Dispersion stirring system having moving function

A technology with dispersing stirring and moving functions, which is applied in the field of dispersing and stirring systems and dispersing and stirring systems with moving functions, which can solve the problems of mixing process influence and low stirring efficiency, achieve diversified stirring positions, improve stirring efficiency, and move quickly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

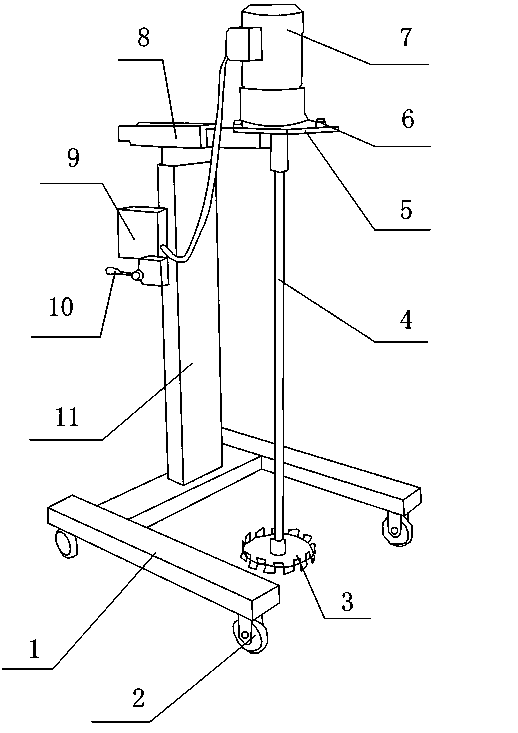

[0016] Such as figure 1 As shown, the dispersing mixing system with moving function includes a support frame 1, a plurality of rollers 2 are arranged on the bottom end of the support frame 1, a support column 11 is provided on the support frame 1, and a support column 11 is arranged on the support column 11. There is an installation platform 8 on which a motor 7 is arranged, and the motor 7 is connected with a dispersing disc 3 . The rapid movement of the system is realized by the roller 2, acting on different positions, avoiding the back and forth movement of the raw material cylinder, and improving the working efficiency.

[0017] The rollers 2 include two groups, each group has two rollers 2 , and the rollers 2 are evenly distributed at the bottom of the support frame 1 . Multiple sets of rollers 2 are provided to make the movement of the system faster and the direction of movement easier to grasp.

[0018] Described mounting table 8 is provided with mounting plate 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com