Nickel base projectile and preparation method thereof

A nickel-based, projectile technology, applied in the direction of manufacturing tools, metal processing equipment, abrasives, etc., can solve problems such as insufficient impact resistance and friction resistance, impact on the service life of the blade surface, and insufficient strengthening effect, etc., to achieve The effect of high durability, high consistency of density and element ratio, and small difference in surface shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

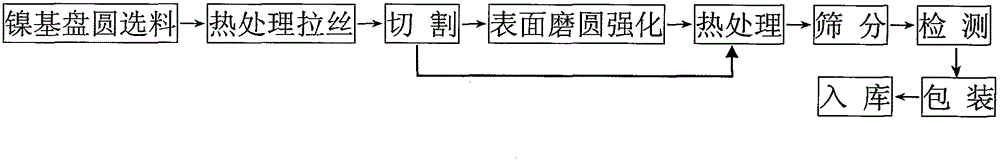

Method used

Image

Examples

Embodiment 2

[0017] A nickel-based projectile, its weight percentage is composed of 76.76% nickel, 21.24% chromium, and the balance is iron and unavoidable impurities.

[0018] The average hardness is 355HV.

Embodiment 3

[0020] A nickel-based projectile, its weight percentage is composed of 77.25% nickel, 20.75% chromium, and the balance is iron and unavoidable impurities.

[0021] The average hardness is 350HV.

[0022] Nickel-based projectile embodiment four

[0023] A nickel-based projectile, its weight percentage is composed of 78.74% nickel, 19.26% chromium, and the balance is iron and unavoidable impurities.

[0024] The average hardness is 345HV.

[0025] Nickel-based projectile embodiment five

[0026] A nickel-based projectile, its weight percentage is composed of 79.25% nickel, 18.75% chromium, and the balance is iron and unavoidable impurities.

[0027] The average hardness is 340HV.

[0028] Nickel-based projectile embodiment six

[0029] A nickel-based projectile, its weight percentage is composed of 80.75% nickel, 17.25% chromium, and the balance is iron and unavoidable impurities.

[0030] The average hardness is 335HV.

[0031] Nickel-based projectile embodiment seven

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com