High-plasticity reinforced longquan celadon ware and preparing method thereof

A plasticity, celadon technology, applied in clay products, other household appliances, applications, etc., can solve problems such as unfavorable daily production of porcelain, affecting the plasticity of blanks, unfavorable celadon molding, etc., to improve physical and chemical properties, high cost, avoidance of The effect of product breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

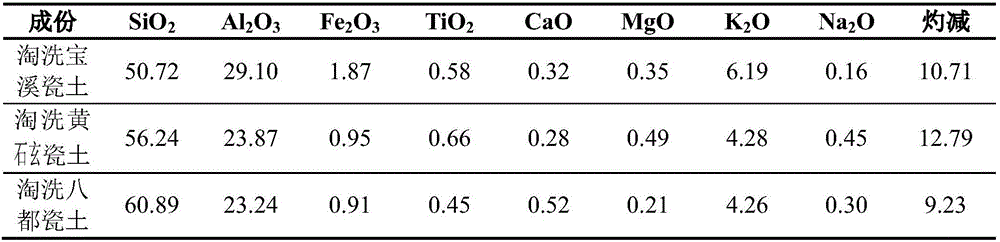

[0049] A high plasticity strengthened Longquan celadon body, the blank includes the following components in terms of weight percentage: 35% of washed Baoxi porcelain clay, 27% of washed Huangshi Xuan porcelain clay, 25% of washed Badu porcelain clay, Al 2 o 3 Micropowder 15%, zirconia micropowder 1%.

[0050]The above-mentioned highly plastic reinforced Longquan celadon mud is used to prepare strengthened Longquan celadon, and the preparation method thereof comprises the following steps:

[0051] (a) The Baoxi porcelain clay, Huangshixuan porcelain clay and Badu porcelain clay which are unique to Longquan are crushed respectively and washed 4 times to minimize the infertile material components in such raw materials, and then dried in a drying room at 100°C to obtain Panning Baoxi porcelain clay, panning Huangshi Xuan porcelain clay, panning Badu porcelain clay;

[0052] (b) According to the preset ratio, mix the above blank components, then add water, and ball mill for 1 to ...

Embodiment 2

[0058] A high plasticity strengthened Longquan celadon body, the blank includes the following components in terms of weight percentage: 55% of washed Baoxi porcelain clay, 13% of washed Huangshi Xuan porcelain clay, 45% of washed Badu porcelain clay, Al 2 o 3 Micropowder 10%, zirconia micropowder 2%.

[0059] The above-mentioned high plasticity strengthened Longquan celadon body is prepared into high plasticity strengthened Longquan celadon, and the preparation method thereof comprises the following steps:

[0060] (a) Grind Baoxi porcelain clay, Huangshi Xuan porcelain clay and Badu porcelain clay respectively and wash them five times to minimize the barren material components in such raw materials, and dry them at a temperature of 100°C;

[0061] (b) Mix the components of the billet according to the preset ratio, then add water, and ball mill for 1 to 2 hours according to the material-ball-water ratio of 1:1:0.8, wherein the ball milling speed is 30r / min, after ball milling...

Embodiment 3

[0067] A high plasticity strengthened Longquan celadon body, the blank includes the following components in terms of weight percentage: 45% of washed Baoxi porcelain clay, 18% of washed Huangshi Xuan porcelain clay, 20% of washed Badu porcelain clay, Al 2 o 3 Micropowder 15%, zirconia micropowder 2%.

[0068] The above highly plastic reinforced Longquan celadon mud is used to prepare highly plastic reinforced Longquan celadon, and the preparation method is the same as that of Example 1.

[0069] The common Longquan celadon in the existing market is selected for comparison. The flexural strength of the common Longquan celadon in the existing market is 45-60Mpa, and the thermal stability is 160-20°C without cracking once exchanged with hot and cold water. However, the highly plastic reinforced Longquan celadon prepared in this example has high strength and thermal stability when fired in a high-temperature reducing atmosphere at 1280-1300 ° C. Its flexural strength can reach 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com