Production method of high-plasticity steel wire rod for welding

A technology for welding steel and a production method, which is applied in the field of production of high-plasticity welding steel wire rods, can solve problems such as uneven welds, cracks, and low tensile strength, and achieve improved section shrinkage, simple process lines, and The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Selection of cast slab: The mass percentage of cast slab is C: 0.08%, Si: 0.15%, Mn: 1.60%, P: 0.012%, S: 0.003%, O: 0.0025%, N: 0.007%, Mo: 0.30%, Ni: 0.20%, Ti: 0.04%, B: 0.004%, the rest is iron and unavoidable impurities;

[0027] (2) Heating: The billet enters the heating furnace for heating. The heating furnace adopts a walking beam heating furnace. The temperature of the preheating section is 500°C, the temperature of the heating section is 1010°C, the temperature of the soaking section is 1080°C, and the heating time is 90min. ;

[0028] (3) Descaling: descaling treatment of cast slabs after being released from the furnace, the pressure of descaling water is 13MPa;

[0029] (4) Rough rolling: the cast slab after descaling is rough rolled to obtain a steel bar, the rough rolling start rolling temperature is 950°C, and 27 rolling mills are used for rough rolling;

[0030] (5) Pre-finish rolling: After rough rolling, the steel bar is pre-finish-rolled, and 27...

Embodiment 2

[0038] (1) Selection of cast slab: The mass percentage of cast slab is C: 0.05%, Si: 0.05%, Mn: 1.65%, P: 0.01%, S: 0.002%, O: 0.0015%, N: 0.006%, Mo: 0.35%, Ni: 0.25%, Ti: 0.06%, B: 0.006%, the rest is iron and unavoidable impurities;

[0039] (2) Heating: The billet enters the heating furnace for heating. The heating furnace adopts a walking beam heating furnace. The temperature of the preheating section is 600°C, the temperature of the heating section is 1100°C, the temperature of the soaking section is 1160°C, and the heating time is 120min ;

[0040] (3) Descaling: descaling treatment of cast slabs after being released from the furnace, the pressure of descaling water is 15MPa;

[0041] (4) Rough rolling: rough rolling the cast slab after descaling to obtain a steel bar, adopt 27 rolling mills for rough rolling, and the rough rolling start rolling temperature is 965°C;

[0042] (5) Pre-finish rolling: After rough rolling, the steel bar is pre-finish-rolled, and 27 rolli...

Embodiment 3

[0050] (1) Selection of cast slab: The mass percentage of cast slab is C: 0.04%, Si: 0.1%, Mn: 1.61%, P: 0.008%, S: 0.001%, O: 0.001%, N: 0.005%, Mo: 0.38%, Ni: 0.23%, Ti: 0.07%, B: 0.007%, the rest is iron and unavoidable impurities;

[0051] (2) Heating: The billet enters the heating furnace for heating. The heating furnace adopts a walking beam heating furnace. The temperature of the preheating section is 560°C, the temperature of the heating section is 1080°C, the temperature of the soaking section is 1100°C, and the heating time is 100min ;

[0052] (3) Descaling: descaling treatment of cast slab after being released from the furnace, the pressure of descaling water is 18MPa;

[0053] (4) Rough rolling: rough rolling the cast slab after descaling to obtain a steel bar, adopting 27 rolling mills for rough rolling, and the rough rolling starting temperature is 975°C;

[0054] (5) Pre-finish rolling: After rough rolling, the steel bar is pre-finish-rolled, and 27 rolling m...

PUM

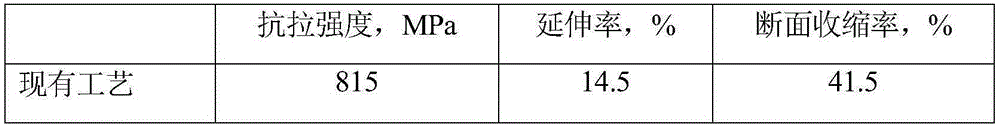

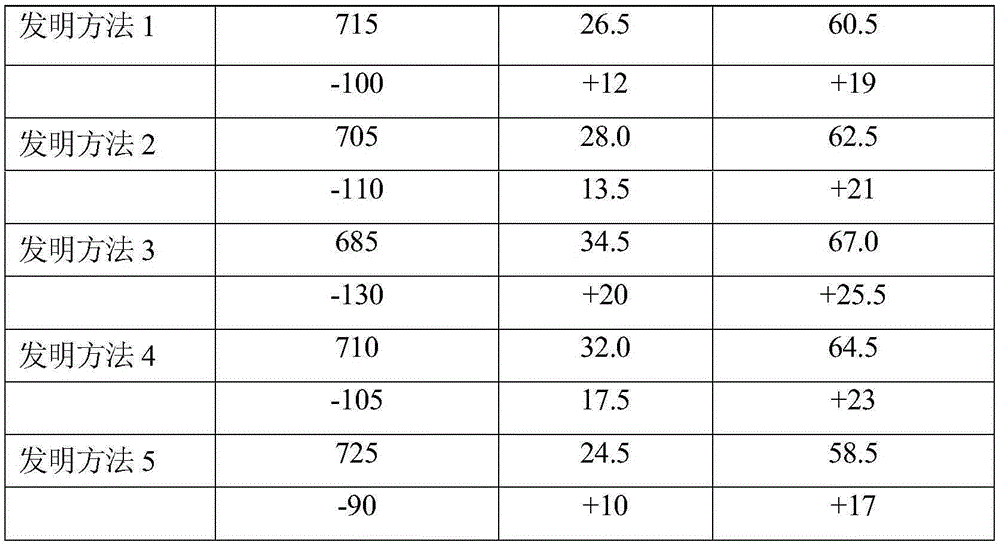

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com