Preparation method and use method of AGE modified PVAc formaldehyde-free environment-friendly adhesive

A technology of aldehyde adhesives and adhesives, which is applied in the field of preparation of AGE-modified PVAc aldehyde-free environmentally friendly adhesives, can solve the problems of unsuitability for large-scale production, fast curing speed, and low bonding strength, and achieve improved solidification. Effects of content and emulsion stability, scale-up, strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

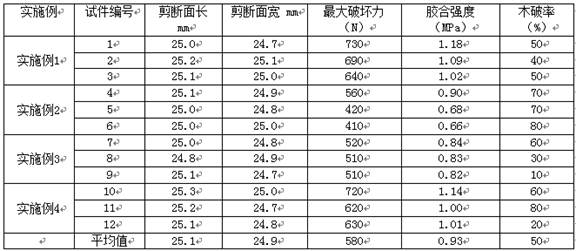

Embodiment 1

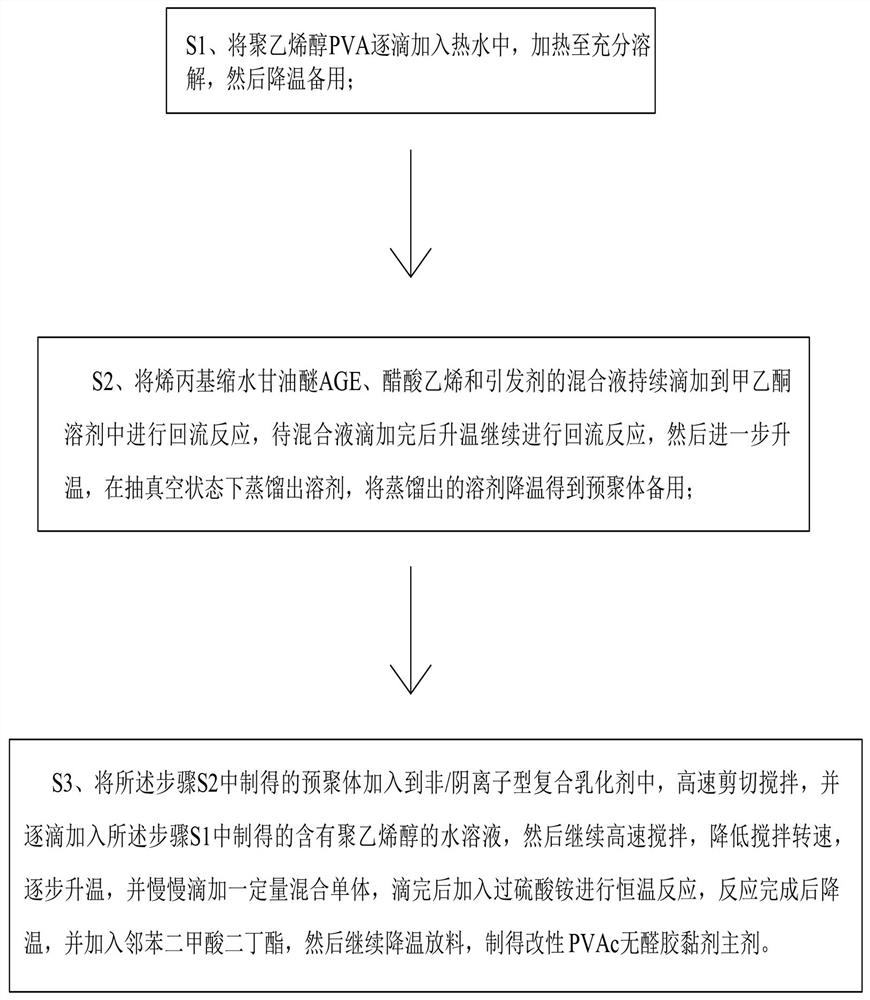

[0038] A kind of preparation method of AGE modified PVAc formaldehyde-free environmental protection adhesive, concrete steps are as follows:

[0039] S1. Add 0.3 parts of polyvinyl alcohol PVA17-88 dropwise to 32 parts of hot water, heat to about 90°C to fully dissolve, then cool down to 50°C for later use;

[0040]S2. Continuously add the mixture of allyl glycidyl ether AGE, vinyl acetate and initiator dropwise into 80°C methyl ethyl ketone solvent for reflux reaction within 3 hours, and heat up to 85°C to continue reflux after the mixture is added dropwise React for 1.5 hours, then further heat up to 90°C, distill off the solvent under vacuum, and cool down the distilled solvent to 43°C to obtain a prepolymer for use;

[0041] S3. Add the prepolymer prepared in the step S2 to 3 parts of non / anionic composite emulsifiers, stir at high speed for 10 minutes, and add the polyvinyl alcohol-containing polyvinyl alcohol prepared in the step S1 dropwise. Then continue to stir at hi...

Embodiment 2

[0050] A kind of preparation method of AGE modified PVAc formaldehyde-free environmental protection adhesive, concrete steps are as follows:

[0051] S1. Add 0.3 parts of polyvinyl alcohol PVA17-88 dropwise to 32 parts of hot water, heat to about 90°C to fully dissolve, then cool down to 50°C for later use;

[0052] S2. Continuously add the mixture of allyl glycidyl ether AGE, vinyl acetate and initiator dropwise into 80°C methyl ethyl ketone solvent for reflux reaction within 3 hours, and heat up to 85°C to continue reflux after the mixture is added dropwise React for 1.5 hours, then further heat up to 90°C, distill off the solvent under vacuum, and cool down the distilled solvent to 43°C to obtain a prepolymer for use;

[0053] S3. Add the prepolymer prepared in the step S2 to 3 parts of non / anionic composite emulsifiers, stir at high speed for 10 minutes, and add the polyvinyl alcohol-containing polyvinyl alcohol prepared in the step S1 dropwise. Then continue to stir at h...

Embodiment 3

[0062] A kind of preparation method of AGE modified PVAc formaldehyde-free environmental protection adhesive, concrete steps are as follows:

[0063] S1. Add 0.3 parts of polyvinyl alcohol PVA17-88 dropwise to 32 parts of hot water, heat to about 90°C to fully dissolve, then cool down to 50°C for later use;

[0064] S2. Continuously add the mixture of allyl glycidyl ether AGE, vinyl acetate and initiator dropwise into 80°C methyl ethyl ketone solvent for reflux reaction within 3 hours, and heat up to 85°C to continue reflux after the mixture is added dropwise React for 1.5 hours, then further heat up to 90°C, distill off the solvent under vacuum, and cool down the distilled solvent to 43°C to obtain a prepolymer for use;

[0065] S3. Add the prepolymer prepared in the step S2 to 3 parts of non / anionic composite emulsifiers, stir at high speed for 10 minutes, and add the polyvinyl alcohol-containing polyvinyl alcohol prepared in the step S1 dropwise. Then continue to stir at h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com