Method for cleaning polycrystal carbon head material

A technology of carbon head material and sulfuric acid, which is applied to the cleaning method using liquid, polycrystalline material growth, cleaning method and utensils, etc., can solve the problems of large silicon loss, slow speed, and inability to ensure the removal of impurities on the surface of silicon materials. Achieve the effect of increasing availability and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

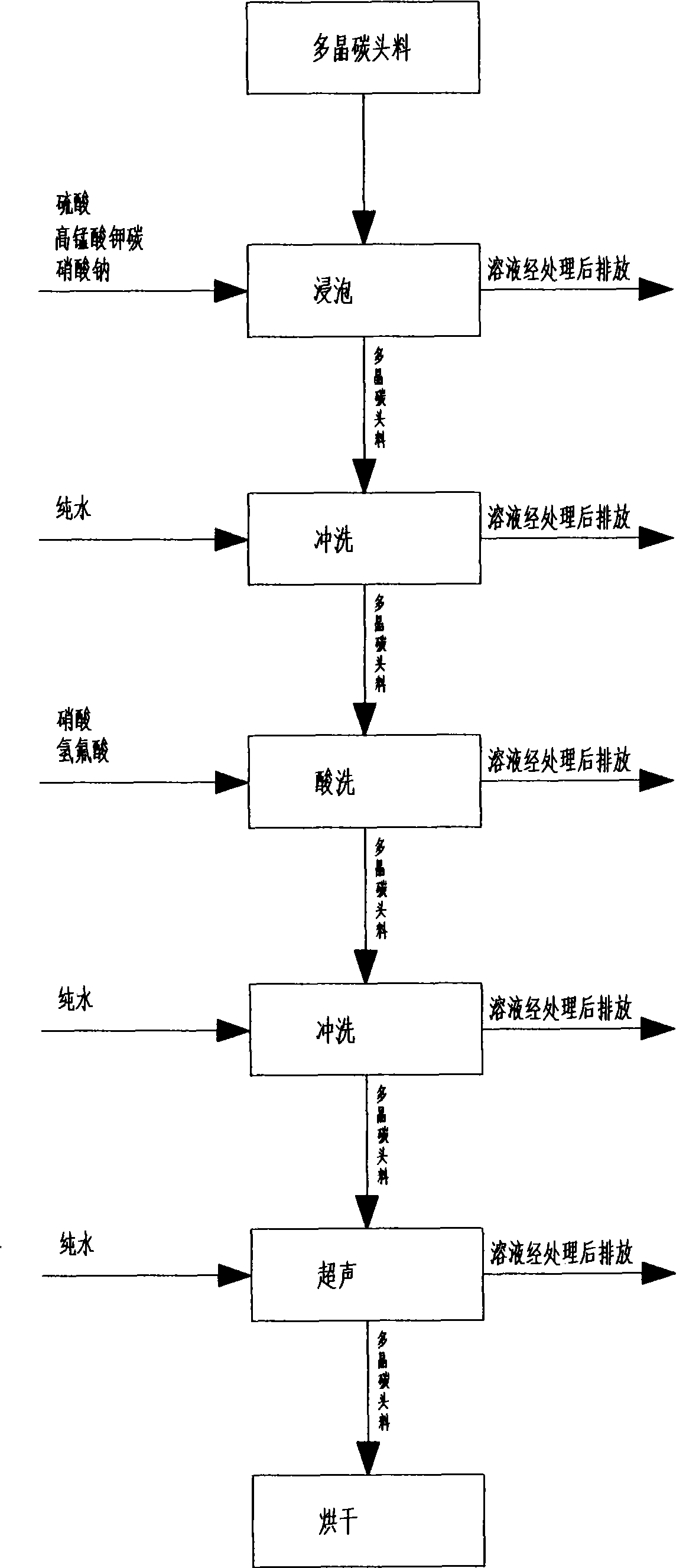

[0017] like figure 1 As shown, the cleaning method of the polycrystalline carbon head material described in this embodiment mainly includes the following steps: configure a mixture of 98% by weight sulfuric acid: solid potassium permanganate: solid sodium nitrate=20:0.1:0.1 in PP Cao liquid, and then carefully put the polycrystalline carbon head into it, and soak for 24 hours. During this process, the graphite in the polycrystalline carbon head material can be completely reacted to achieve the purpose of removing the graphite attached to the polycrystalline carbon head material; then the polycrystalline carbon head material is taken out, rinsed with clean water, and then washed with acid After the basket is installed, put it into a mixed solution of 75% nitric acid: 49% hydrofluoric acid = 10:1 to corrode for 1-3 minutes. This process can completely remove the dirt on the surface of the polycrystalline carbon head material; then take out the polycrystalline carbon head Rinse ...

Embodiment 2

[0019] The cleaning method of the polycrystalline carbon head material described in this embodiment, the weight ratio of the three main solutes of sulfuric acid, potassium permanganate, and sodium nitrate solution is 20:0.5:0.5, and the polycrystalline carbon head material After soaking in the solution for 12 hours, it can be taken out and cleaned. After cleaning, it is put into a solution with a weight ratio of 70% nitric acid: 60% hydrofluoric acid=15:1 through a pickling basket for corrosion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com