Method for manufacturing titanium alloy sheet springs for smart drill pipes

A thin-film spring and manufacturing method technology, which is applied to manufacturing tools, metal processing equipment, forming tools, etc., can solve problems such as low surface gloss, achieve high surface gloss, facilitate mass production, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

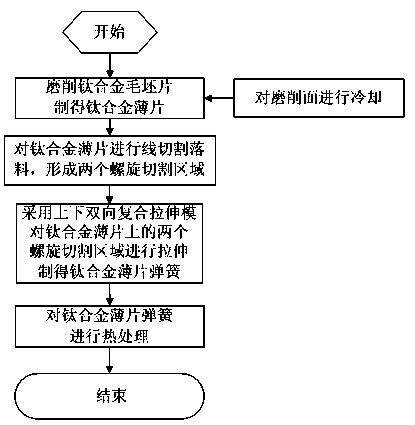

[0020] Such as figure 1 As shown, the manufacturing method of the titanium alloy leaf spring for intelligent drill rod provided by the present invention comprises the following steps:

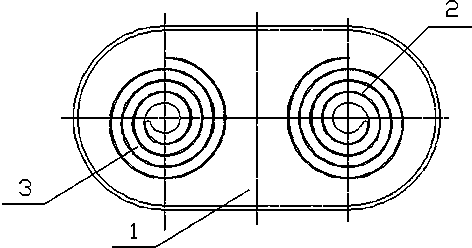

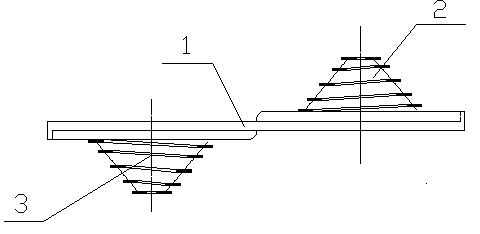

[0021] First, the titanium alloy blank is ground. During grinding, the distance of sliding friction on the plane can be reduced and the wear can be reduced by changing the grinding wheel material, grinding wheel structure and clamping method. While grinding, the grinding surface is cooled by the coolant, and the heat generated in the grinding is taken away by the coolant. The temperature of the grinding surface is basically controlled at room temperature, and the surface of the final processed material is magnified by 50 times. Obvious processing transition traces, the titanium alloy flake 1 with surface roughness ≤ 0.6 μm, flatness < 0.05 mm, and thickness tolerance ≤ 0.05 mm is produced. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com