Cold-charge heating method of bearing steel continuous casting billet

A heating method and continuous casting billet technology, applied in the field of heat treatment, can solve the problems of surface cracks, coarse grains, decarburization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

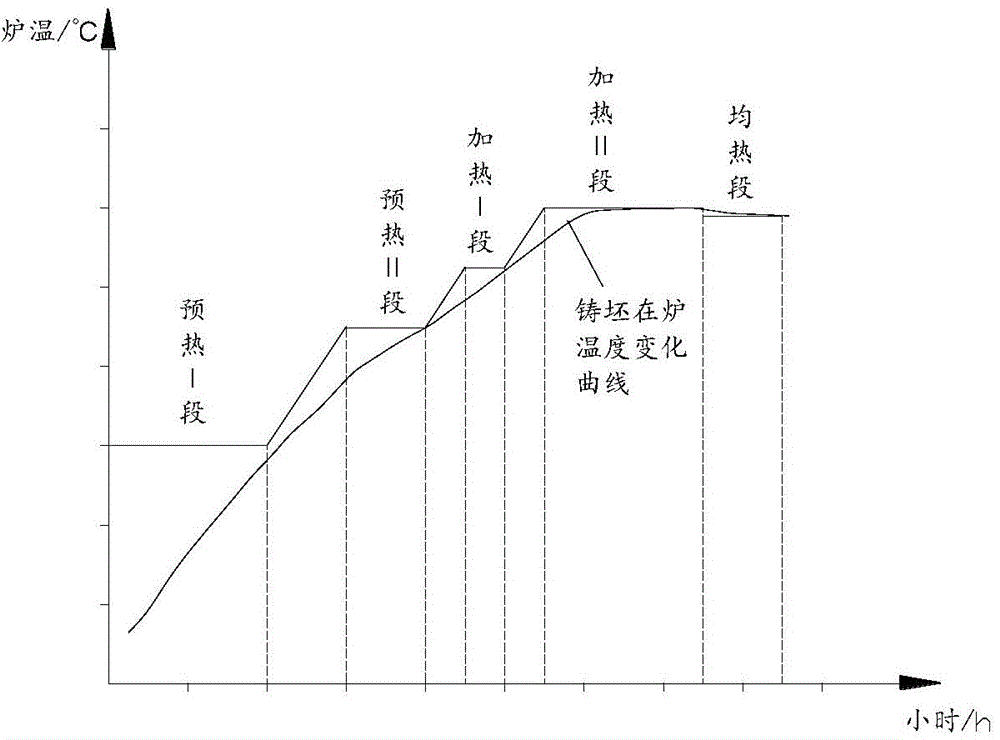

[0028] use figure 1 The process curve shown is for heating. The Φ650mm bearing steel continuous casting slab GCr15SiMn enters the slow cooling pit and slowly cools below 200°C after leaving the pit, and then puts it into the heating furnace in the cold state to start heating in the preheating stage I. At this time, the temperature in the preheating stage I is 600°C. The segmental billet is heated at a heating rate of 150°C / h for 4 hours;

[0029] The slab enters the preheating stage II at a heating rate of 150°C / h, and the heating time is 2 hours;

[0030] At this time, the temperature in the preheating stage II is 900°C, and the slab is heated at a heating rate of 150°C / h for 2 hours in the preheating stage II;

[0031] The slab enters the heating section I at a heating rate of 150°C / h, and the heating time is 1h;

[0032] At this time, the temperature in the heating stage I is 1050°C, and the slab is heated at a heating rate of 150°C / h for 1 hour in the heating stage I; ...

Embodiment 2

[0045] use figure 1 The process curve shown is for heating. The Φ650mm bearing steel continuous casting slab GCr15SiMn enters the slow cooling pit and slowly cools below 200°C after leaving the pit, and then puts it into the heating furnace in the cold state to start heating in the preheating stage I. At this time, the temperature in the preheating stage I is 550°C. The segmental billet is heated at a heating rate of 100°C / h for 5.5 hours;

[0046] The slab enters the preheating stage II at a heating rate of 100°C / h, and the heating time is 4.5h;

[0047]At this time, the temperature in the preheating stage II is 900°C, and the slab is heated at a heating rate of 100°C / h for 3 hours in the preheating stage II;

[0048] The slab enters the heating section I at a heating rate of 150°C / h, and the heating time is 1h;

[0049] At this time, the temperature of the heating stage I is 1050°C, and the slab is heated at a heating rate of 100°C / h for 1.5 hours in the heating stage I; ...

Embodiment 3

[0060] use figure 1 The process curve shown is for heating. The Φ650mm bearing steel continuous casting slab GCr15SiMn enters the slow cooling pit and slowly cools below 200°C after leaving the pit, and then puts it into the heating furnace in the cold state to start heating in the preheating stage I. At this time, the temperature in the preheating stage I is 600°C. The segmental billet is heated at a heating rate of 150°C / h for 4 hours;

[0061] The slab enters the preheating stage II at a heating rate of 150°C / h, and the heating time is 2 hours;

[0062] At this time, the temperature in the preheating stage II is 900°C, and the slab is heated at a heating rate of 200°C / h for 2 hours in the preheating stage II;

[0063] The slab enters the heating section I at a heating rate of 200°C / h, and the heating time is 0.75h;

[0064] At this time, the temperature in the heating stage I is 1050°C, and the slab is heated at a heating rate of 200°C / h for 1 hour in the heating stage I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com