Preparation method of strengthened steel pill

A technology for strengthening steel and steel shots, which is applied in the direction of manufacturing tools, metal processing equipment, abrasives, etc., can solve the problems of large hardness deviation, short service life, and easy breakage, and achieve small differences in surface shape, long service life, and surface strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

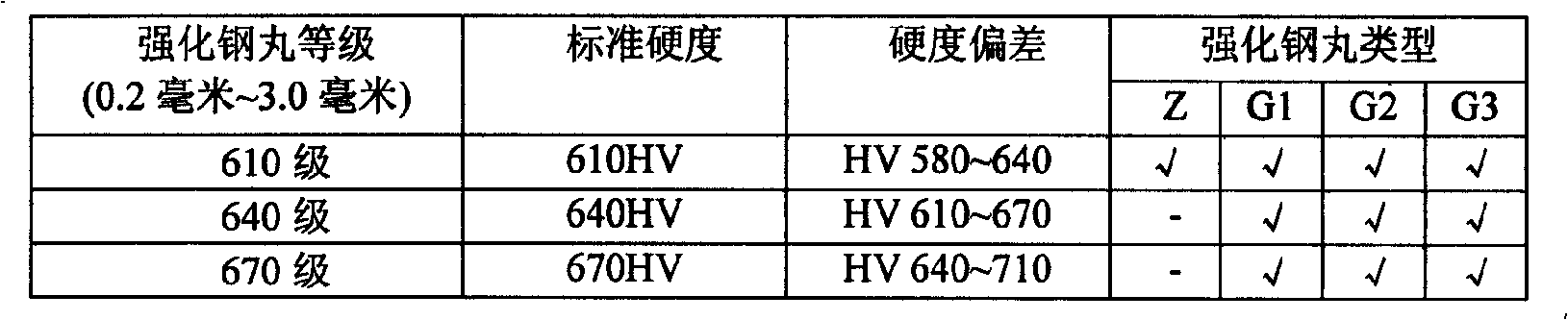

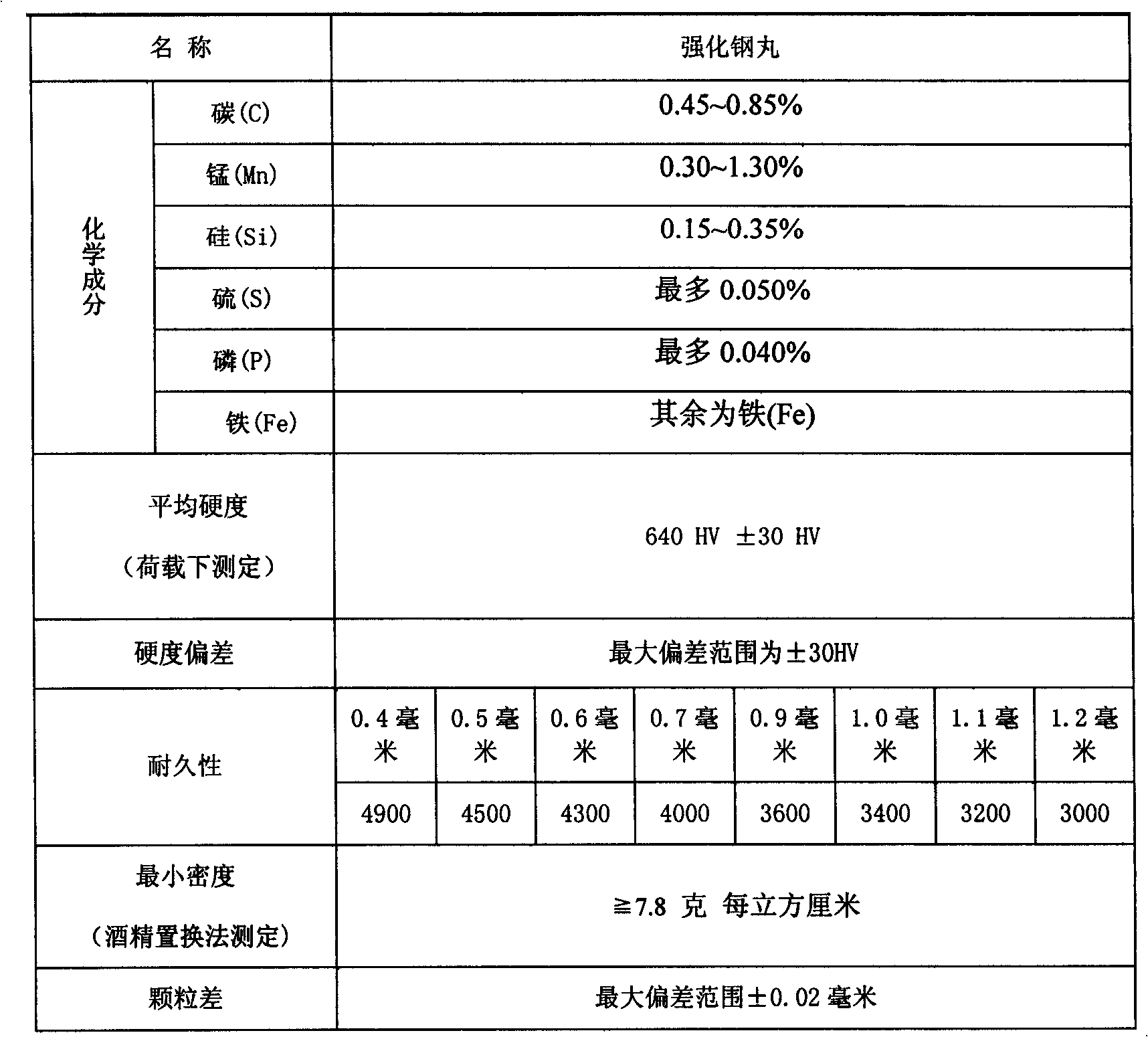

[0016] A kind of reinforced steel shot, its weight percentage is composed of carbon 0.45-0.85%, manganese 0.30-1.30%, silicon 0.15-0.35%, sulfur ≤ 0.050%, phosphorus ≤ 0.040%, and the balance is iron and unavoidable impurities. The average hardness is 640HV, and the hardness deviation range is ±25HV.

[0017] Reinforced steel shot can be divided into four categories according to the shape:

[0018] Cylindrical type - code-named Z;

[0019] Ellipse - code-named G1;

[0020] Quasi-spherical type - code-named G2;

[0021] Ball type - code-named G3.

[0022] To produce the above-mentioned reinforced steel shot, its production process is:

[0023] Material selection→drawing→cutting→sieving→testing→storage,

[0024] Or: material selection→wire drawing→cutting→surface rounding strengthening→sieving→testing→storage.

[0025] The selection of materials refers to the selection of elemental components according to the percentage by weight: carbon 0.45-0.85%, manganese 0.30-1.30%, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com