Method for preparing porous material from short metal fibers

A technology of short metal fibers and porous materials, which is applied in the field of the preparation method of short metal fibers and its cutting device, can solve the problems of no mutual restraint of fibers, no guarantee of stability, difficulty in mass production, etc., and achieve small and uniform diameters, The effect of low production cost and no surface cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

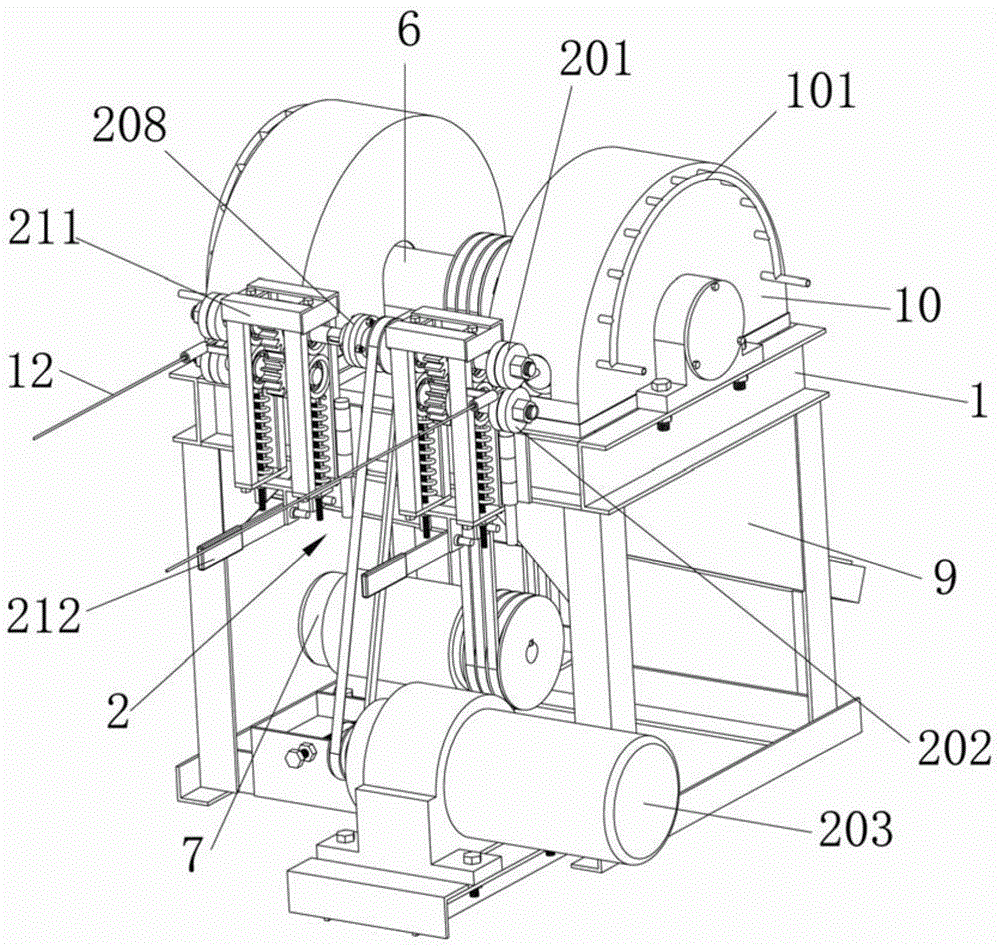

[0040] The preparation method of the short metal fiber of the present invention is firstly to make the long metal fiber wire material forward under the action of the pinch mechanism, and enter the through-die hole of the fixed knife die through the guide tube, wherein the The fixed knife die is equipped with a movable knife die that cooperates with it to cut the long metal fiber wire, and the outlet of the through die hole of the fixed knife die is a cutting edge; Continue to feed forward under the action, and pass through the through-die hole of the fixed knife die. When the long metal fiber material stretches out of the preset length through the die hole, the moving knife die makes a circular motion, and its linear blade The cutting edge of the die hole that is close to the fixed knife die passes, and the two blades form a pair of shearing motions, and finally cut the long metal fiber that protrudes through the die hole to produce short fibers of the required length.

[0041...

Embodiment 2

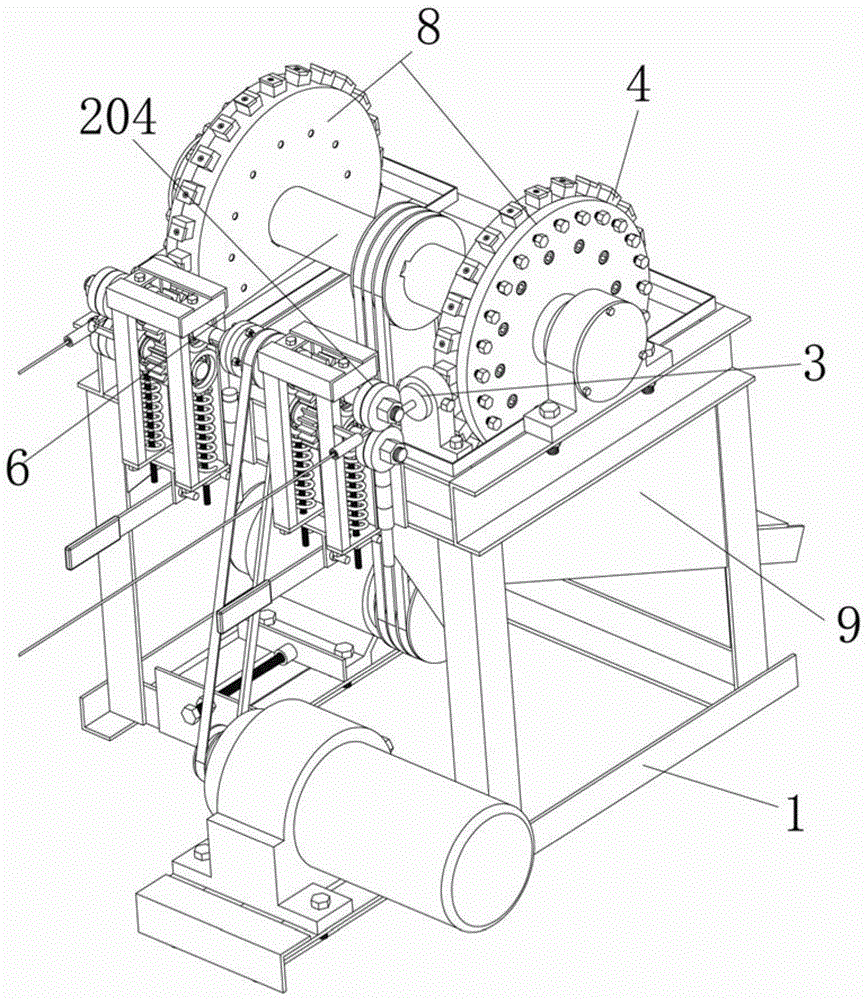

[0050] Such as Figure 9 to Figure 12 As shown, the difference from Embodiment 1 is that the pinch mechanism 2 described in this embodiment includes two relatively pressed and rotatable guide rollers 205, 206, and the guide rollers are driven to rotate by a power source. The roller surface is provided with a plurality of annular grooves 207 along its circumference at intervals along its length direction. The shape and size of the annular grooves 207 are adapted to the shape and size of the long fibers. The two guide rollers 205, 206 The annular grooves 207 on the top correspond one-to-one, and can be combined to form a plurality of passages for long fibers to pass through. One end of the long fiber 12 is placed in the corresponding passage, and the friction force of the guide roller realizes forward movement. send in. The rotating shaft 6 is equipped with at least two cutter heads 8 spaced apart, and in this embodiment there are eight specifically, and the periphery of each c...

Embodiment 3

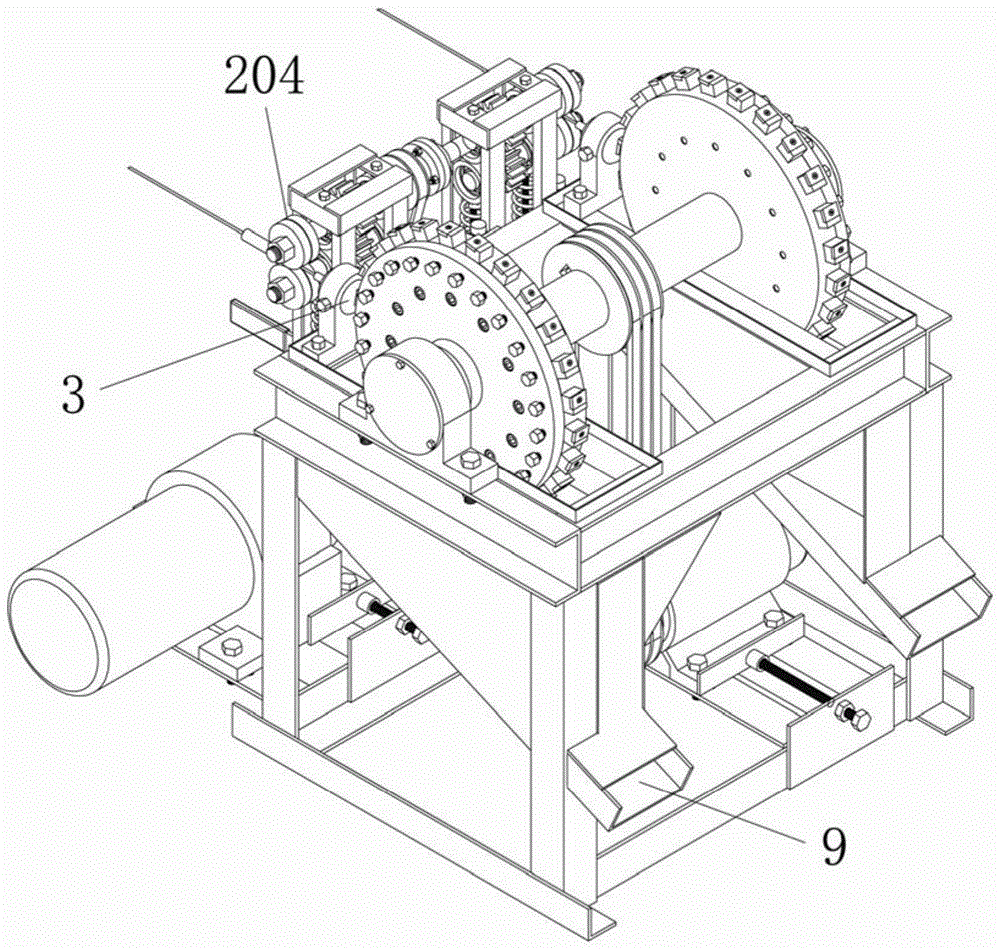

[0052] Such as Figure 13 As shown, the difference from Embodiment 1 is that there are multiple fixed knife dies 3 (specifically twelve) arranged in the circumferential direction of the single cutter head 8 in this embodiment and the guide pressure guides matched with the fixed knife dies 3 . wheel set, such that the cutter head 8 rotates once a week, the twelve fixed knife dies 3 are sheared at the same time, and its efficiency is 12 times that only one fixed knife die 3 is arranged in the circumferential direction of a single cutter head 8 . As long as it is not limited by the spatial arrangement, the number of fixed knives arranged in the circumferential direction of a single cutter head 8 is not limited to twelve. In order to ensure that the shortened fibers can smoothly enter the collection chamber, the present embodiment Figure 13 The normal direction is perpendicular to the ground, that is, the rotating shaft 6 used to bring the cutter head 8 to rotate is perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com