Ceramic tile and its preparing process

A production process and ceramic tile technology, applied in the field of ceramic tiles and their production process, can solve the problems of no antibacterial, purify the environment, etc., and achieve the effects of good strength and hardness, hard texture, and natural and simple color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A ceramic tile is fired from the following raw materials in weight percentage: 65% of Jin'an pottery clay, 10% of Hushan pottery clay, and 25% of bamboo charcoal powder.

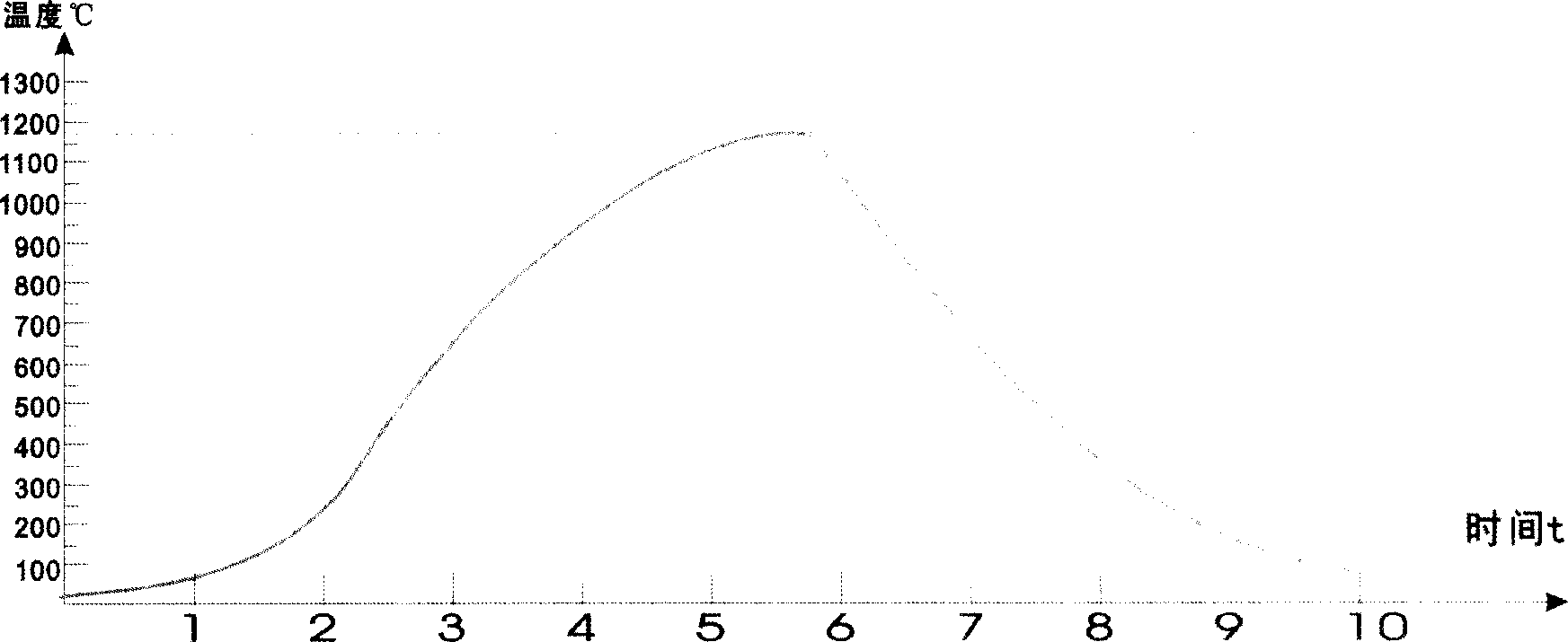

[0020] The invention relates to a ceramic tile manufacturing process, which includes the steps of material selection, water washing, clay refining, molding, drying, glaze dipping, firing and the like.

[0021] (1) Material selection: Jin'an pottery clay 65%, Hushan pottery clay 10%, bamboo charcoal powder 25%

[0022] Jin'an pottery clay has strong plasticity and toughness, and can be shaped into various shapes. After drying, it can still maintain its original shape and hardness. It can be bent at will and is not easy to break. Strong, low firing temperature, the tiles after firing have high strength and are not easy to corrode; black nano-scale bamboo charcoal powder can make the color of the tiles black inside and outside, and the color is natural and simple. Bamboo charcoal powder is mainly compose...

Embodiment 2

[0031] A ceramic tile is fired from the following raw materials in weight percentage: 55% of Jin'an pottery clay, 15% of Hushan pottery clay, and 230% of bamboo charcoal powder.

[0032] Compared with Example 1, the present embodiment selects 55% of Jin'an pottery clay, 15% of Hushan pottery clay, and 30% of bamboo charcoal powder as raw materials, and the other process steps are all the same.

Embodiment 3

[0034] A ceramic tile is fired from the following raw materials in weight percentage: 50% of Jinan pottery clay, 15% of Hushan pottery clay, and 35% of bamboo charcoal powder.

[0035] Compared with Example 1, the present embodiment selects 50% of Jin'an pottery clay, 15% of Hushan pottery clay, and 35% of bamboo charcoal powder as raw materials, and the other process steps are all the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com