Cold rolling and annealing preparation method of high-tungsten high-cobalt nickel alloy ultra-fine grain panel

A technology of cold-rolling annealing and nickel alloy, which is applied in the field of cold-rolling annealing preparation of high-tungsten, high-cobalt-nickel alloy ultra-fine-grained sheets, can solve the problems of undiscovered cold-rolling annealing preparation method and grain uniformity control, and achieve microscopic Excellent results in tissue and macroscopic quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) An exemplary high-tungsten and high-cobalt nickel alloy for a drug-type mask contains, by mass percentage: 35% tungsten, 20% cobalt and the balance nickel.

[0026] 2) According to the element ratio of the alloy described in step 1), the raw materials are weighed, including: metal tungsten bar, metal cobalt plate and metal nickel plate. It was then melted in a vacuum induction furnace and cast into 25kg ingots.

[0027] 3) The ingot obtained in step 2) is homogenized, billeted, and hot-rolled, and then two passes of cold-rolled annealing are carried out, and the deformation of each pass is controlled at 30%. The time is 60 minutes, the annealing atmosphere is nitrogen, and the annealed sheet is air-cooled.

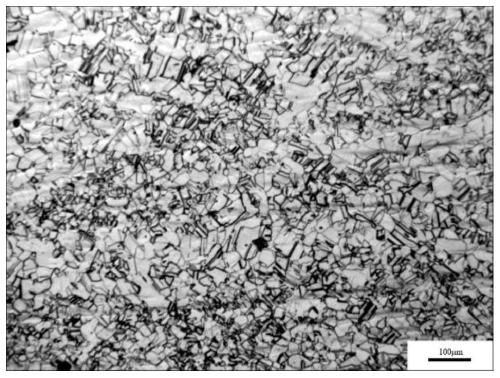

[0028] 4) The grain size is 8.5 grades, and the grain size difference is 1.5 grades;

[0029] 5) The elongation rate reaches 76%, and the tensile strength reaches 960MPa;

[0030] 6) The yield strength reaches 588MPa, which is 10.3% higher than the published d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com