Flame retardant sodium-ion battery electrolytic solution and application thereof

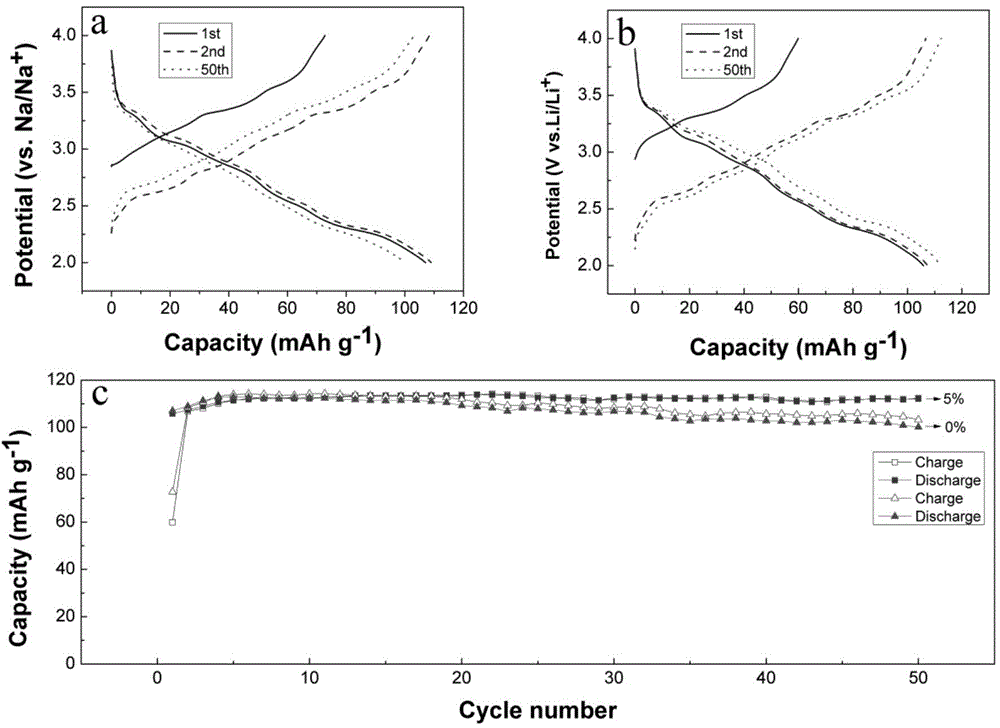

A sodium-ion battery and electrolyte technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of less research on flame-retardant electrolytes for sodium batteries, and achieve good electrochemical performance, wide application market, and good flame retardancy performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

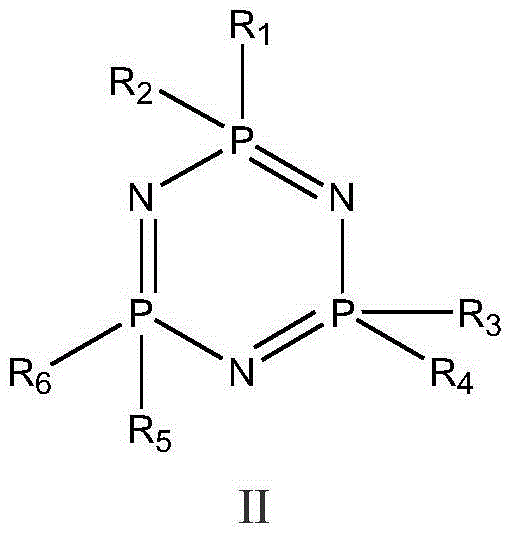

Method used

Image

Examples

Embodiment 1

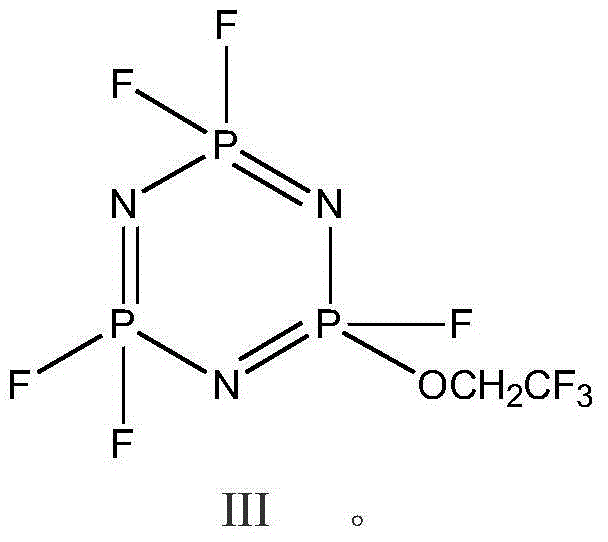

[0031] The preparation process of methoxy pentafluorocyclotriphosphazene:

[0032] Ethoxypentachlorocyclotriphosphazene was added to 200g of acetonitrile with constant stirring, and 105g of NaF was added. After fluorination at 80°C for 5 hours, distillation was carried out to obtain methoxypentafluorocyclotriphosphazene.

Embodiment 2

[0034] The preparation process of 1-propoxy-pentafluorocyclotriphosphazene:

[0035] Put 8g of hexafluorocyclotriphosphazene in 90ml of chlorobenzene, add the catalyst ferric chloride and 1.6g of sodium propoxide under constant stirring, react for 4 hours at 80°C, carry out vacuum distillation, and obtain the derivative of phosphazene after refining. Compound: 1-propoxy-pentafluorocyclotriphosphazene.

Embodiment 3

[0037] The preparation process of hexaphenoxycyclotriphosphazene:

[0038] Put 34.8g of hexachlorocyclotriphosphazene crystals and hexane in a 500ml three-necked bottle equipped with a stirrer, a thermometer, and a back distillation condenser, stir until it dissolves evenly, and react with 50g of sodium phenoxide at a temperature of 70°C for 5 hours , Distilled and purified to obtain phosphazene derivatives: hexaphenoxycyclotriphosphazene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com