Flue-cured tobacco raw material sensory quality evaluation method applicable to mixed type cigarettes

An evaluation method and technology of raw materials, applied in the field of sensory quality evaluation of flue-cured tobacco raw materials, can solve problems such as inability to evaluate the applicability of cigarette leaf group formulations, inapplicability to mixed cigarettes, and different grades, etc., to achieve a refined sensory quality evaluation system, The role of extension, the effect of expanding thinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

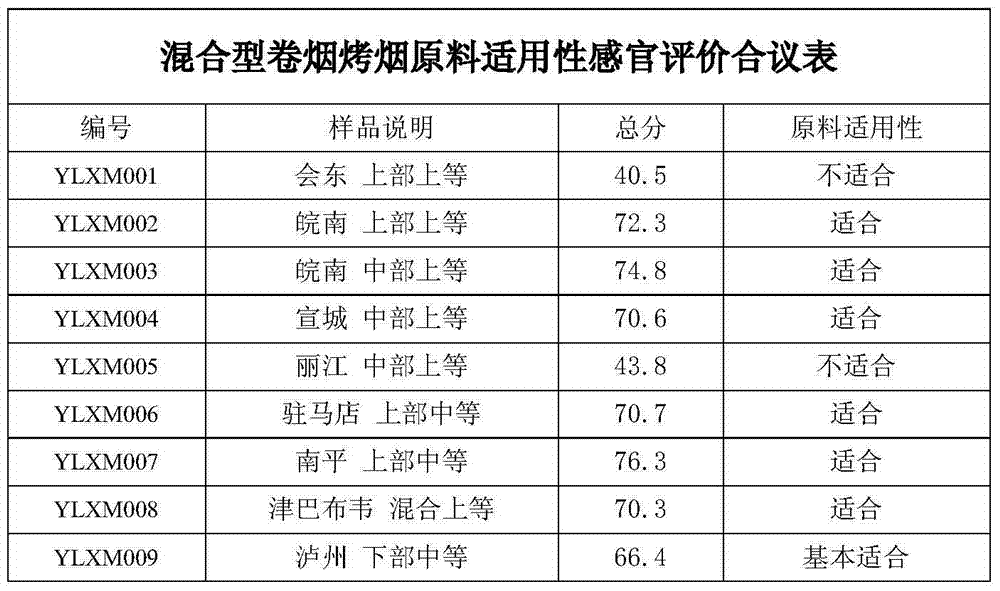

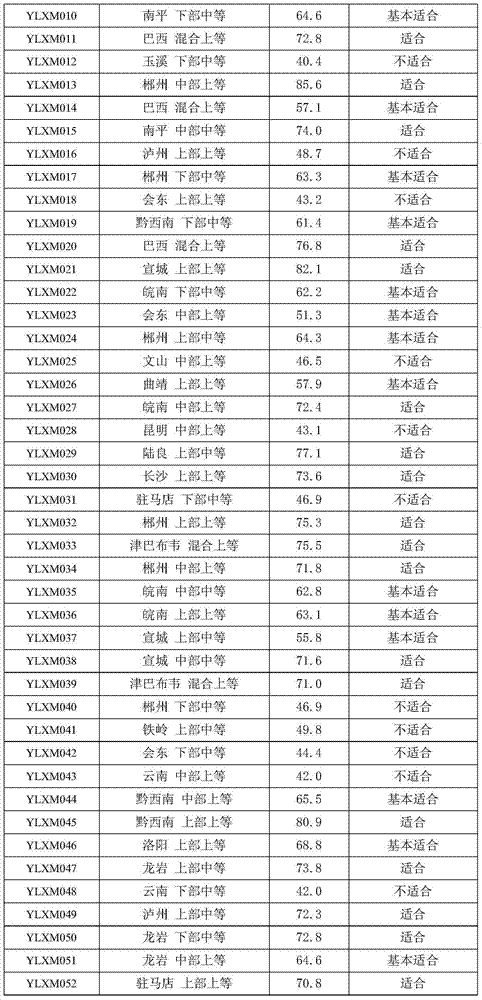

[0021] Embodiment: The method for evaluating the sensory quality of flue-cured tobacco raw materials suitable for mixed cigarettes according to the present invention; it includes the following steps:

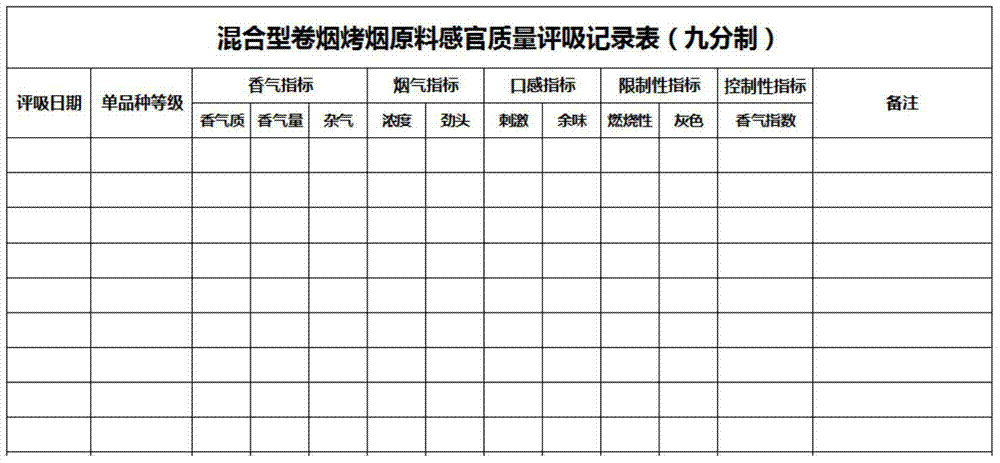

[0022] (1) Set ten evaluation indicators of aroma quality, aroma quantity, miscellaneous gas, smoke concentration, strength, irritation, aftertaste, flammability, gray, and control indicators;

[0023] (2) For the calculation method of the total score of the evaluation method, except for the other nine indicators of the control indicators, the statistical scores of the nine-point system are converted into a hundred-point system, and the final score weights of the ten indicators are calculated as follows:

[0024] (a) Aroma quality, aroma quantity, miscellaneous smell, smoke concentration, irritation, aftertaste, flammability, and gray sensory evaluation are scored according to the nine-point system, and the order from high to low is 9, 8, 7, 6, 5 , 4, 3, 2, 1, the minimum scorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com