Preparation method of russula vinosa powder

A technology of red mushroom and red mushroom powder is applied in the field of preparation of red mushroom powder, which can solve the problems of high yield but not harvest of red mushroom, waste of scrap resources, and difficulty in storage of red mushroom, etc. Simple production line, good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

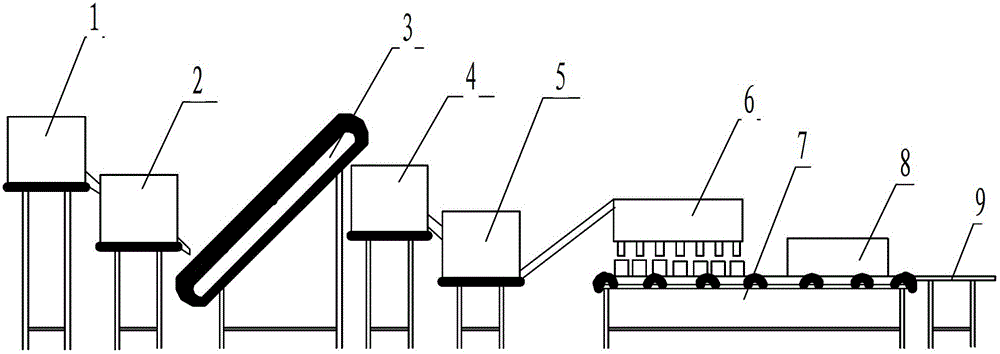

[0024] One side of the rinsing machine 1 is provided with a drying box 2, one side of the drying box 2 is provided with a first conveyor belt 3, the other side of the first conveyor belt 3 is provided with a pulverizer 4, and the other side of the pulverizer 4 is provided with a milling equipment 5, A sieve is set inside the powder equipment 5, and the sieve is 40-200 mesh. The other side of the powder mill 5 is provided with a canning machine 6. A conduit is set between the outlet of the mill equipment 5 and the feed port of the can machine 6. A second conveyor belt 7 is set under the installed machine 6, a sterilization chamber 8 is set in the middle of the second conveyor belt 7, and an inspection platform 9 is installed on the other side of the second conveyor belt 7, and the surface of the inspection platform 9 is at the same level as the surface of the second conveyor belt 7 .

Embodiment 2

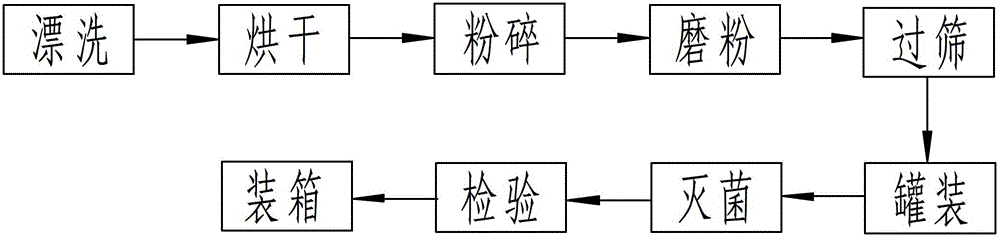

[0026] Select fresh, non-rotten russula mushrooms and leftovers, pour the russula raw materials into the rinse machine 1, add 3-5 times the water, rinse for 5-8 minutes, drain the water, and the russula raw materials pass through the rinse machine 1. The discharge port enters the drying box 2, the baking temperature is set to 40-50 degrees, and the baking time is 6-8 hours. The dry material of red mushroom enters the first conveyor belt 3 through the discharge port of the drying box 2, and the Conveyor belt 3 sends the dry material of russula to the pulverizer 4, and the pulverized russula debris enters the milling equipment 5 through the discharge port of the pulverizer 4, and adds directly purchased from the market in the pulverizing equipment 5. Special preservatives for edible fungi (Senbai preservatives, complex vitamin C derivative preservatives, nisin, lysozyme, one or a combination of them), accounting for 1%-2% of the total weight, food preservatives (benzoic acid, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com