Plasma multi-stage cracking technology and apparatus capable of processing multiple organic wastes simultaneously

A plasma and organic waste technology, applied in the field of plasma cracking, can solve the problems of high cost, inability to process multiple different types of waste at the same time, high power consumption, etc., to save energy and time, save power consumption, and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

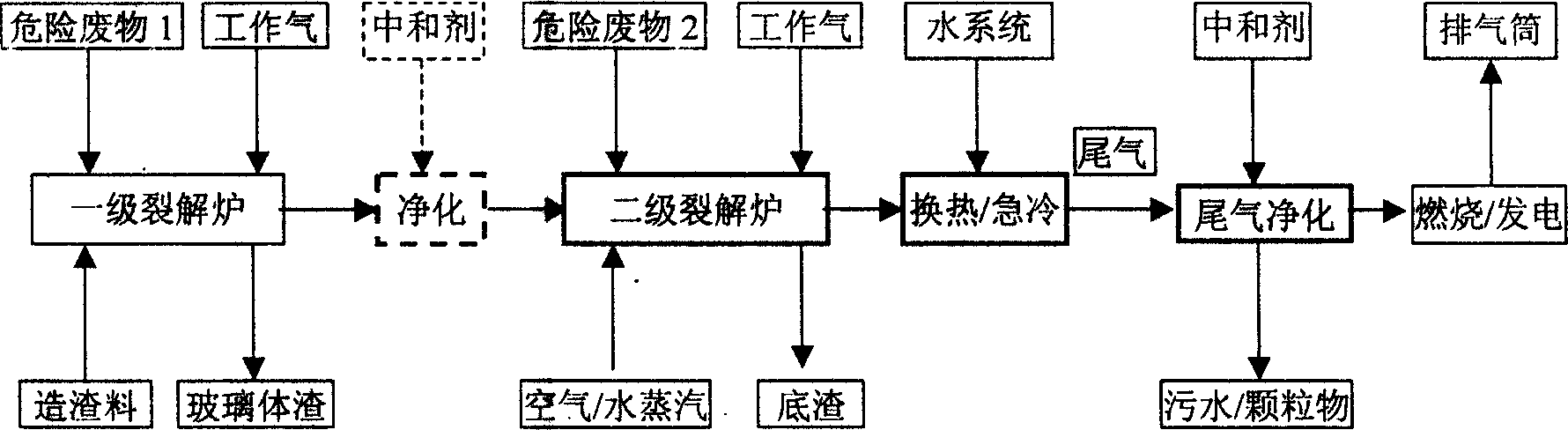

[0066] Refer to attached figure 1 With the accompanying drawings and specific examples, the process and the plasma furnace of the present invention for plasma cracking organic waste composed in series are further described in detail.

[0067] Embodiment 1 of the present invention adopts the method for treating solid hazardous waste in series, and proceeds according to the following steps:

[0068] (1) First, the toxic and harmful solid wastes containing fluorine and polychlorinated biphenyl residues to be treated are pulverized, and then continuously transported to the plasma arc furnace of the present embodiment 1 by a screw conveying system. What is produced is a plasma arc, using hydrogen as the working gas of the plasma generator, the power is 150kW, and it can process 60kg per hour; the cracking treatment temperature is 1800-2000K; by adding 30 parts of silicon dioxide, calcium carbonate, 40 parts of sodium mixture, 20 parts of ferric oxide and metal iron flakes are used...

Embodiment 2

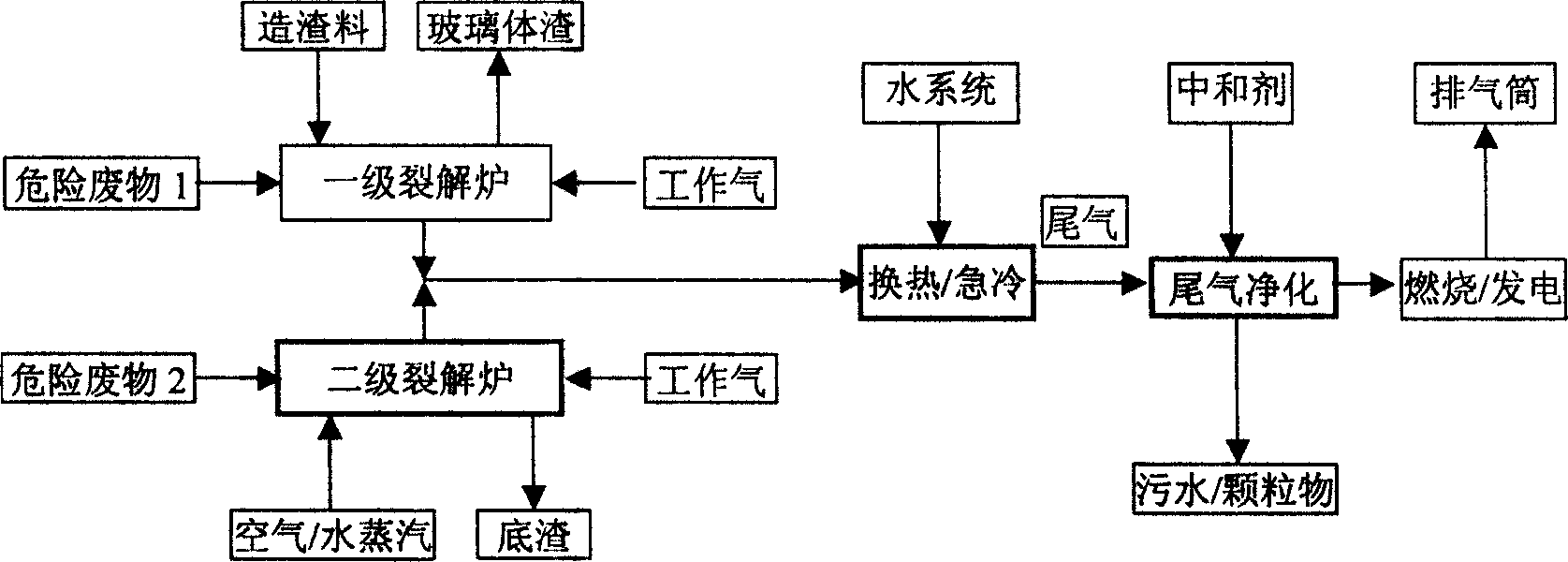

[0077] combined with figure 2 , apply the plasma cracking furnace of the embodiment of the present invention 2, carry out cracking treatment phosphorus-containing fertilizer pesticide, carry out according to the following steps:

[0078] (1) The non-pesticides to be treated are pulverized, and then continuously transported to the plasma arc furnace of the present embodiment 2 through the feeding system; what it produces during operation is a plasma arc, and hydrogen is used as the plasma to generate The working gas of the device uses a DC power supply, the working voltage is 40V, the power is 25kW, and it can process 15kg per hour; the cracking temperature is 1600-1700K;

[0079] (2) At the same time, waste plastics are fed into the secondary plasma cracking furnace through a hydraulic feeder, and the feed hydraulic push rod and plunger are installed at the feed port of the furnace body; the time interval that can be used in the intermittent feeding method depends on the temp...

Embodiment 3

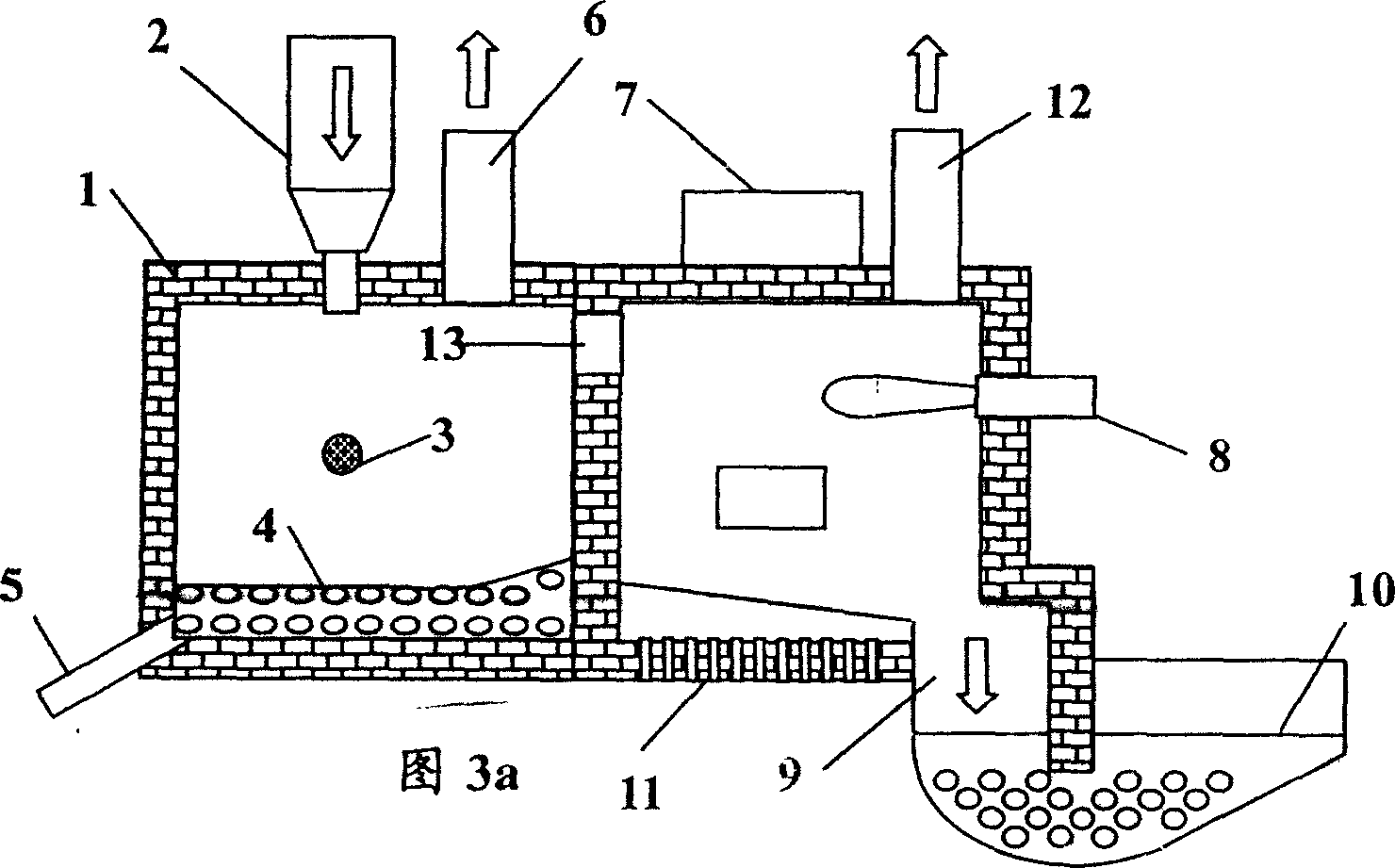

[0086] Embodiment 3: apply the integrated cracking furnace of the present invention and the method serial type of the present invention to process solid hazardous waste, its step is similar to embodiment 1, because the waste that the primary cracking furnace handles contains fluorine, chlorine etc. to form the composition of acid gas Therefore, the purification measures of the primary cracking furnace tail gas can be omitted in the technological process ( figure 1 The part marked with a dotted line in the middle) adopts the integrated furnace body 1 (Fig. 3a, Fig. 3b, Fig. 3c), and does not set the exhaust port 6 of the primary cracking furnace. The specific process is carried out in the following order:

[0087] (1) the rubber intermediate (waste) of the rubber plant to be treated is broken, and then continuously delivered to the first-level cracking hearth of the present invention by the first-level cracking furnace screw feeding device 2, and the first-level cracking furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com