Preparation method for pholiota nameko soup

A technology of Huazi mushroom soup and Huazi mushroom, which is applied in the field of mushroom processing, can solve the problems that are not conducive to people’s health, difficult to store Huazi mushroom, consume resources, energy and time, etc., so as to enhance human immunity and solve the problem of high yield and poor harvest , Ease of storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

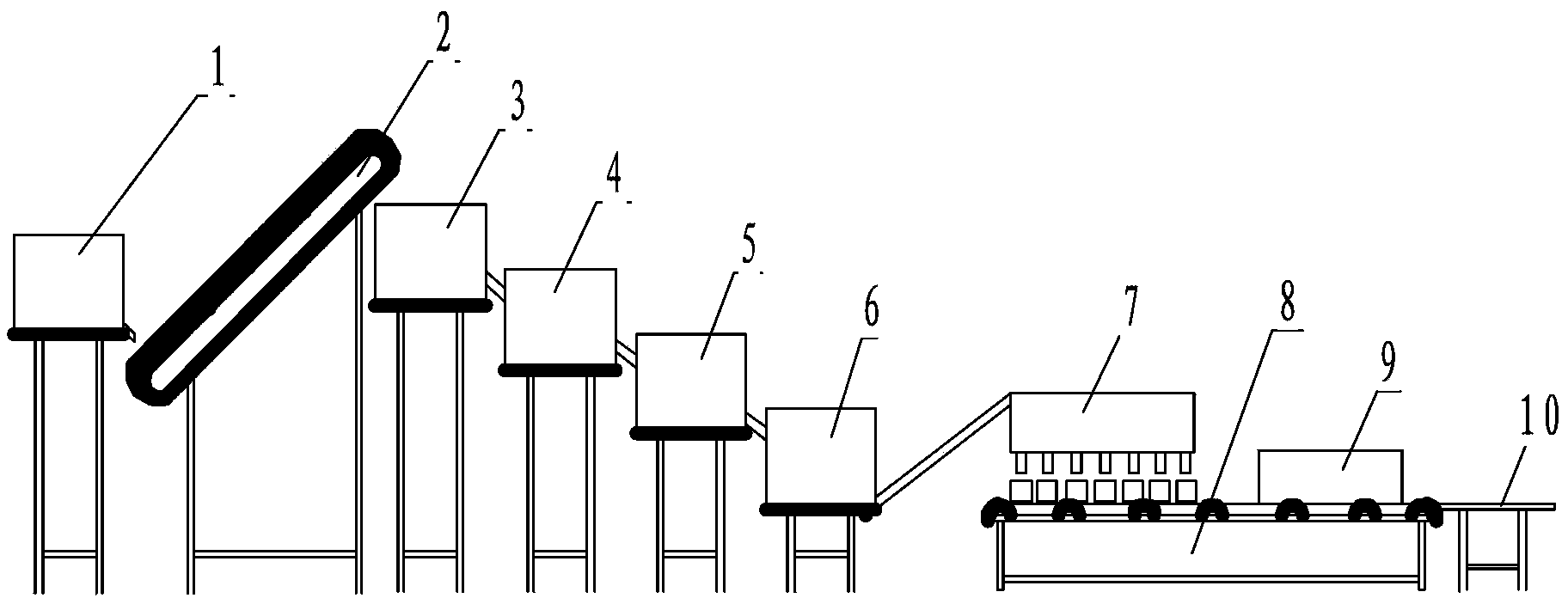

[0023] One side of the rinsing machine 1 is provided with a first conveyor belt 2, the other side of the first conveyor belt 2 is provided with a pulverizer 3, the other side of the pulverizer 3 is provided with a chipping machine 4, and the other side of the chipping machine 4 is provided with a beater 5, and the beating The other side of the machine 5 is provided with a soup cooker 6, the other side of the soup cooker 6 is provided with a canning machine 7, a conduit is provided between the outlet of the soup cooker 6 and the feed port of the canning machine 7, and the bottom of the canning machine 7 is provided The second conveyor belt 8, the middle part of the second conveyor belt 8 is provided with a sterilization chamber 9, and the other side of the second conveyor belt 8 is provided with an inspection platform 10, and the inspection platform 10 is at the same level as the surface of the second conveyor belt 8.

Embodiment 2

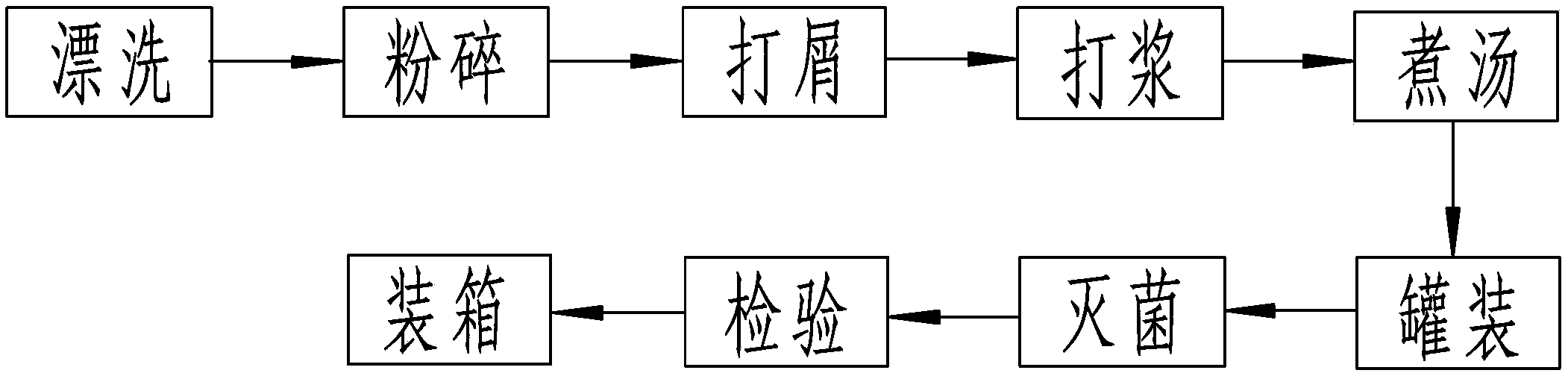

[0025] Select fresh, non-rotten Huazi mushroom and leftovers, pour the selected Huazi mushroom raw materials into the rinsing machine 1, add 3-5 times the water, rinse for 5-8 minutes, drain the water, and the Huazi mushroom raw materials go through the rinsing machine 1. The discharge port enters the first conveyor belt 2, and the first conveyor belt 2 moves upward to bring the raw materials of the slider mushroom into the crusher 3. The raw materials of the slider mushroom are crushed in the crusher 3, and the scraps of the slider mushroom are passed through the crusher. 3. The discharge port enters the chipping machine 4. The shredded slider mushrooms become granular after being chipped. The slider mushroom particles enter the beater 5 through the chipping machine 4 outlet. The total weight of the slider mushroom particles is doubled. Water, beater 5 runs for 5-10 minutes to make slider mushroom pulp, slider mushroom pulp enters soup cooking machine 6 through the outlet of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com