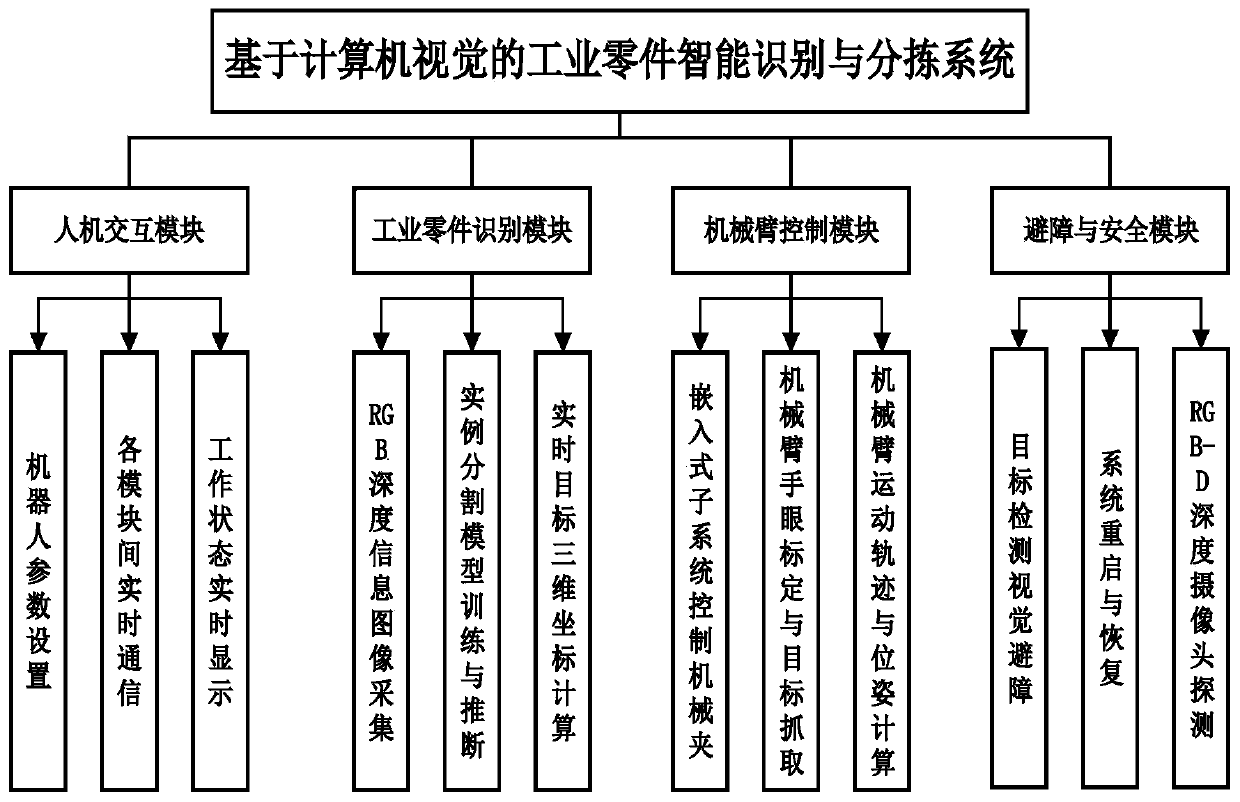

Industrial part intelligent identification and sorting system based on computer vision

A computer vision and intelligent recognition technology, applied in sorting, manipulators, manufacturing tools, etc., can solve problems affecting production efficiency, slow sorting speed, and low efficiency, so as to improve the probability of successful grabbing, reduce manual participation, The effect of ensuring human-machine safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

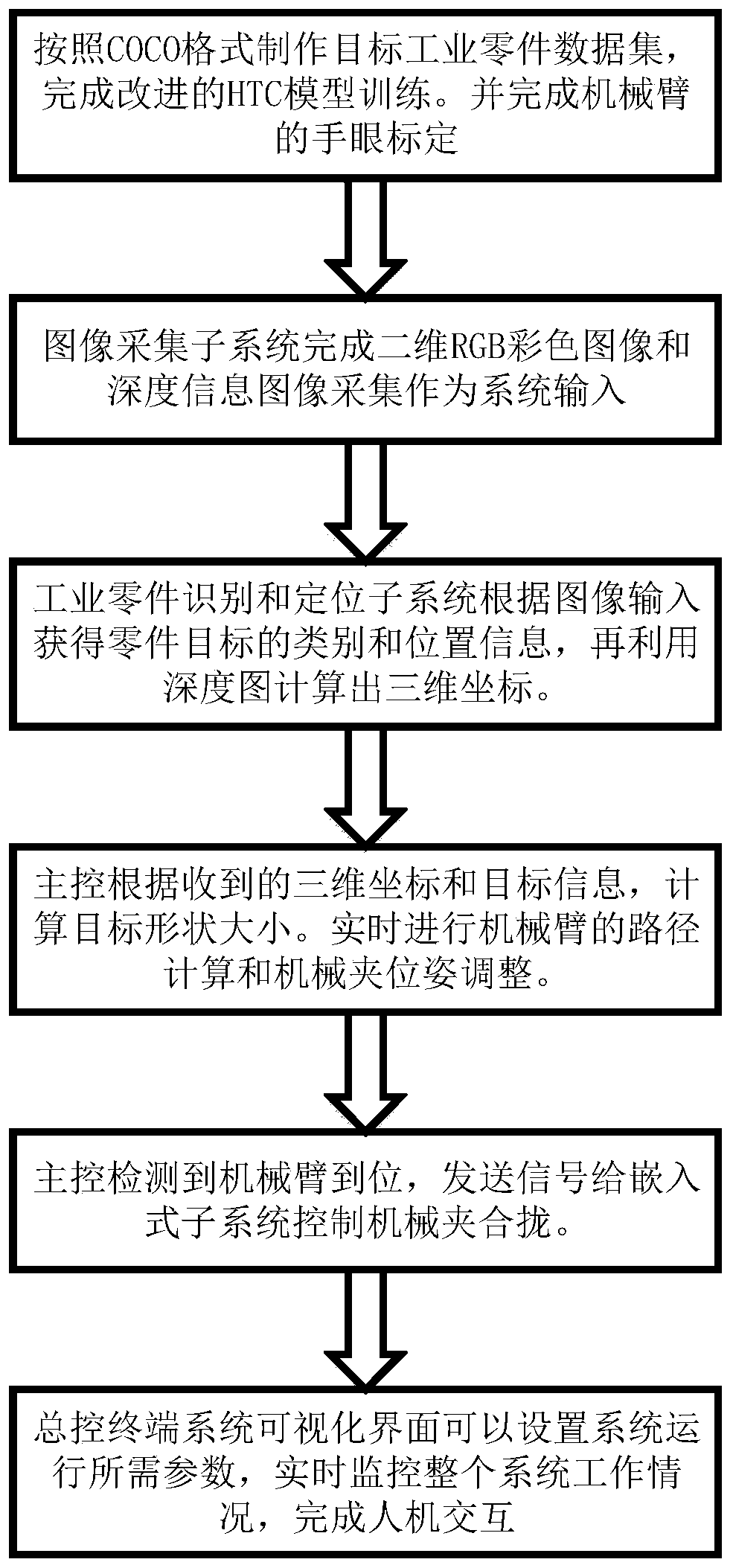

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

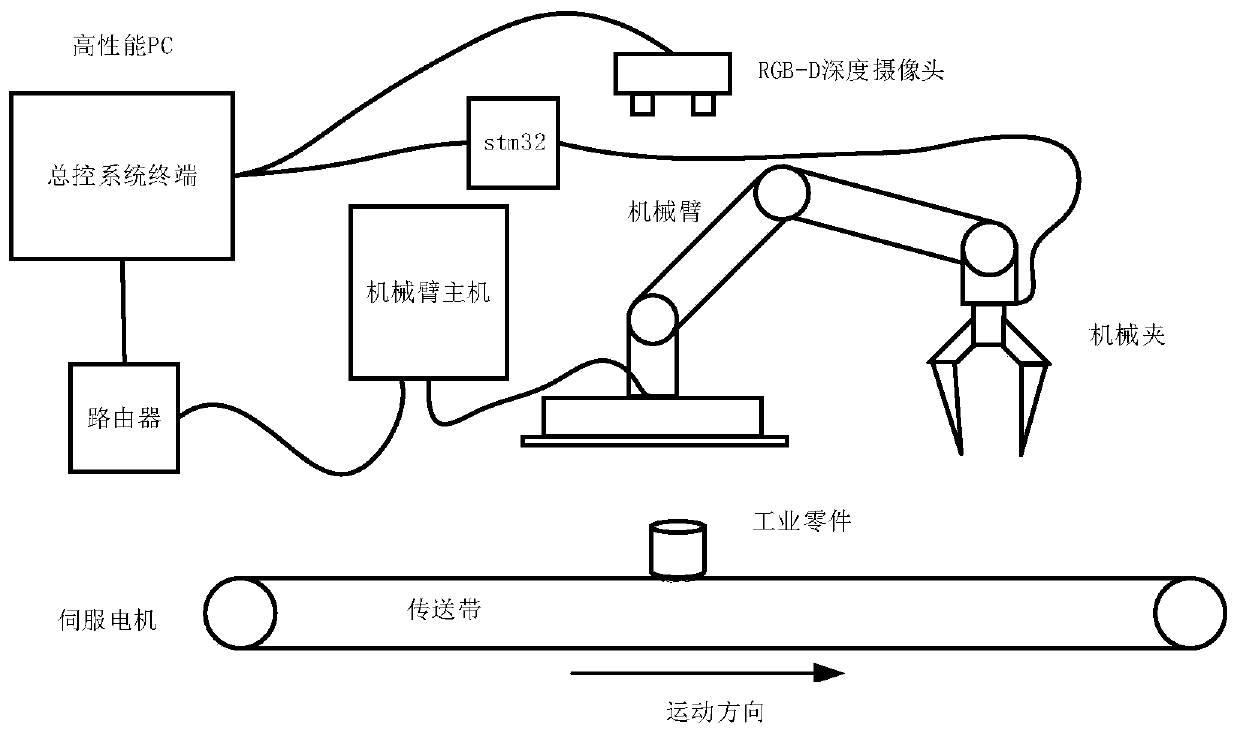

[0025] The specific hardware used in the embodiment is:

[0026] The master control system terminal is a high-performance PC equipped with GPU;

[0027] The robotic arm is the terminal robotic arm of the UR5 master control system;

[0028] The main machine of the mechanical clamp is a stm32 single-chip microcomputer;

[0029] The image collector is a RealScene D435 depth camera, and is equipped with four soft light LED light sources around it to eliminate the light and shadow effects of the objects to be sorted and provide stable lighting conditions to obtain a clearer image of the items to be sorted.

[0030] The host of the mechanical arm and the host of the mechanical clamp communicate with the terminal of the master control system using the TCP protocol. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com