Pneumatic polishing mechanism and pneumatic device for automatically polishing and removing chips of inner wall of workpiece to be processed

A technology for grinding mechanisms and workpieces to be processed, which is applied in the directions of automatic grinding control devices, grinding/polishing safety devices, grinding workpiece supports, etc., which can solve the problems of difficult powder removal and difficult polishing, etc., and achieves wide application range, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

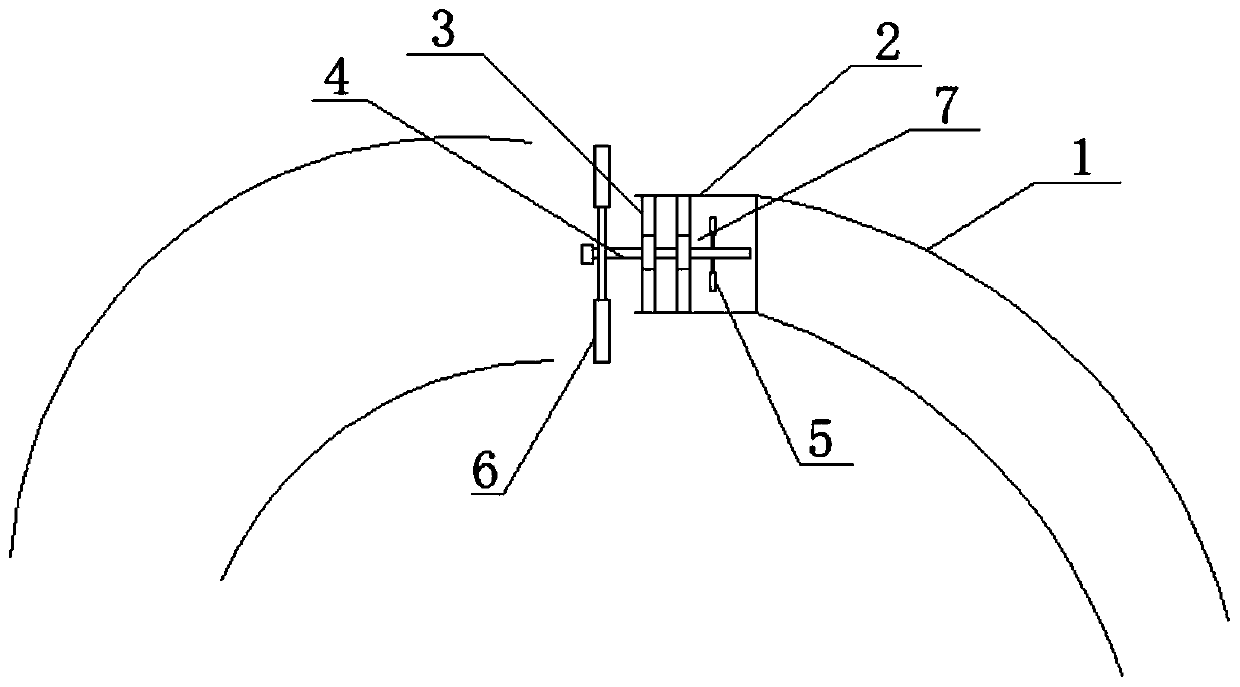

[0055] Such as figure 1 As shown, a pneumatic grinding mechanism provided in the embodiment of the present application includes the following components:

[0056] Gas conduit 1, the first end of the gas conduit 1 is connected to the gas source, the gas conduit 1 in the embodiment of the application can be replaced to ensure that the gas conduit 1 corresponds to the workpiece to be processed, so that the gas conduit 1 can Extend into the workpiece to be processed to complete the polishing and chip removal of the inner wall of the workpiece; after the first end of the gas conduit 1 is connected to the gas source, the gas flows through the gas conduit 1 to form an airflow and provide power.

[0057] Straight pipe section 2, the straight pipe section 2 is installed at the second end of the gas conduit 1, that is, the straight pipe section 2 and the gas source are respectively located at both ends of the gas conduit 1, and the straight pipe section 2 and the gas conduit 1 are direc...

Embodiment 2

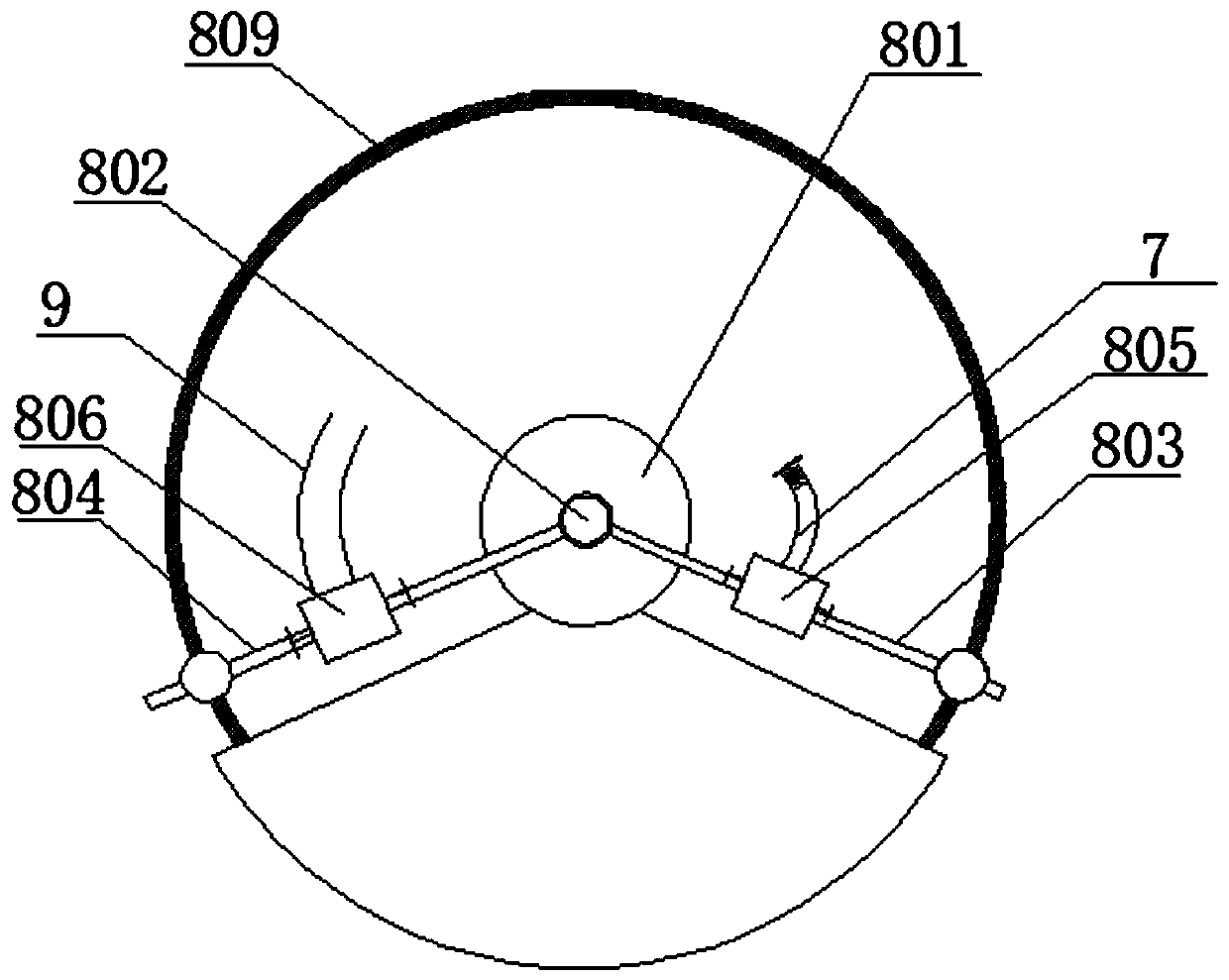

[0062] The embodiment of the present application discloses a device for automatically polishing and removing debris on the inner wall of a pneumatic workpiece to be processed, which includes the pneumatic grinding mechanism 7 described in Embodiment 1, the stroke control mechanism 8 and the workpiece 9 to be processed, the pneumatic grinding mechanism 7, the workpiece to be processed 9 intervals are installed on the stroke control mechanism 8; in the embodiment of the application, the workpiece 9 to be processed is the workpiece to be processed, and the pneumatic grinding mechanism 7 is the mechanism described in Embodiment 1, which is used for processing the workpiece 9, The gas conduit 1 in the pneumatic grinding mechanism 7 needs to be replaced according to the specific structure of the workpiece 9, because the straight pipe section 2 of the pneumatic grinding mechanism 7 needs to extend into the workpiece 9, so the gas conduit 1 needs to be processed. Item 9 corresponds.

...

Embodiment 3

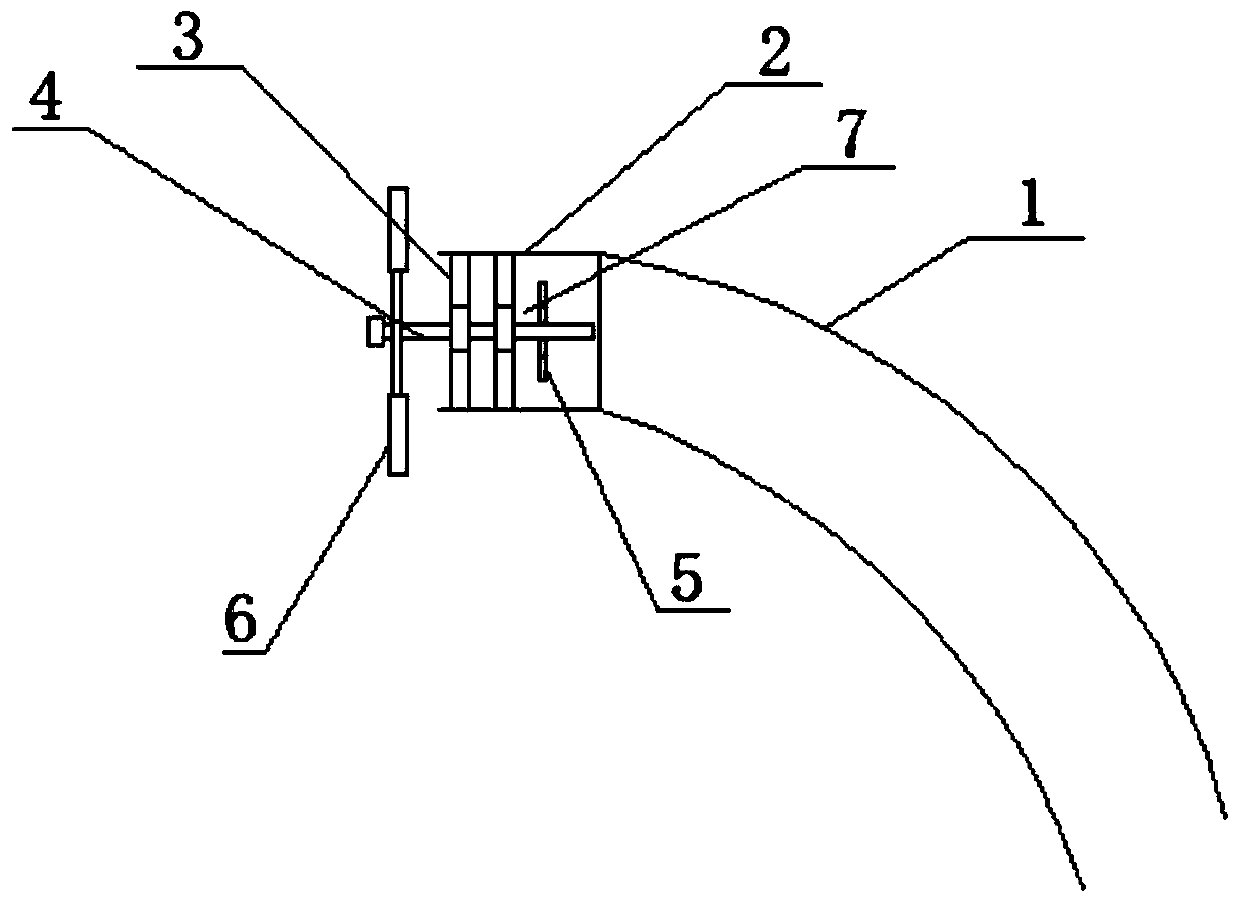

[0074] Such as Figure 5 , 6 As shown, in the embodiment of the present application, on the basis of Embodiment 2, the stroke control mechanism 8 is replaced to realize the internal polishing process on the three-way pipe fitting. At this time, the workpiece 9 to be processed is a three-way pipe fitting, and the stroke The control mechanism 8 includes a supporting platform 816, a third horizontal shaft 817, a third connecting column 818, a fourth connecting column 819 and a second drive motor 823, and the third connecting column 818 and the fourth connecting column 819 are installed at intervals on the third On the horizontal axis 817; compared with Embodiment 2, the embodiment of the present application discloses another mechanism of the stroke control mechanism 8, wherein the third connecting column 818 is spaced with a plurality of third connecting holes 820 from top to bottom , the first end of the gas conduit 1 of the pneumatic grinding mechanism 7 is installed inside on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com