High-protein non-dairy cream and preparation method thereof

A high-fat cream and high-protein technology, which is applied in the direction of cream preparations, dairy products, edible oil/fat components, etc., can solve the problems of high fat and low protein, and achieve good whipping performance, good stability, and good smoothness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

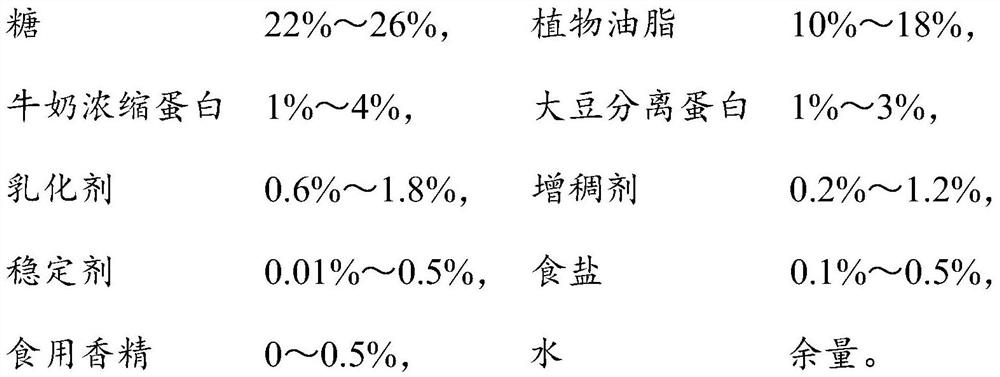

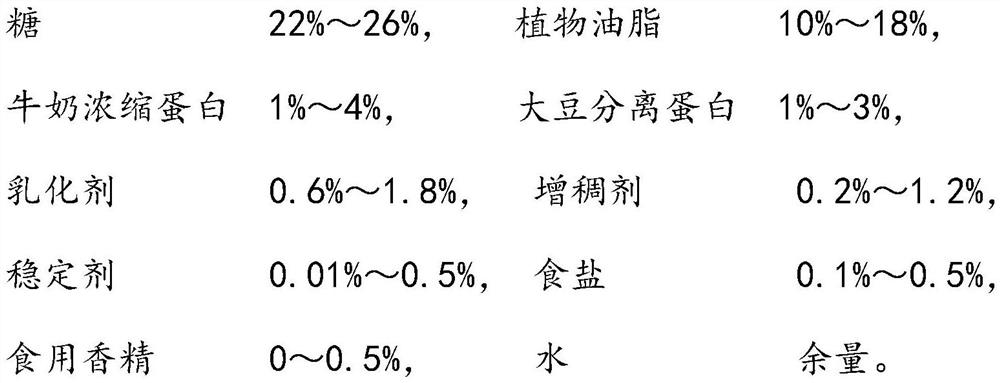

[0031] This embodiment provides a kind of high-protein whipped cream, which consists of the following raw materials in terms of weight percentage:

[0032] White sugar 20kg, trehalose 4kg, hydrogenated palm kernel oil 16kg, milk protein concentrate 3kg, soybean protein isolate 2kg, mono-diglyceride fatty acid ester 0.3kg, polyglycerol fatty acid ester 0.3kg, sodium stearoyl lactylate 0.3kg, alginic acid Sodium 0.06kg, carrageenan 0.06kg, xanthan gum 0.06kg, hydroxypropyl methylcellulose 0.06kg, trisodium phosphate 0.02kg, disodium hydrogen phosphate 0.02kg, salt 0.1kg, food flavor 0.5kg and water 53.22kg , a total of 100kg.

[0033] The preparation method of this high-protein whipped cream comprises the following steps:

[0034] S1. Heating the hydrogenated palm kernel oil and controlling it at 70°C to 72°C to form the oil phase;

[0035] S2. Put white granulated sugar, trehalose, milk protein concentrate, soybean protein isolate, and salt into water at 75°C to 80°C, stir to...

Embodiment 2

[0045] This embodiment provides a kind of high-protein whipped cream, which consists of the following raw materials in terms of weight percentage:

[0046] White sugar 22kg, trehalose 4kg, hydrogenated palm kernel oil 16kg, milk protein concentrate 1kg, soybean protein isolate 3kg, mono-diglyceride fatty acid ester 0.25kg, polyglycerol fatty acid ester 0.25kg, sodium stearoyl lactylate 0.25kg, alginic acid Sodium 0.06kg, carrageenan 0.06kg, xanthan gum 0.06kg, hydroxypropyl methylcellulose 0.06kg, trisodium phosphate 0.02kg, disodium hydrogen phosphate 0.02kg, salt 0.1kg, food flavor 0.5kg and water 52.37kg , a total of 100kg.

[0047] The preparation method of this high-protein whipped cream comprises the following steps:

[0048] S1. Heating the hydrogenated palm kernel oil and controlling it at 70°C to 72°C to form the oil phase;

[0049] S2. Put white granulated sugar, trehalose, milk protein concentrate, soybean protein isolate, and salt into water at 75°C to 80°C, stir...

Embodiment 3

[0059] This embodiment provides a kind of high-protein whipped cream, which consists of the following raw materials in terms of weight percentage:

[0060] White sugar 22kg, trehalose 4kg, hydrogenated palm kernel oil 16kg, milk protein concentrate 4kg, soybean protein isolate 1kg, mono-diglyceride fatty acid ester 0.25kg, polyglycerol fatty acid ester 0.25kg, sodium stearoyl lactylate 0.25kg, alginic acid Sodium 0.06kg, carrageenan 0.06kg, xanthan gum 0.06kg, hydroxypropyl methylcellulose 0.06kg, trisodium phosphate 0.02kg, disodium hydrogen phosphate 0.02kg, salt 0.1kg, food flavor 0.5kg and water 51.37kg , a total of 100kg.

[0061] The preparation method of this high-protein whipped cream comprises the following steps:

[0062] S1. Heating the hydrogenated palm kernel oil and controlling it at 70°C to 72°C to form the oil phase;

[0063] S2. Put white granulated sugar, trehalose, milk protein concentrate, soybean protein isolate, and salt into water at 75°C to 80°C, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com