Method for preparing carbon clad lithium iron phosphate

A carbon-coated lithium iron phosphate and phosphate technology, which is applied to electrical components, battery electrodes, circuits, etc., can solve the problems of uneven particle size, long synthesis cycle, and irregular crystal shape of the product, and achieve low cost and small grain size , The effect of simple process lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

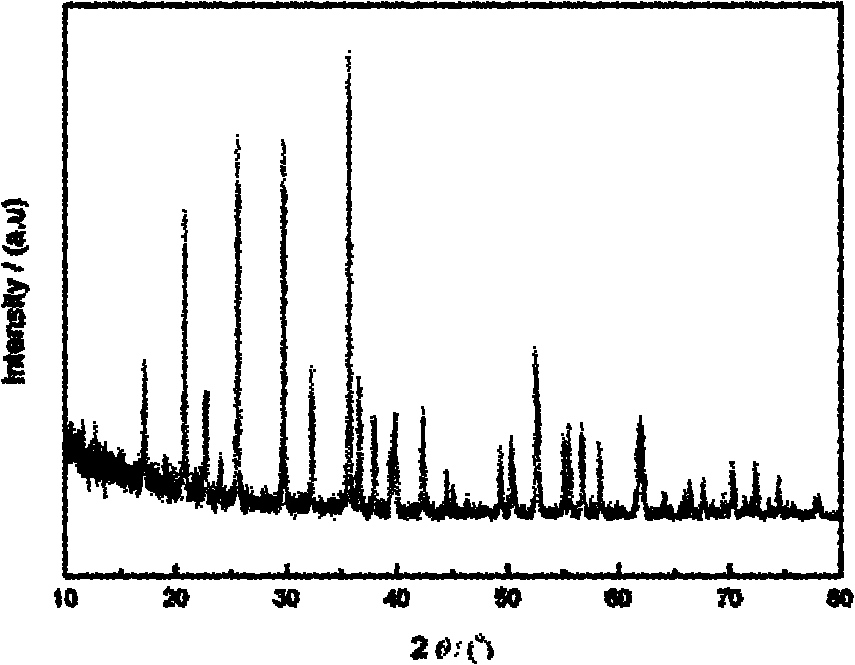

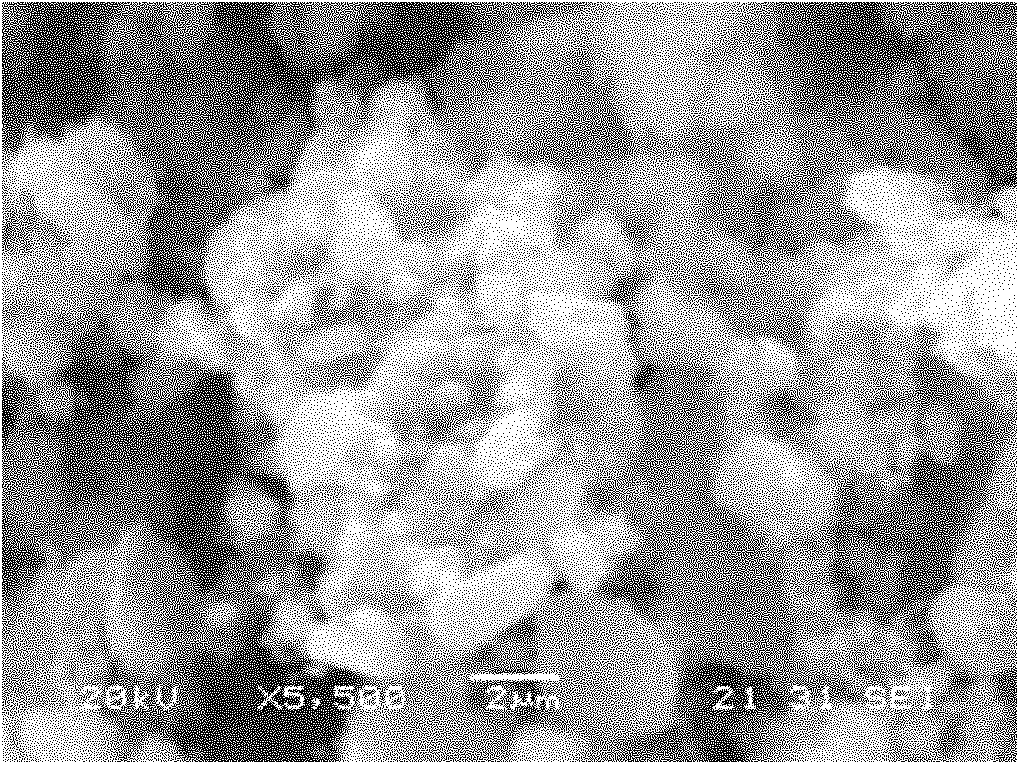

[0020] Example 1. Put 2.6g of lithium carbonate, 8g of ammonium dihydrogen phosphate, 12.3g of ferrous oxalate and 1g of glucose into 100mL of ethanol for mixing and then directly place them in the ultrasonic radiation equipment for ultrasonic radiation treatment. The frequency of ultrasonic radiation is 20KHz, the power of ultrasonic radiation is 500W, the time of ultrasonic radiation is 1h, and the temperature is controlled at about 35°C. LiFePO obtained after filtering the mixed material treated with ultrasonic radiation 4 The precursor, after centrifugal washing treatment, was calcined at 500°C for 24 hours under the protection of nitrogen atmosphere to obtain carbon-coated lithium iron phosphate (see figure 1 , 2 ).

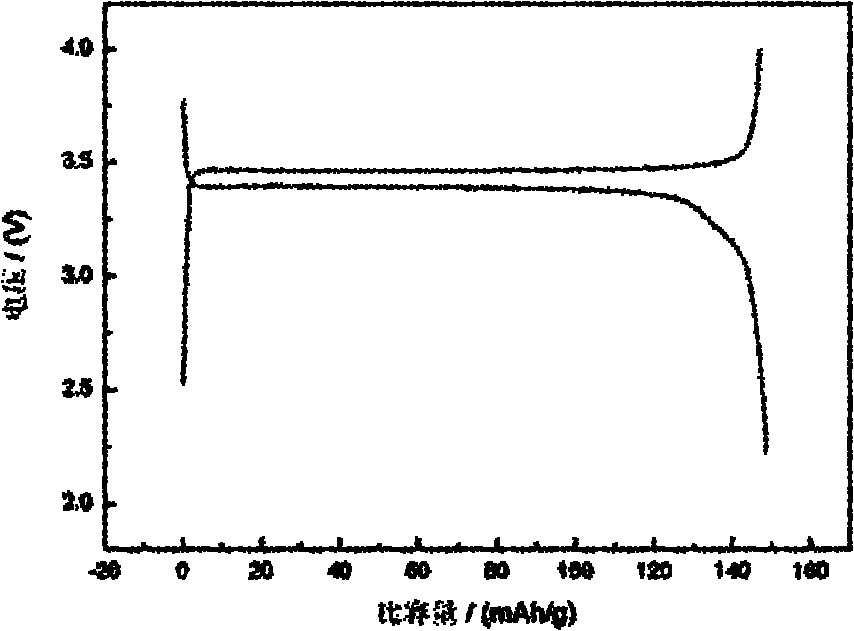

[0021] Using the carbon-coated lithium iron phosphate prepared in Example 1, the conductive carbon black and the binder polyvinylidene fluoride are mixed according to the mass ratio of 82:10:8, and N-methylpyrrolidone is used as a solvent, rolled into she...

Embodiment 2

[0022] Example 2. Put 55g of lithium sulfate, 198.1g of ammonium hydrogen phosphate, 173.5g of ferrous acetate and 17.1g of sucrose into 10L of ethanol for mixing and then directly place them in ultrasonic radiation equipment for ultrasonic radiation treatment. The frequency of ultrasonic radiation is 100KHz, the power of ultrasonic radiation is 5KW, the time of ultrasonic radiation is 5h, and the temperature is controlled at about 35°C. LiFePO obtained after filtering the mixed material treated with ultrasonic radiation 4 The precursor, after centrifugal washing treatment, is calcined at 800°C for 10 hours under the protection of nitrogen atmosphere to obtain carbon-coated lithium iron phosphate.

Embodiment 3

[0023] Example 3. Put 7.8g of lithium carbonate, 48.7g of ammonium phosphate, 36g of ferrous nitrate and 1.6g of starch into 1L of deionized water for mixing and then directly place them in ultrasonic radiation equipment for ultrasonic radiation treatment. The frequency of ultrasonic radiation is 50KHz, the power of ultrasonic radiation is 800W, the time of ultrasonic radiation is 5h, and the temperature is controlled at about 35°C. LiFePO obtained after filtering the mixed material treated with ultrasonic radiation 4 The precursor, after centrifugal washing treatment, was calcined at 300°C for 12 hours under the protection of nitrogen atmosphere to obtain carbon-coated lithium iron phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com