A kind of high-performance bonded platinum alloy fine material for encapsulation and preparation method thereof

A platinum alloy, high-performance technology, applied in the field of high-performance bonded platinum alloy micro-materials for packaging and its preparation, to achieve the effects of uniform alloy composition without segregation, uniform and adjustable performance, and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

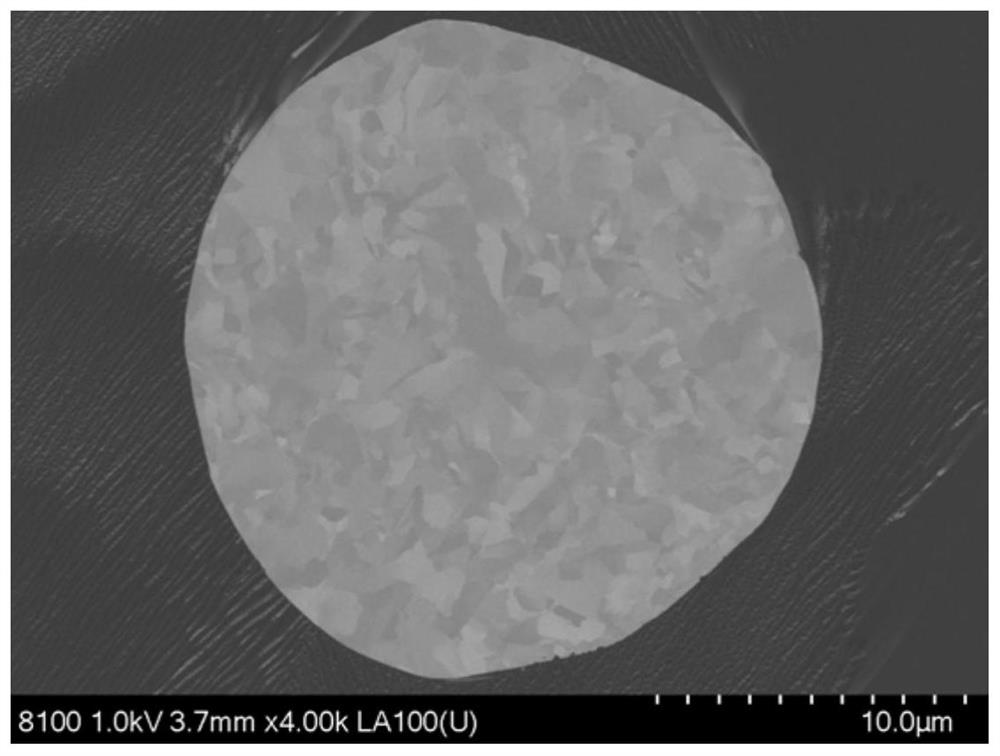

Image

Examples

preparation example Construction

[0040] The preparation method of the above-mentioned platinum alloy fine material comprises the following steps: 1. Preparation of master alloy; 2. Cast alloying of "continuous down drawing + directional solidification"; 3. "Rough drawing + online annealing + fine drawing"; 4. "Precise drawing Rolling + online resistance heating softening treatment".

[0041] 1) Master alloy preparation: In order to reduce burning loss and ensure the uniformity of alloy composition, Pt-Dy and Pt-Eu master alloys were first prepared by vacuum intermediate frequency induction melting method; the conditions were: vacuum degree 1.0×10 -3 Pa~1.0×10 -4 Pa, the smelting temperature is 1600-2000°C, after complete melting, stand for 1-3 minutes for refining, then close the vacuum, fill with argon, and quickly cast it into a water-cooled copper mold to obtain an intermediate alloy ingot.

[0042] 2) Alloying: The down-drawing continuous casting method is adopted, and a forced means is used during the s...

Embodiment 1

[0050] Preparation of Pt-10Dy and Pt-10Eu master alloys:

[0051] Put 500g of Pt into the crucible and evacuate to 1×10 -3 Below Pa, raise the temperature to 2000°C, after the Pt is completely melted, add 50g of Dy or Eu by post-feeding method when the temperature drops to 1600°C, until the temperature drops to 1400°C after the melt is completely melted, stand for refining for 3-5min, and then Under the protection of argon or nitrogen, it is quickly cast into a water-cooled copper mold, so that the uniformity of the composition can be achieved through instantaneous cooling, and Pt-10Dy and Pt-10Eu master alloys are obtained.

Embodiment 2

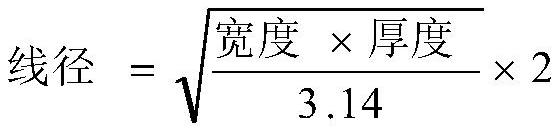

[0053] Prepare a high-performance bonded platinum alloy fine flat ribbon with a thickness of 12.5 μm and a width of 75 μm for high-end electronic packaging. In the platinum alloy, Ir: 0.5wt%, Ge: 1.0wt%, (Be+Dy): 0.03wt%, The balance is Pt.

[0054] 1. "Down-drawing continuous casting + directional solidification" alloying. Put 5gIr, 10gGe, 0.2gBe, 1gPt-10Dy master alloy (prepared in Example 1) and 983.8gPt into the crucible, vacuumize and heat to 2000°C for melting; carry out down-draw continuous casting, and the continuous casting speed is controlled at 50mm / min, The alloy melt temperature is controlled at 1750°C, the cooling water temperature at the continuous casting outlet is controlled below 25°C, and the cooling water flow range is 150L / h to ensure the crystallization speed of the melt and the stability of directional solidification, so as to realize Φ8mm single crystal Near net shape of billets.

[0055] 2. "Online annealing + drawing". The fine platinum alloy wire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com