Energy-accumulation type ultrasonic cleaning device applied to spinneret plate in spinning industry

A cleaning device and ultrasonic technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of vibration plate corrosion, high ultrasonic frequency, high replacement cost, etc., to meet cleaning requirements and improve Cleaning efficiency, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

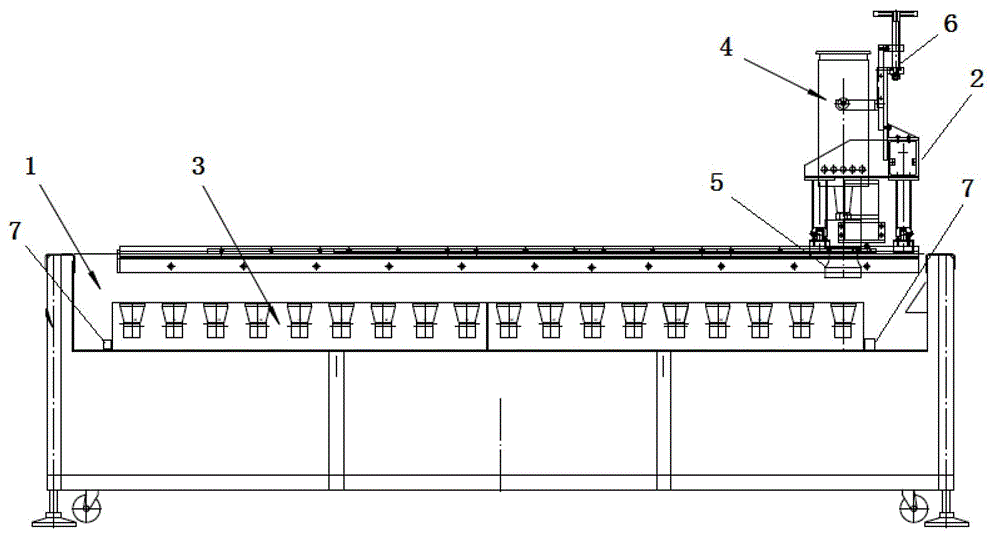

[0016] Such as figure 1 As shown, an energy-concentrating ultrasonic cleaning device applied to spinnerets in the spinning industry includes a cleaning tank 1 and two sets of energy-concentrating ultrasonic cleaning devices 2, and the energy-concentrating ultrasonic cleaning device 2 includes an energy-concentrating transducer 4 A vibrating head 5 is installed at the lower end of the energy-collecting transducer 4, and a lifting device for controlling its movement up and down is also provided on the energy-collecting transducer 4. The energy-concentrating ultrasonic cleaning device 2 is set above the cleaning water tank 1, and can reciprocate along the axial direction of the cleaning water tank 1. In the cleaning water tank 1, there are two sets of distributed ultrasonic waves corresponding to the energy-concentrating ultrasonic cleaning device 2. The vibrating box 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com