Long-span working-at-height rapid construction special cage

A technology for high-altitude operations and special vehicles, applied in the direction of lifting devices, etc., can solve the problems of large manpower and material resources, slow construction progress, and few operable personnel, so as to reduce traffic impact, improve practicability and reliability, and reduce the ground The effect of the influence of traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

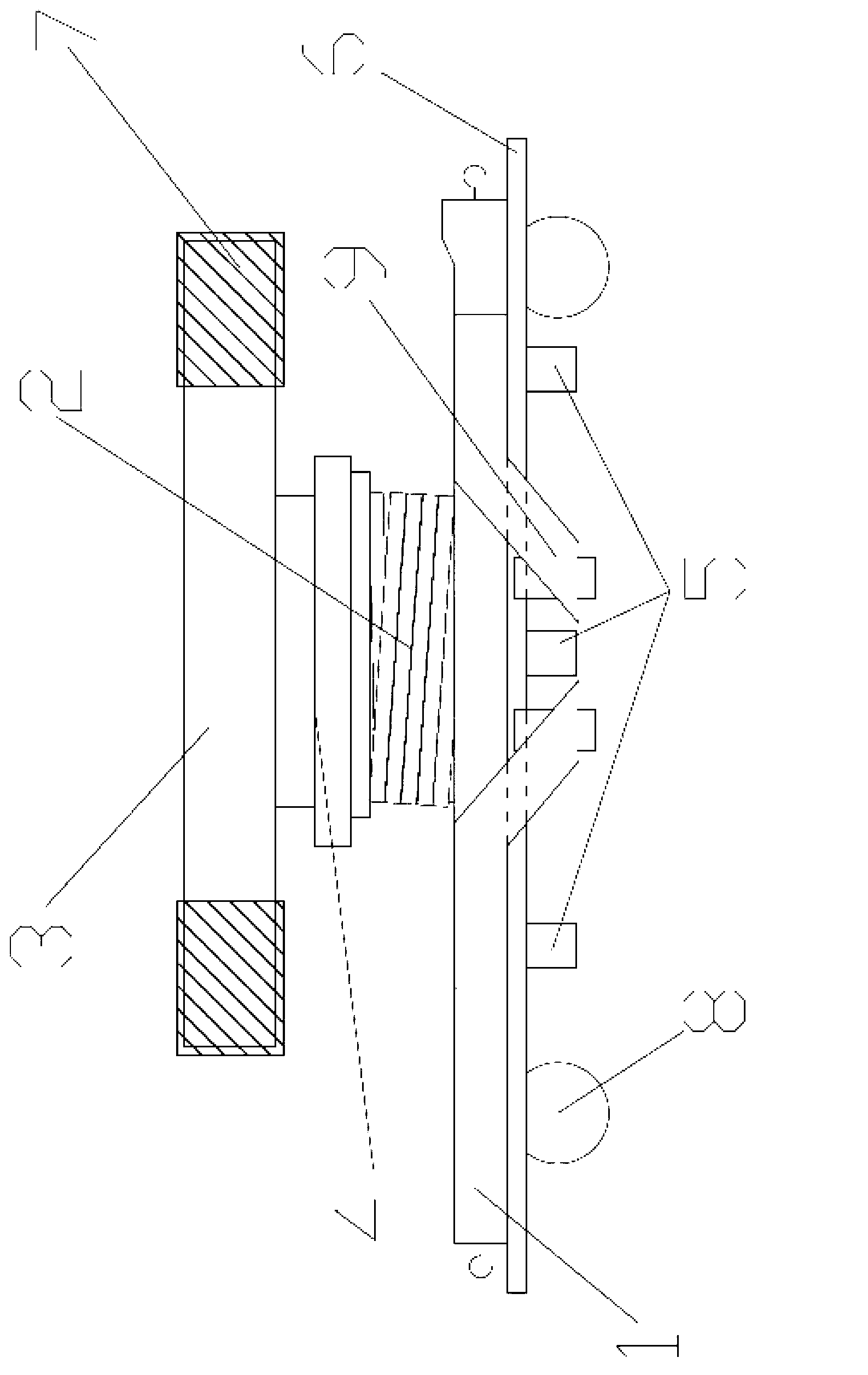

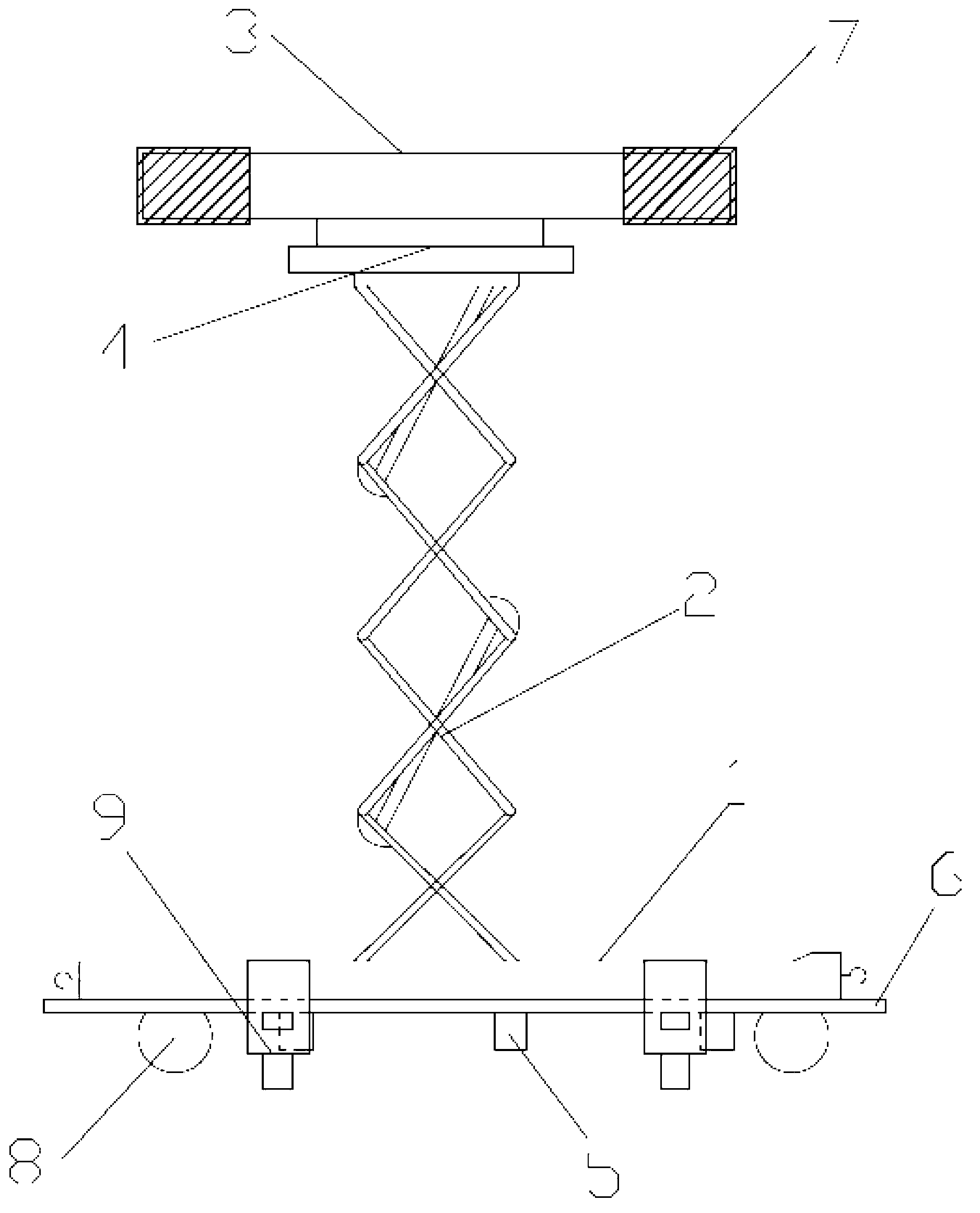

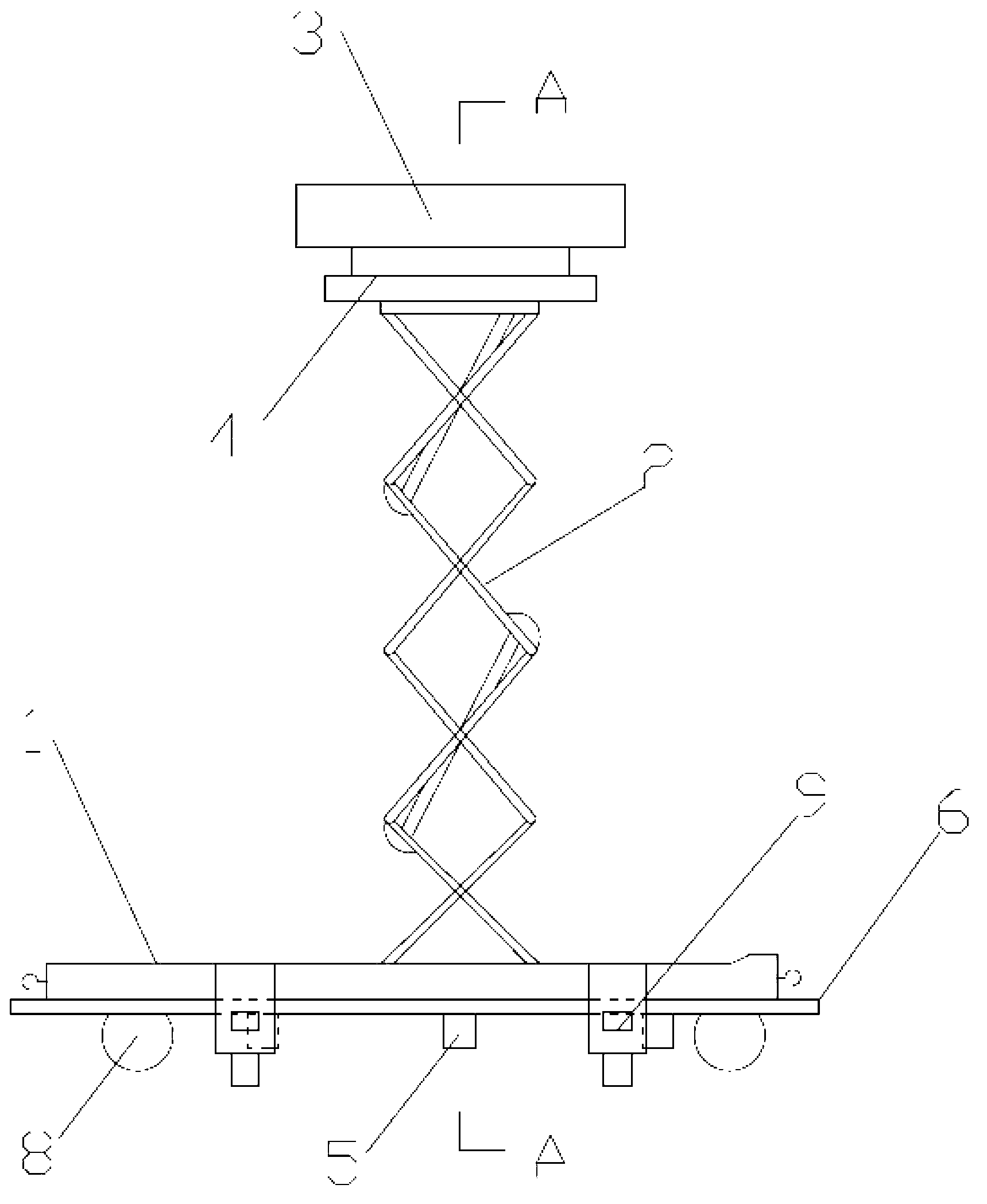

[0025] Such as Figure 1 to Figure 4 As shown, this embodiment proposes a large-span high-altitude operation rapid construction special vehicle, including a chassis 1, a lifting device 2 and a working platform 3, and the working platform 3 is arranged above the chassis 1 in a liftable manner through the lifting device 2; The special vehicle of the embodiment also includes a horizontal turntable 4 for driving the work platform 3 to rotate horizontally and three sets of liftable hydraulic support devices 5, the horizontal turntable 4 is arranged between the work platform 3 and the lifting device 2, and the liftable hydraulic support device 5 The slide is set under chassis 1.

[0026] As a further specific implementation of this embodiment, the lifting device 2 of this embodiment adopts a scissor-type lifting mechanism. The working platform 3 adopts a rectangular platform with a length of 7.5 meters and a width of 1.0 meters, and a connecting device 7 for overlapping with the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com