Suspension self-shifting type full-circumference rotary mounting machine and application method

A self-moving, installation machine technology, applied in vertical shaft equipment, earth-moving drilling, wellbore lining, etc., can solve the problems of high labor intensity, low safety, large installation, etc., and achieve automatic installation and improve installation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

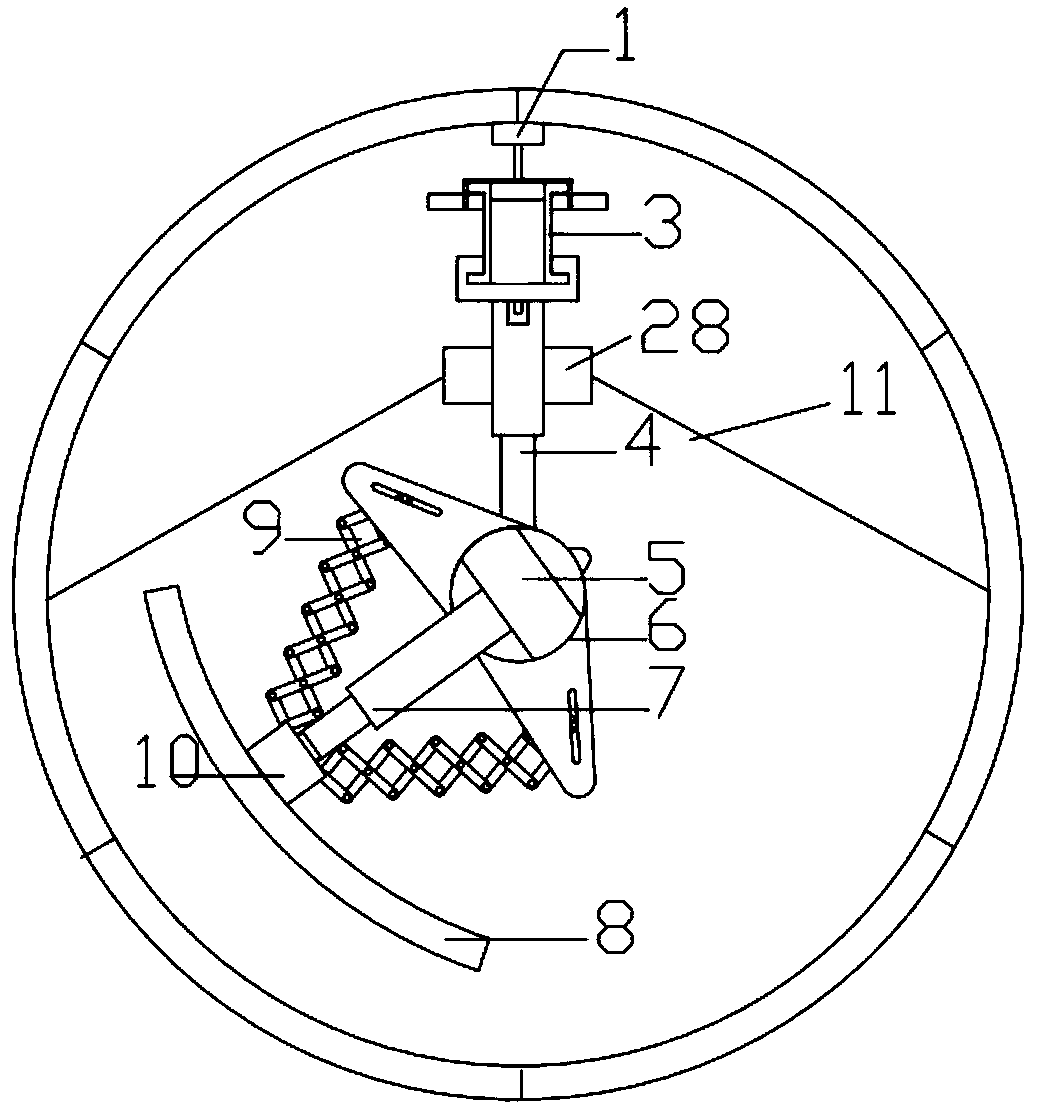

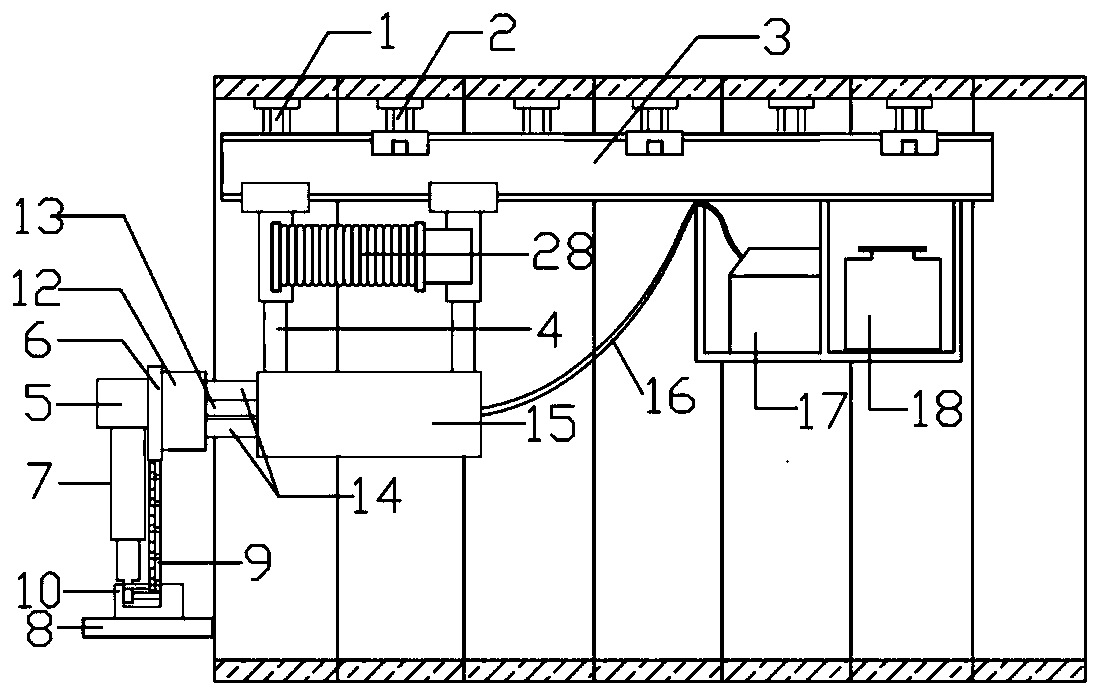

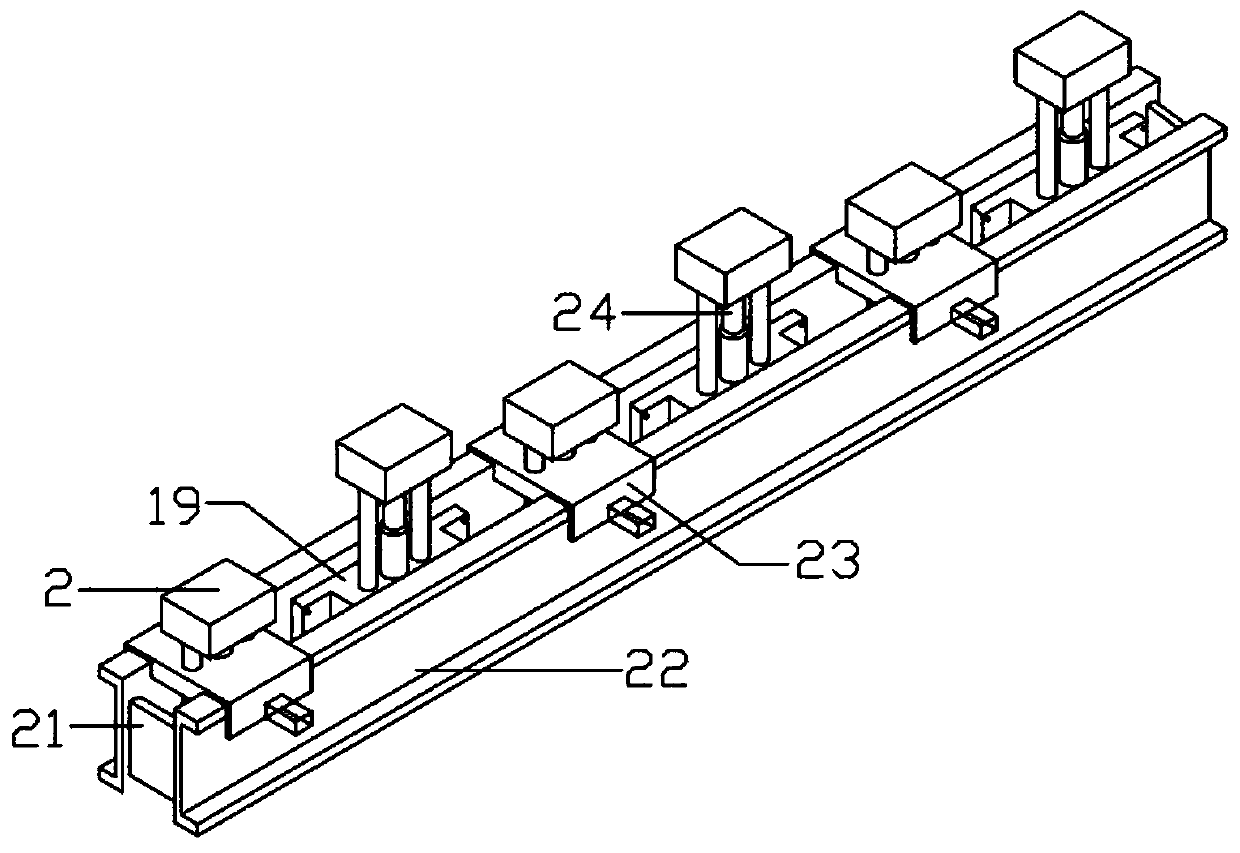

[0029] Attached below Figure 1-Figure 6 The present invention is described in detail, specifically, the structure is as follows:

[0030] This embodiment provides a hanging self-moving full-circle rotation installation machine, such as figure 1 and figure 2 As shown, it includes a self-moving walking beam device, a mounting arm, a vertical telescopic mechanism, and a rotating mounting mechanism. The mounting arm is fixed at the front end of the rotating mounting mechanism, and the rotating mounting mechanism is fixed to the self-moving walking beam Below the beam device, it can move back and forth with the self-moving walking beam device. The rotating installation mechanism is connected to one end of the installation arm to realize the installation of the arc plate 8 to be installed.

[0031] The self-moving walking beam device includes a load beam 3, a fixed electromagnetic gripper 1, and a mobile electromagnetic gripper 2. The fixed electromagnetic gripper 1 and the mob...

Embodiment 2

[0046] This embodiment provides a method for using a suspended self-moving full-circle rotation installation machine, the steps of which include:

[0047] In the first step, after the temporary support of the roadway is completed, the installation of the front six-ring arc plate is completed using the traditional manual hoisting method. After the full-circle rotation installation machine is in place, the steel wire rope 11 of the electric hoist is fixed to the installed arc plate, and the hoist is tightened. Wire rope 11, fixed installation machine.

[0048] The second step is to control the first telescopic oil cylinder 4 to adjust the up and down position of the installation machine.

[0049] The third step is to control the second telescopic oil cylinder 13 to adjust the front and rear positions of the installation machine.

[0050] In the fourth step, after the third telescopic oil cylinder 7 is stretched to a suitable position, the electromagnetic chuck 10 is energized t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com