Machine part washing unit

A cleaning device and a technology for mechanical parts, applied in the fields of home appliances, machinery, and automobiles, can solve the problems of dead corners and monotonous scrubbing in parts cleaning, and achieve the effects of convenient operation, low labor intensity, and avoiding direct or potential damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

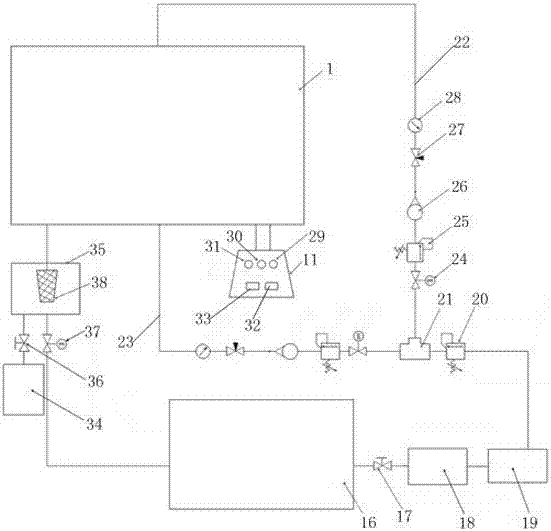

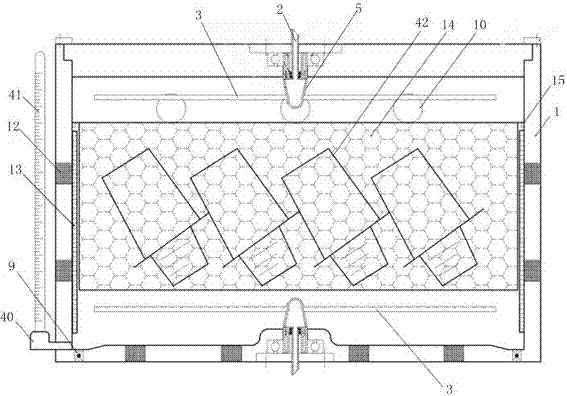

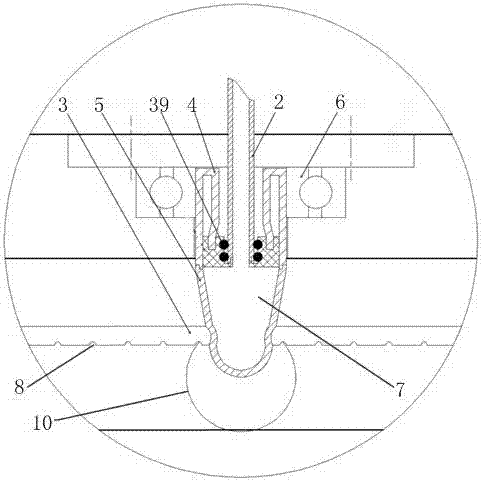

[0026] like Figure 1~3 As shown, a mechanical parts cleaning device includes a liquid pressurization system, a flow control system, an ultrasonic system, and a cleaning box 1; the cleaning box 1 is composed of an inner tank and an outer shell, which are welded by stainless steel through argon arc welding, and the inner tank The outer surface of the ultrasonic transducer is bonded to the ultrasonic transducer, and the cleaning liquid is contained in the tank. The inner wall of the tank, especially the radiant plate with the transducer attached, must be smooth and polished without scars, otherwise cavitation corrosion will easily occur and the service life will be shortened.

[0027] The upper and lower plates of the cleaning box 1 are respectively provided with an upper spray system and a lower spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com