Die-casting method of induction motor copper cage rotor and die casting device thereof

A squirrel-cage rotor and induction technology, applied in the directions of rotors, transmission devices, stators, etc., can solve the problems of poor casting flow, generation of air bubbles, affecting the working performance of motors, etc., to achieve the effect of reasonable process and device, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Die-cast 10HP copper rotor

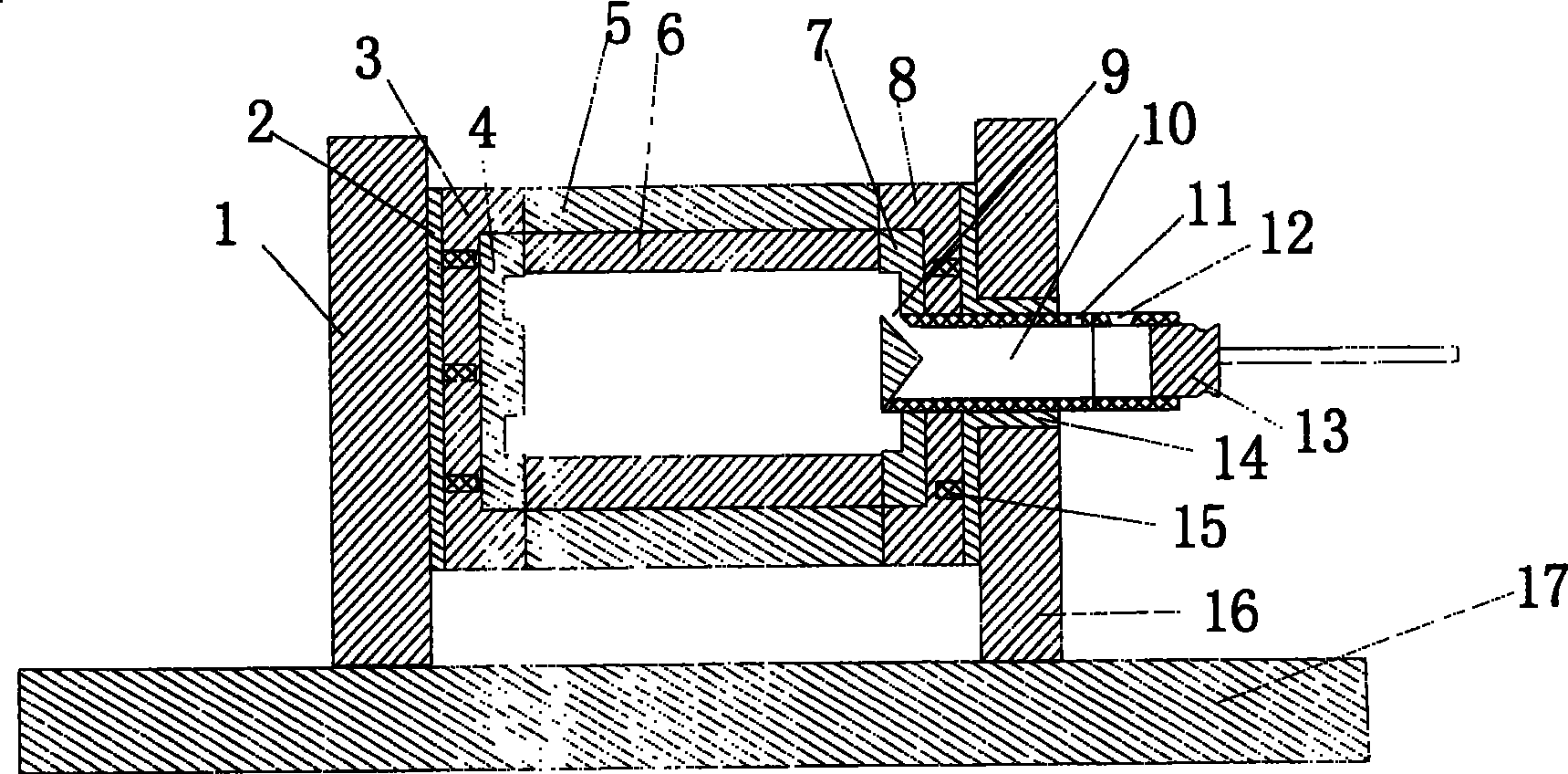

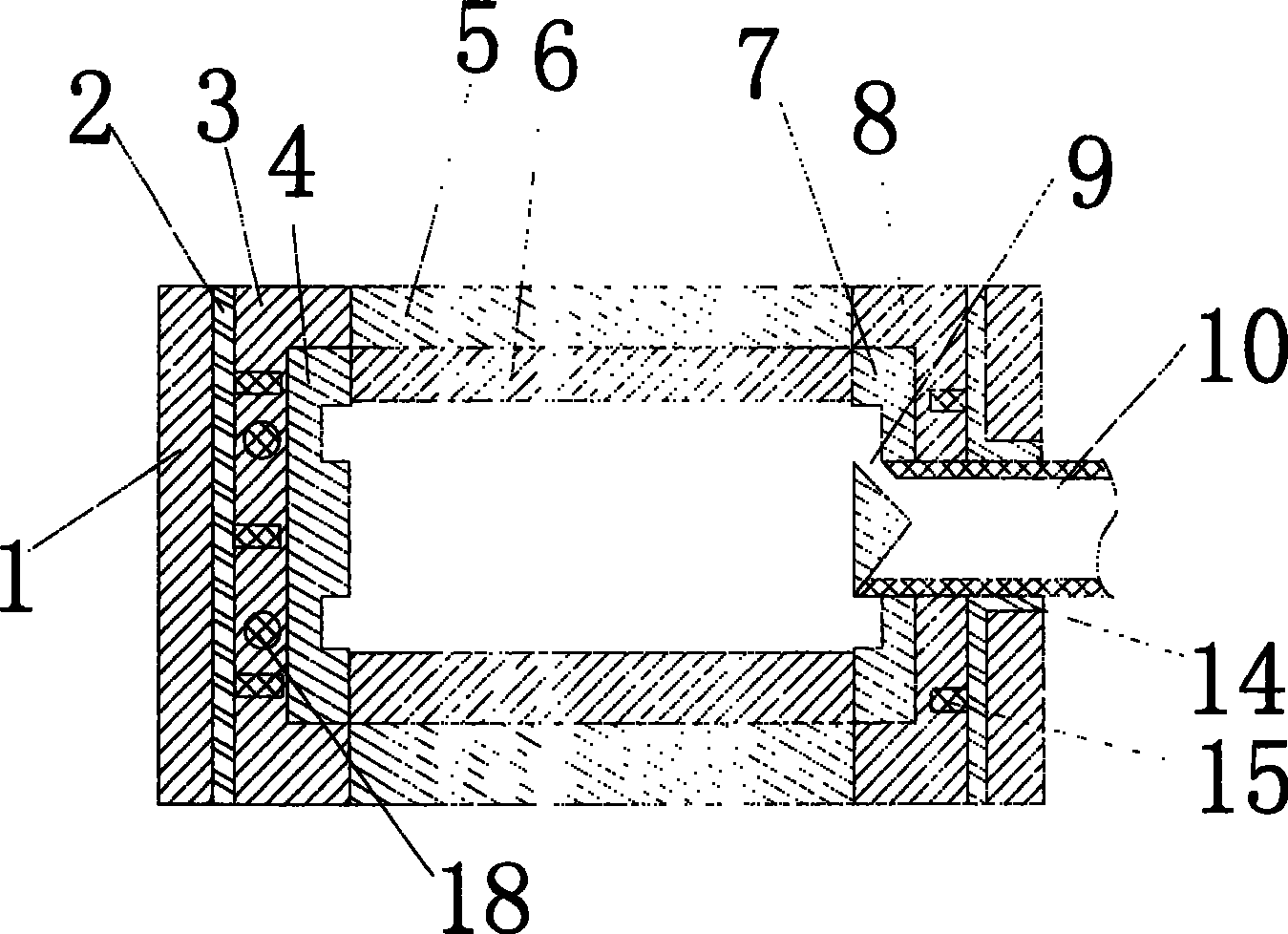

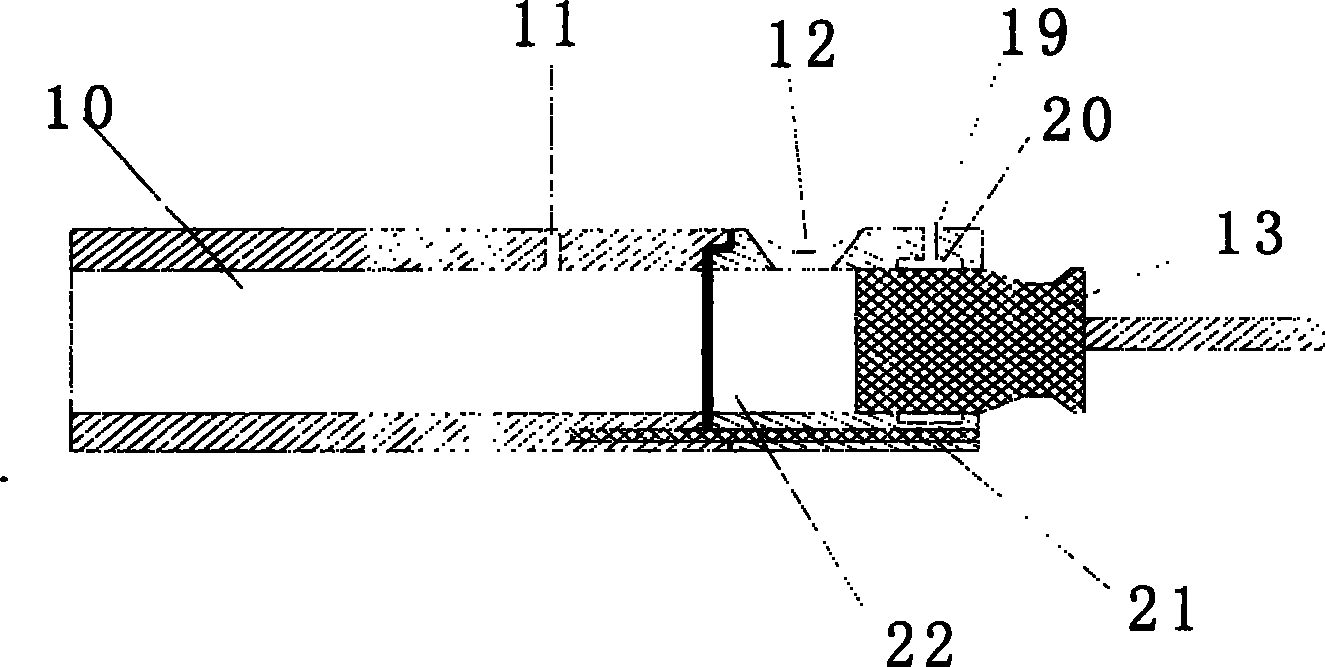

[0048] The die-casting method and die-casting device are as described in the Summary of the Invention and shown in the accompanying drawings.

[0049] The die casting process is:

[0050] 1. Preheating process

[0051] a. The die-casting mold uses a heating mold frame to preheat the mold, and the preheating temperature is controlled at 350-650°C;

[0052] b. The pressure chamber is preheated by concentrating on the lower half of the heating chamber, and the preheating temperature is controlled at 350-650°C;

[0053] c. Laminate the silicon steel sheet and heat it with an intermediate frequency furnace. The preheating temperature is kept at 350-500°C, and put it into the preheated mold cavity;

[0054] 2. Copper smelting

[0055] a. Copper material pretreatment: copper material is pure copper with a copper content greater than 99.995%. 6.4kg of pure copper raw material is processed into a copper rod with a length of 4cm. The co...

Embodiment 2

[0063] Basically with embodiment 1. The differences are:

[0064] The heating time is 40 minutes, and the mold temperature reaches 430°C; the copper material is a high-copper alloy with a copper content of not less than 90%, and 6.4kg of high-copper alloy raw material is processed into a copper rod with a length of 5cm, and the copper rod is blasted Remove the dirt, and then put it into the cold furnace, which can be preheated and smelted with the furnace; the feeding rate of the mixed gas is 0.6L / min, and the mixed gas is N 2 with H 2 Mixed, the mixed gas contains more than 95% nitrogen; the injection speed is 1.2m / s, and the injection pressure is 51.8Mpa.

Embodiment 3

[0066] Basically with embodiment 1. The differences are:

[0067] The heating time is 60 minutes, and the mold temperature reaches 500°C; the copper material is a high-copper-containing alloy with a copper content of not less than 90%, and 6.4kg of high-copper-containing alloy raw material is processed into a copper rod with a length of 6cm; Brush the head, pressure chamber and mold cavity with a paste lubricant mixed with Wolfrakote organic and inorganic substances sold on the market to treat the punch, pressure chamber and mold cavity; the mixed gas is N 2 Mixed with CO, the mixed gas contains more than 95% nitrogen; the injection speed is 2.83m / s, and the injection pressure is 81Mpa.

[0068] The product produced by the method of the present invention has no defects such as casting cracks, poor filling, sticky mold, etc., and its vibration present value meets the R-level regulation in IEC34-14 (1996), which is higher than the N-level specified in the Y series motor technic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com