Full-automatic camera parameter calibration method based on colored calibration board

A camera parameter and calibration method technology, applied in the field of computer vision, can solve the problems of low precision and error zoom lens calibration requiring a lot of repetitive work, so as to improve the calibration accuracy and reduce manual participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

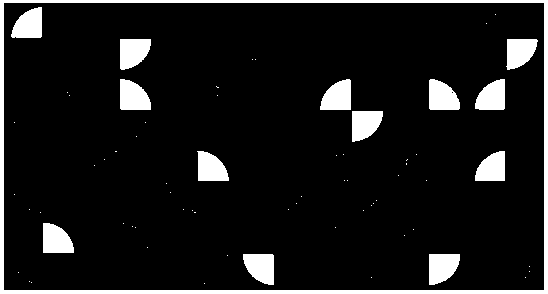

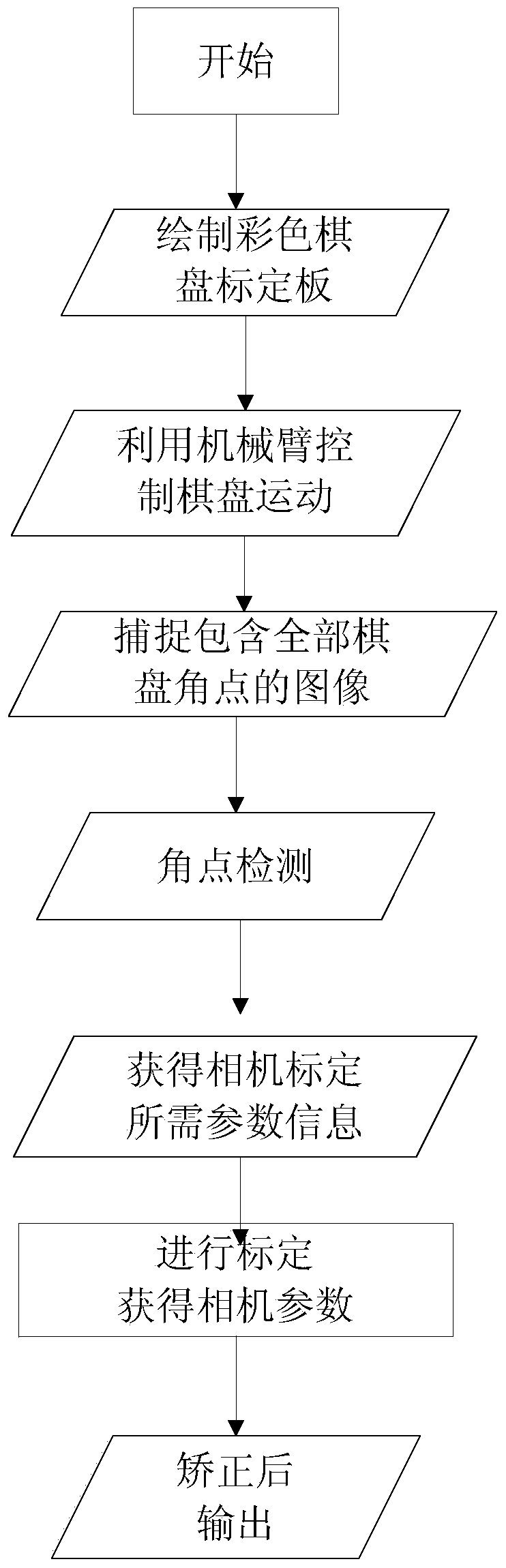

[0028] The color calibration board designed by this method is arranged in different color combinations, so that each corner point has a unique color combination coordinate (hereinafter referred to as "color standard"), and the corner points designed in this way can be rotated when the calibration board is rotated or the camera is focused. When , the "color scale" remains unchanged, that is, the corner points have the characteristics of rotation and scale invariance; and the movement of the chessboard is controlled by the mechanical arm to capture the calibration image. Then the camera is automatically calibrated. This method can correct the distortion effect caused by camera hardware design, reduce manual participation, and improve calibration accuracy.

[0029] Aiming at the deficiencies in the prior art, the present invention proposes a fully automatic camera parameter calibration method based on a color checkerboard. In this method, the required color calibration board is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com