Online chip cleaning and drying equipment

A technology of drying equipment and vacuum drying equipment, which is applied in the field of mechanical equipment, can solve the problems of chip coating material damage, broken chip spotting, and watermarks, etc., to achieve the effect of protecting chips, realizing modernization, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with embodiment the present invention is described in further detail:

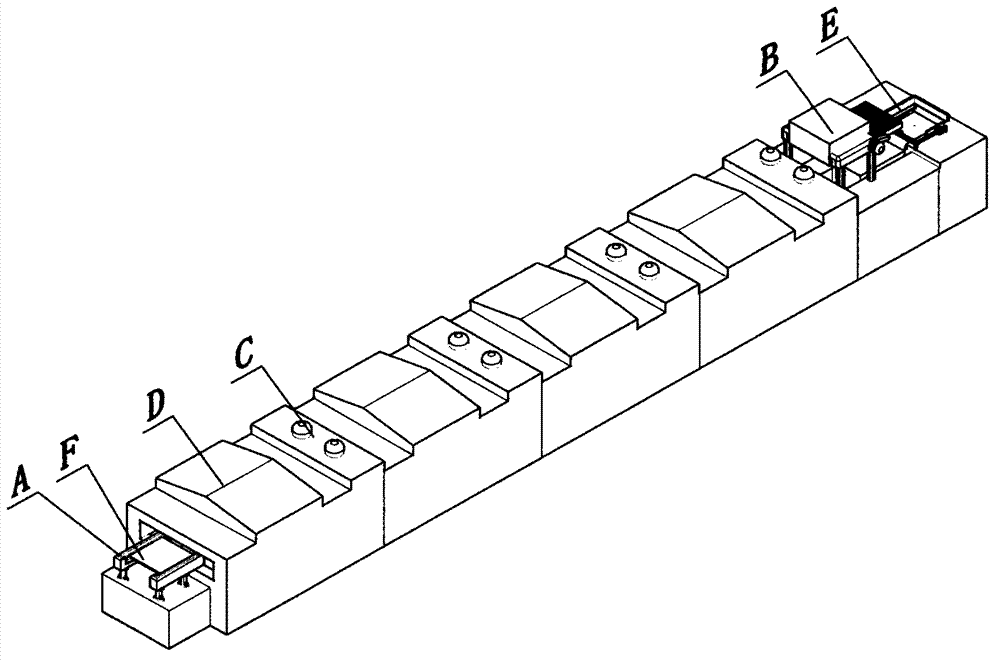

[0035] On-line chip cleaning and drying equipment, including automatic feeding mechanism A, spray cleaning device, vacuum drying equipment B, and positioning platform E.

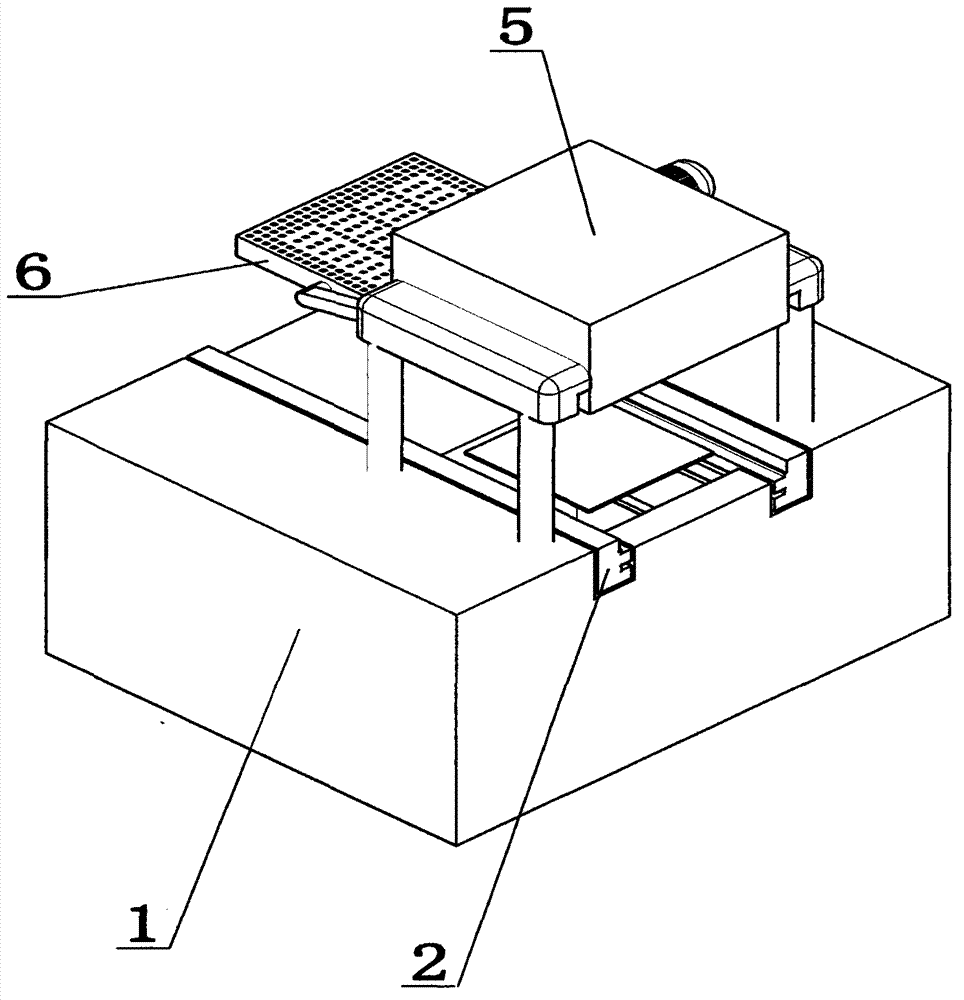

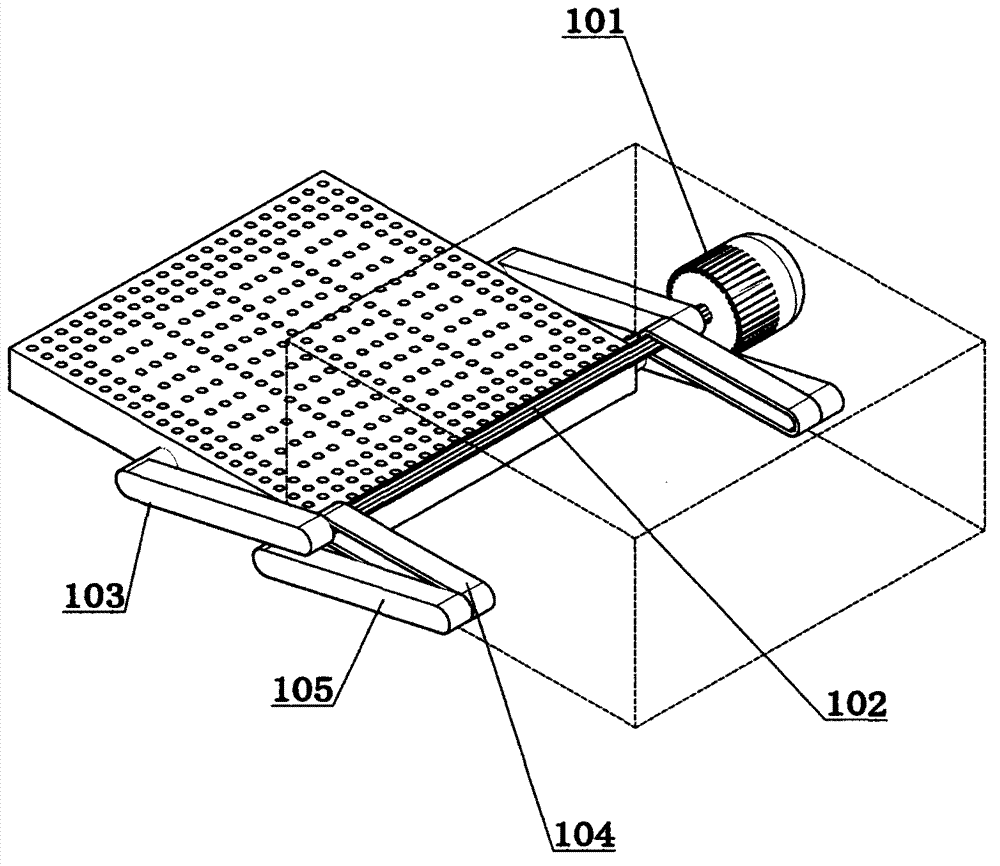

[0036] The automatic feeding mechanism A is set at the front end of the first online cleaning and drying equipment, such as figure 1 and Figure 8 As shown, the automatic feeding mechanism A is connected to the front end of the spray cleaning device, and a pair of double-chain conveyor belts 43 that are integrated or separated from the spray conveyor belt in the spray cleaning device are supported by a support frame 41. The outer side of 43 is provided with a fixed slot 42 , the size of which corresponds to the size of the chip, and is used for preliminary positioning of the chip F placed thereon.

[0037] The spray cleaning device such as Figure 5-7 As shown, it includes two parts: spray cabinet D and wind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com