFood preparationProduction lineNutritive values

The invention relates to a preparation method of oyster mushroom soup, which comprises the following steps: rinsing raw material oyster mushroom in a rinser, pulverizing in a pulverizer, granulating in a granulator, making oyster mushroom pulp in a pulping machine, decocting in a soup decocting machine for 3-6 hours to obtain oyster mushroom soup, canning, sterilizing, inspecting on an inspection platform to obtain qualified products, and boxing. The invention solves the problems of low income in spite of high yield of oyster mushroom, unnecessary economic loss for people due to rotting of the oyster mushroom which is hard to store, and severe waste of oyster mushroom leftover resources, and enhances the utilization ratio of the oyster mushroom leftovers and the added value of the oyster mushroom; and the oyster mushroom soup is convenient to carry and eat, fully utilizes the pure natural nutritive value of the oyster mushroom, can be absorbed by the human body more easily, and enhances the immunological competence of the human body. The invention has the advantages of simple technical production line, high production efficiency, low investment and high income, is economical and practical, has an active action on environmental protection, has wide market prospects, and is suitable for popularization.

Owner:LUOYANG CHUNKUI AGRI DEV

Method for preparing carbon clad lithium iron phosphate

InactiveCN102013478AImprove electrochemical performanceWell mixedCell electrodesUltrasonic radiationNew energy

The invention discloses a method for preparing carbon clad lithium iron phosphate, belongs to the technical field of new energy materials, and aims to provide a preparation method in which preliminary materials are mixed uniformly, precursor crystal particles are small, and carbon clad lithium iron phosphate with high electrochemical performance can easily obtained in the late stage of sintering. The technical key point is that the method comprises the following steps of: preparing a lithium source, ferrite, phosphate and a carbon source according to a stoichiometric ratio of 1:1:1-1.5:0.05-0.1, throwing into solution and mixing, and directly putting in ultrasonic radiation equipment for performing ultrasonic radiation treatment; and centrifugally washing and treating LiFePO4 precursors obtained by filtration, and roasting at the temperature between 300 and 1,000 DEG C for 6 to 24 hours at a nitrogen protective atmosphere so as to prepare the carbon clad lithium iron phosphate. The method has low cost, and a simple technical route and industrial continuous production can be easily realized.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

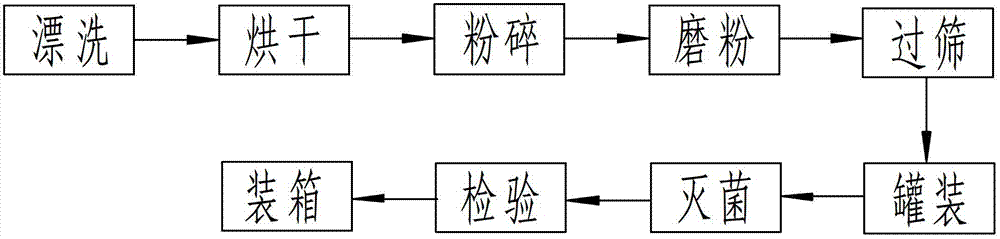

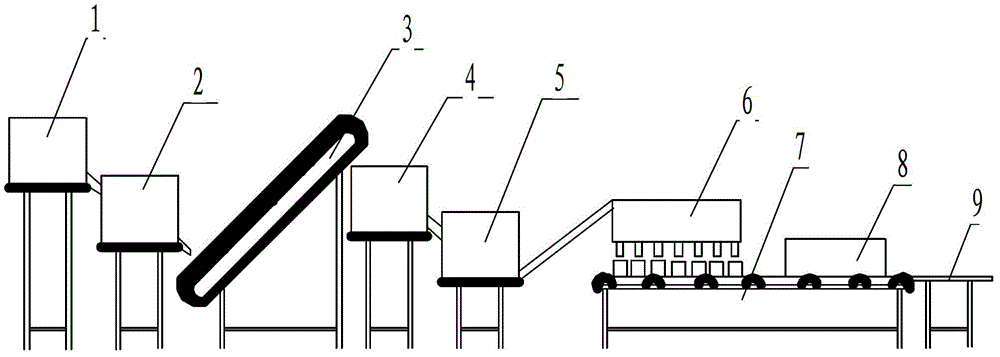

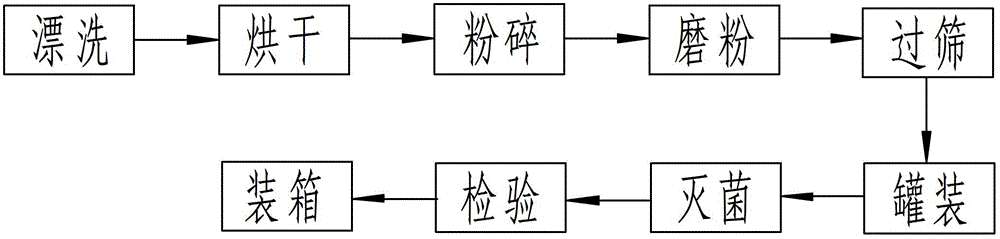

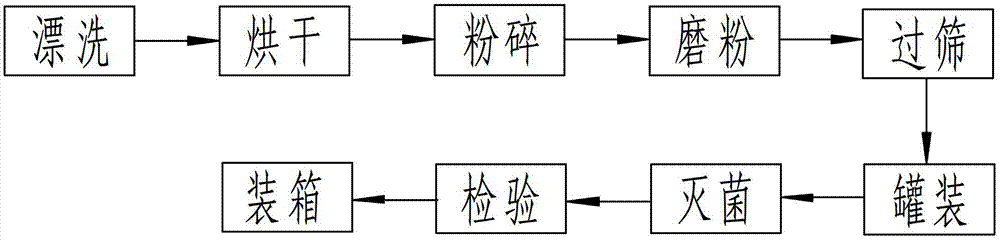

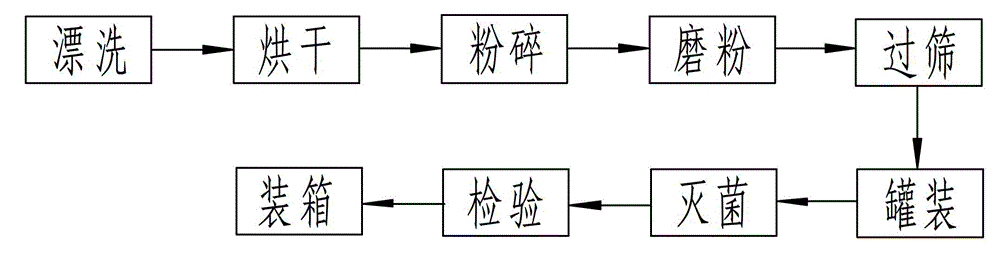

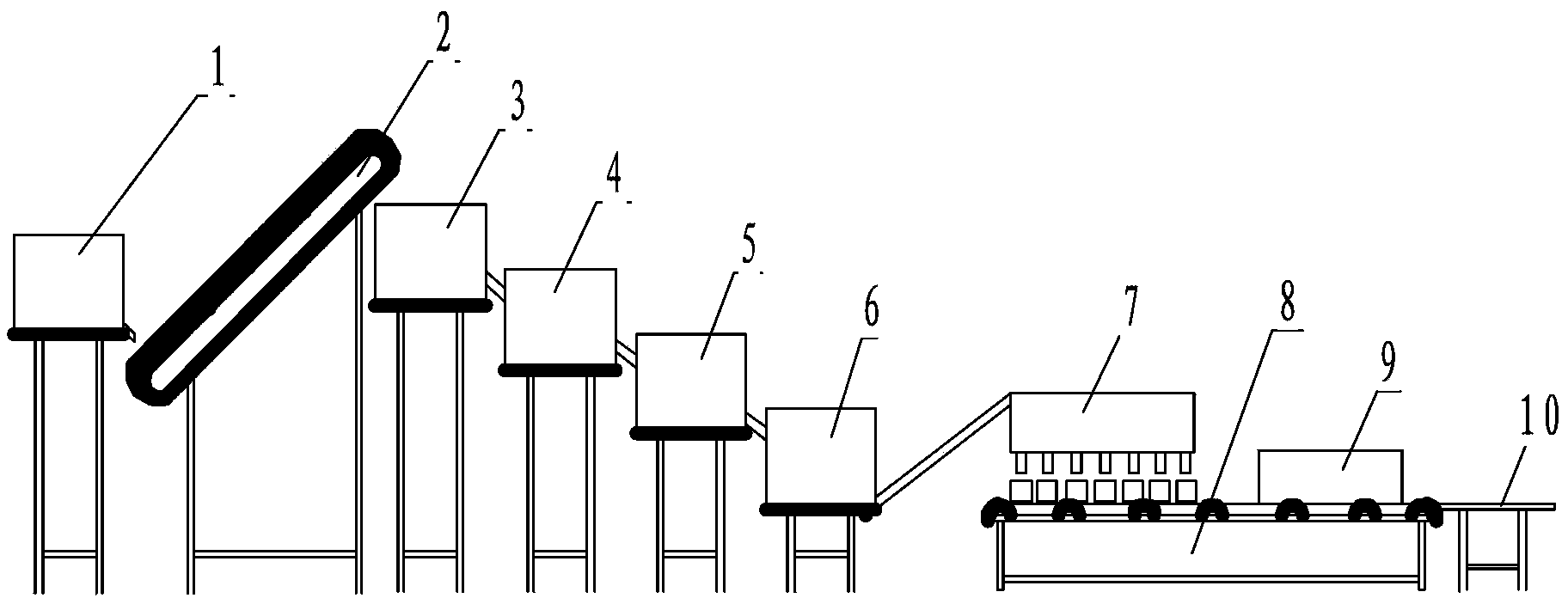

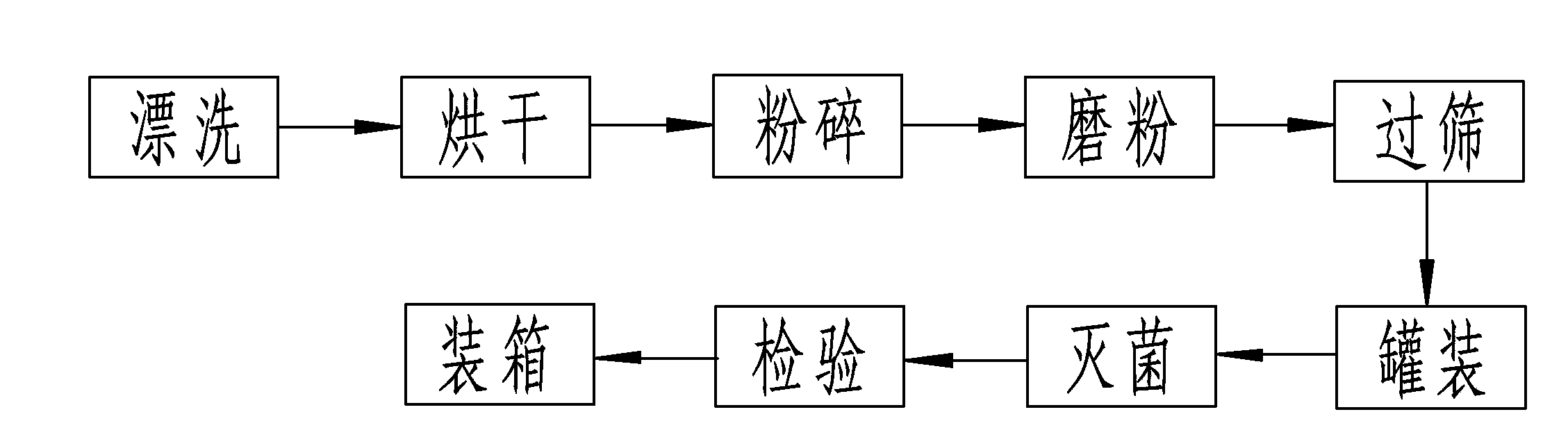

Preparation method of flammulina velutipes powder

A preparation method of flammulina velutipes powder comprises pouring the raw material flammulina velutipes into a washing machine, rinsing, drying in a drier, crushing in a grinding mill to obtain the flammulina velutipes powder of 40 - 200 meshes in the grinding mill, canning, sterilizing, testing on test platform, and packing after the test is passed. The method solves problems of high yield but low income of the flammulina velutipes, unnecessary economic losses to people caused by difficult storage and thus decaying of the flammulina velutipes, and serious waste of leftover flammulina velutipes; and also increases utilization of the leftover flammulina velutipes and added values of the flammulina velutipes. The flammulina velutipes powder is easy to carry and convenient to eat, fully utilizes natural nutritional values of the flammulina velutipes, and is relatively conducive to human body's absorption, thereby enhancing human immunity. The method has advantages of simple production line, high production efficiency, low investment and high return, is economical and practical, has positive effects on environmental protection, is broad in market prospects, and thus is suitable for popularization and use.

Owner:LUOYANG CHUNKUI AGRI DEV

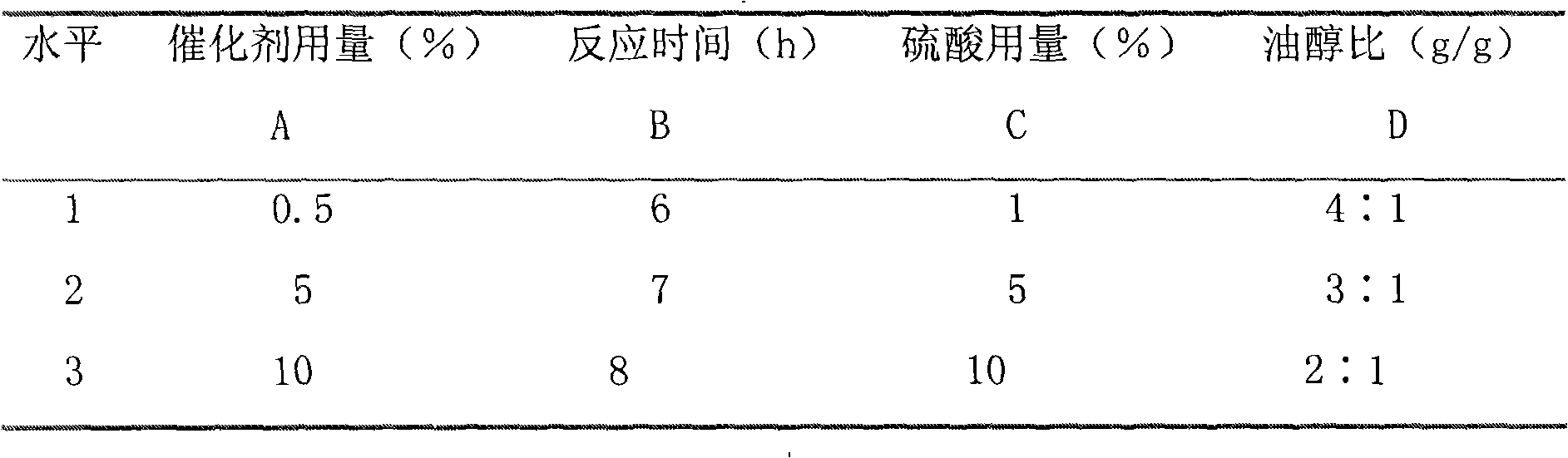

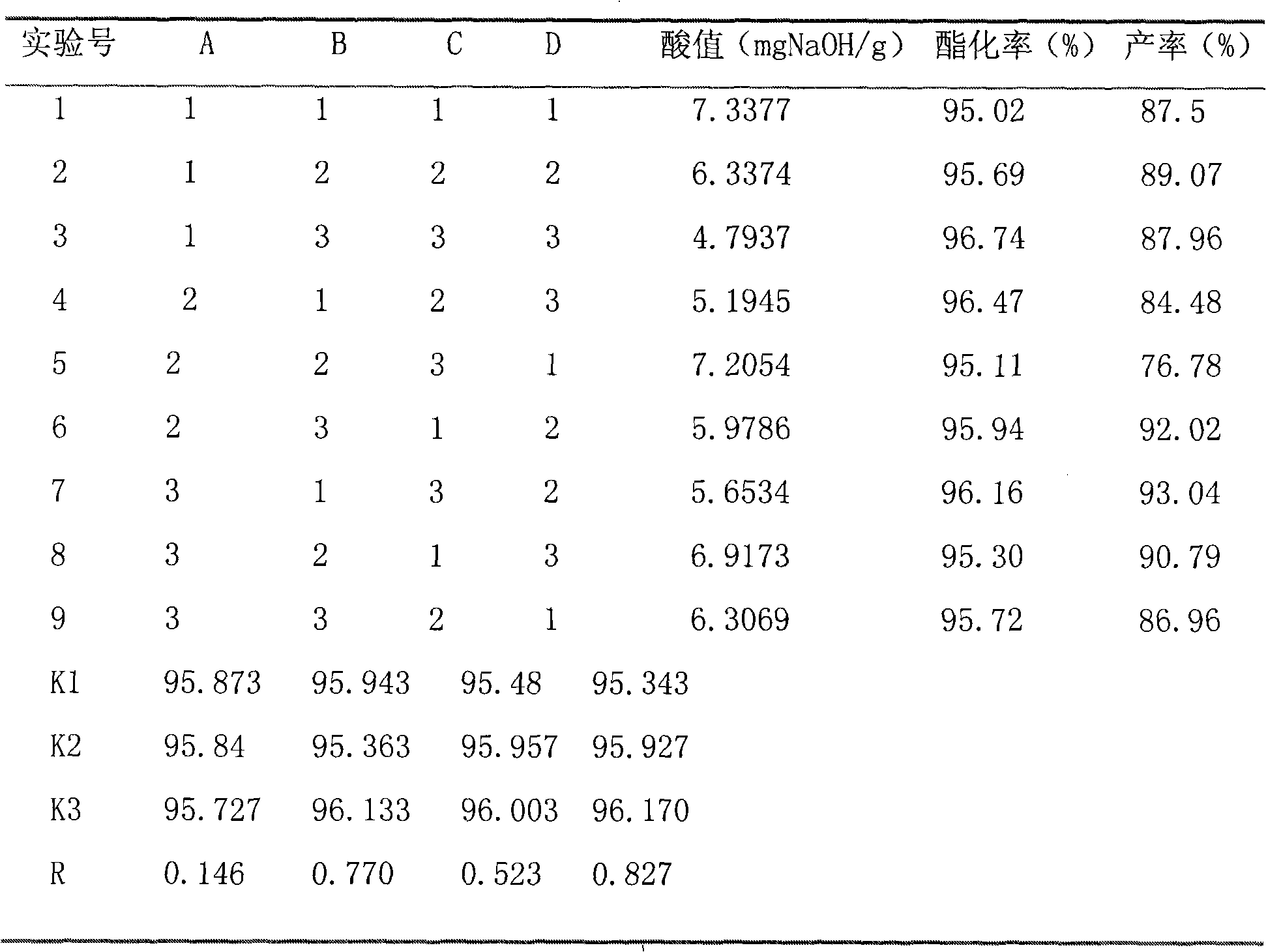

Method for preparing biological diesel oil by using inversed micelle catalyst

InactiveCN101294098AThe process line is simpleIncrease productivityFatty oils/acids recovery from wastePhysical/chemical process catalystsChemistrySulfuric acid

A method for preparing bio-diesel by using reverse micelle catalyst is specifically suitable for the resource utilization of various waste oil such as tailings of oil plants, cooking oil, waste oil, soapstock, swill oil and so on to directly transform waste oil into the increasingly demanded diesel substitute, i.e. bio-diesel, in a reverse micelle catalysis system. The reverse micelle catalyst is composed of surfactant, water and alcohol at a proper ratio. The method comprises the following steps: adding sulfuric acid in the waste oil, introducing steam, boiling, washing with water, and separating to obtain an acidified oil layer; and adding a reverse micelle catalyst at an amount of 0.5 to 10% that of the oil and alcohol at an amount of 10 to 50% that of the acidified oil slowly, stirring at a speed of 1,500 to 3,000 rpm to form a reverse micelle catalysis reaction system, heating and reflowing for 3 to 10 h, washing with water, standing to obtain crude bio-diesel, and distilling at 200 to 250 DEG C and under 0.001 to 0.0001MPa to obtain the pure bio-diesel with a total yield above 75%. The method has the advantages of simple and reliable process flow, high production efficiency, low energy consumption and less waste water discharge.

Owner:CHINA THREE GORGES UNIV

Preparation method of pine mushroom powder

InactiveCN103141822AChange the way you eatPromote absorptionFood preparationProduction lineNutritive values

The invention relates to a preparation method of pine mushroom powder, which comprises the following steps: rinsing raw material pine mushroom in a rinser, drying in a drying box, pulverizing in a pulverizer, grinding in a grinder to obtain 40-200-mesh pine mushroom powder, canning, sterilizing, inspecting on an inspection platform to obtain qualified products, and boxing. The invention solves the problems of low income in spite of high yield of pine mushroom, unnecessary economic loss for people due to rotting of the pine mushroom which is hard to store, and severe waste of pine mushroom leftover resources, and enhances the utilization ratio of the pine mushroom leftovers and the added value of the pine mushroom; and the pine mushroom powder is convenient to carry and eat, fully utilizes the pure natural nutritive value of the pine mushroom, can be absorbed by the human body more easily, and enhances the immunological competence of the human body. The invention has the advantages of simple technical production line, high production efficiency, low investment and high income, is economical and practical, has an active action on environmental protection, has wide market prospects, and is suitable for popularization.

Owner:LUOYANG CHUNKUI AGRI DEV

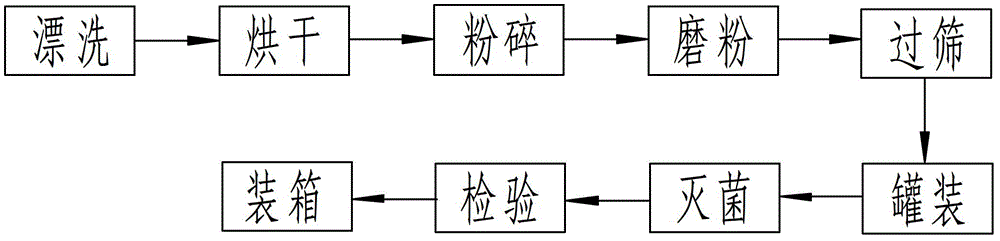

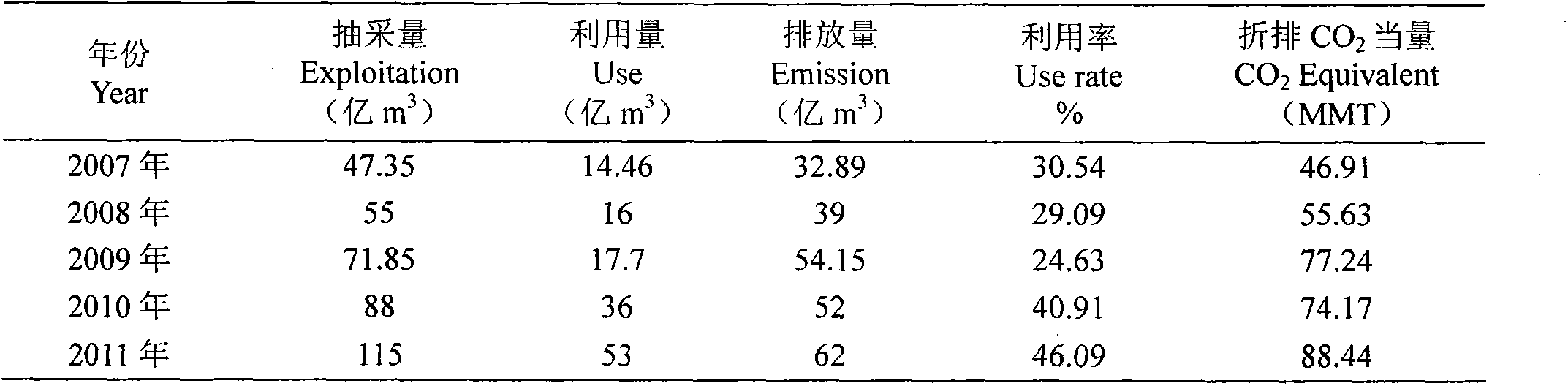

Coal bed gas enrichment process

The invention discloses a coal bed gas enrichment process comprising the steps of: adsorbing methane in a coal bed gas with an ethyl ether solvent; then desorbing a solvent rich solution which adsorbs methane to separate methane; collecting to obtain a methane-rich gas; removing ethyl ether from the methane-rich gas to prepare a methane product. The coal bed gas enrichment process is simple in route, convenient to operate and small in investment.

Owner:XIAN UNIV OF SCI & TECH

Low carbon high sulfur free-cutting steel production process

InactiveCN101580912BReduce manufacturing costSave energyProcess efficiency improvementElectric furnaceElectric arc furnaceSlag

The invention provides a low carbon high sulfur free-cutting steel production process, comprising the following steps: 1) an electric furnace is used to blow oxygen for melting without supplying electricity, the ratio of hot molten iron and waste steel reaches 7.0:1.0-3.0, a carbon-oxygen gun arranged on a furnace door and an oxygen-coal sublance gun arranged on a furnace wall are used for blowing oxygen for melting with rich carbon in the furnace; 2) the operation of eccentric bottom tapping and retained slag and steel are carried out, pre-deoxidation is processed on the furnace rear, then slag is produced; 3) low-basicity slag is produced in a refining furnace, the refined slag comprises the following components by weight percentage: 40-50% of CaO, 15-30% of SiO2, 20-35% of Al2O3 and 5-15% of MgO; when each element chemical composition in the steel reaches the requirements under the temperature of 1580-1600 DEG C, Ca lines or Ca-Si lines are put in the refining furnace, the time of soft blowing is 8-15min, crater formation modified atmosphere packaging is put on a continuous casting platform; 4) a four pass arc continuous casting machine is used for continuous casting, a long nozzle arch welding joint is used for sealing and protecting and argon is blown in an intermediate container to protect casting; low cooling process is adopted for secondary cooling, electromagnetic mixing is adopted by a crystallizer, wherein the electric current is 600-700A and the frequency is 4-5 Hz.

Owner:武钢集团有限公司

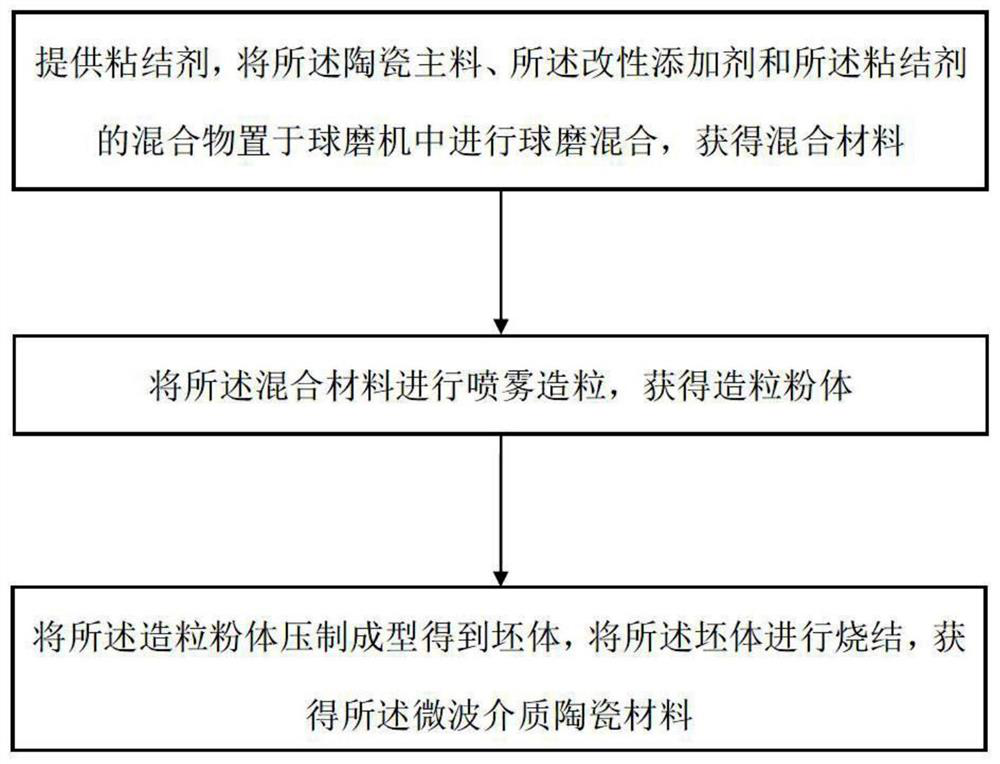

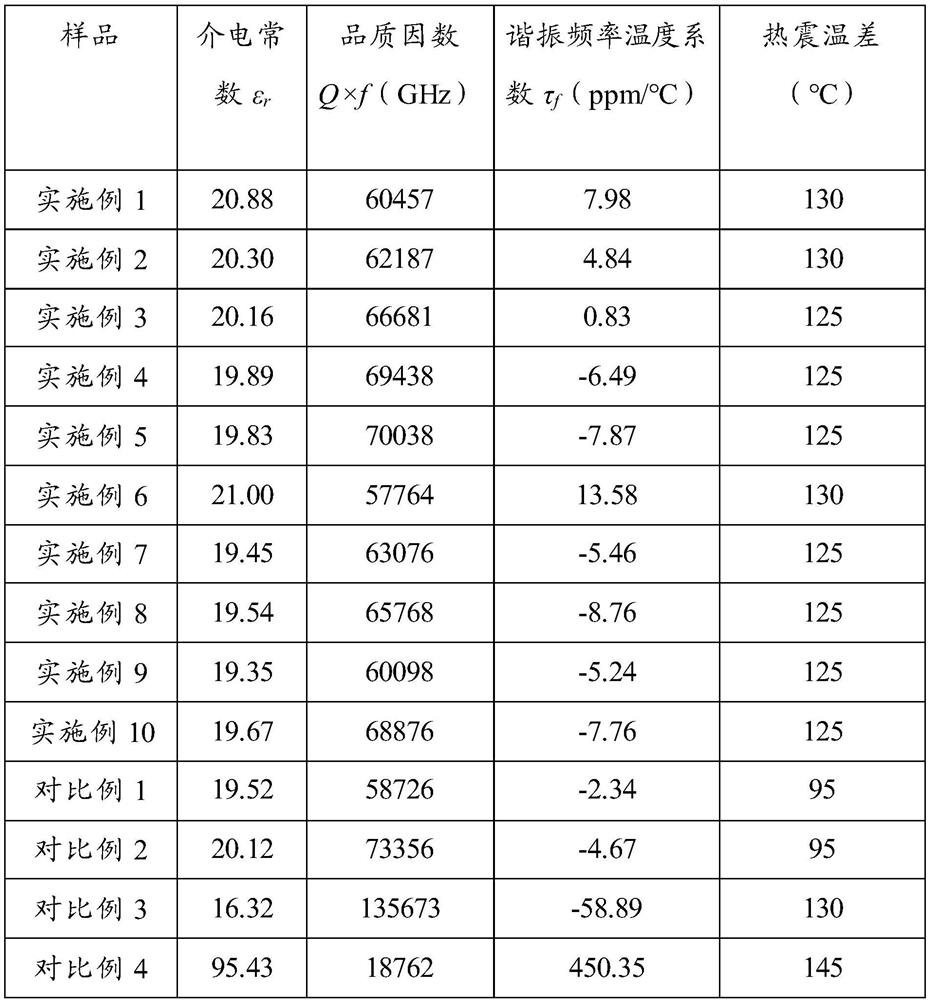

Microwave dielectric ceramic material, preparation method and application

InactiveCN113336539AImprove thermal shock resistanceHigh quality factorDielectricDielectric permittivity

The invention provides a microwave dielectric ceramic material, a preparation method and application, and relates to the technical field of ceramic materials. The microwave dielectric ceramic material comprises MgTiO3, (Mg0.5Zn0.5)Al2O4 and (Ca0.8Sr0.2)TiO3, wherein the mass of the MgTiO3 accounts for 75%-85% of the mass of a ceramic main material; the mass of the (Mg0.5Zn0.5)Al2O4 accounts for 10%-15% of the mass of the ceramic main material; the mass of the (Ca0.8Sr0.2)TiO3 accounts for 5%-10% of the mass of theceramic main material. According to the invention, under the condition that the dielectric constant epsilon r of the microwave dielectric ceramic material provided by the invention is kept at 20 + / - 1, the quality factor Q * f can reach 57000-70000GHz, and the temperature coefficient of resonance frequency tau f is close to 0; meanwhile, the thermal shock temperature difference [delta]Tmax of the microwave dielectric ceramic is 125-130 DEG C, so that the microwave dielectric ceramic has relatively high thermal shock resistance and relatively good comprehensive performance.

Owner:无锡市高宇晟新材料科技有限公司

Preparation method of Pleurotus eryngii powder

The invention relates to a preparation method of Pleurotus eryngii powder, which comprises the following steps: rinsing raw material Pleurotus eryngii in a rinser, drying in a drying box, pulverizing in a pulverizer, grinding in a grinder to obtain 40-200-mesh Pleurotus eryngii powder, canning, sterilizing, inspecting on an inspection platform to obtain qualified products, and boxing. The invention solves the problems of low income in spite of high yield of Pleurotus eryngii, unnecessary economic loss for people due to rotting of the Pleurotus eryngii which is hard to store, and severe waste of Pleurotus eryngii leftover resources, and enhances the utilization ratio of the Pleurotus eryngii Pleurotus eryngii and the added value of the Pleurotus eryngii; and the Pleurotus eryngii powder is convenient to carry and eat, fully utilizes the pure natural nutritive value of the Pleurotus eryngii, can be absorbed by the human body more easily, and enhances the immunological competence of the human body. The invention has the advantages of simple technical production line, high production efficiency, low investment and high income, is economical and practical, has an active action on environmental protection, has wide market prospects, and is suitable for popularization.

Owner:LUOYANG CHUNKUI AGRI DEV

Preparation method of Coprinus comatus powder

InactiveCN103202464AChange the way you eatFull use of nutritional valueFood preparationProduction lineTest platform

A preparation method of Coprinus comatus powder comprises pouring the raw material Coprinus comatus into a washing machine, rinsing, drying in a drier, crushing in a grinding mill to obtain the Coprinus comatus powder of 40 - 200 meshes in the grinding mill, canning, sterilizing, testing on a test platform, and packing the test is passed. The method solves problems of high yield but low income of the Coprinus comatus, unnecessary economic losses to people caused by difficult storage and thus decaying of the Coprinus comatus, and serious waste of leftover Coprinus comatus; and also increases utilization of the leftover Coprinus comatus and added values of the Coprinus comatus. The Coprinus comatus powder is easy to carry and convenient to eat, fully utilizes natural nutritional values of the Coprinus comatus, and is more conducive to human body's absorption, therby enhancing human immunity. The method has advantages of simple production line, high production efficiency, low investment and high return, is economical and practical, has positive effects on environmental protection, is broad in market prospect, and thus is suitable for popularization and use.

Owner:LUOYANG CHUNKUI AGRI DEV

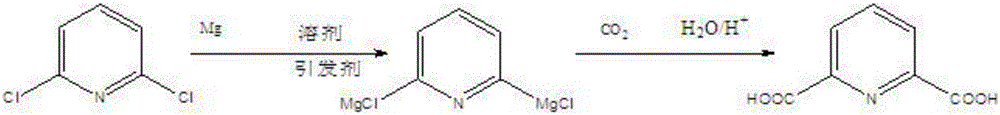

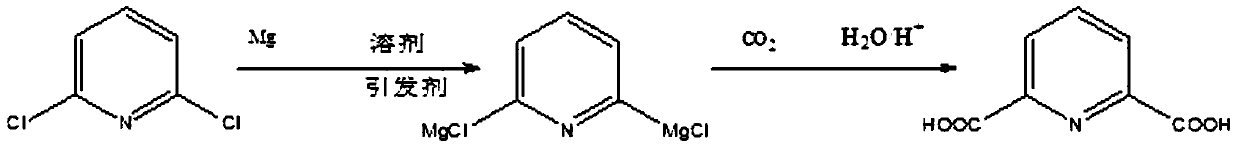

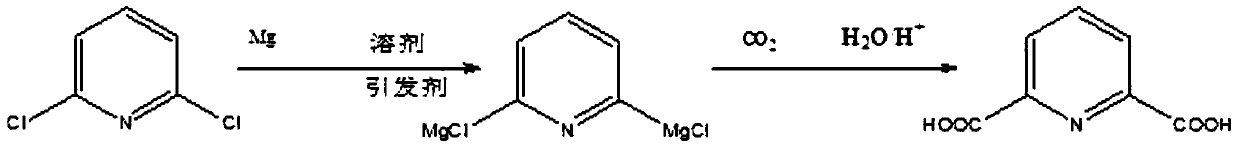

Method for synthesizing 2,6-dipicolinic acid

The invention discloses a method for synthesizing 2,6-dipicolinic acid. The method comprises the following steps: under the condition of air isolation, by using anhydrous diethyl ether or THF (tetrahydrofuran) as solvent, reacting 2,6-dichloropyridine used as a raw material with active metal under the action of an initiator to obtain a Grignard reagent; and cooling, then introducing excessive dry carbon dioxide gas, and acidifying to obtain the 2,6-dipicolinic acid. According to the invention, the cheap 2,6-dichloropyridine is used as the raw material, so the cost is low; and the synthesis process route is simple and easy to control, and can easily implement industrial production.

Owner:NANJING REDSUN BIOCHEM CO LTD

Rolling method of low-banded structure gear steel

ActiveCN103194580BImprove fatigue lifeReduce manufacturing costRoll mill control devicesMetal rolling arrangementsOperabilityHigh pressure water

The invention discloses a rolling method of low-banded structure gear steel. The method comprises the following steps of: (1) heating a steel blank within a three-section type heating furnace; (2) carrying out dephosphorization on the heated steel blank by high-pressure water, and sequentially carrying out rough rolling, intermediate rolling, water cooling, and finish rolling; (3) water-cooling and air-cooling the finish-rolled steel blank sequentially; and (4) slowly cooling the cooled round bar steel to be lower than 200DEG C after shearing. Due to the use of the rolling method, the production technology difficulty that the level of the high-end hardenability carburized gear steel banded structure is hard to lower due to the conventional rolling technology can be overcome, so that that the level of the banded structure of the gear steel is lowered to be lower than 1.0 grade from 3.0 grade of the conventional rolling technology, and therefore, the aim of prolonging the fatigue life of the gear can be achieved. The rolling method further has the characteristics of being simple in technical route, low in production cost, high in operability and the like.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Preparation method for coprinus comatus soup

InactiveCN104068428AChange the way you eatFull use of nutritional valueFood preparationProduction lineNutritive values

The invention relates to a preparation method for coprinus comatus soup. The preparation method comprises the following steps: firstly, coprinus comatus raw materials are poured into a rinsing machine to be rinsed; then, the raw materials are crushed in a crushing machine, and are made into particles by a chip making machine; the particulate raw materials enter a pulping machine to be formed into coprinus comatus pulp; then, the coprinus comatus pulp is decocted in a soup cooking machine for 3-6 hours to be made into the coprinus comatus soup; then the coprinus comatus soup is canned and disinfected; and the canned coprinus comatus soup can be packed in boxes after the coprinus comatus soup is qualified through inspection on an inspection platform. The preparation method solves the difficult problem that coprinus comatus is in a good harvest but the income is not high, solves the problem of unnecessary economic losses to people due to the situation that the coprinus comatus is decomposed because the coprinus comatus is difficult to store, solves the problem that the coprinus comatus scrap resources are seriously wasted, improves the utilization rate of coprinus comatus scraps, and increases the additional value of the coprinus comatus; the coprinus comatus soup is convenient to carry and eat, and the purely natural nutritive value of the coprinus comatus is fully utilized, so that the coprinus comatus soup is more favorable for human bodies to absorb, and the immunocompetence of the human bodies is enhanced. The technology production line is simple, the production efficiency is high, the investment is low, the income is high, and the preparation method is economical and practical. The preparation method has a positive effect on environmental protection, and the market prospects are broad, so that the preparation method is suitable for promotion and use.

Owner:LUOYANG CHUNKUI AGRI DEV

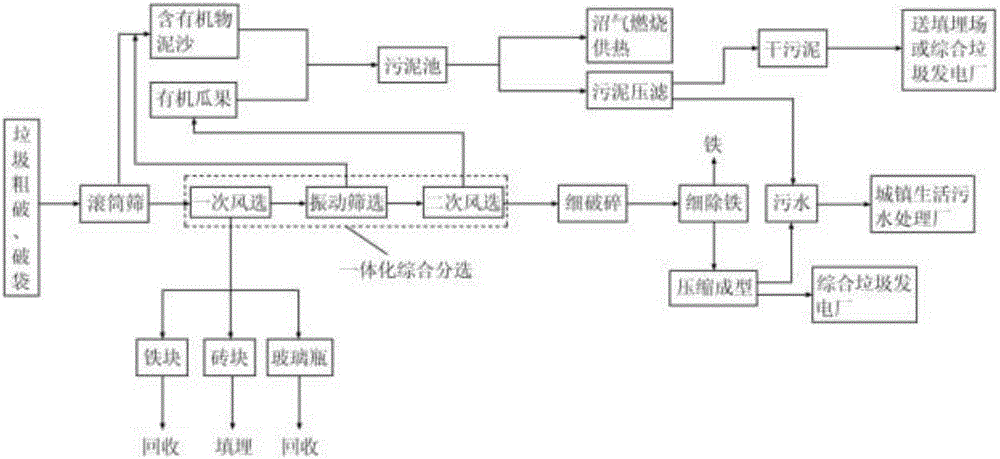

Comprehensive treatment technique for town domestic waste

InactiveCN106623350AIncrease profitLow process costSolid waste disposalEnvironmental resistanceBrick

The invention discloses a comprehensive treatment technique for town domestic waste. The technique comprises the following steps that (1), the municipal solid waste is sent into a trommel sieve after being subjected to coarse breaking and bag breaking, and sand containing organics and waste are subjected to preliminary separation; (2), the preliminarily separated domestic waste obtained in the step (1) is sent to an integration comprehensive sorting machine, firstly, first air sorting is conducted to separate iron blocks, bricks and glass bottles from the domestic waste, then vibration screening is conducted, residual sand containing organics in the domestic waste is screened out, and then second air sorting is conducted to separate the organic fruits from the domestic waste, the domestic waste subjected to integration comprehensive sorting is obtained; and (3), the domestic waste subjected to integration comprehensive sorting and obtained in the step (2) is sent to a fine crusher to be crushed, then second iron removing is conducted, and fine domestic waste is obtained and subjected to compression forming. The treatment technique is low in treatment cost, high in resource using efficiency, economical and environmentally friendly.

Owner:高细平

Preparation method of oyster mushroom powder

The invention relates to a preparation method of oyster mushroom powder, which comprises the following steps: rinsing raw material oyster mushroom in a rinser, drying in a drying box, pulverizing in a pulverizer, grinding in a grinder to obtain 40-200-mesh oyster mushroom powder, canning, sterilizing, inspecting on an inspection platform to obtain qualified products, and boxing. The invention solves the problems of low income in spite of high yield of oyster mushroom, unnecessary economic loss for people due to rotting of the oyster mushroom which is hard to store, and severe waste of oyster mushroom leftover resources, and enhances the utilization ratio of the oyster mushroom leftovers and the added value of the oyster mushroom; and the oyster mushroom powder is convenient to carry and eat, fully utilizes the pure natural nutritive value of the oyster mushroom, can be absorbed by the human body more easily, and enhances the immunological competence of the human body. The invention has the advantages of simple technical production line, high production efficiency, low investment and high income, is economical and practical, has an active action on environmental protection, has wide market prospects, and is suitable for popularization.

Owner:LUOYANG CHUNKUI AGRI DEV

Preparation method for pholiota nameko soup

InactiveCN104068374AChange the way you eatFull use of nutritional valueFood shapingFood preparationProduction lineNutritive values

The invention relates to a preparation method for pholiota nameko soup. The preparation method comprises the following steps: firstly, pholiota nameko raw materials are poured into a rinsing machine to be rinsed; then, the raw materials are crushed in a crushing machine, the raw materials are made into particles by a chip making machine, and the particulate raw materials enter a pulping machine to be formed into pholiota nameko pulp; then, the pholiota nameko pulp is decocted in a soup cooking machine for 3-6 hours to be made into the pholiota nameko soup; then the pholiota nameko soup is canned and disinfected; and the canned pholiota nameko soup can be packed in boxes after the pholiota nameko soup is qualified through inspection on an inspection platform. The preparation method solves the difficult problem that pholiota nameko is in a good harvest but the income is not high, solves the problem of unnecessary economic losses to people due to the situation that the pholiota nameko is decomposed because the pholiota nameko is difficult to store, solves the problem that pholiota nameko scrap resources are seriously wasted, improves the utilization rate of pholiota nameko scraps, and increases the additional value of the pholiota nameko; the pholiota nameko soup is convenient to carry and convenient to eat, the purely natural nutritive value of the pholiota nameko is fully utilized, the pholiota nameko soup is more favorable for human bodies to absorb, and the immunocompetence of the human bodies is enhanced. The technology production line is simple, the production efficiency is high, the investment is low, the income is high, the preparation method is economical and practical, the preparation method has a positive effect on environmental protection, and the market prospects are broad, so that the preparation method is suitable for promotion and use.

Owner:LUOYANG CHUNKUI AGRI DEV

A high-rate aqueous alkaline metal electrochemical cell positive electrode material and preparation method thereof

ActiveCN103441259BPromote prolapseImprove electrochemical performanceAlkaline accumulatorsCell electrodesHigh rateAqueous electrolyte

Provided are a high-magnification anode material of an aqueous alkali metal electrochemical cell, and preparation method thereof. The anode material is characterized in that the anode material is alkali-metal-containing manganite having the general formula AxMnO2, wherein A is one or both of Na and K, 0<x<1, and the crystal structure of the alkali-metal-containing manganite is a layered structure. The anode material has nano-crystallization three-dimensional topology, thus increasing the specific surface area of the material, reducing the transfer paths of ions and electrons in aqueous electrolyte, and effectively improving the magnification property of the electrode material.

Owner:ENPOWER ENERGY TECH ANHUI CO LTD +1

A kind of refining method of spring steel

Owner:武汉钢铁有限公司

Method for preparing PEM membrane electrode for hydrogen production by electrolyzing water through electrostatic spinning method

PendingCN114807974AImprove performanceFacilitate conductionElectro-spinningElectrodesPtru catalystElectrolysed water

The invention discloses a method for preparing a PEM membrane electrode for hydrogen production by electrolyzing water through an electrostatic spinning method. Specifically, catalyst slurry is uniformly spun on a membrane electrode base membrane by adopting an electrostatic spinning method, the spun catalyst layer is fluffy and porous, and a channel is provided for smoothly transferring reactant water to a reaction site of catalyst particles, so that the performance of the membrane electrode is greatly improved; the spun catalyst layer contains a large amount of-OH,-NH2 and other groups, and a hydrophilic region formed by the groups can accelerate proton conduction and improve the performance of the membrane electrode; the process for preparing the PEM membrane electrode for hydrogen production through water electrolysis by adopting the electrostatic spinning method is simple in line, the raw materials are cheap and easy to obtain, continuous production can be realized, and the technology is the development direction of the PEM membrane electrode for hydrogen production through water electrolysis in the future.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

A method for synthesizing 2,6-pyridinedicarboxylic acid

InactiveCN106187875BThe process line is simpleEasy to controlOrganic chemistryGrignard reagentCarboxylic acid

The invention discloses a method for synthesizing 2,6-dipicolinic acid. The method comprises the following steps: under the condition of air isolation, by using anhydrous diethyl ether or THF (tetrahydrofuran) as solvent, reacting 2,6-dichloropyridine used as a raw material with active metal under the action of an initiator to obtain a Grignard reagent; and cooling, then introducing excessive dry carbon dioxide gas, and acidifying to obtain the 2,6-dipicolinic acid. According to the invention, the cheap 2,6-dichloropyridine is used as the raw material, so the cost is low; and the synthesis process route is simple and easy to control, and can easily implement industrial production.

Owner:NANJING REDSUN BIOCHEM CO LTD

Preparation method for pholiota nameko powder

InactiveCN104068376AChange the way you eatFull use of nutritional valueFood preparationProduction linePholiota

The invention discloses a preparation method for pholiota nameko powder. The preparation method comprises the following steps of: pouring pholiota nameko raw materials in a poaching machine and poaching at first, and then drying in a drying oven, conveying in a crushing machine and crushing, grinding in grinding equipment into the pholiota nameko powder with 40-200 meshes, then canning and sterilizing, and boxing after passing an inspection on an inspection platform. According to the preparation method, the problem that pholiota nameko is high in fertility but is low in harvest is solved, the case of unnecessary economic losses on people due to that pholiota nameko is rotted because of being difficult to store is solved, the problem of serious resource waste of pholiota nameko leftovers is solved, the utilization rate of the pholiota nameko leftovers is increased, and the added value of pholiota nameko is increased; and the pholiota nameko powder is convenient to carry, convenient to eat, capable of adequately utilizing the purely natural nutritional values of pholiota nameko, more beneficial to the absorption of human body, and capable of enhancing the immunocompetence of human body. The preparation method is simple in technique production line, high in production efficiency, low in investment, high in earnings, economic and practical, active in action on environmental protection, wide in market prospect, and suitable for being popularized and used.

Owner:LUOYANG CHUNKUI AGRI DEV

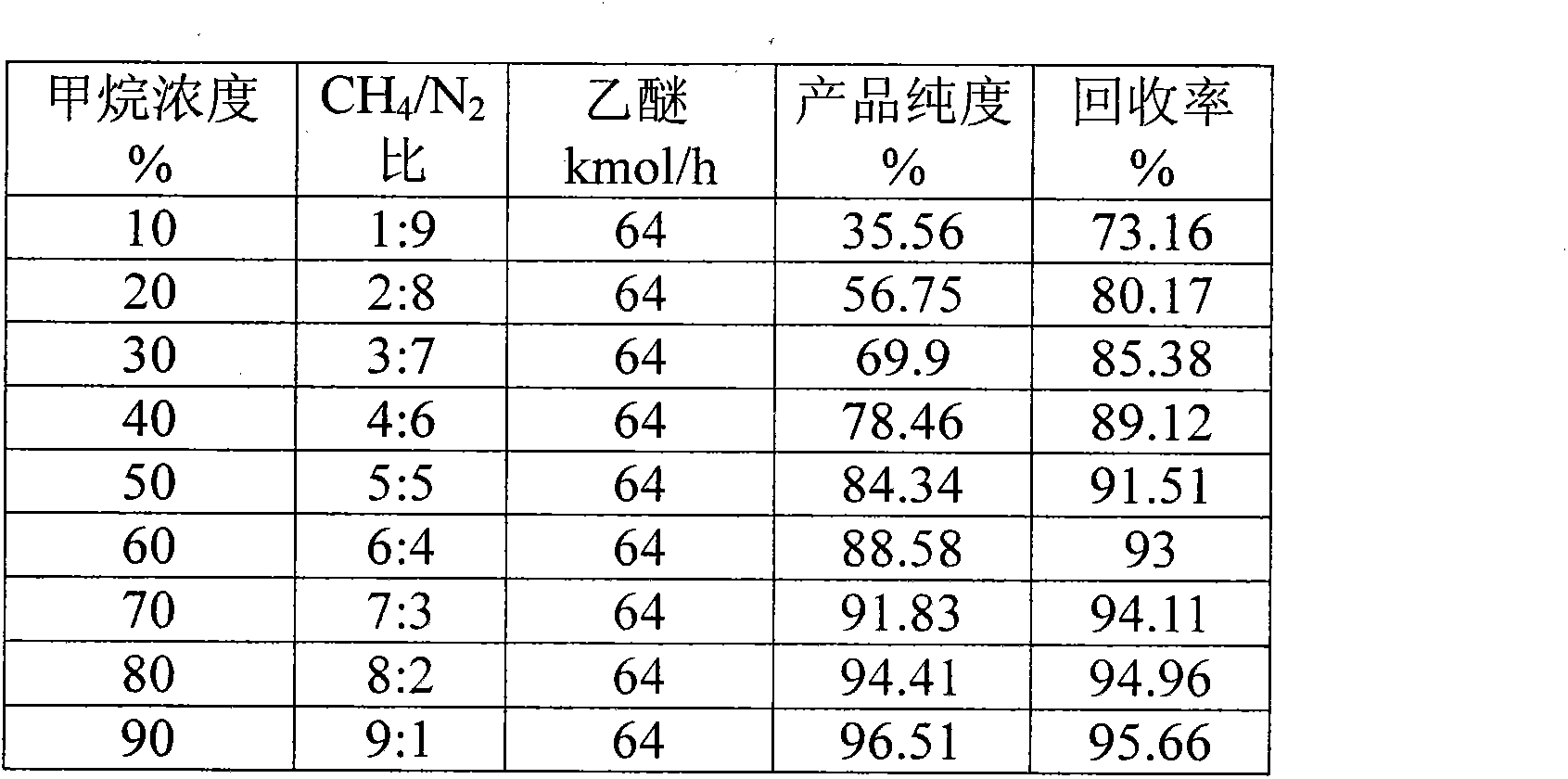

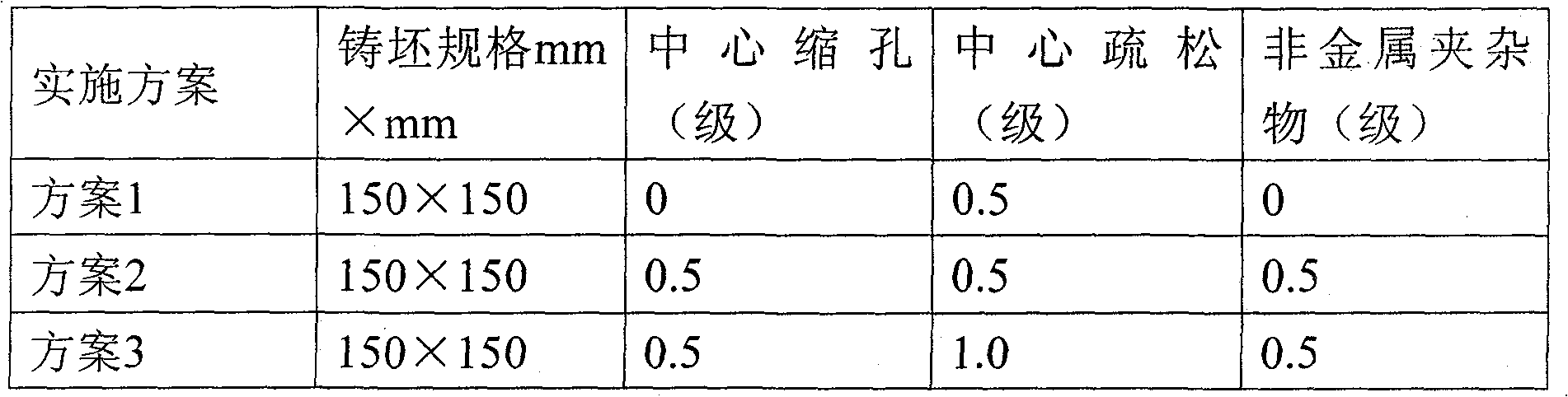

Production method of high-sulfur phosphorus high-strength steel continuous casting slab for expanding connecting rod

ActiveCN104087708BGuaranteed Phosphorus ContentReduce corrosionElectric furnaceProcess efficiency improvementEtchingSlag

The invention discloses a production method of a high sulfur, high phosphorus and high strength steel continuous casting slab for a heaving broken connecting rod. The method comprises the following steps: 1, electric furnace smelting: carrying out rapid heating decarburization and less running slag operation in the early stage, and controlling the phosphorus content at the oxidation end point in a range of 0.030-0.045%; 2, electric furnace flanged bottom center tapping: carrying out remaining steel and remaining slag operation in tapping, and controlling the sulfur content in tapped steel in a range of 0.050-0.060%; 3, LF furnace refining: adopting a low alkalinity slag system, and controlling the sulfur content in molten steel in a range of 0.040-0.050%; and 4, continuous casting: adopting full-protection casting, crystallizing, electromagnetically stirring, and carrying out weak cooling on the obtained continuous casting slab. The adoption of the rapid heating decarburization and less running slag operation in the early stage of the electric furnace smelting guarantees the phosphorus content in the molten steel, and allows ferrophosphorus not to be added to steel, so alloy is saved; the adoption of the low alkalinity slag system in the refining stage guarantees the sulfur component stabilization and reduces the etching of ladle linings; and the P content and the S content in the continuous casting slag are controlled at 0.030-0.050% and 0.035-0.045% respectively, the low power level of the casting slag is not greater than 1.0 level, the oxygen content is not greater than 20ppm, and the surface quality of the casting slab is excellent.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com