Mining lifting machine

A technology for elevators and mines, which is applied in the direction of lifting devices, etc., can solve the problems of safety, hidden dangers, and ladders that cannot adapt to the environment, etc., and achieve the effects of safe and convenient use, increased safety, and saved working time and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

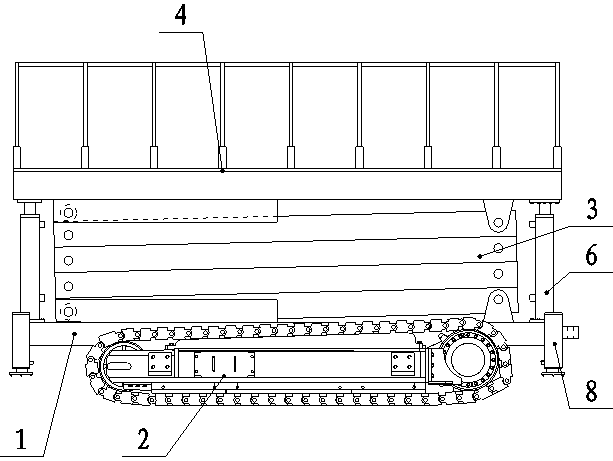

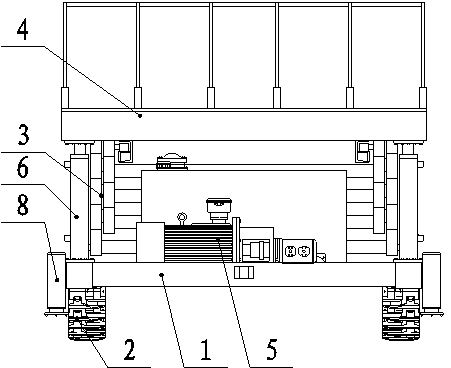

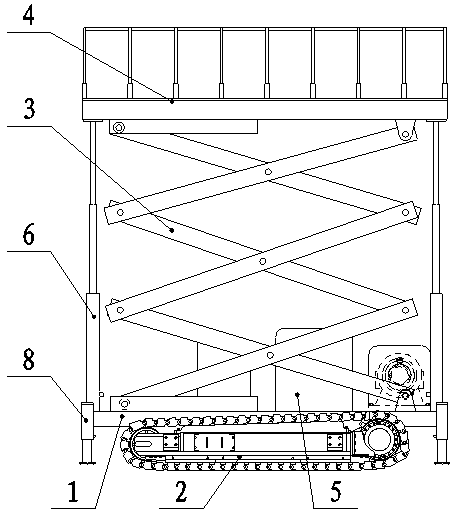

[0027] Such as Figure 1-3 , Figure 7 As shown, the mining elevator includes a frame 1, a running part 2, an elevator 3, a platform 4, a pump station 5 and a telescopic oil cylinder 6, and a running part 2 is installed on the lower part of the frame 1, and the running part 2 is a crawler walking mechanism. , the frame 1 and the platform 4 are connected together by two elevators 3, the structure of the elevators 3 is that a plurality of connecting rods are hinged to form a telescopic connected rhombus frame, and the ends of the two connecting rods at the lower end of the elevators 3 It is hinged with the frame 1, and the two connecting rod ends at the upper end of the elevator 3 are hinged with the bottom surface of the platform 4. A pump station 5 is installed on the frame 1 between the two elevators 3. The four ends of the frame 1 The corners are connected to four corresponding end corners of the platform 4 through a telescopic oil cylinder 6 , and the telescopic oil cylind...

Embodiment 2

[0033] Such as Figure 4-7 As shown, the mining elevator includes a frame 1, a running part 2, an elevator 3, a platform 4, a pump station 5 and a telescopic oil cylinder 6, and the bottom part of the frame 1 is equipped with a running part 2, and the running part 2 is a solid tire. Frame 1 and platform 4 are connected together by two elevators 3, and the structure of described elevators 3 is that a plurality of connecting rods are hinged into a telescopic connected rhombus frame, and the two connecting rod ends at the lower end of elevators 3 are connected to The frame 1 is hinged, the two connecting rod ends at the upper end of the elevator 3 are hinged with the bottom surface of the platform 4, and the pump station 5 is installed on the frame 1 between the two elevators 3, and the four end corners of the frame 1 The four corresponding end angles of the platform 4 are all connected through a telescopic oil cylinder 6 , and the telescopic oil cylinder 6 is powered by the pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com