Force-taking power testing platform of paver spiral distributor and using method thereof

A technology of auger and paver, which is used in the testing of machine/structural components, the testing of mechanical components, force/torque/work measuring instruments, etc., can solve the problem of unfavorable product batch testing equipment development, rapid testing, human error factors, testing standards, etc., to improve the efficiency of subsequent production and research and development, ensure safety and reliability, and ensure the accuracy of stopping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, and the present invention is not limited to the following embodiments.

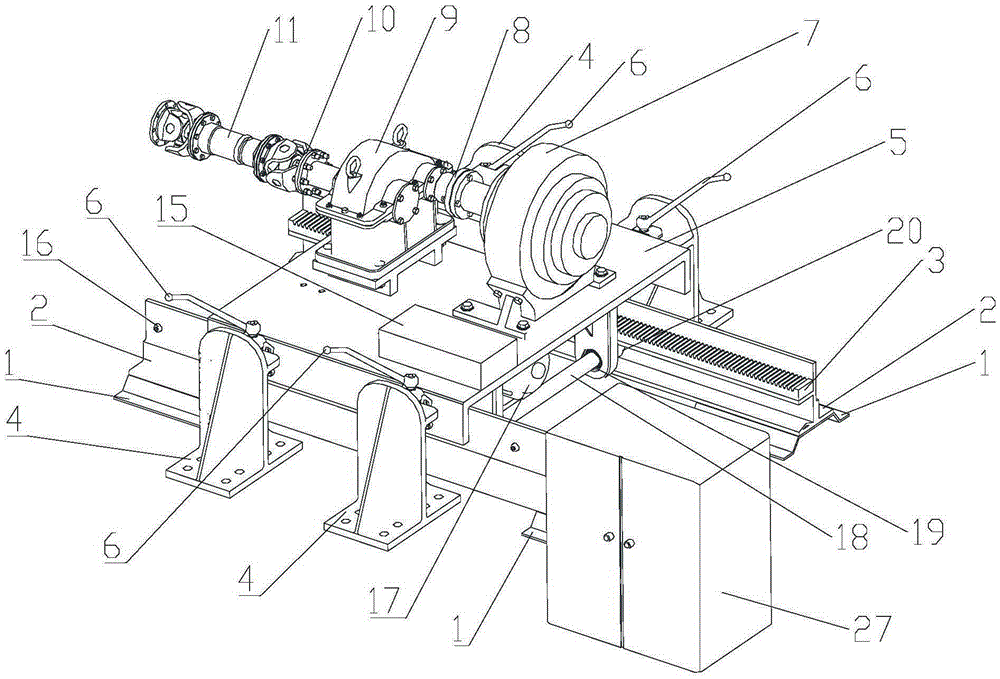

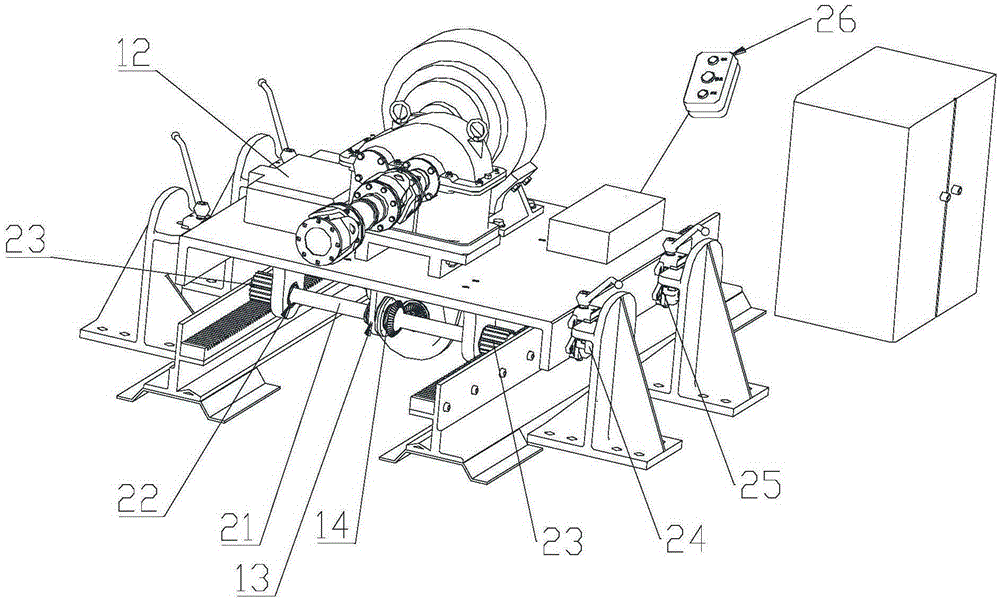

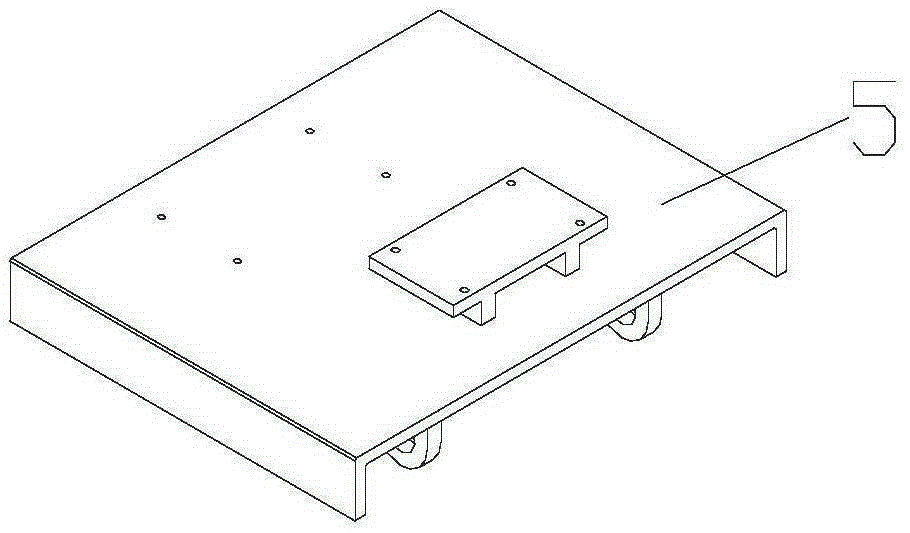

[0048] Such as Picture 1-1 , Figure 1-2 As shown, the present invention includes a mobile platform 5 (such as figure 2 shown), the test assembly installed on the mobile platform 5, the toolbox 12 for the electrical assembly and the mobile platform test, the mobile platform traction system installed at the bottom of the mobile platform 5 (such as Figure 8 As shown), the left and right support guide mechanism (guide rail) 2 of the platform installed on the foundation and matched with the walking system of the traction system of the mobile platform (such as Figure 6 As shown), the left and right sides of the mobile platform 5 are equipped with a mobile platform locking mechanism 6 (as shown in Figure 3).

[0049] Such as Picture 1-1 , Figure 1-2 As shown, the test ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com