Coal bed gas enrichment process

A coalbed methane enrichment technology, applied in gaseous fuel, petroleum industry, hydrocarbon purification/separation, etc., can solve the problems of complex process, high operating cost, large investment in basic equipment, etc., and achieve simple process line and low engineering loss , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

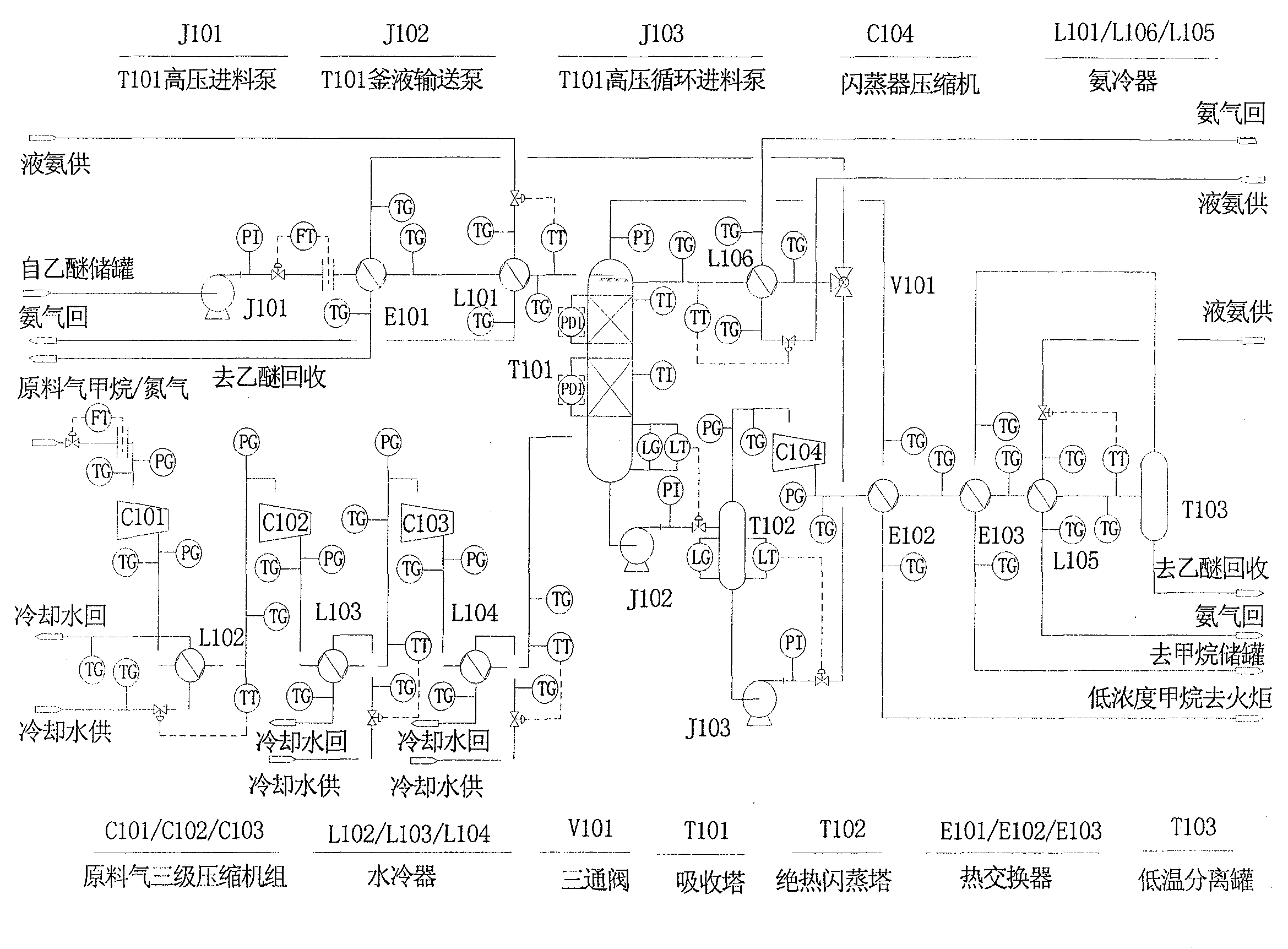

[0036] The idea of the whole process provided by the present invention is: use ether solvent to adsorb methane in coalbed methane, then desorb the solvent-rich liquid after adsorbing methane to separate methane, collect methane-enriched gas, and desorb methane-enriched gas Ether treatment, the system methane products.

[0037] During its operation: first pressurize and cool the ether solvent to 1.3MPa and -25°C, pressurize the coal bed gas to 1.3 MPa, and then contact and absorb the pressurized and cooled ether solvent and pressurized coal bed gas in the absorption tower T101 Methane in the coalbed methane, and then the solvent-rich liquid ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com