Normal-temperature processed cheese and preparation method thereof

A technology of processed cheese at room temperature, applied in dairy products, cheese substitutes, applications, etc., can solve the problems of hard and brittle texture, easily damaged tissue, inedible, etc., and achieve mild flavor, easy storage, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

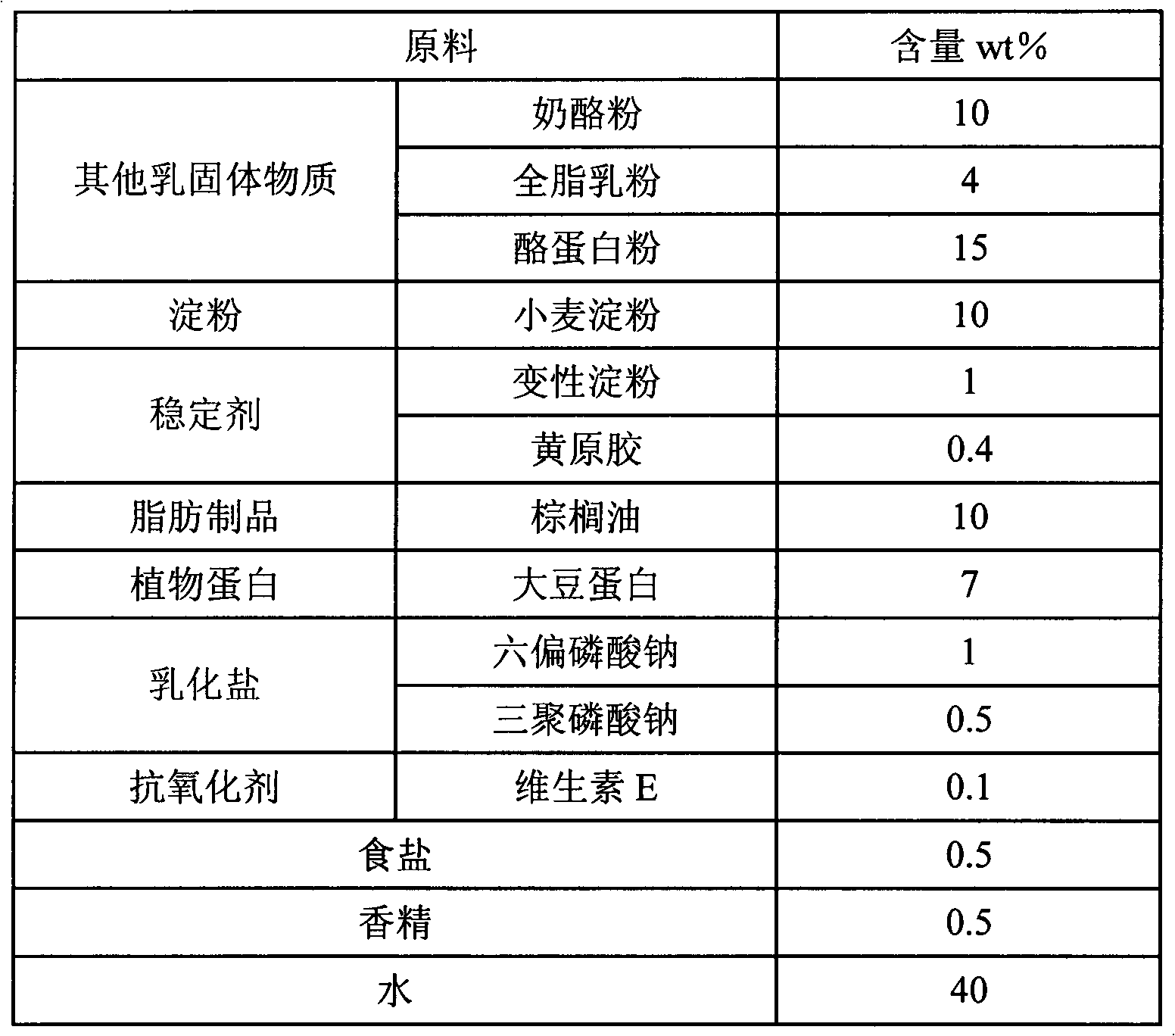

[0030] Raw material formula:

[0031]

[0032] Preparation:

[0033] ① According to the above formula, put all the raw materials into the melting pot, heat the steam to 50°C, and shear and stir at 600rpm for 1min to obtain the premixed slurry;

[0034] ② Stir and emulsify the pre-mixed slurry at a speed of 900rpm, directly heat the steam to a temperature of 90°C, and then keep it warm for 2 minutes;

[0035] ③Hot filling aseptic vacuum packaging, the vacuum degree is -0.8bar; the oxygen permeability of the vacuum packaging material is 5cc / m 2 ·Below 24h.atm.

[0036] ④Molding and cooling with tap water.

[0037] After testing, the index of processed cheese obtained is: 25% protein; 16% fat; 10% carbohydrate; 43% moisture; pH 5.7.

Embodiment 2

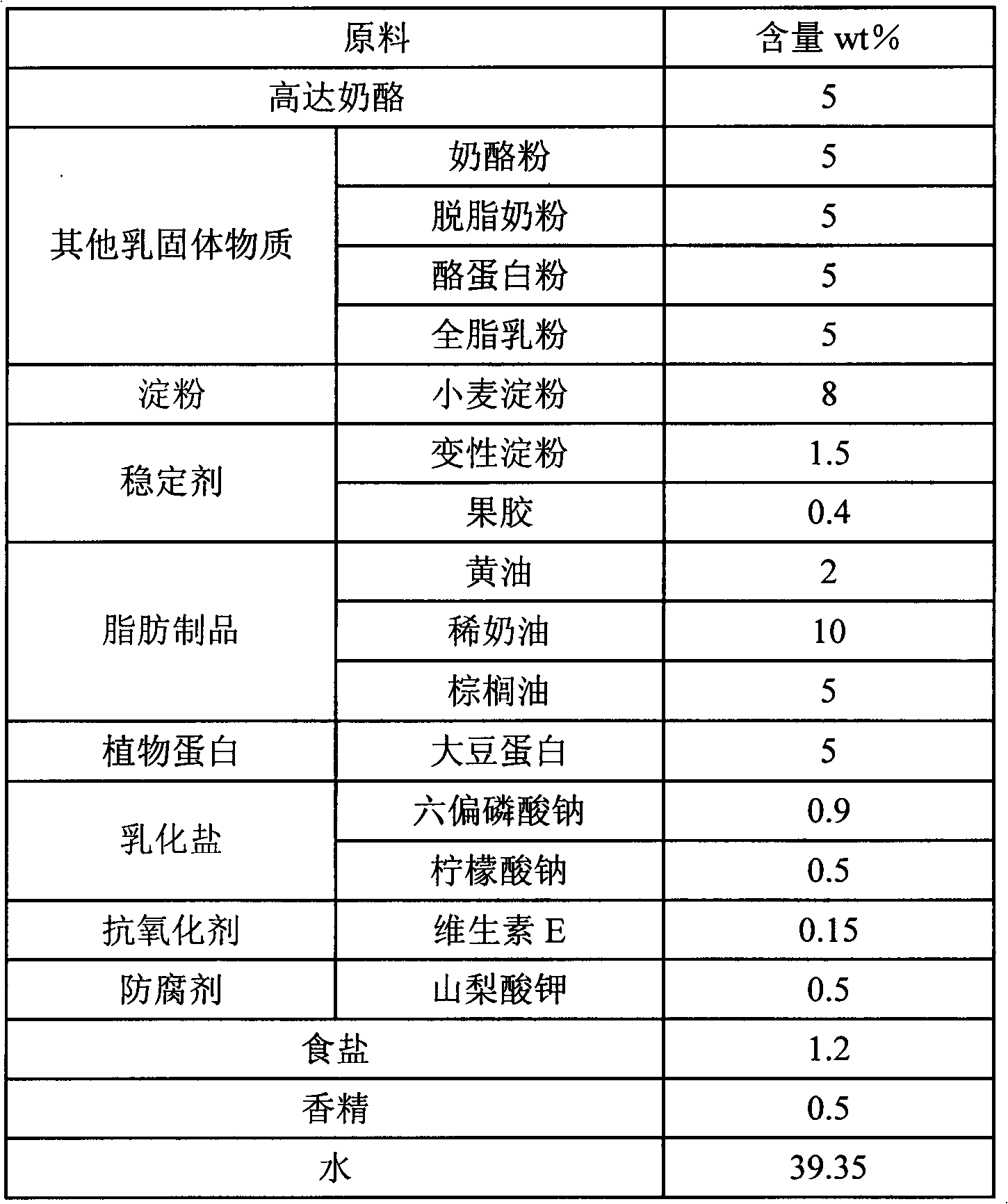

[0039] Raw material formula:

[0040]

[0041] Preparation:

[0042] ① According to the above formula, put all the raw materials into the melting pot, heat the steam directly to a temperature of 35°C, and shear and stir at 600rpm for 1min to obtain a premixed slurry;

[0043] ② Stir and emulsify the pre-mixed slurry at a speed of 1200rpm, heat the steam directly to a temperature of 88°C, and then keep it warm for 4 minutes;

[0044] ③Hot filling aseptic vacuum packaging, the vacuum degree is -0.9bar; the oxygen permeability of the vacuum packaging material is 5cc / m 2 ·Below 24h.atm.

[0045] ④Molding and cooling with tap water.

[0046] After testing, the index of the obtained processed cheese is: 15.7% protein; 16.2% fat; 12.8% carbohydrate; 49% moisture; pH 5.3.

Embodiment 3

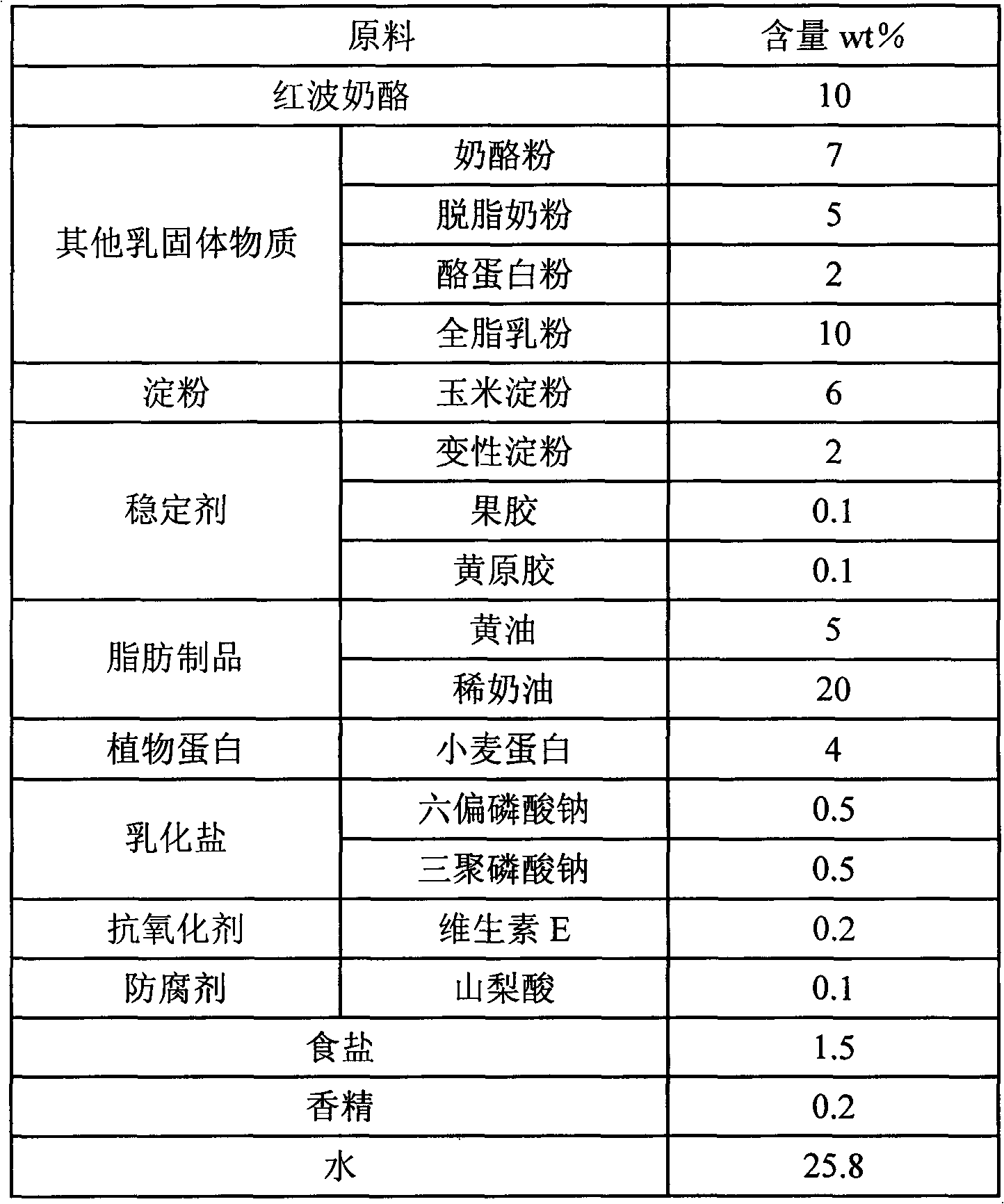

[0048] Raw material formula:

[0049]

[0050] Preparation:

[0051] ① According to the above formula, put all the raw materials into the melting pot, heat the steam directly to a temperature of 40°C, and shear and stir at 700rpm for 3 minutes to obtain a premixed slurry;

[0052] ② Stir and emulsify the pre-mixed slurry at a speed of 1500rpm, heat it directly with steam to a temperature of 92°C, and then keep it warm for 5 minutes;

[0053] ③Hot filling aseptic vacuum packaging, the vacuum degree is -0.8bar; the oxygen permeability of the vacuum packaging material is 5cc / m 2 ·Below 24h.atm.

[0054] ④Molding and cooling with tap water.

[0055] After testing, the index of processed cheese obtained is: 15.2% protein; 21.8% fat; 13.5% carbohydrate; 42.68% moisture; pH 5.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com