Normal-temperature cheese food and preparation method thereof

A cheese and food technology, applied in the field of normal temperature cheese food and its preparation, can solve the problems of easy oil and water separation, unstable quality, granulated texture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

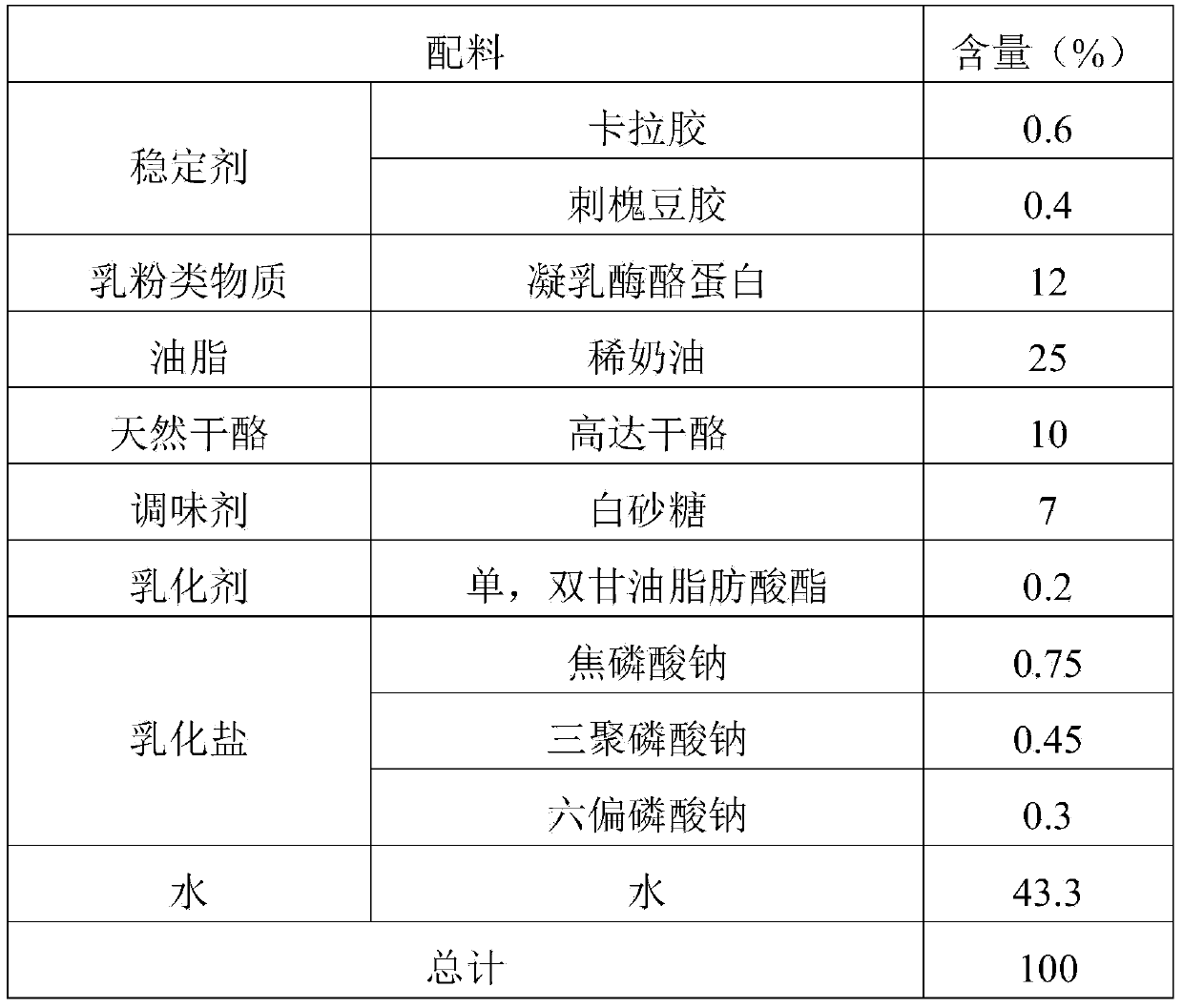

[0045] The raw material formula of the normal temperature cheese food of the present embodiment is as shown in table 1:

[0046] The raw material formula of the normal temperature cheese food of table 1 embodiment 1

[0047]

[0048] Preparation:

[0049] (1) Put the stabilizer, milk powder, flavoring agent, emulsifier and emulsified salt into the drum-type material homogenizer for pre-mixing;

[0050] (2) Stir the mixture of step (1), natural cheese and oil into the water, stir at 700RPM and heat up to 90°C, keep warm for 8min;

[0051] (3) Homogeneous, the primary pressure is 150bar, the secondary pressure is 50bar, and the homogeneous temperature is 88°C;

[0052] (4) Pouring and cooling to 0°C for molding;

[0053] (5) The cheese food obtained in step (4) is vacuum-dried at 0° C., and the moisture reaches 12%, and then vacuum-packed.

Embodiment 2

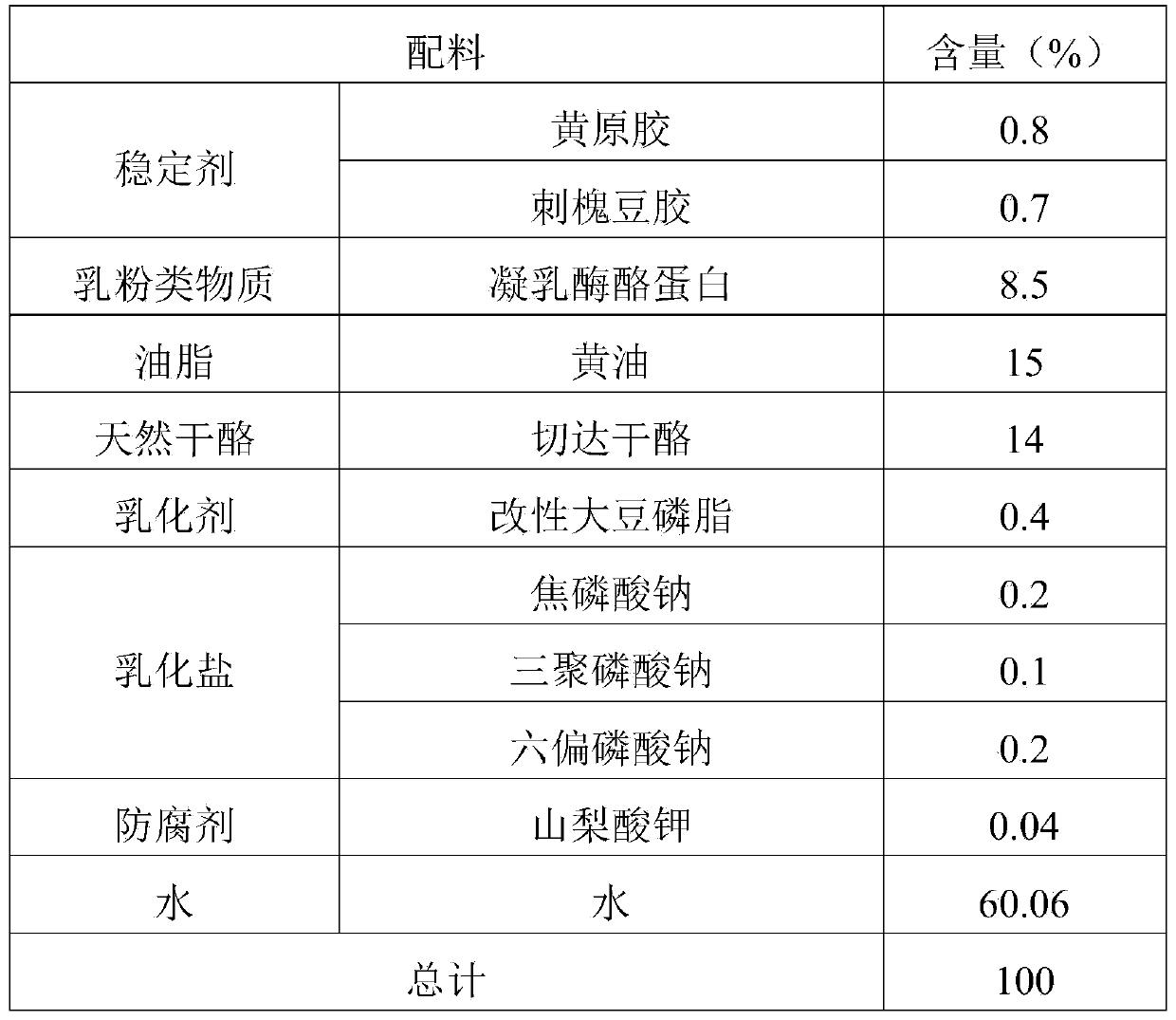

[0055] The raw material formula of the normal temperature cheese food of the present embodiment is as shown in table 2:

[0056] The raw material formula of the normal temperature cheese food of table 2 embodiment 2

[0057]

[0058] Preparation:

[0059] (1) Put stabilizers, milk powder substances, emulsifiers, emulsifying salts and preservatives into the drum-type material homogenizer for pre-mixing;

[0060] (2) Stir the mixture of step (1), natural cheese and oil into the water, stir at 600RPM and heat up to 95°C, keep warm for 5min;

[0061] (3) Homogeneous, the primary pressure is 160bar, the secondary pressure is 40bar, and the homogeneous temperature is 95°C;

[0062] (4) Pouring and cooling to 10°C for molding;

[0063] (5) Vacuum-dry the cheese food obtained in step (4) at 10° C., pack with nitrogen after the moisture reaches 20%.

Embodiment 3

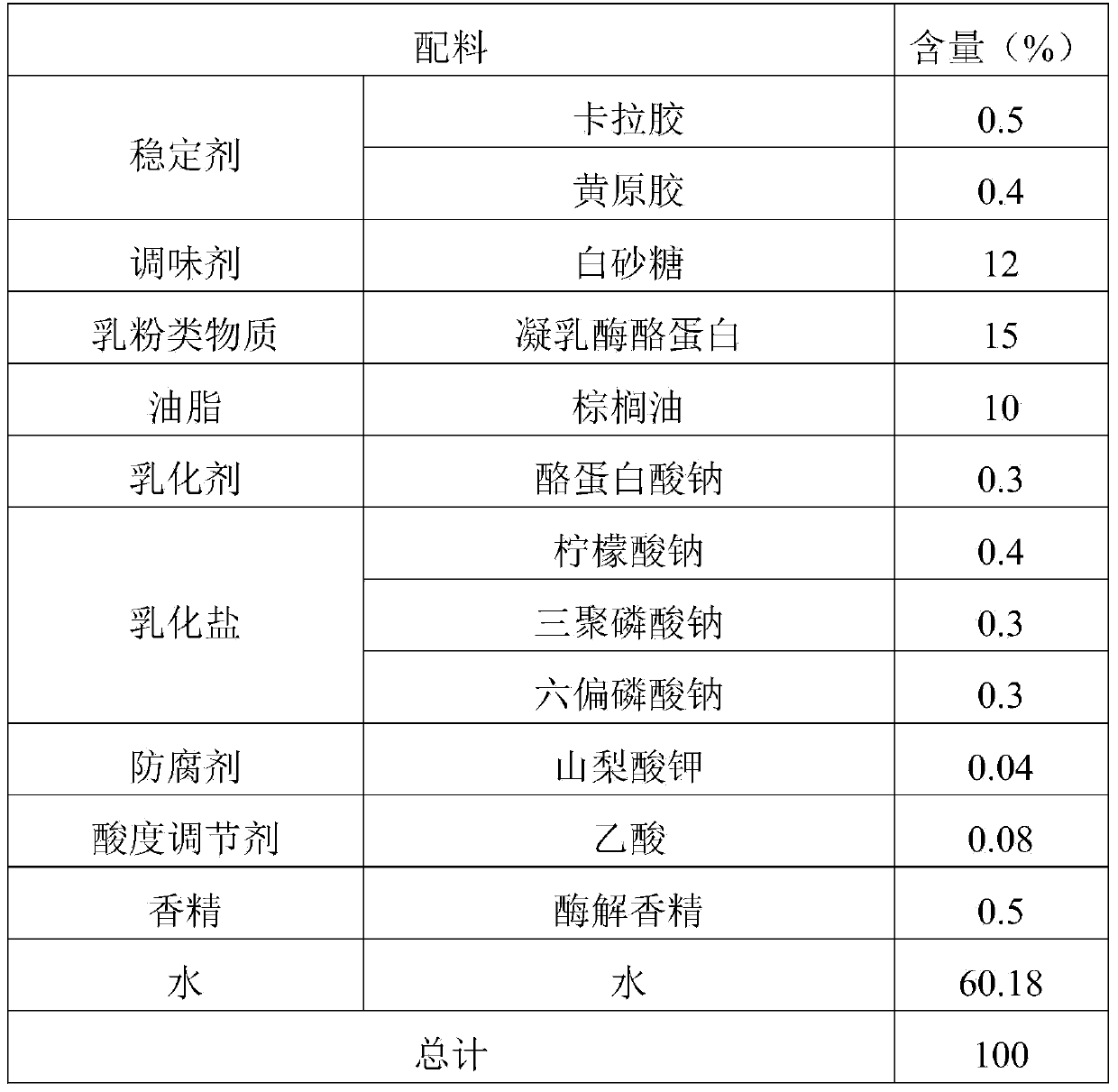

[0065] The raw material formula of the normal temperature cheese food of the present embodiment is as shown in table 3:

[0066] The raw material formula of the normal temperature cheese food of table 3 embodiment 3

[0067]

[0068] Preparation:

[0069] (1) Put stabilizers, milk powder substances, flavoring agents, emulsifiers, emulsifying salts and preservatives into a vertical material homogenizer for pre-mixing;

[0070] (2) Stir the mixture, oil, acidity regulator and essence in step (1) into water, stir at 800RPM and heat up to 92°C, and keep warm for 6 minutes;

[0071] (3) Homogeneous, the primary pressure is 150bar, the secondary pressure is 50bar, and the homogeneous temperature is 91°C;

[0072] (4) Pouring and cooling to 20°C for molding;

[0073] (5) Dry the cheese food obtained in step (4) with carbon dioxide blowing at 20° C., and pack it with carbon dioxide after the moisture reaches 22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com