Large section gear steel continuous casting round billet heating process

A technology of continuous casting round billet and heating process, which is applied in the field of metallurgical engineering, and can solve problems such as excessive band structure, potential safety hazards in use, and reduced reliability and service life of gears.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

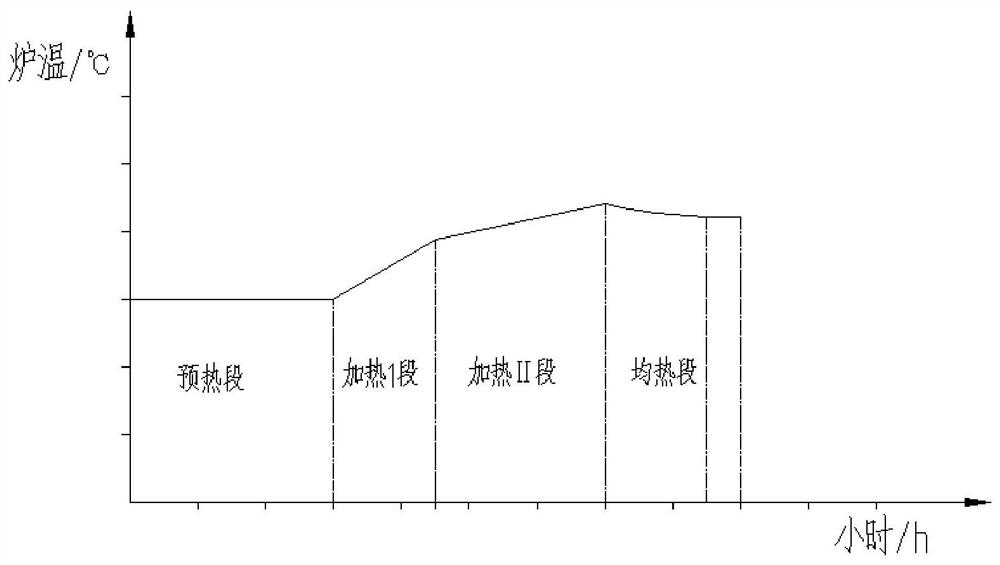

[0022] The φ650mm gear steel continuous casting round billet is put into the heating furnace to start heating in the preheating stage I. At this time, the temperature in the preheating stage I is 550°C, and the billet is heated in the preheating stage I for 3.0 hours, and enters the heating stage I;

[0023] At this time, the temperature of the heating section I is 1060°C, and the billet is heated for 1.5 hours in the heating section I, and enters the heating section II;

[0024] At this time, the temperature of the heating section II is 1230°C, and the billet is heated in the heating section II for 2.5 hours, and the high temperature diffusion time is 1.5h, and enters the soaking section;

[0025] At this time, the temperature in the soaking section is 1210° C., and the heating is carried out in the soaking section for 2.0 hours.

[0026] The total heating time from loading to firing of the φ650mm gear steel continuous casting round billet is 9 hours, and the high temperature...

Embodiment 2

[0029] The φ650mm gear steel continuous casting round billet is loaded into the heating furnace to start heating in the preheating stage I. At this time, the temperature in the preheating stage I is 850°C. The billet is heated in the preheating stage I stage for 3 hours, and enters the heating stage I;

[0030] At this time, the temperature in the heating section I is 1170°C, and the billet is heated in the heating section I for 1.5 hours, and then enters the heating section II;

[0031] At this time, the temperature in the heating section II is 1270°C, the billet is heated in the heating section II for 2.5 hours, and the high temperature diffusion time is 1.5h, and enters the soaking section;

[0032] At this time, the temperature in the soaking section is 1240° C., and the heating is carried out in the soaking section for 2 hours.

[0033] The total heating time from loading to firing of the φ650mm gear steel continuous casting round billet is 9 hours, and the high temperatu...

Embodiment 3

[0036] The φ650mm gear steel continuous casting round billet is loaded into the heating furnace to start heating in the preheating stage I. At this time, the temperature in the preheating stage I is 750°C, and the billet is heated in the preheating stage I for 4 hours, and enters the heating stage I;

[0037] At this time, the temperature of the heating section I is 1120°C, and the billet is heated for 2.0 hours in the heating section I, and enters the heating section II;

[0038] At this time, the temperature in the heating section II is 1250°C, the billet is heated in the heating section II for 3.0 hours, and the high temperature diffusion time is 2.0h, and enters the soaking section;

[0039] At this time, the temperature in the soaking section was 1230° C., and the heating was carried out in the soaking section for 3.0 hours.

[0040] The total heating time from the furnace loading to the discharge of the φ650mm gear steel continuous casting round billet is 12 hours, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com