Patents

Literature

34results about How to "Good base" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite roofing members having improved dimensional stability and related methods

InactiveUS6044604AGood baseRoof covering using slabs/sheetsConstruction materialGlass fiberPolymer science

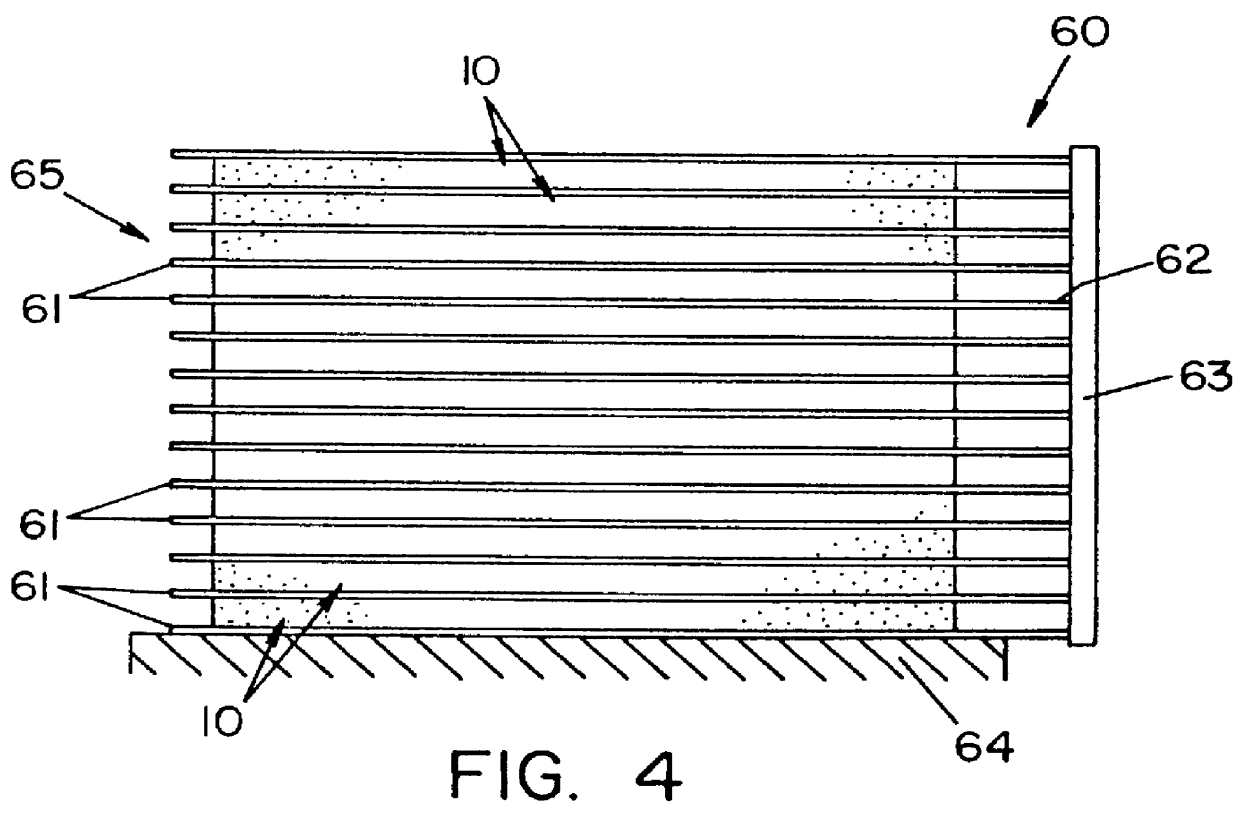

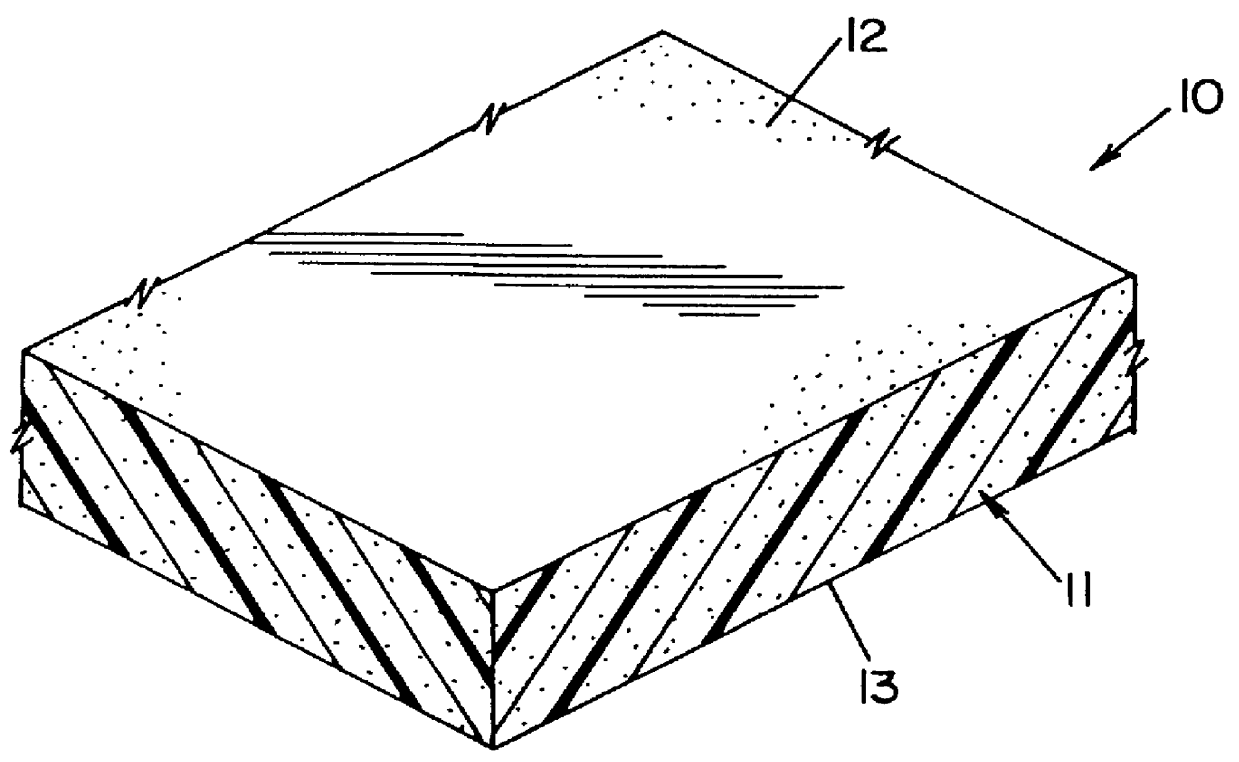

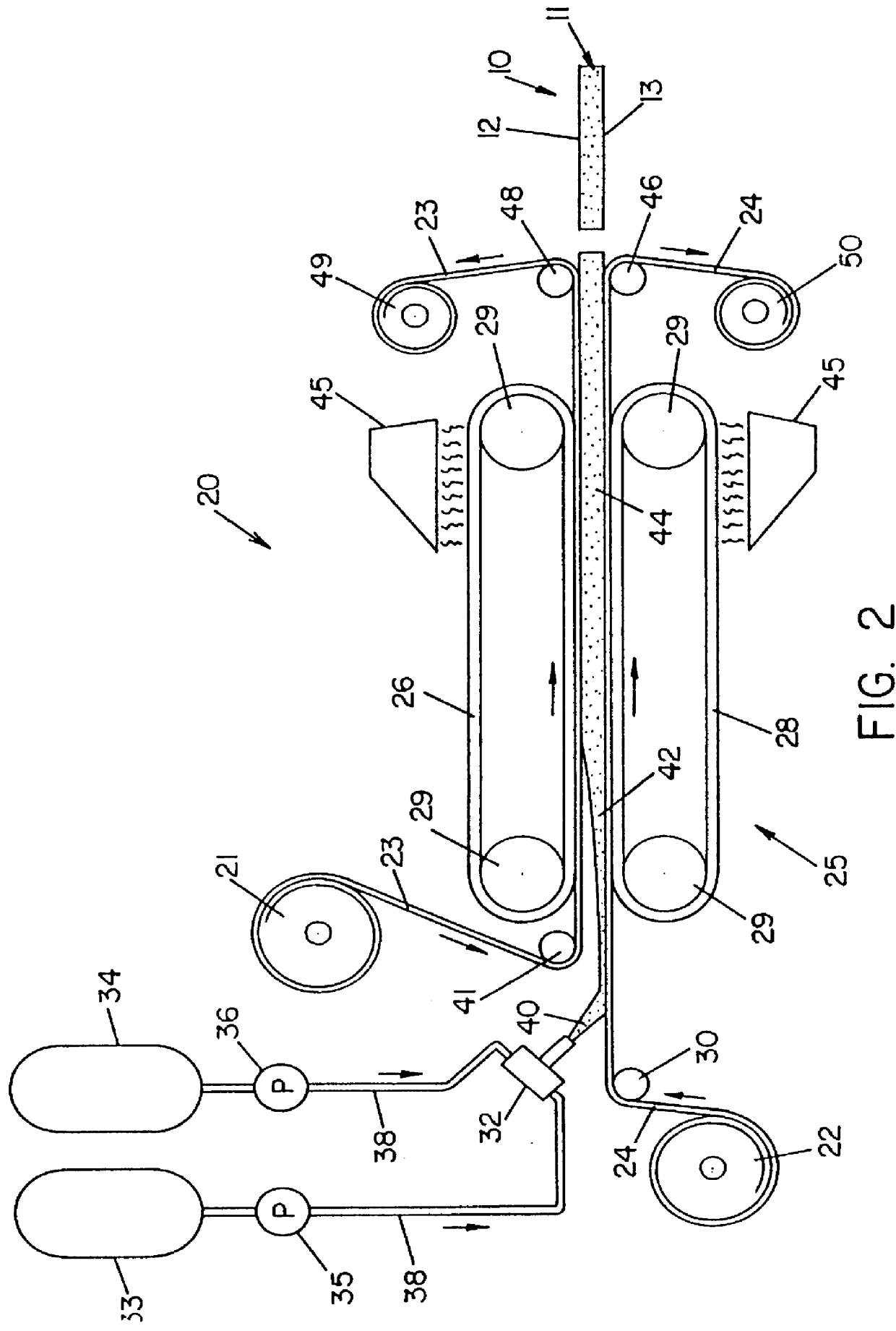

A composite recovery board (10) containing a foam core (11) of polyisocyanurate, polyurethane materials or mixtures thereof; a facer (15), applied to one major surface (13) of the foam core, where the facer includes polymer materials, reinforced polymer materials, cellulosic materials, paper, aluminum foil or trilaminates thereof, wherein the reinforced polymer material and the cellulosic material are reinforced with glass strands, glass fibers, or mixtures thereof; and, gypsum board (14), applied to the opposite major surface (12) of the foam core. A method of reroofing a roof by applying composite recovery boards of the present invention to a roof deck; and, applying a weather protective layer over the recovery boards. A continuous method of making a composite recovery board by feeding gypsum board (14) into a laminator assembly (21); depositing a foamable polymer liquid (36) onto the gypsum board; feeding a facer material (15) into the laminator assembly above the foamable polymer liquid; allowing the polymer liquid to rise between the gypsum board and facer material forming polymer foam of a pre-determined thickness; curing the polymer foam under heat (44) to create the composite board; and cutting the composite board to desired lengths.

Owner:FIRESTONE BUILDING PRODS

Roofing members without auxiliary facers and related methods

InactiveUS6117375ADimensionally stableGood baseConstruction materialLamination ancillary operationsPolyisocyanurateEngineering

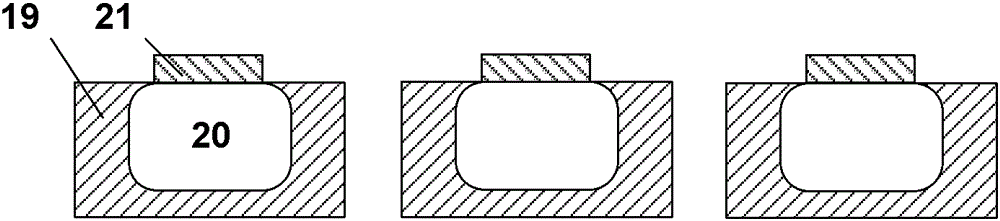

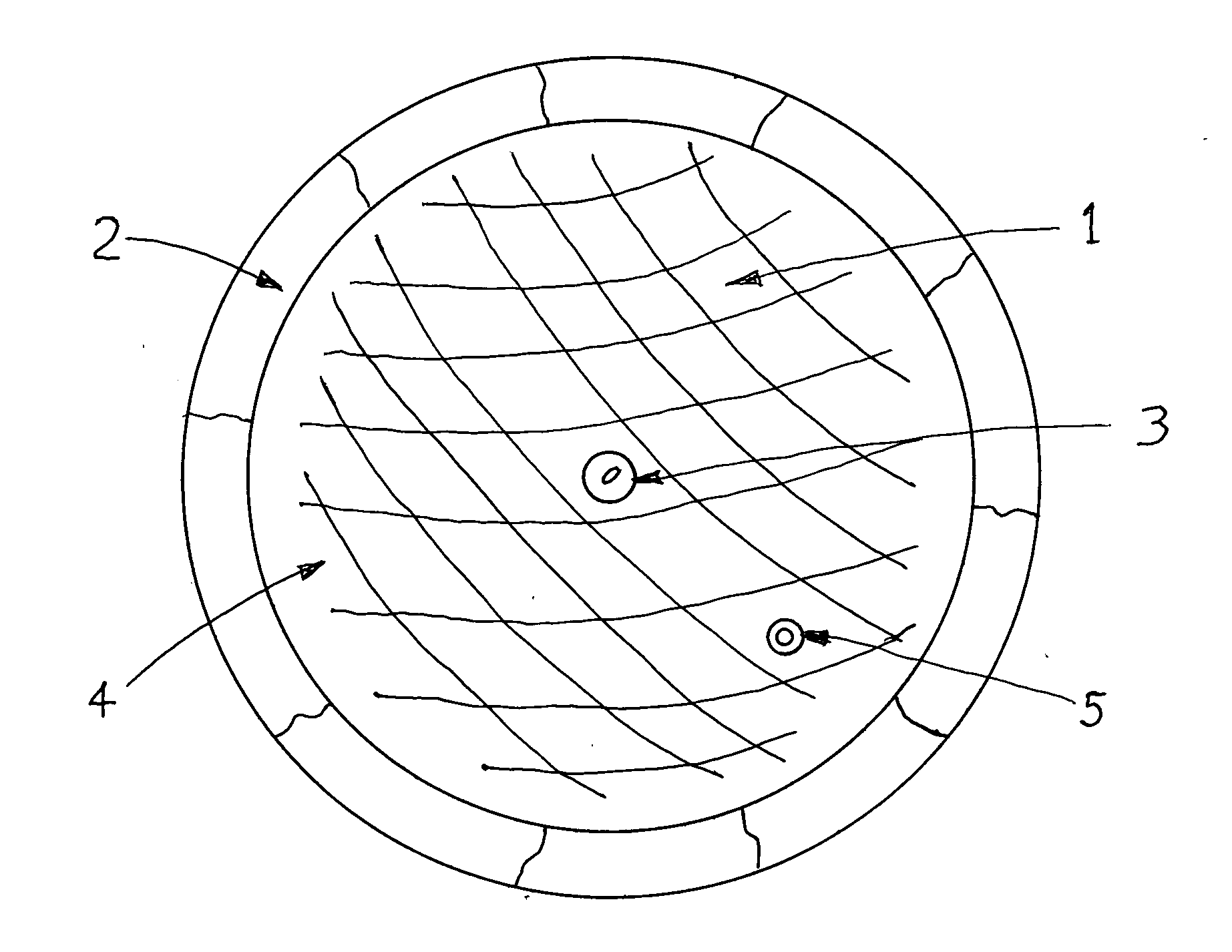

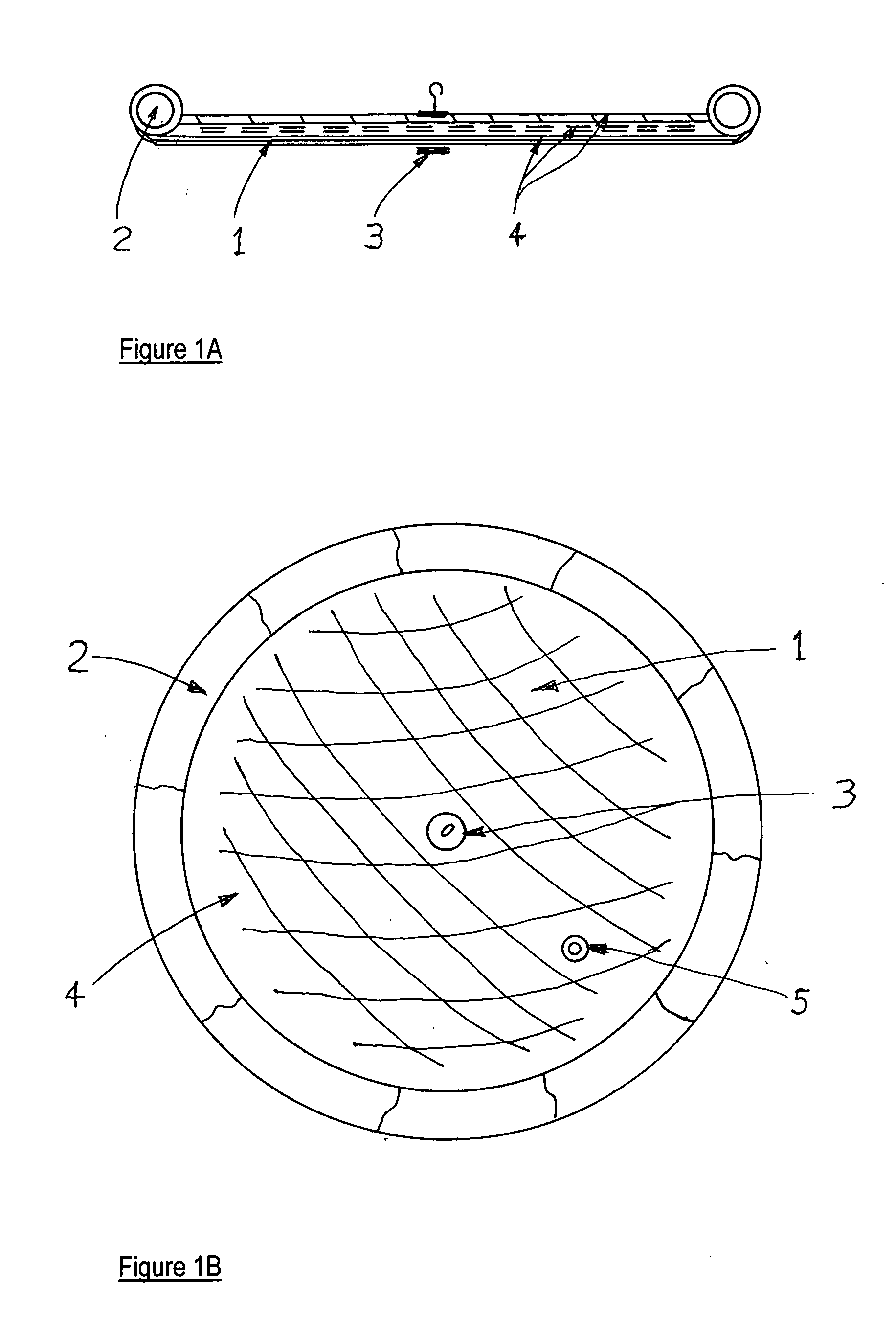

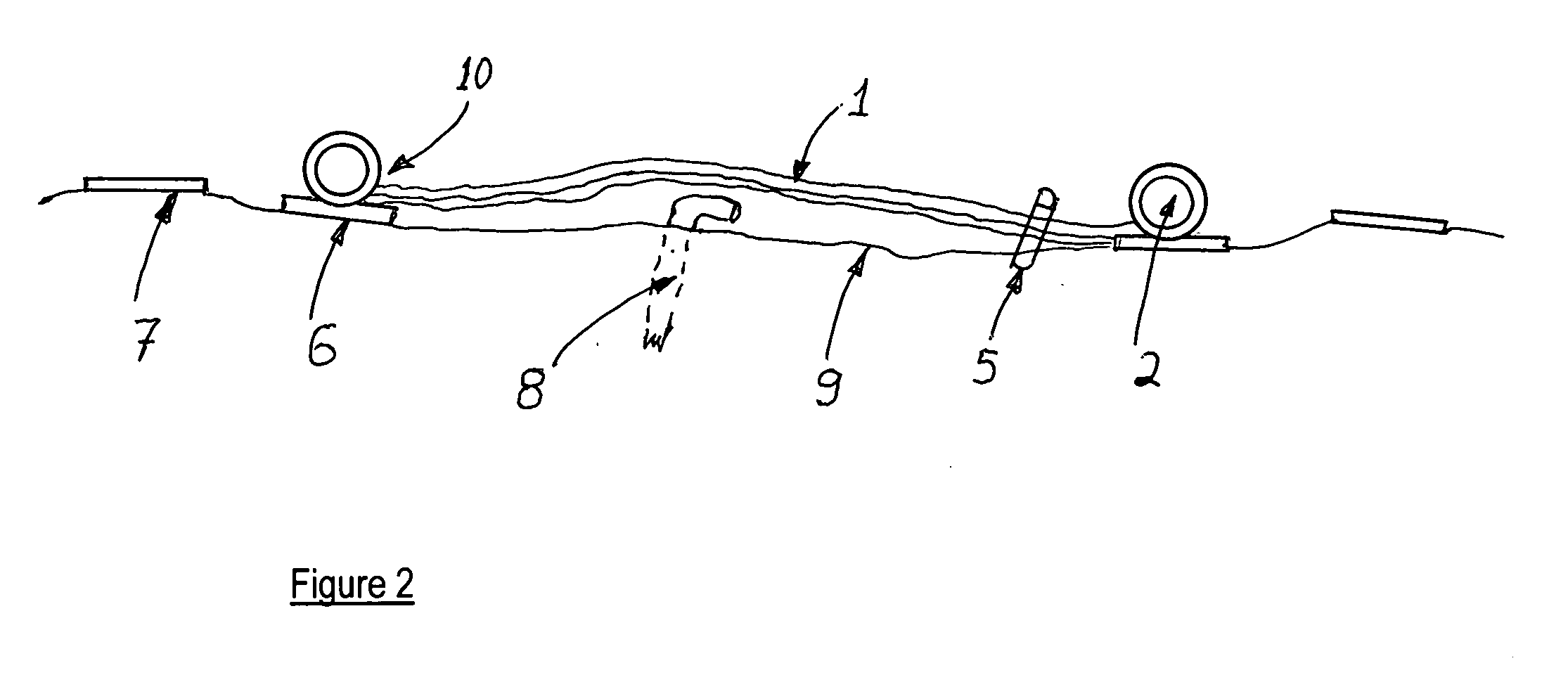

An insulation board (10) insulation board comprising a foam core (11) selected from the group consisting of polyisocyanurate and polyurethane materials and mixtures thereof; the board being devoid of facers. A method of covering roofs comprises applying insulation boards to a roof deck, the insulation boards comprising a foam core selected from the group consisting of polyisocyanurate and polyurethane materials and mixtures thereof, the boards being devoid of facers; and, applying a weather protective layer over the insulation boards. A continuous method of making a facerless insulation board comprising the steps of feeding a first sheet (24) of temporary facer material into a laminator (25); depositing a foamable polymer liquid (40) onto the first sheet; feeding a second sheet (23) of temporary facer material into the laminator above the foamable polymer liquid; allowing the polymer liquid to rise between the first and second sheets forming polymer foam (44) of a pre-determined thickness; curing the polymer foam under heat (45) to create the insulation board; removing the first and second sheets from the board prior to final curing and cooling; and cutting the board to desired lengths.

Owner:FIRESTONE BUILDING PRODS

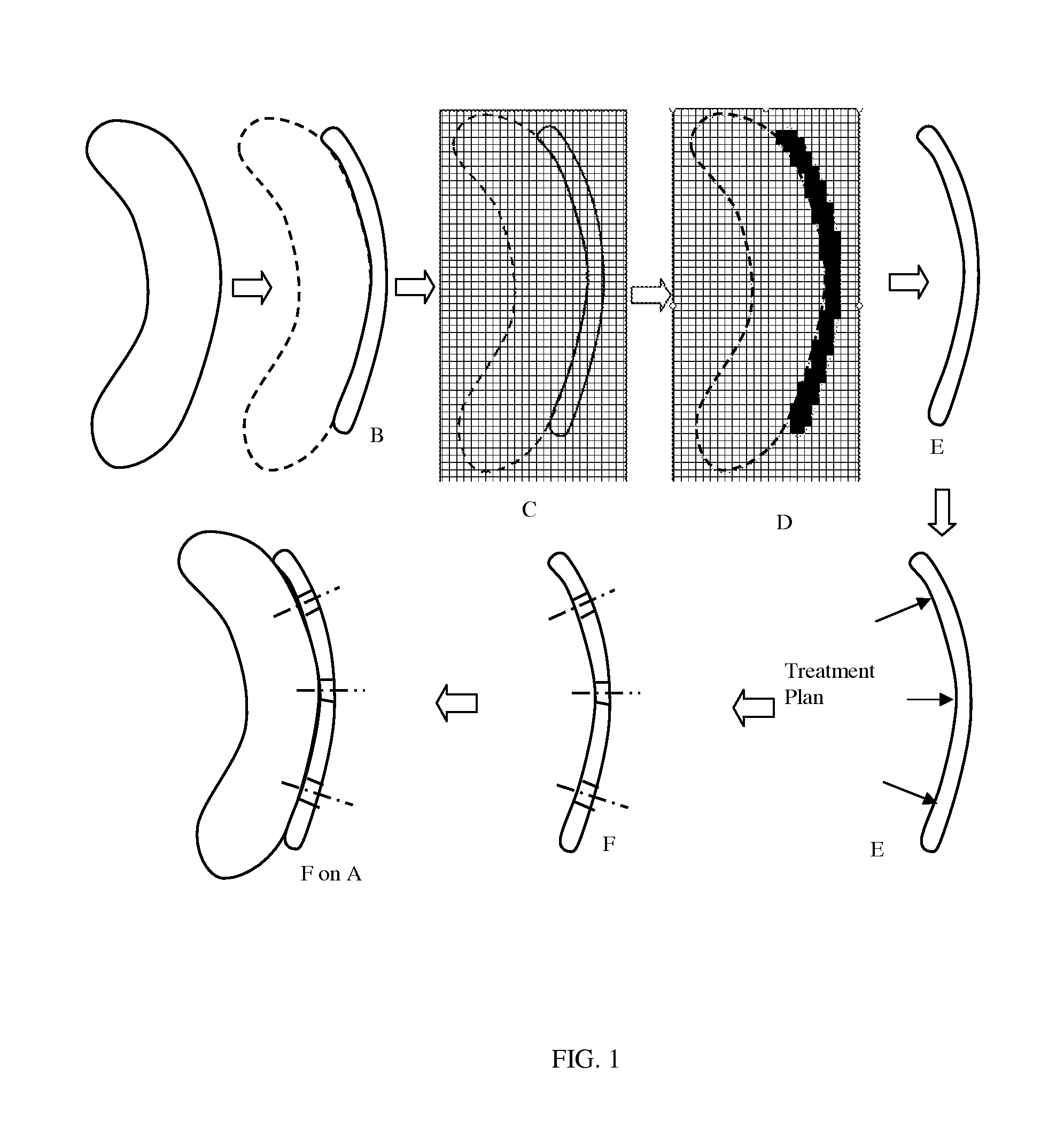

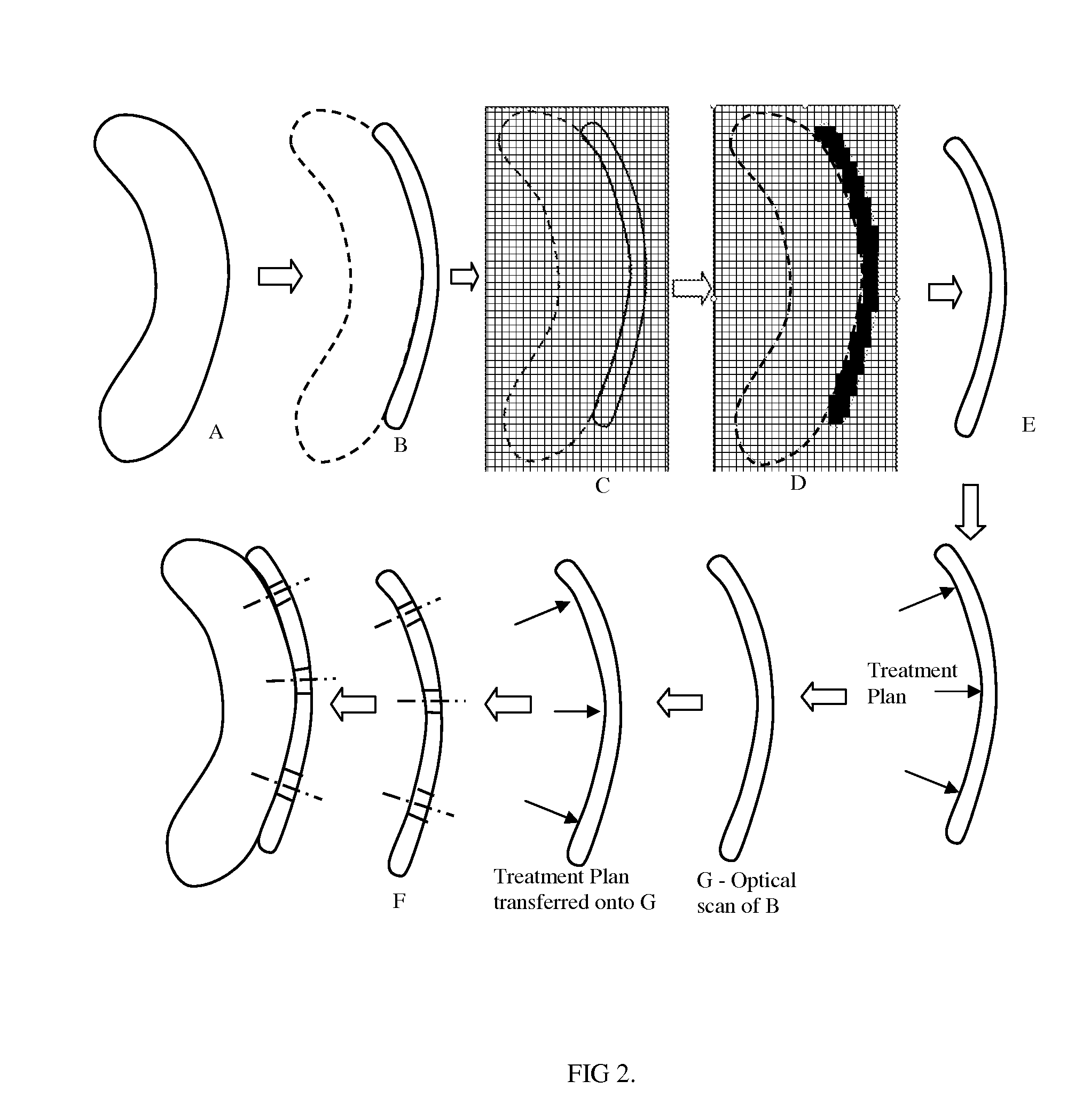

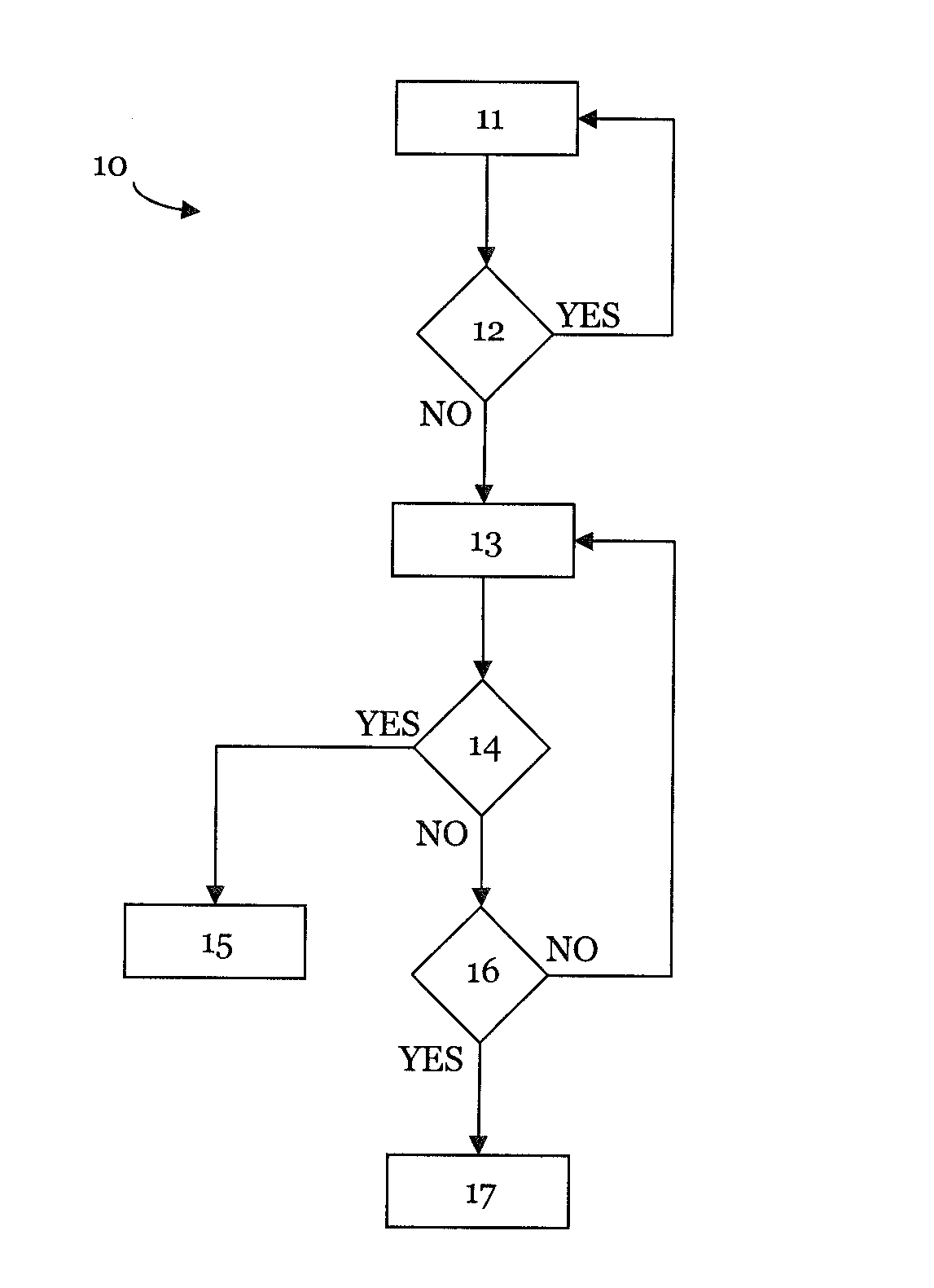

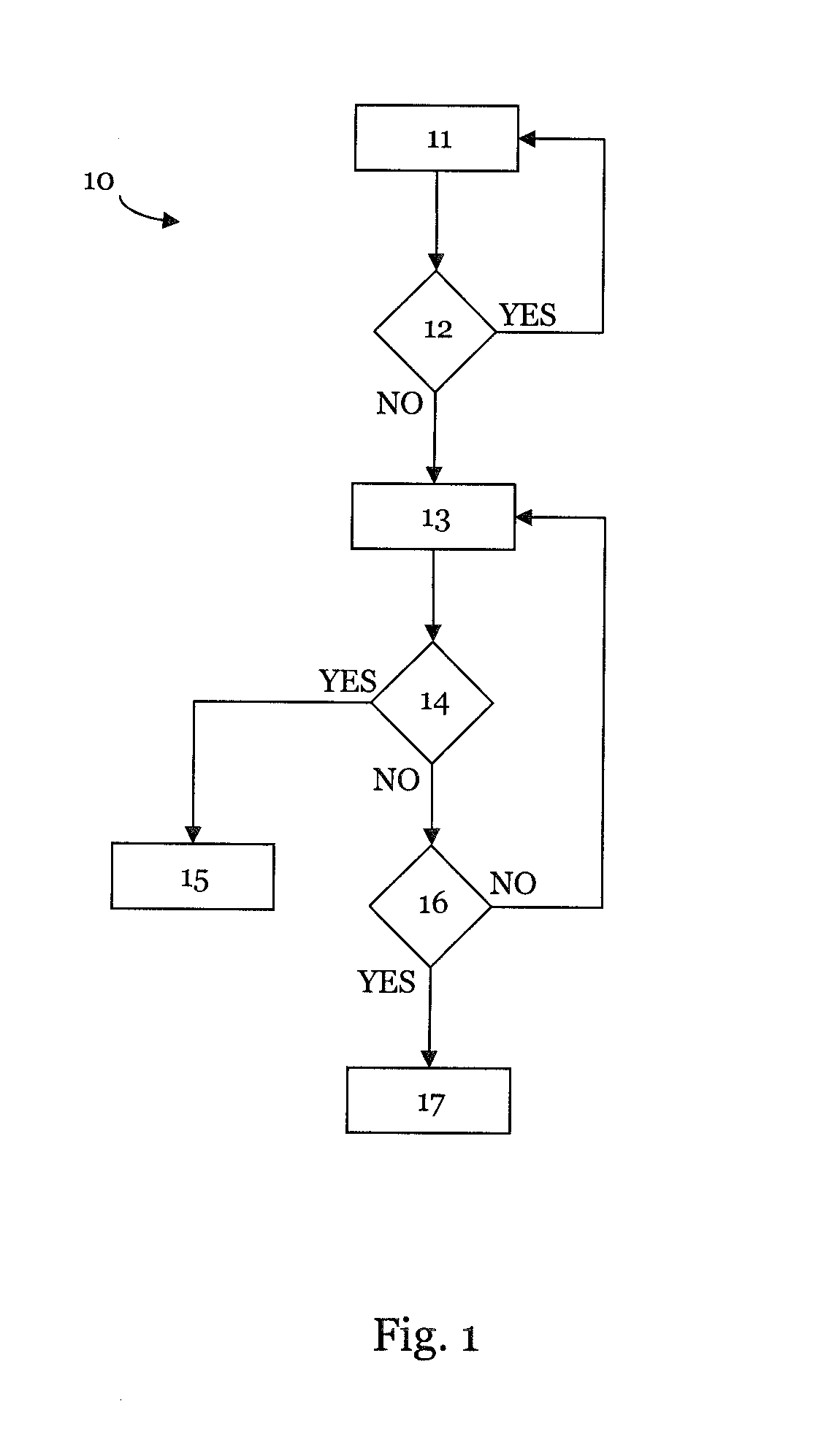

Design method of surgical scan templates and improved treatment planning

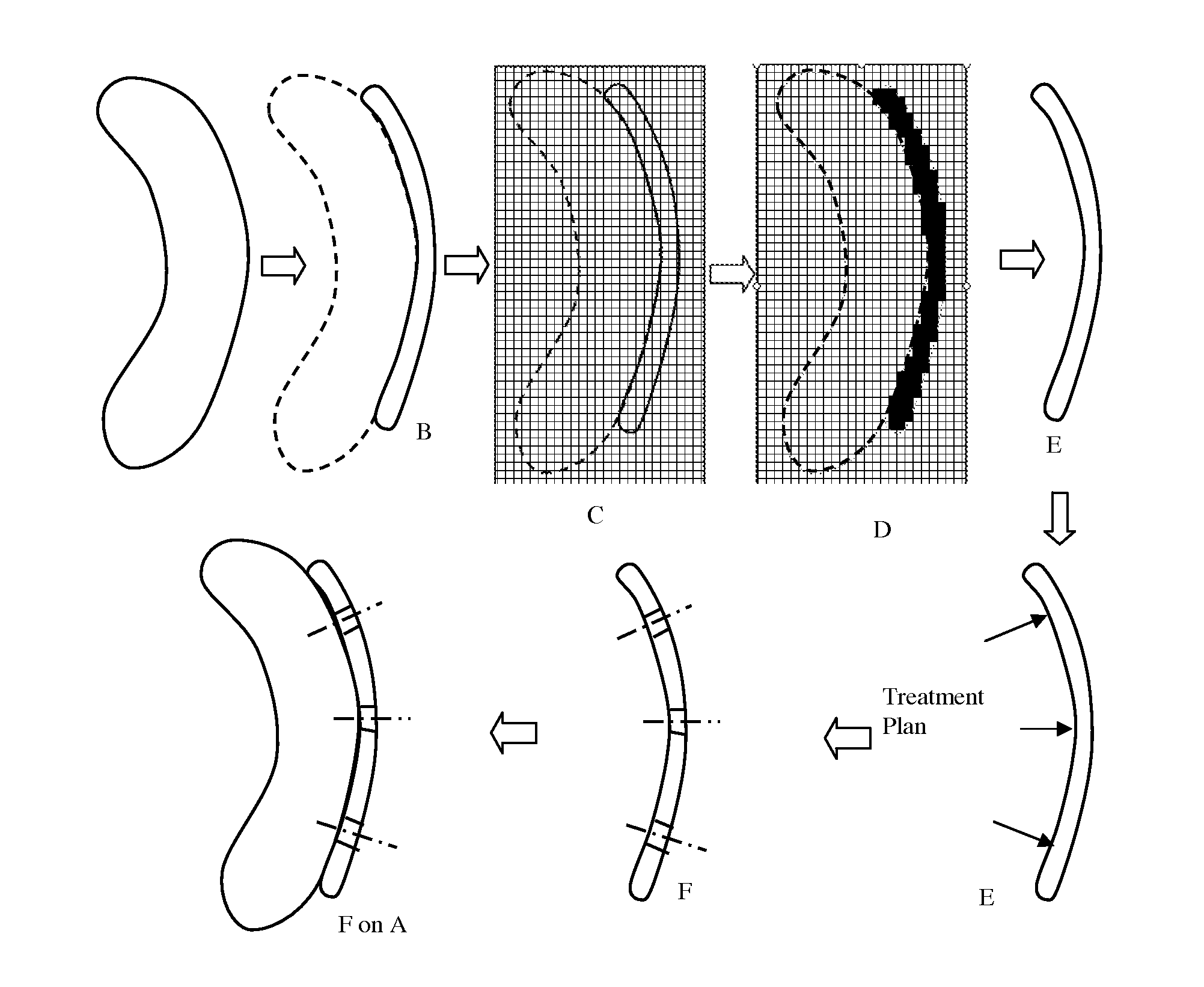

InactiveUS20110275029A1Good baseEasy to implementBoring toolsDental prostheticsImage segmentationProgram plan

In implant dentistry, scan templates, also known as scan appliances or radiographic guides, are fabricated according to patients' anatomy, and later on transferred into surgical guides through CT scan, image segmentation, surface reconstruction, CAD modification, and manufacturing. This approach may be also applied to other kinds of surgery. The final manufactured surgical guides can hardly match the actual geometry of the initial scan templates, thus cannot fit well into patients' mouths, which can pose serious risks for surgery.This invention introduces calibration features to design and make a scan template, and accordingly the workflow to perform treatment planning with the template. Calibration features are geometric form features or their patterns. Iterations are utilized to make sure the reconstructed model of a scan template can replicate or match with the calibration features. After treatment planning, calibration features are removed from the model (an optional step), and a surgical guide is designed and fabricated. This invention also includes some special calibration feature designs. The treatment planning workflow is greatly improved with calibration features introduced.

Owner:GAO FEI

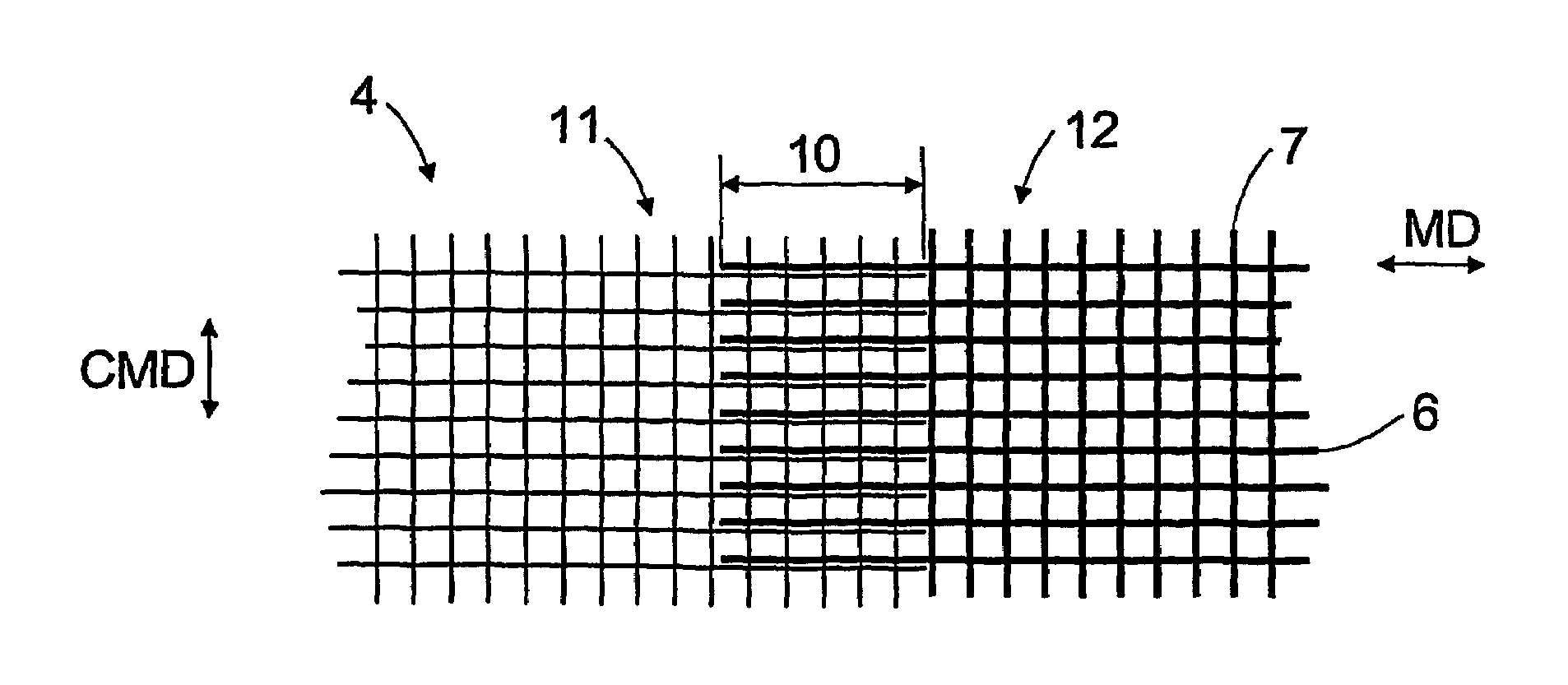

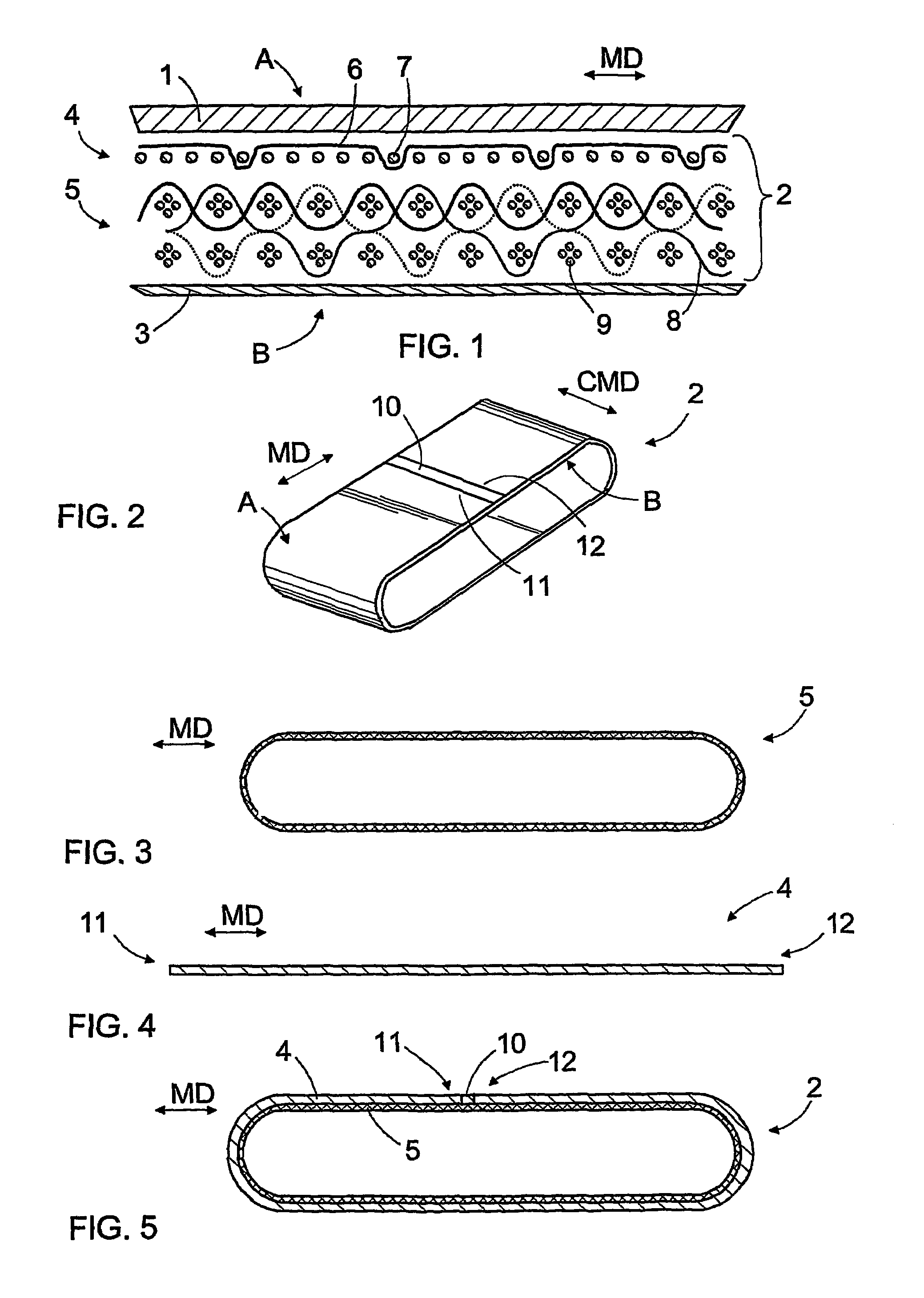

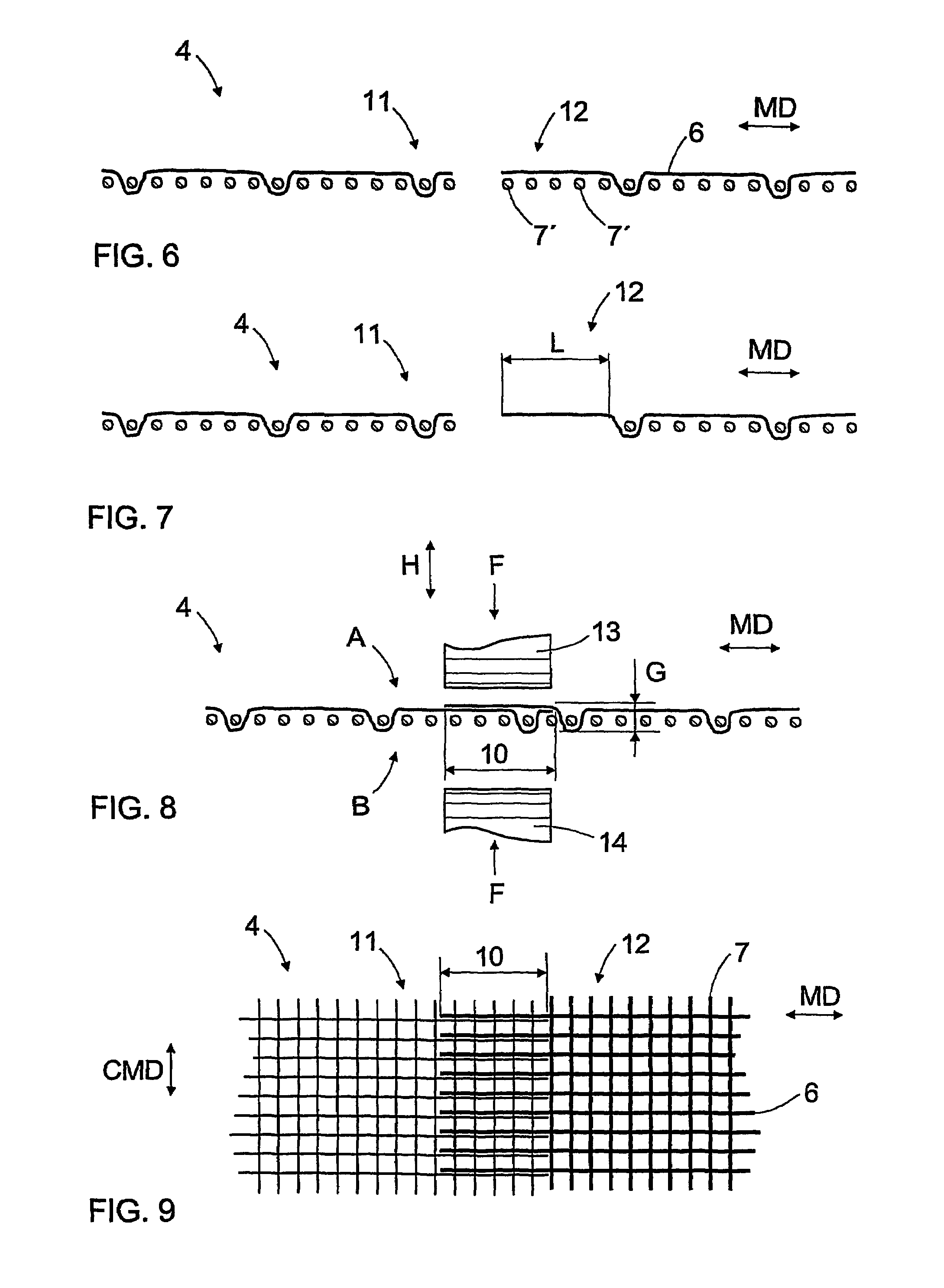

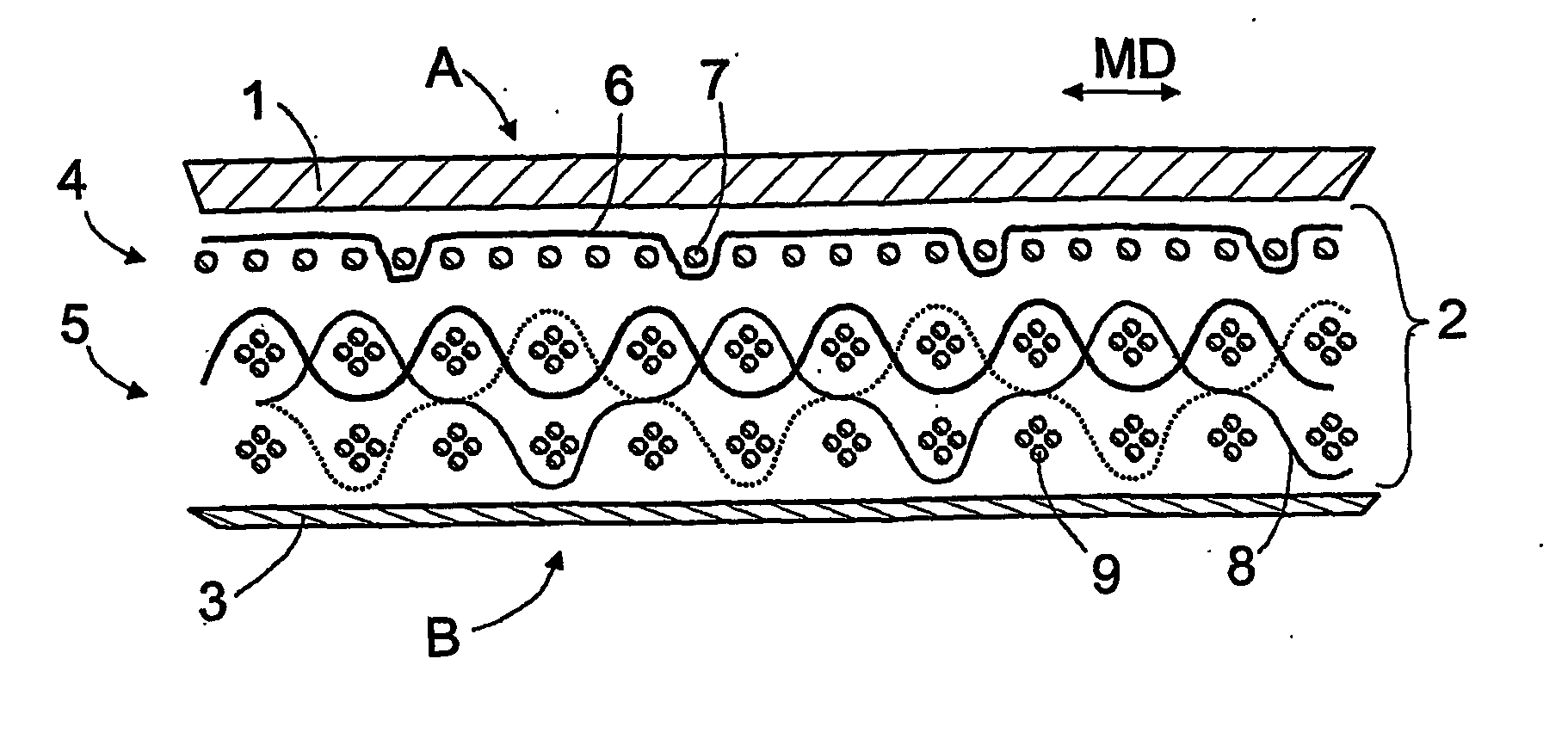

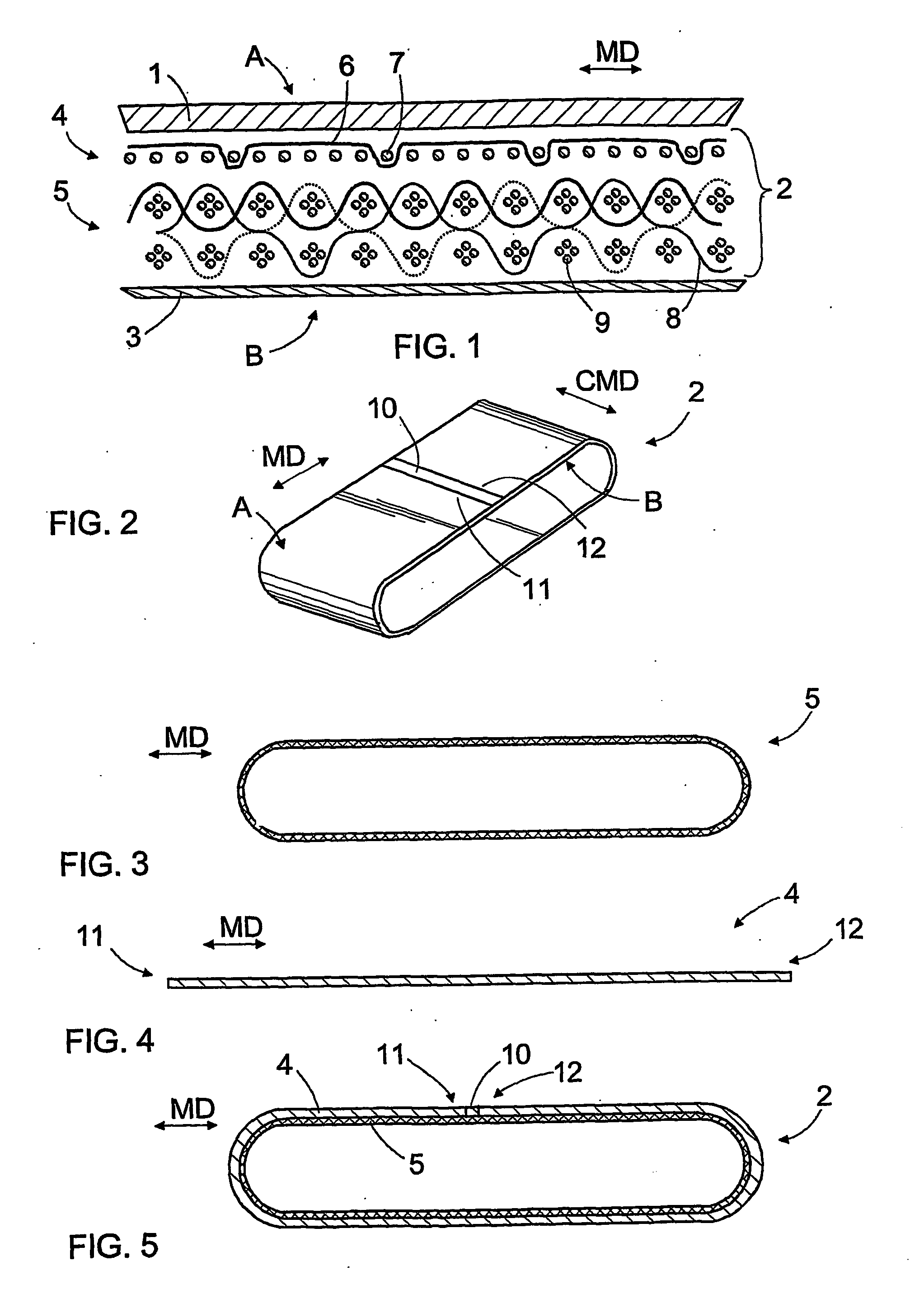

Method of manufacturing a press felt, and a press felt, with the shape of a closed loop

ActiveUS7381307B2Easy to manufactureFast preparationMechanical cleaningPressure cleaningClosed loopMechanical engineering

Owner:TAMFELT PMC OY

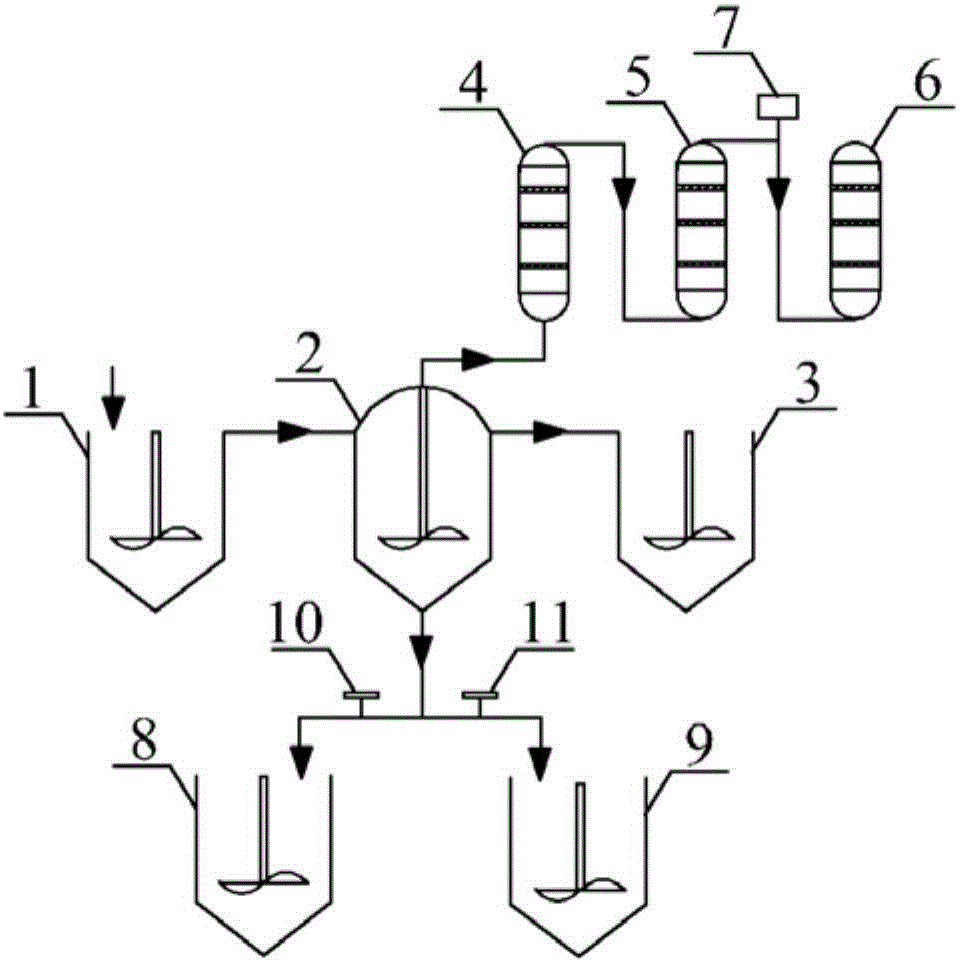

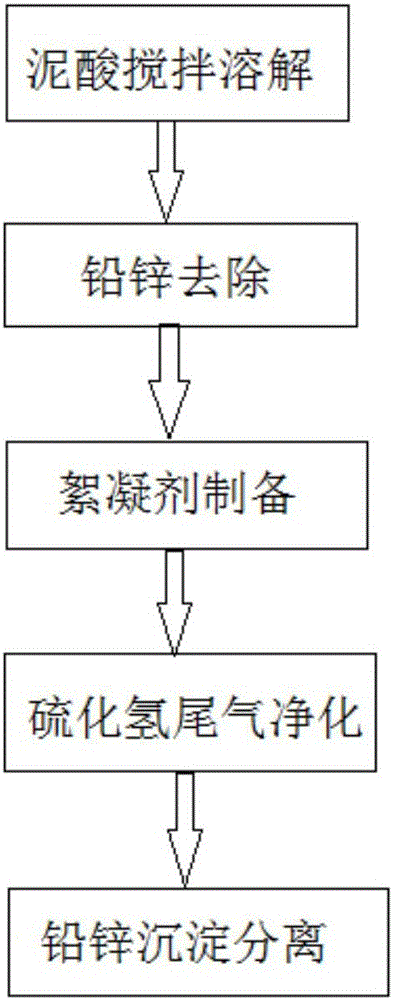

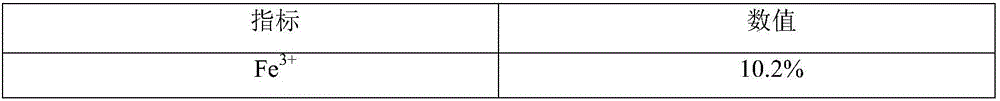

Steel wire rope picking waste acid and high zinc and lead-containing sludge co-disposal system and process

ActiveCN106186445APollution realizedReduce pollutionSludge treatmentOrganic compound preparationSludgeEngineering

The invention discloses a steel wire rope picking waste acid and high zinc and lead-containing sludge co-disposal system and process and belongs to the technical fields of environmental protection and wastewater treatment. The steel wire rope picking waste acid and high zinc and lead-containing sludge co-disposal system disclosed by the invention comprises a mud acid stirring and dissolving device, a lead and zinc removal device, a flocculating agent preparation device, a hydrogen sulfide absorption device and a lead and zinc precipitation separation device, wherein the mud acid stirring and dissolving device is connected with the lead and zinc removal device through a pipeline; and the lead and zinc removal device is connected with the flocculating agent preparation device, the hydrogen sulfide absorption device and the lead and zinc precipitation separation device through pipelines. The steel wire rope picking waste acid and high zinc and lead-containing sludge co-disposal process disclosed by the invention comprises the following steps: stirring and dissolving mud acids, removing lead and zinc, preparing polyferric flocculants, purifying hydrogen sulfide tail gas and performing lead and zinc precipitation separation. According to the invention, steel wire rope picking waste acid and high zinc and lead-containing sludge co-disposal can be realized, the elements such as zinc and lead can be effectively removed, and industrial products with high additive values are prepared.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

Method of manufactring a press felt, and a press felt, with the shape of a closed loop

ActiveUS20060016571A1Manufacture quicklyEasy to implementMechanical cleaningPressure cleaningMechanical engineeringClosed loop

Owner:TAMFELT PMC OY

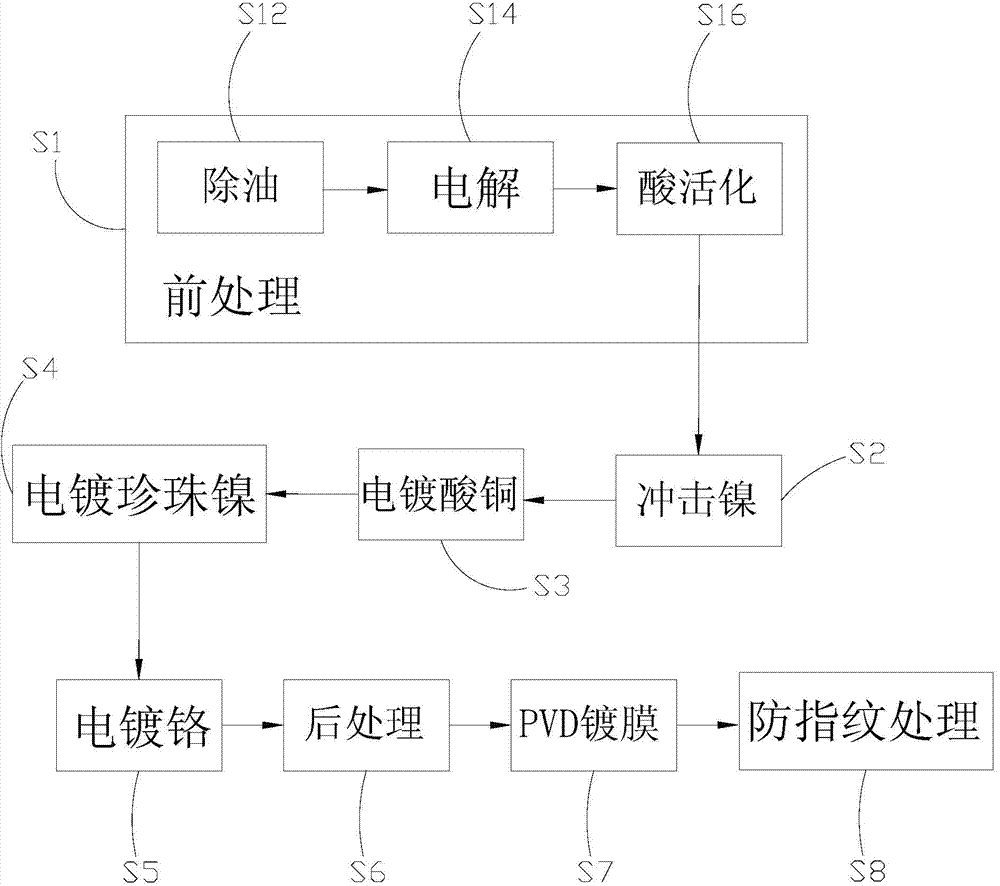

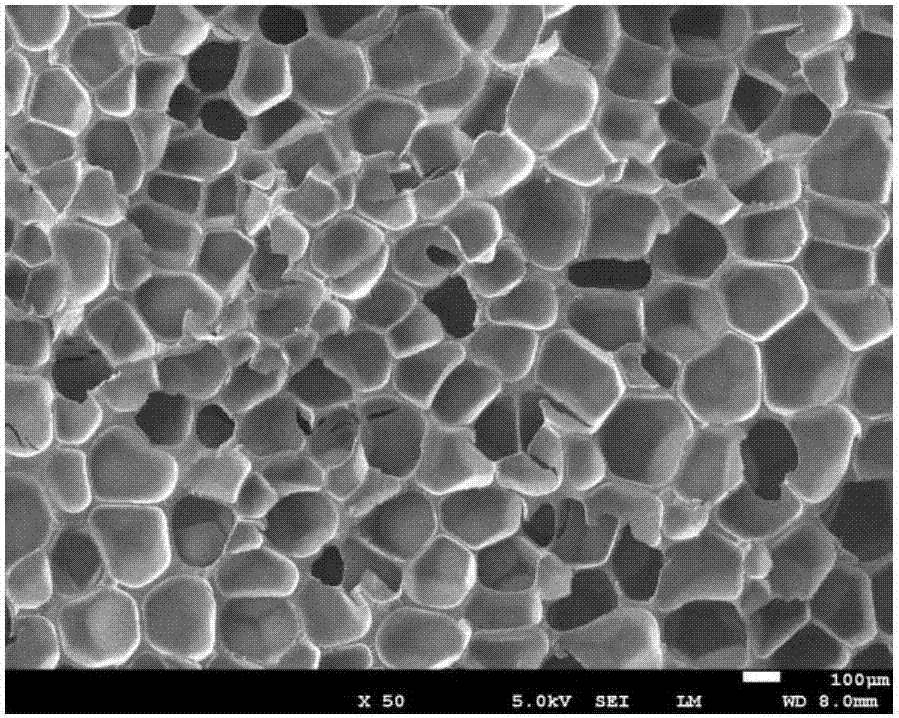

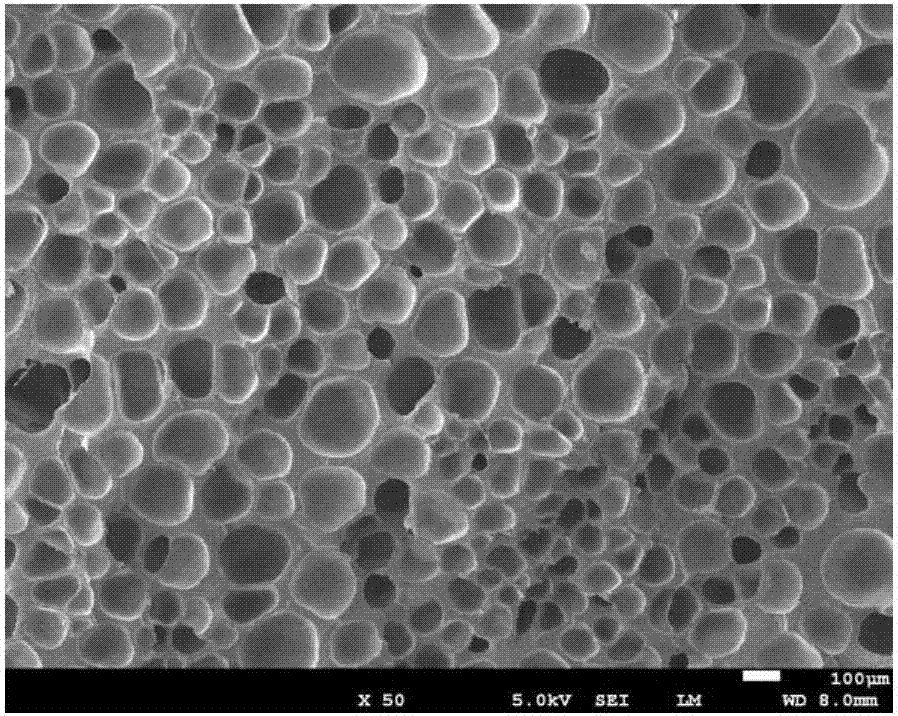

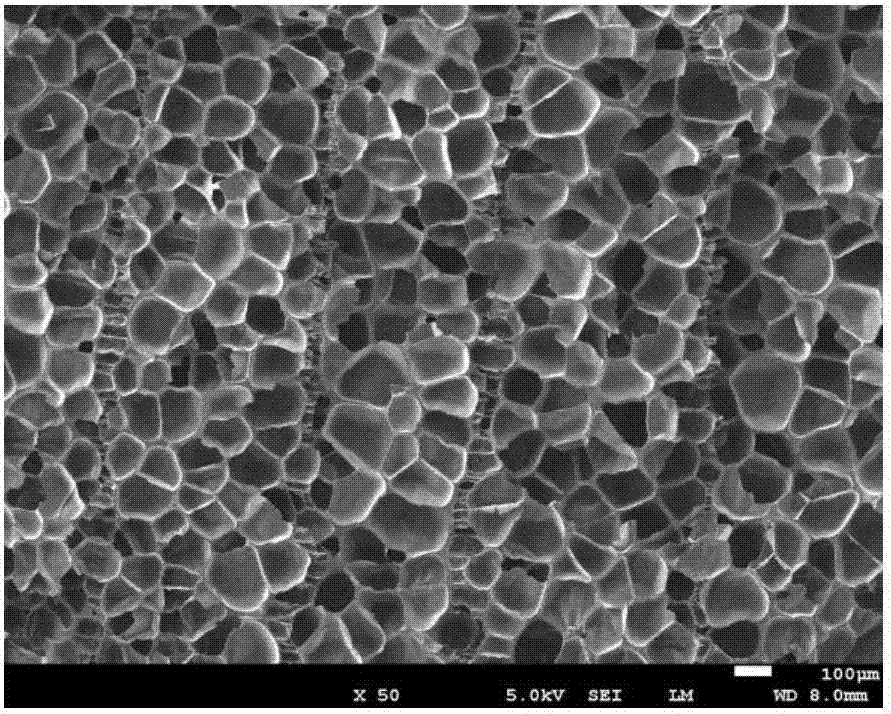

Stainless steel surface treatment method

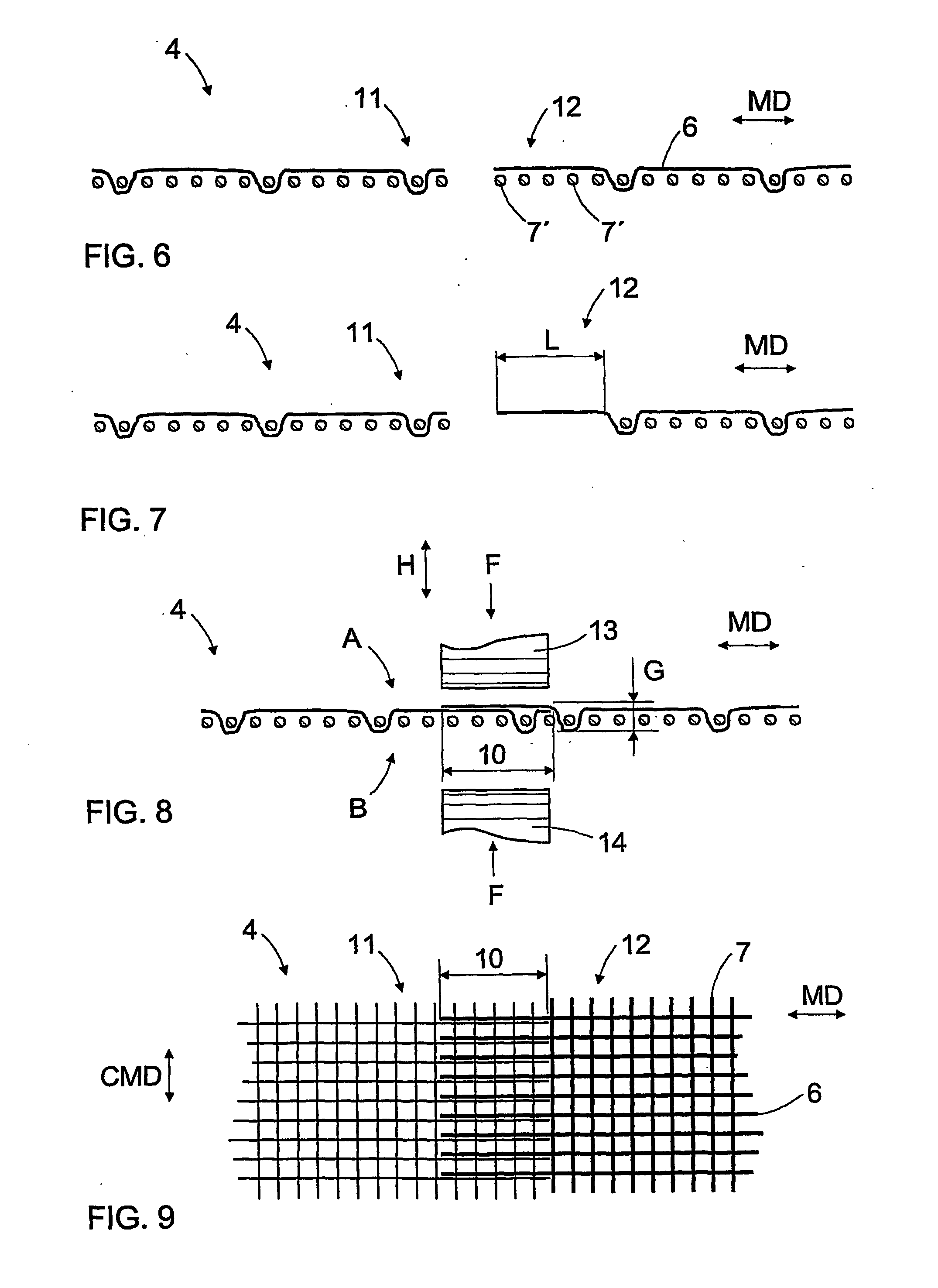

ActiveCN104726911AImprove corrosion resistanceWith silvery white metal textureSuperimposed coating processCopper coatingSurface layer

The invention is suitable for the technical field of metal surface treatment methods, provides a stainless steel surface treatment method and aims at solving the technical problem of failure in showing stainless steel three-dimensional texture after stainless steel surface treatment in the prior art. The stainless steel surface treatment method comprises the following steps: pretreatment, namely cleaning the surface of a stainless steel substrate; impacting nickel, namely performing impacting electronickelling on the stainless steel substrate to obtain an impact nickel layer; acidic copper electroplating, namely performing acidic copper electroplating treatment on the impact nickel layer and forming a copper coating; pearl nickel electroplating, namely performing pearl nickel electroplating treatment on the surface of the copper coating and obtaining a pearl nickel layer with sand feeling; electrochroming, namely forming a protective chrome layer on the surface layer of the pearl nickel layer; and aftertreatment. The pearl nickel electroplating treatment is adopted to increase the sand feeling of the copper coating and then the surface with the three-dimensional texture can be obtained; and the electrochroming treatment is adopted to form the protective film on the surface of the pearl nickel layer, and therefore, the stainless steel substrate also has silver white metal texture.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Fluororubber microcellular foam material and preparation method thereof

The invention provides a fluororubber microcellular foam material and a preparation method thereof; the fluororubber microcellular foam material comprises, according to its formulation, 100 parts of fluororubber, 0-100 parts of a filling material, 5-20 parts of an acid absorbent, 1-2 parts of a processing aid, 0-3 parts of a modifier, 1-3 parts of a vulcanizing agent, and 0-5 parts of an accelerant. The preparation method is provided according to the above formulation; foam materials having different properties are prepared through the microcellular foaming process and are nontoxic and environmentally friendly. The fluororubber microcellular foam material is mainly applied to rubber pipes, adhesive tapes, diaphragms, seals and others having good resistance to high temperature, oil and media; the fluororubber microcellular foam material is applicable to electronic parts, electrical parts, various packaging materials, heat-resistance gasket materials and the like.

Owner:QINGDAO UNIV OF SCI & TECH

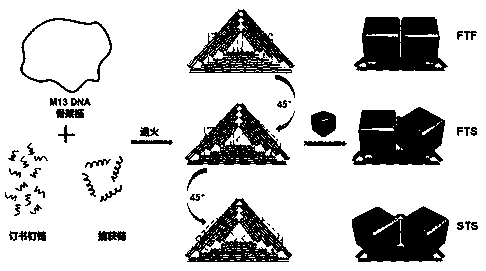

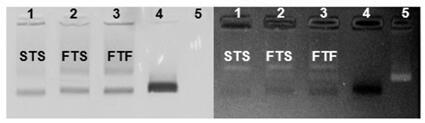

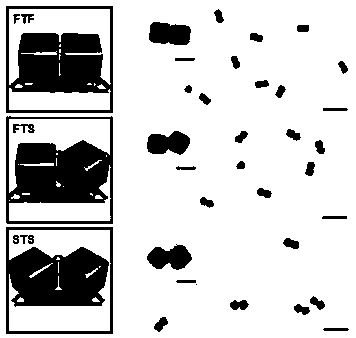

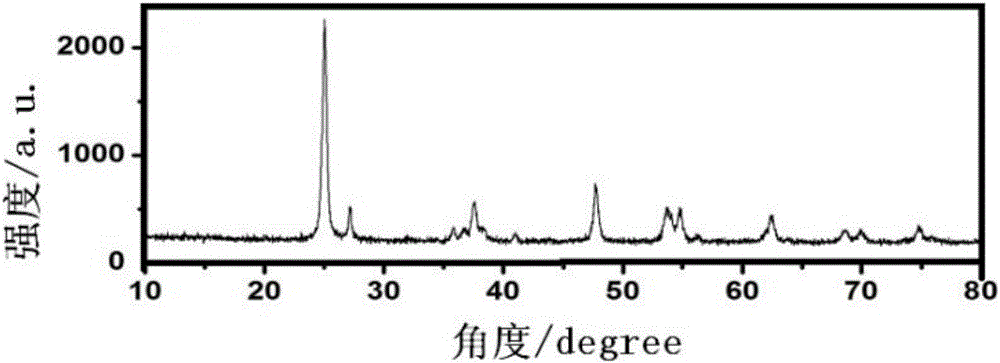

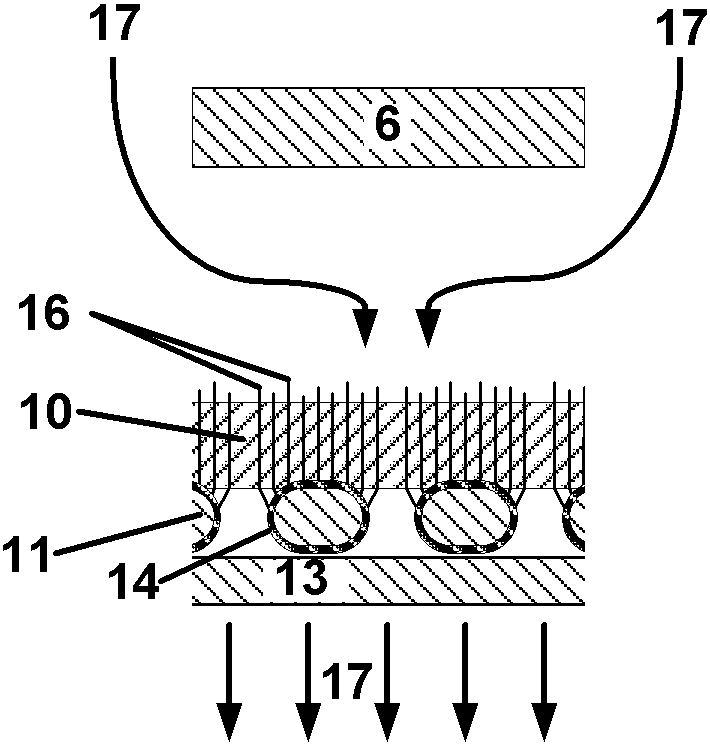

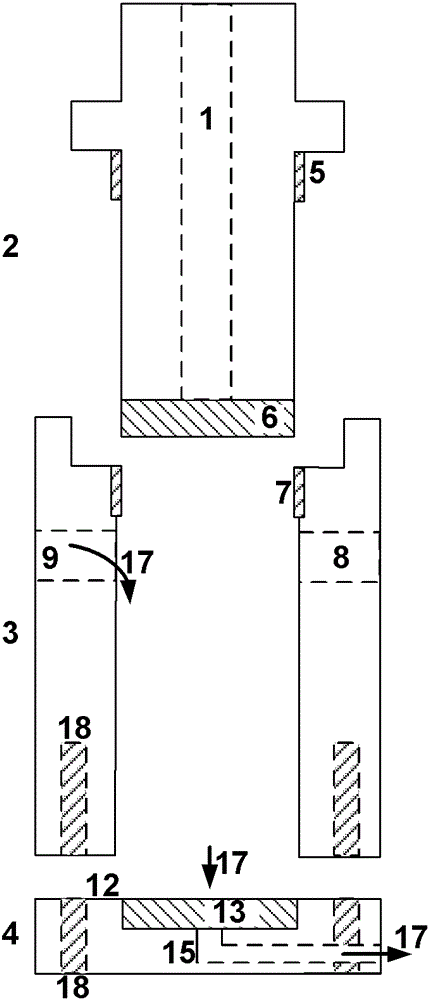

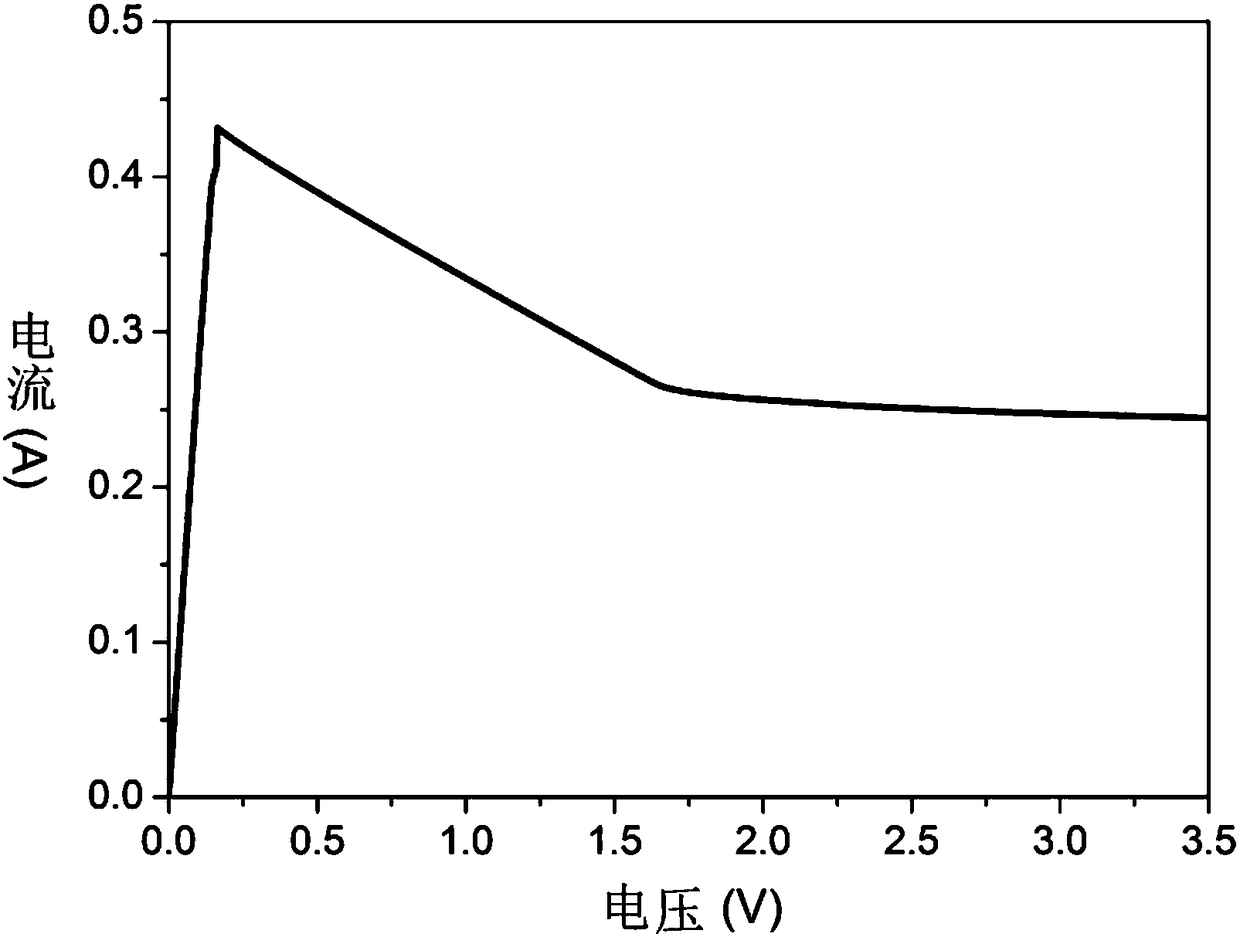

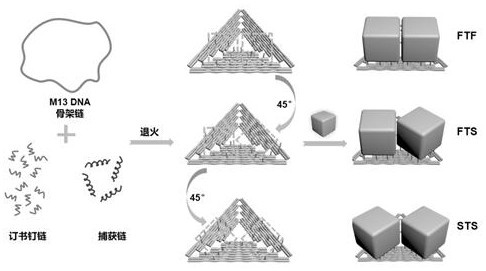

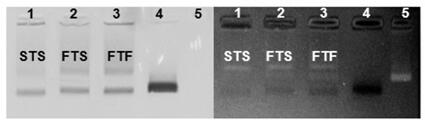

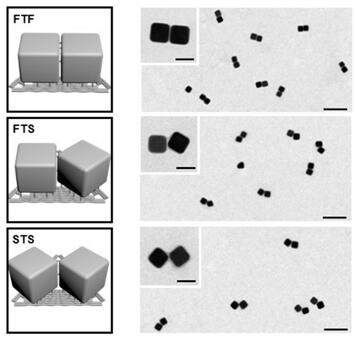

Method for forming dimer structure by assembling DNA origami template and nanometer gold cube based on surface enhanced Raman effect

ActiveCN110057806AEfficient and accurate assemblyEfficient assemblyRaman scatteringFermentationScanning electron microscopeA-DNA

The invention discloses a method for forming a dimer structure by assembling a DNA origami template and a nanometer gold cube based on a surface enhanced Raman effect. The method specifically comprises the five steps of preparation of triangular DNA origami with specific sites; preparation of a sulfydryl DNA modified nanometer gold cube; preparation of three dimer configurations; and high efficiency precise assembly by using agarose gel electrophoresis and a transmission electron microscope representational structure, and surface enhanced Raman scattering by using a scanning electron microscope and dark-field microscope co-location detection assembly structure. The method solves the problems of low assembly repeatability and poor structural stability, a new idea is also provided for construction of nanometer optical materials due to establishment of the method, and the method is of great significance to research of nanophotonics.

Owner:NANJING UNIV OF POSTS & TELECOMM

Organic compound fertilizer produced by using sludge with water content of 80% and production method

PendingCN109851451AShort processing timeGood effectCalcareous fertilisersMagnesium fertilisersChlorine dioxideResource utilization

The invention relates to an organic compound fertilizer produced by using sludge with a water content of 80% and a production method. The production method is characterized by comprising the steps ofadopting the sludge with the water content of 80%, coal ash, agricultural waste, quick lime, ferrous sulfate, magnesium sulfate, polyacrylamide and chlorine dioxide for even mixing, using a belt conveyor for transporting a mixture to a sealed high-temperature fermentation machine, elevating temperature in the fermentation machine to 100 DEG C through oil-electric heat conduction, maintaining an outage for 2 hours, maintaining temperature at 60 DEG C, adding high-temperature-loving active compound bacteria for fermentation, adjusting a stirring system of the fermentation machine to turn on an intermittent stirring function, and enabling fermentation time of the sludge in the fermentation machine to be 12 hours to effectively kill harmful microorganisms, eggs, weed seeds and pathogenic bacteria in the sludge; and ageing, crushing and screening a fermented cooked material to produce powder, and using an automatic electronic weighing and packaging machine for packaging the powder to produce an organic compound fertilizer product. Therefore, the problem of treating the sludge with the water content of 80% is solved, resource utilization of the sludge is achieved, and pollution to the natural environment is reduced.

Owner:李健

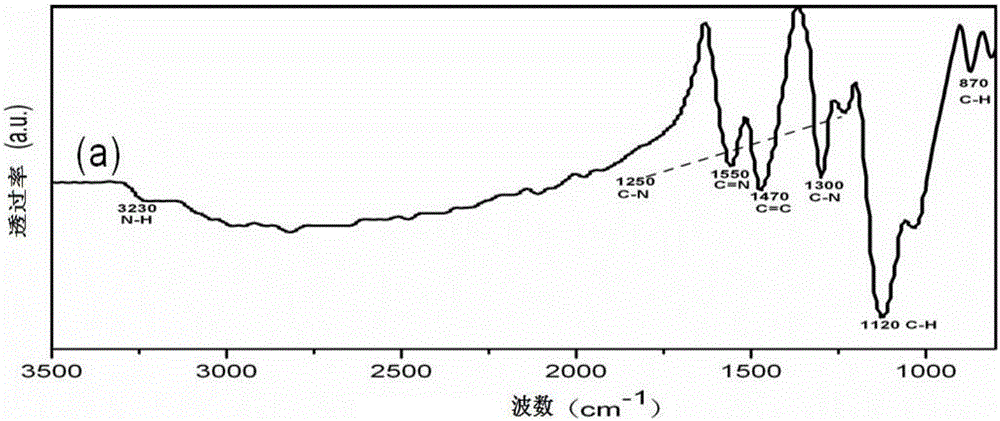

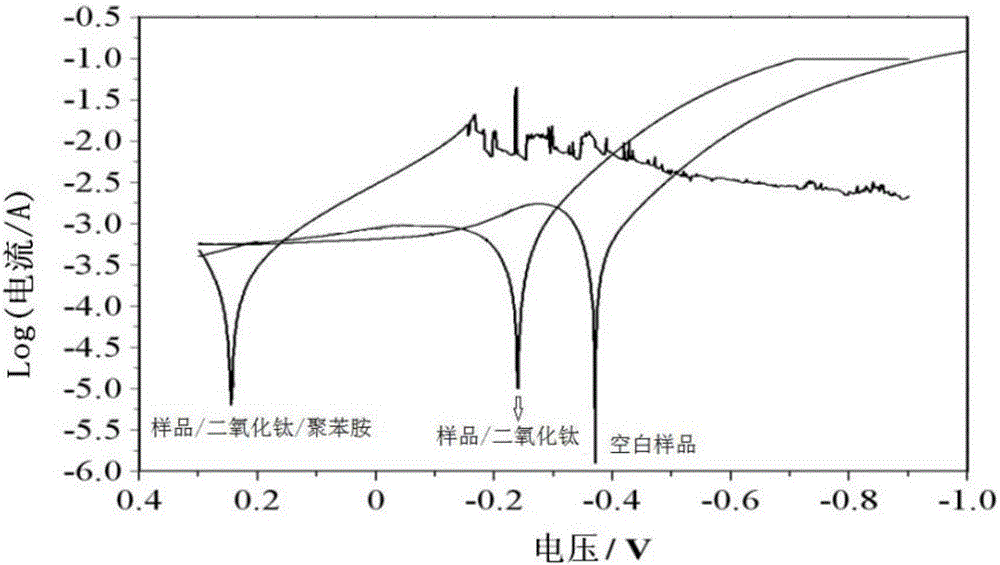

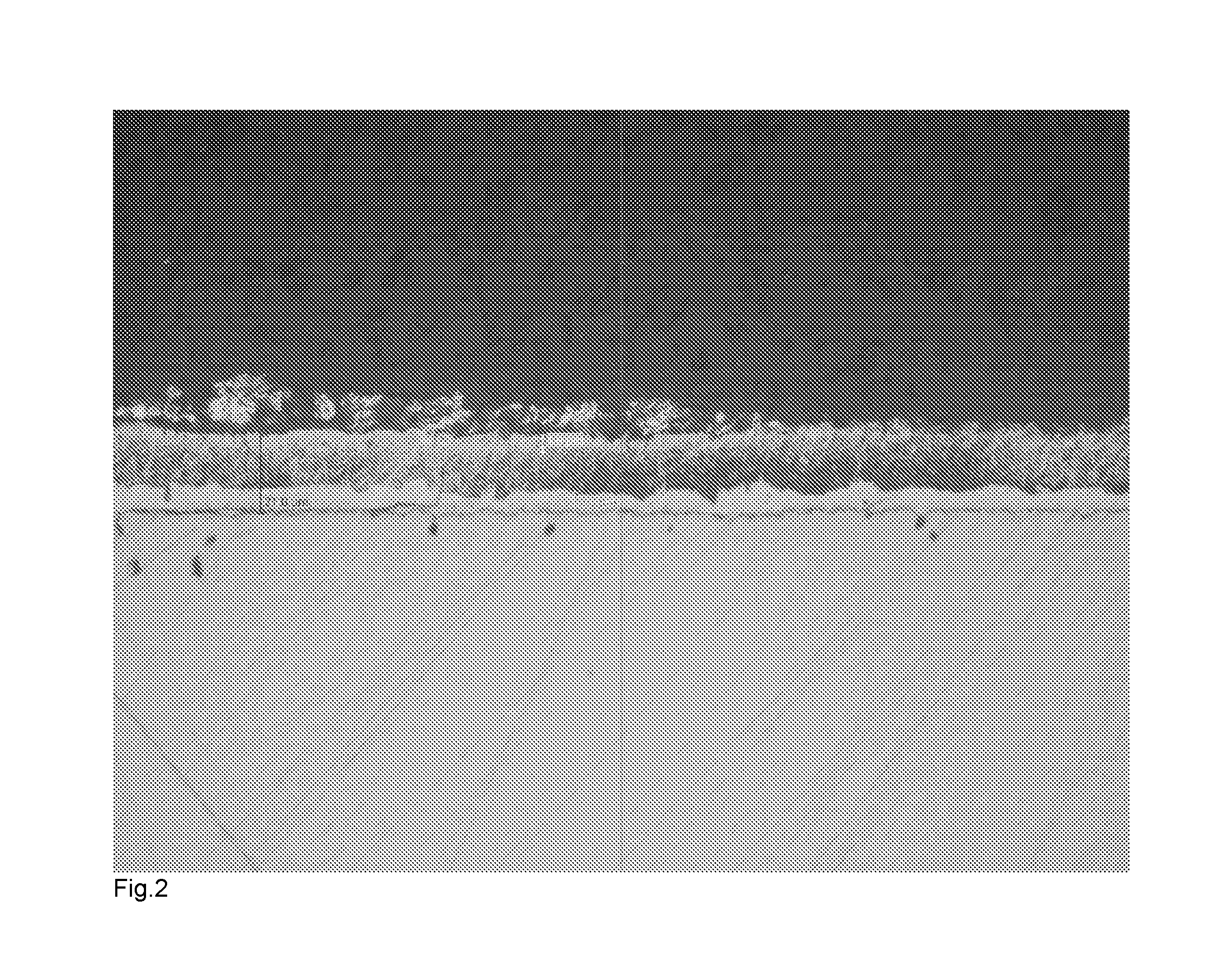

Preparation method of organic/inorganic composite coating

InactiveCN105951065AAvoid breakingImprove stabilityElectrophoretic coatingsSolid/suspension decomposition chemical coatingHigh resistancePre treatment

The invention discloses a preparation method of an organic / inorganic composite coating and belongs to the technical field of function material and metal surface protection. The preparation method comprises steps as follows: metal substrate pretreatment and preparation of a nanometer inorganic metal oxide coating and an organic polymer coating. According to the preparation method of the organic / inorganic composite coating, the nanometer inorganic metal oxide coating is taken as an inner layer, the organic polymer coating is taken as an outer layer, and through sufficient combination of respective advantages of organic metal oxide and organic polymer, the nanometer inorganic metal oxide / organic polymer composite coating with better protective performance is prepared. The inorganic metal oxide coating provides a good substrate for growth of the organic polymer coating, breakage of the inorganic metal oxide coating is avoided by means of coverage of the organic polymer coating, and the composite coating has better stability and protective performance. Compared with a single coating, the composite coating has more positive corrosion potential, higher resistance and better corrosion resistance.

Owner:BEIHANG UNIV

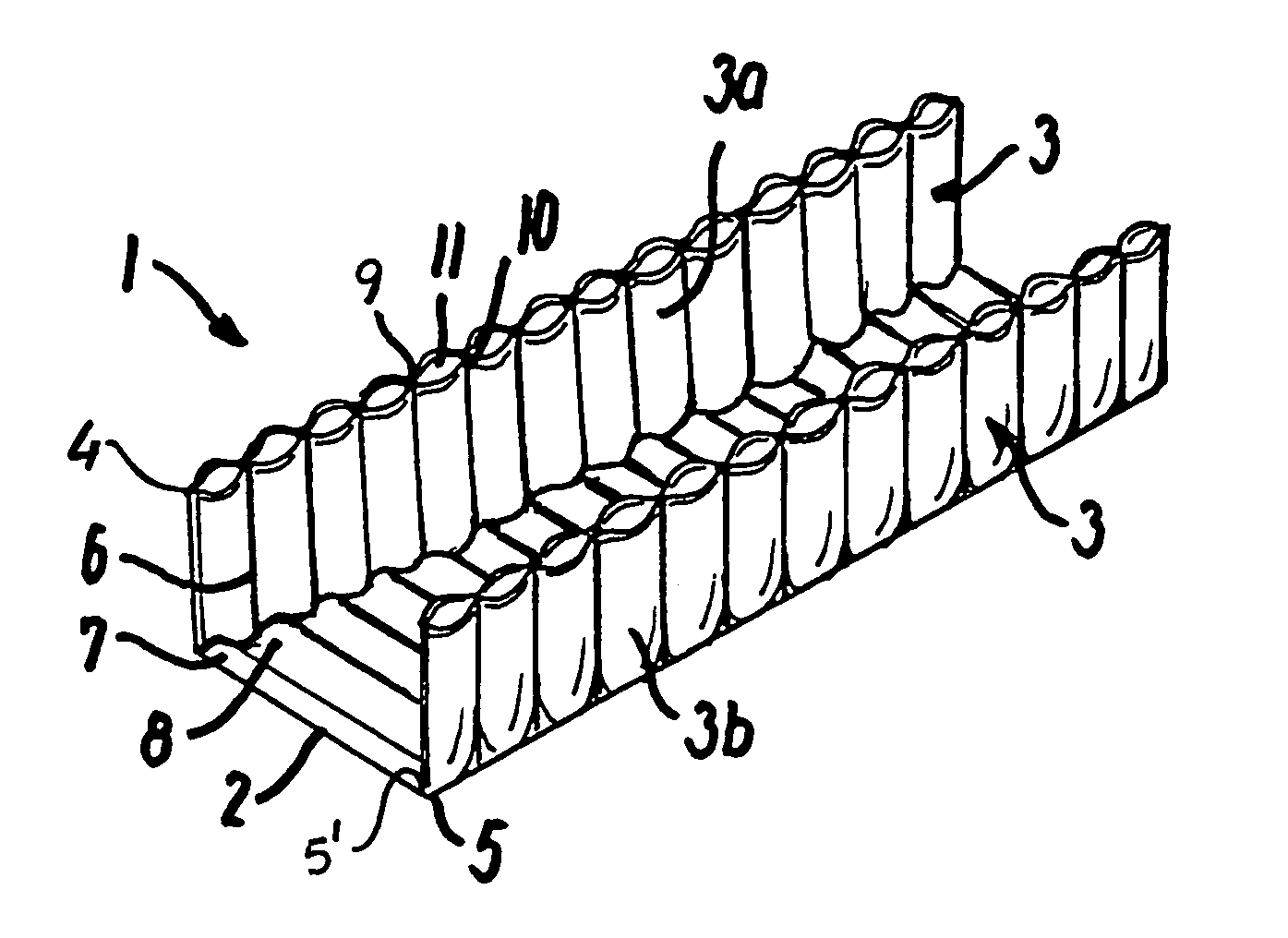

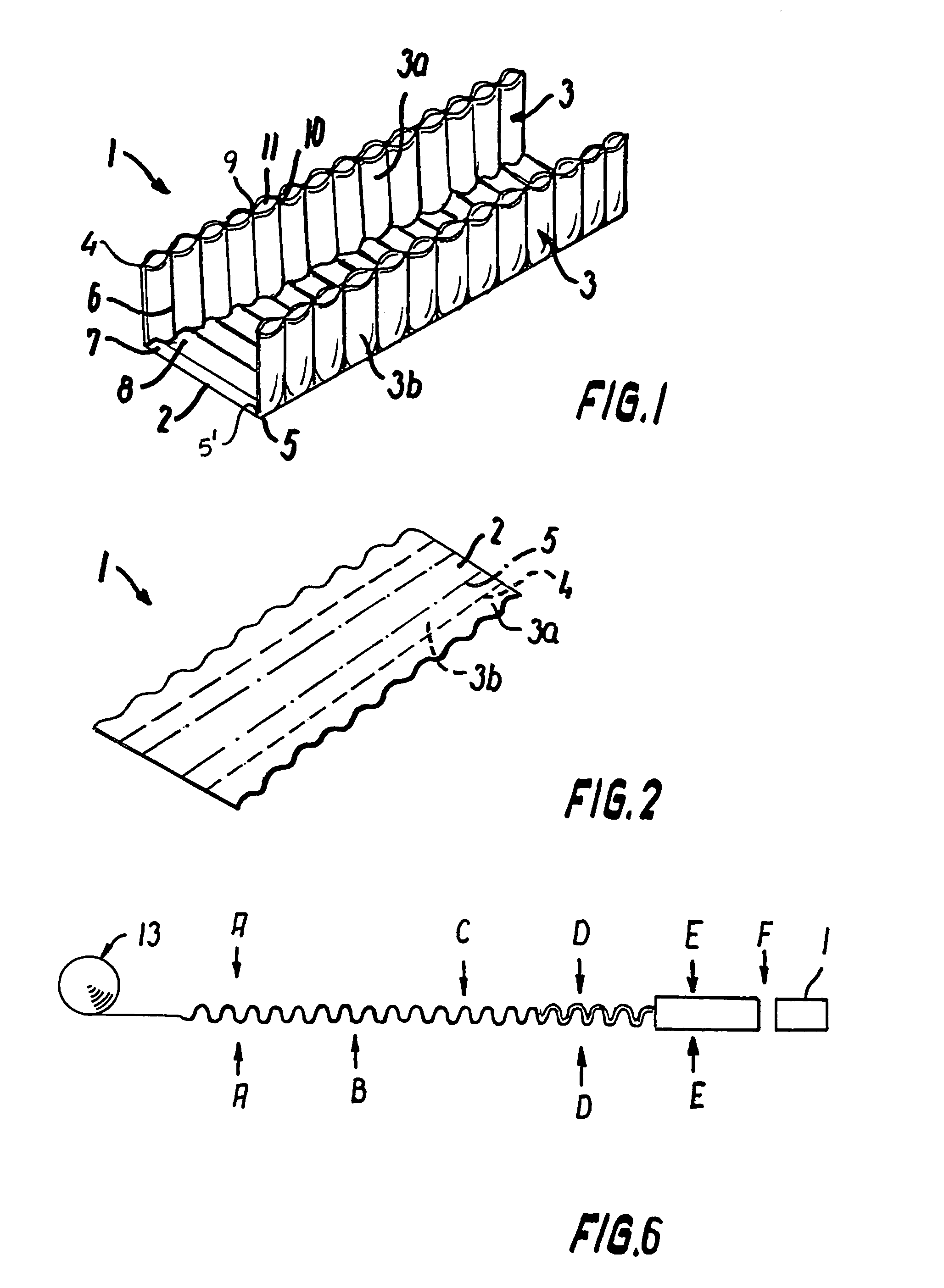

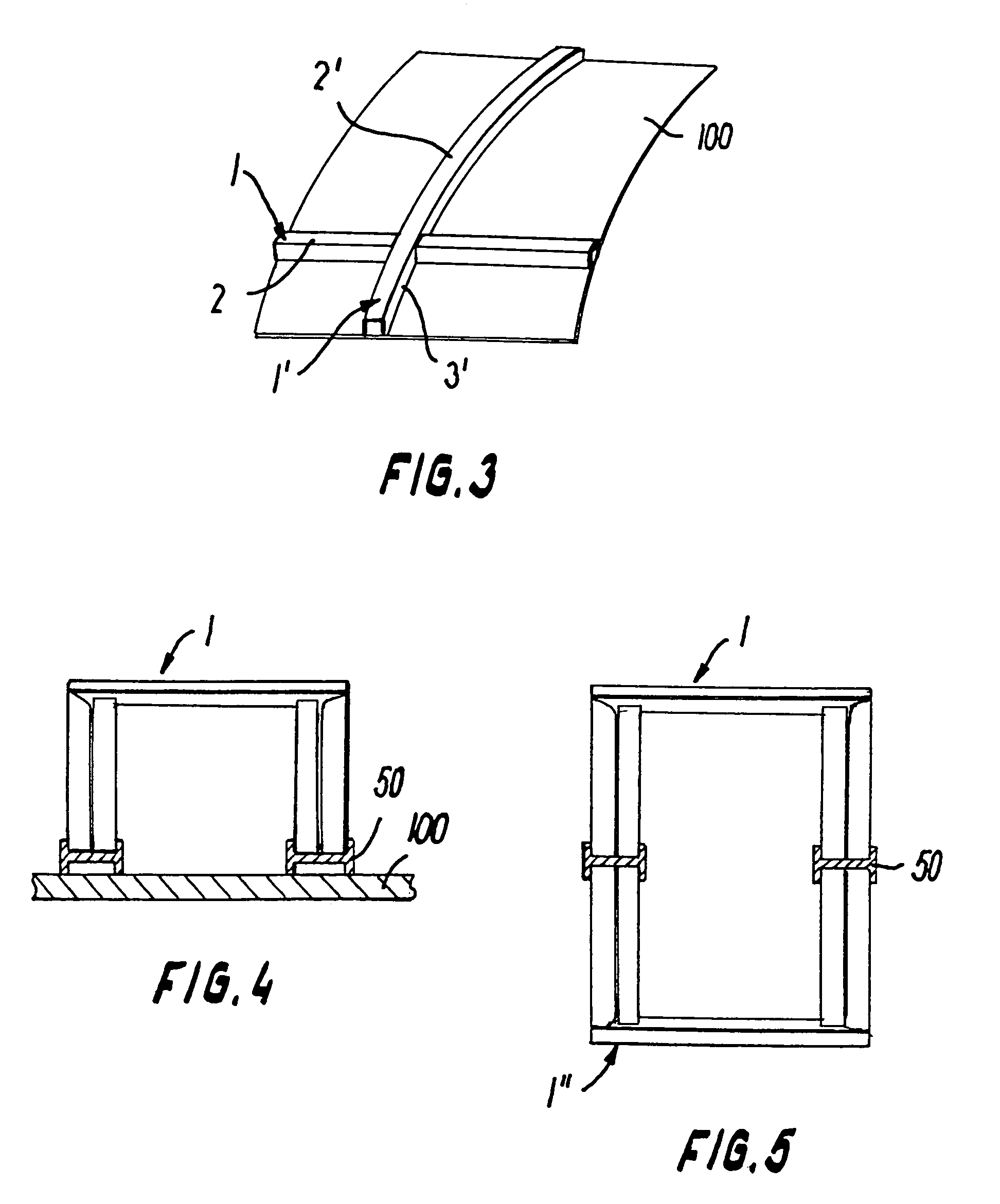

Structural member and a method of manufacturing said member

The structural member (1) has a generally U-shaped cross-section and comprises a base portion (2) and two leg portions (3) extending at substantially right angles from said base portion. The member comprises at least one thin sheet or foil which is corrugated in a continuous waveform in the longitudinal direction of the member. Each leg portion (3) includes a first section (3a) forming an inner wall of the leg portion and a second section (3b) parallel with said first section and joining the first section along a first joining line (4) and the base portion along a second joining line (5). The structural member according to the invention is flexible so that it may conform to the surface to which it is to be fastened, but is after fastening to the surface resistant to bending, torsional, tensile and compressive forces and creates a good base for placement of load-carrying composite material, primarily on the base portion. The corrugated structure makes it possible to use a material having a substantially reduced thickness in relation to other elements having corresponding properties with respect to rigidity and strength. The structural member is intended to be connected with a structure to be reinforced or in order to provide eg. heating or ventilation.

Owner:MDT VMORTEN DAHL

Method for treating sludge with water content of 80% in high speed and producing derivatives

InactiveCN109796113AShort processing timeImprove protectionCalcareous fertilisersBio-organic fraction processingChlorine dioxideResource utilization

The invention relates to a method for treating sludge with water content of 80% in high speed and producing derivatives. The method is characterized in that the sludge with the water content of 80%, waste ashes, waste plants, quick lime, ferric sulphate, magnesium sulfate, polyacrylamide and chlorine dioxide are adopted to be uniformly mixed and delivered into a sealed high-temperature fermentation machine by using a belt conveyor, the temperature in a fermentation machine is increased to 100 DEG C through oil electric thermal conductivity, electricity is cut out after maintaining for 2 hours,the temperature is maintained to be 60 DEG C or above, fermentation is conducted by adding a thermophilic active compound bacterial agent, a fermentation stirring system is adjusted to an intermittent stirring function, the fermentation time of the sludge in the fermentation machine is 12 hours, and harmful microorganism eggs, weed seeds and pathogenic bacteria in the sludge are effectively sterilized; fermented clinker is prepared into a powder material after ageing, pulverizing and screening, and organic products are produced by an automatic electronic packaging machine after packaging. Themethod has the advantages that the difficult problem of treating the sludge with the water content of 80% is solved to achieve sludge resource utilization, and the pollution on the natural environment is reduced.

Owner:李健

Manufacturing method for quickly processing municipal solid waste and derivatives at high temperature

PendingCN110090851AShort processing timeGood effectSolid waste disposalFurniture waste recoveryChlorine dioxideHeat conducting

The invention relates to a manufacturing method for quickly processing municipal solid waste and derivatives at the high temperature. The manufacturing method is characterized in that the municipal solid waste, waste plant powder, kitchen waste, quick lime, ferrous sulfate, magnesium sulfate and chlorine dioxide are uniformly mixed, sealed high-temperature fermentation equipment is adopted, the temperature of the interior of the fermentation equipment is increased to 100 DEG C through oil-electricity heat conducting and keeps for 2 hours, the temperature is kept at 60-80 DEG C, a thermophilicanti-high-temperature active multiple species inoculant is added for fermentation, the intermittent stirring function of a fermentation machine stirring system is performed, the municipal solid wasteferments in the fermentation machine for 12 hours, and harmful microorganism eggs, weed seeds and pathogenic bacteria in the municipal solid waste are effectively killed; the fermented clinker is madeinto powder through an ageing smashing screen, and the powder is weighed by an automatic electronic scale and packaged into organic matter products through packaging machine; and accordingly, the municipal solid waste disposal problem is solved, recycling comprehensive utilization of the municipal solid waste is achieved, and pollution to the natural environment is reduced.

Owner:李桓宇

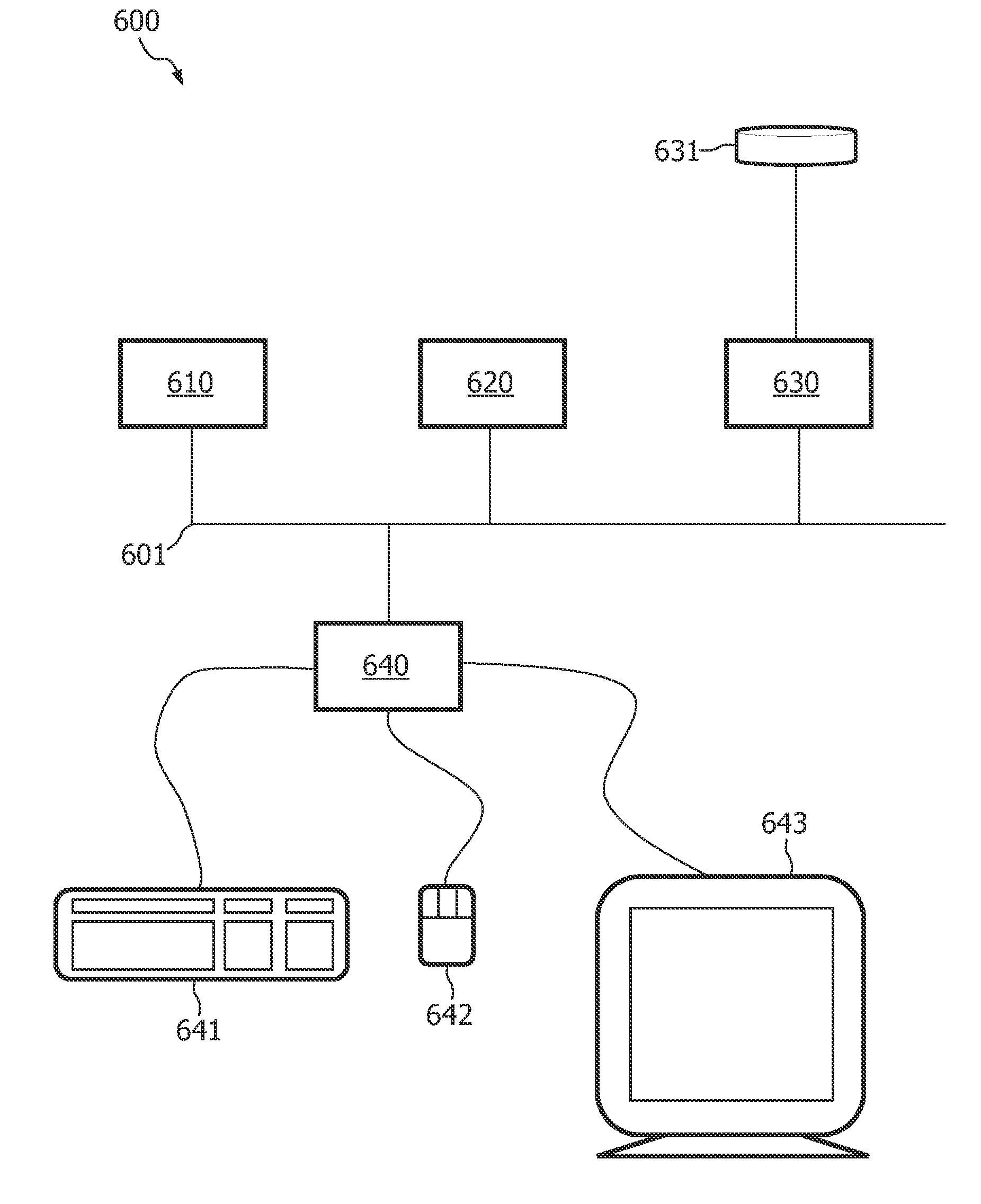

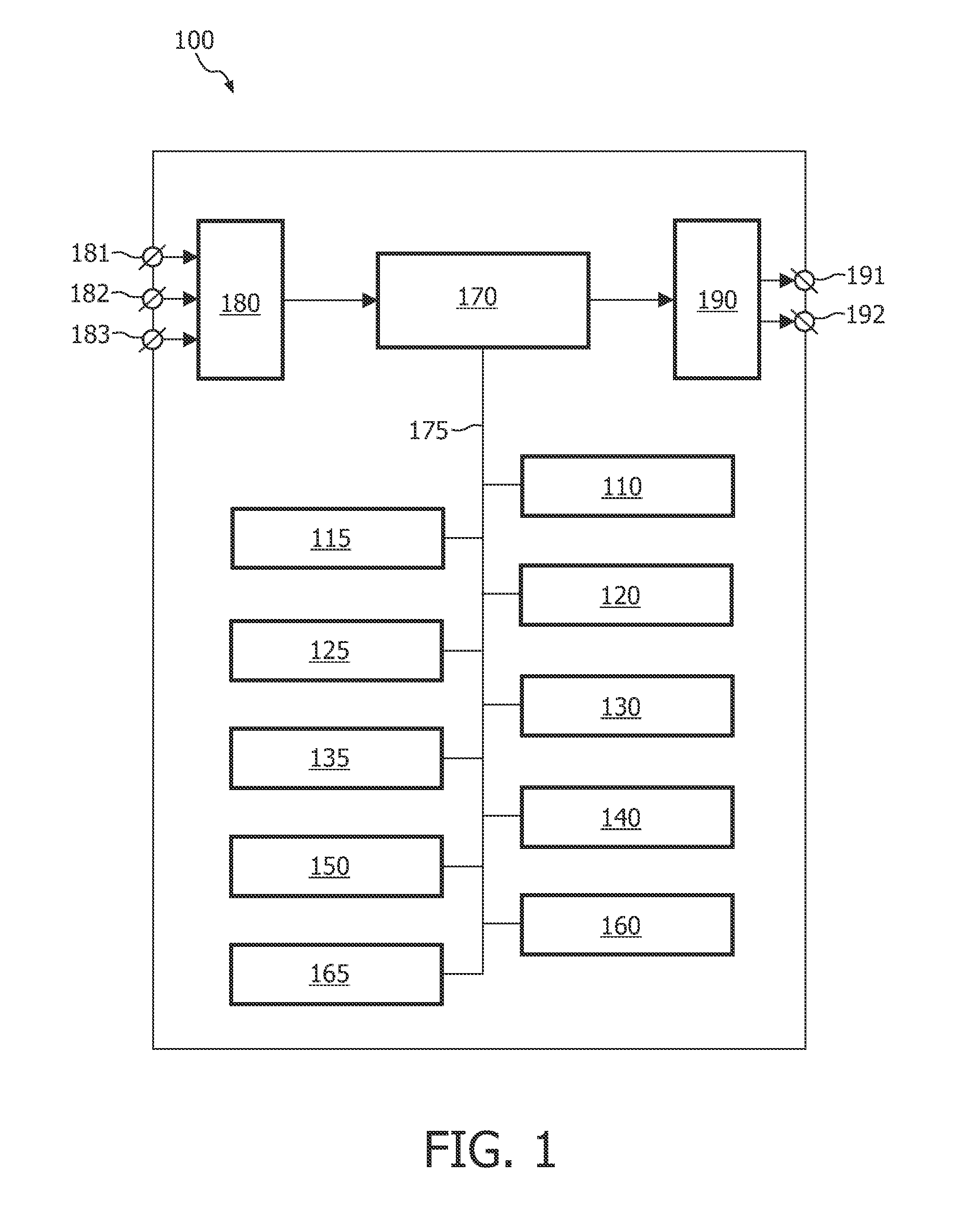

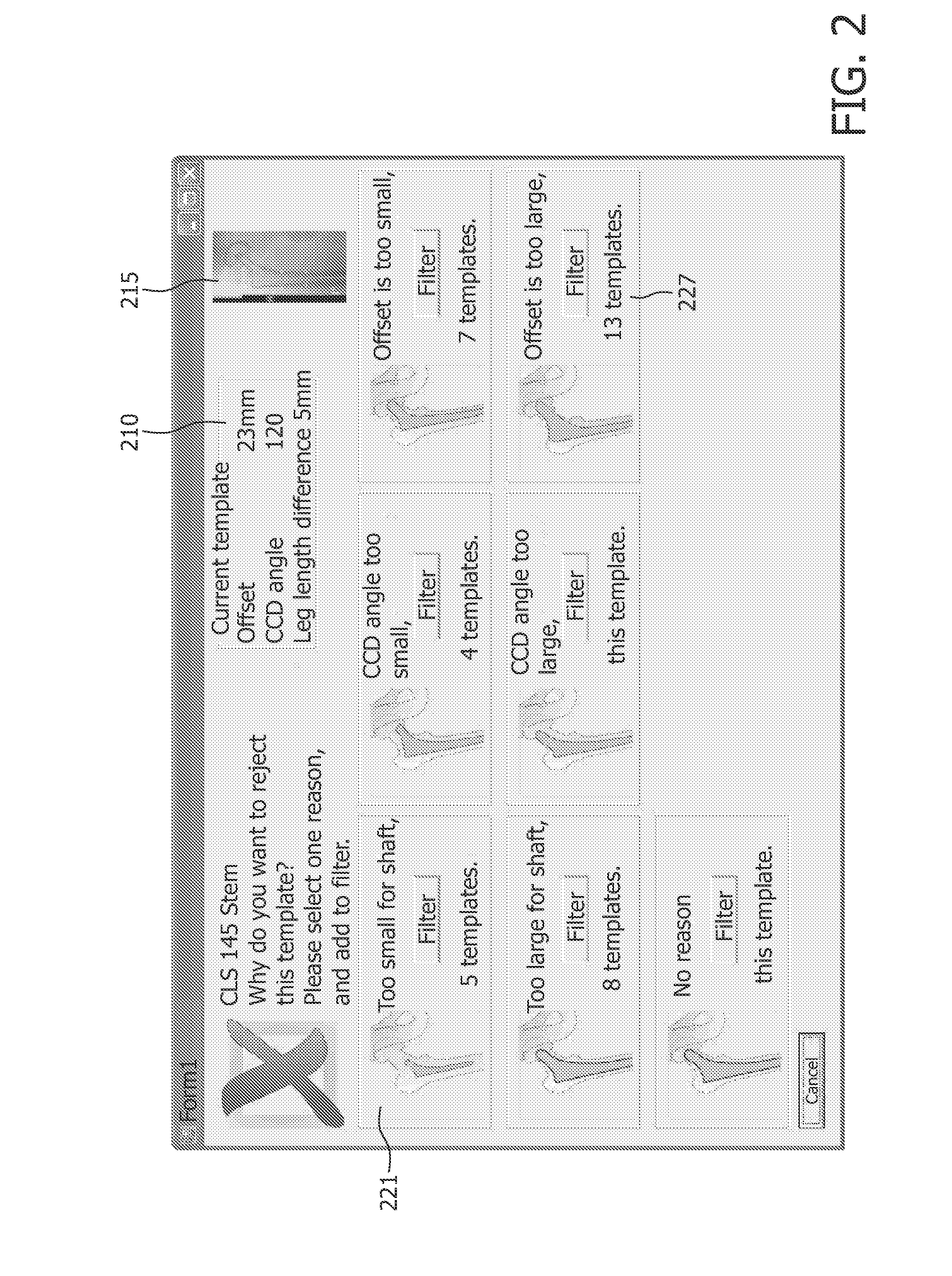

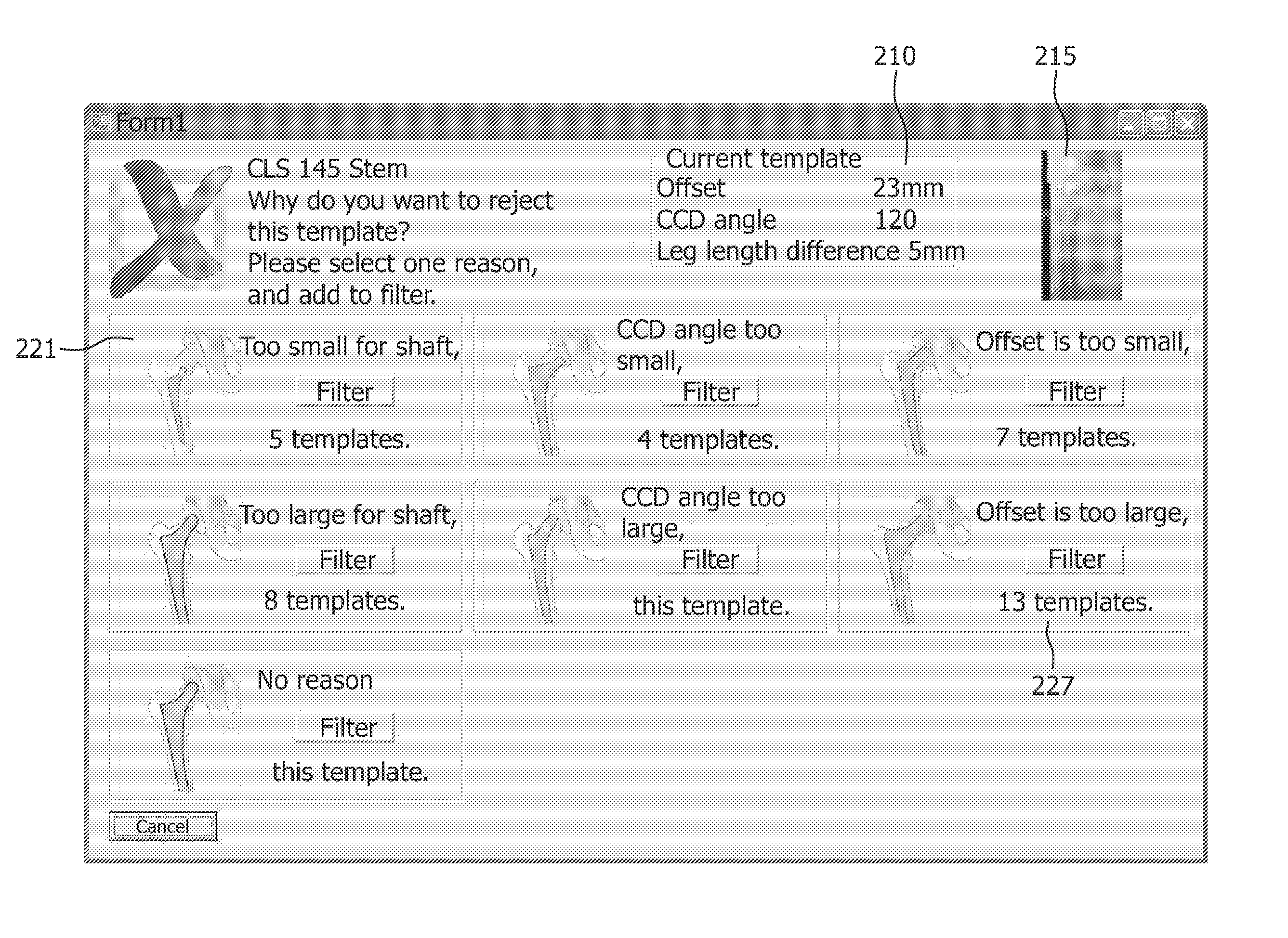

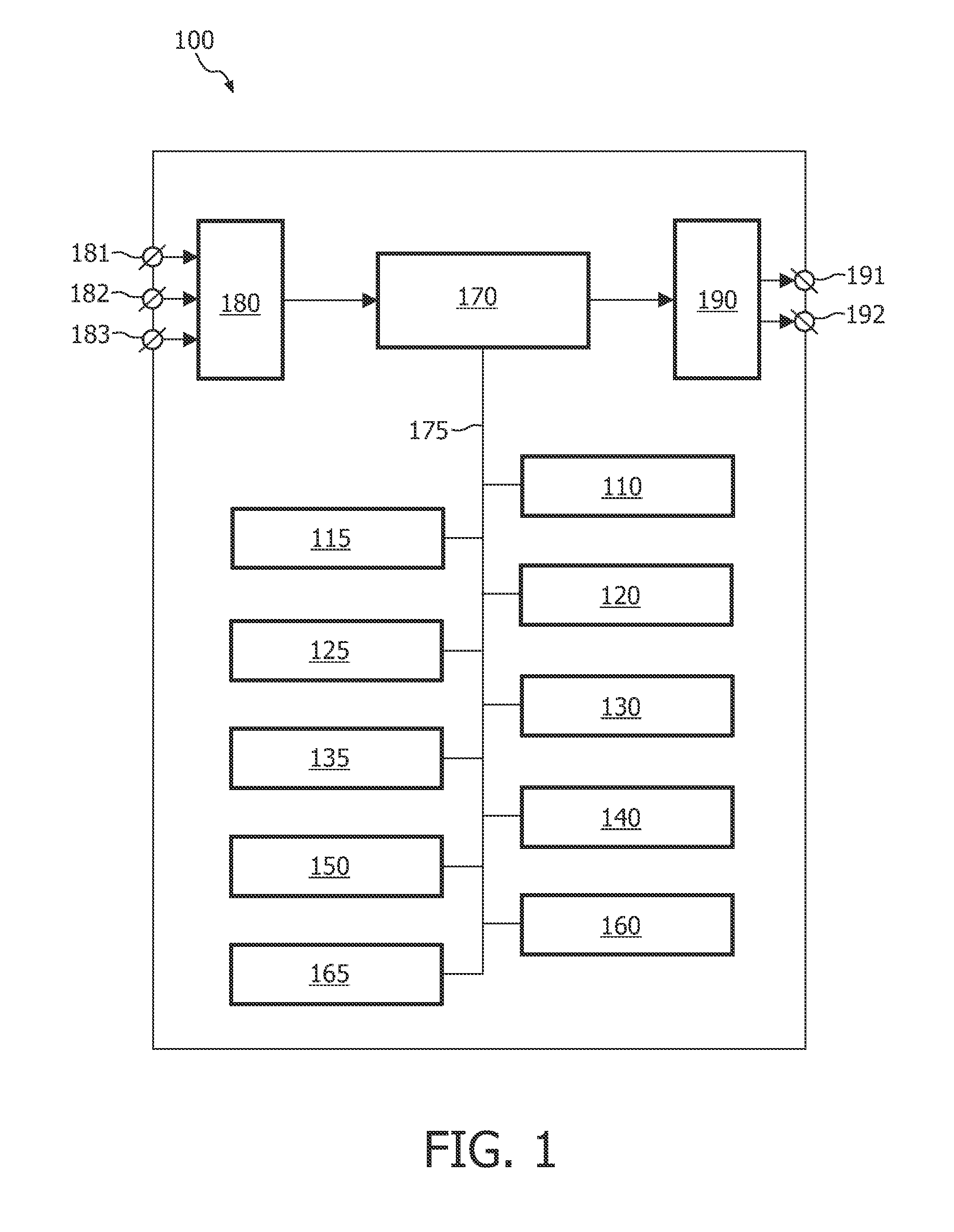

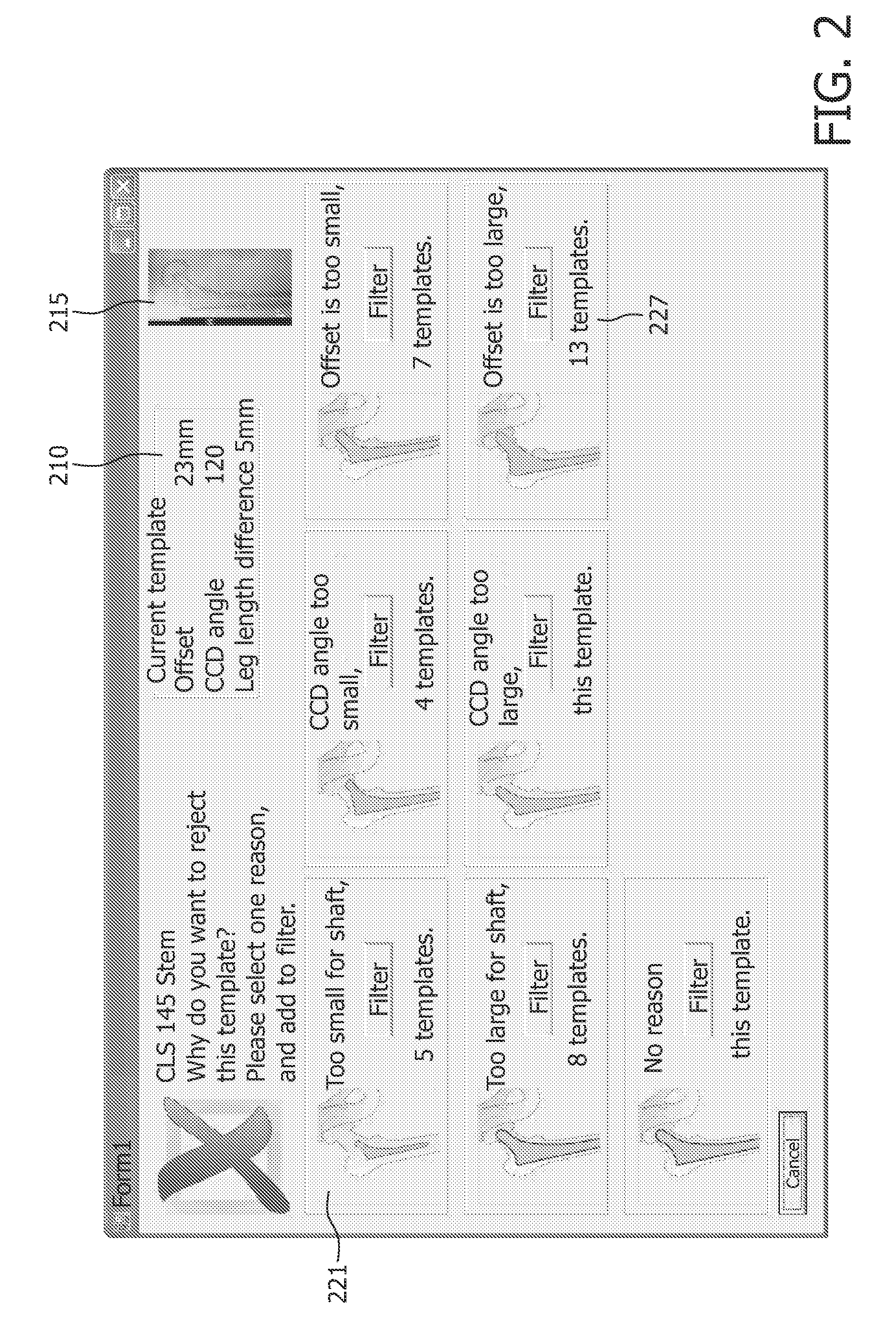

Filter by example

ActiveUS20100121846A1Good baseEasy to FeedbackDigital data processing detailsMedical imagesData miningData science

The invention relates to a system (100) for identifying a certain data-object of a set of data-objects, wherein each data-object of the set of data-objects is described by a plurality of discriminating characteristics, the system comprising: a composition unit (110) for composing a query for identifying the certain data-object; an identification unit (120) for identifying a candidate data-object of the set of data-objects, based on the query; a presentation unit (130) for presenting a description of the candidate data-object to a user; a feedback unit (140) for receiving user feedback on a discriminating characteristic of the plurality of discriminating characteristics, the discriminating characteristic describing the candidate data-object; and an update unit (150) for updating the query for identifying the certain data-object, based on the user feedback on the discriminating characteristic describing the candidate data-object. Thus, the user may evaluate a discriminating characteristic of the candidate data-object, based on information obtained from the presentation unit, and provide user feedback comprising a reason specifying why the retrieved data is relevant and / or not relevant

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

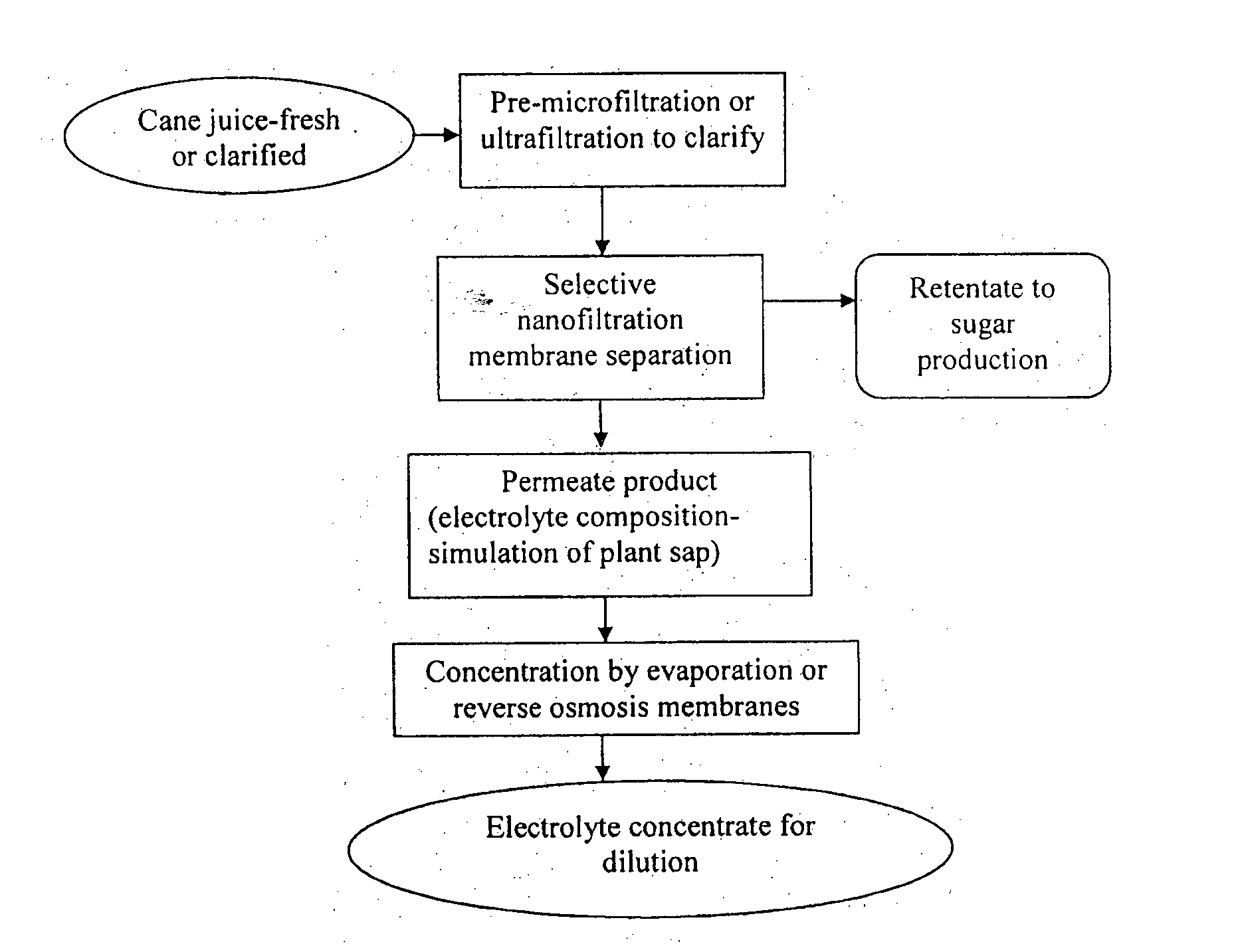

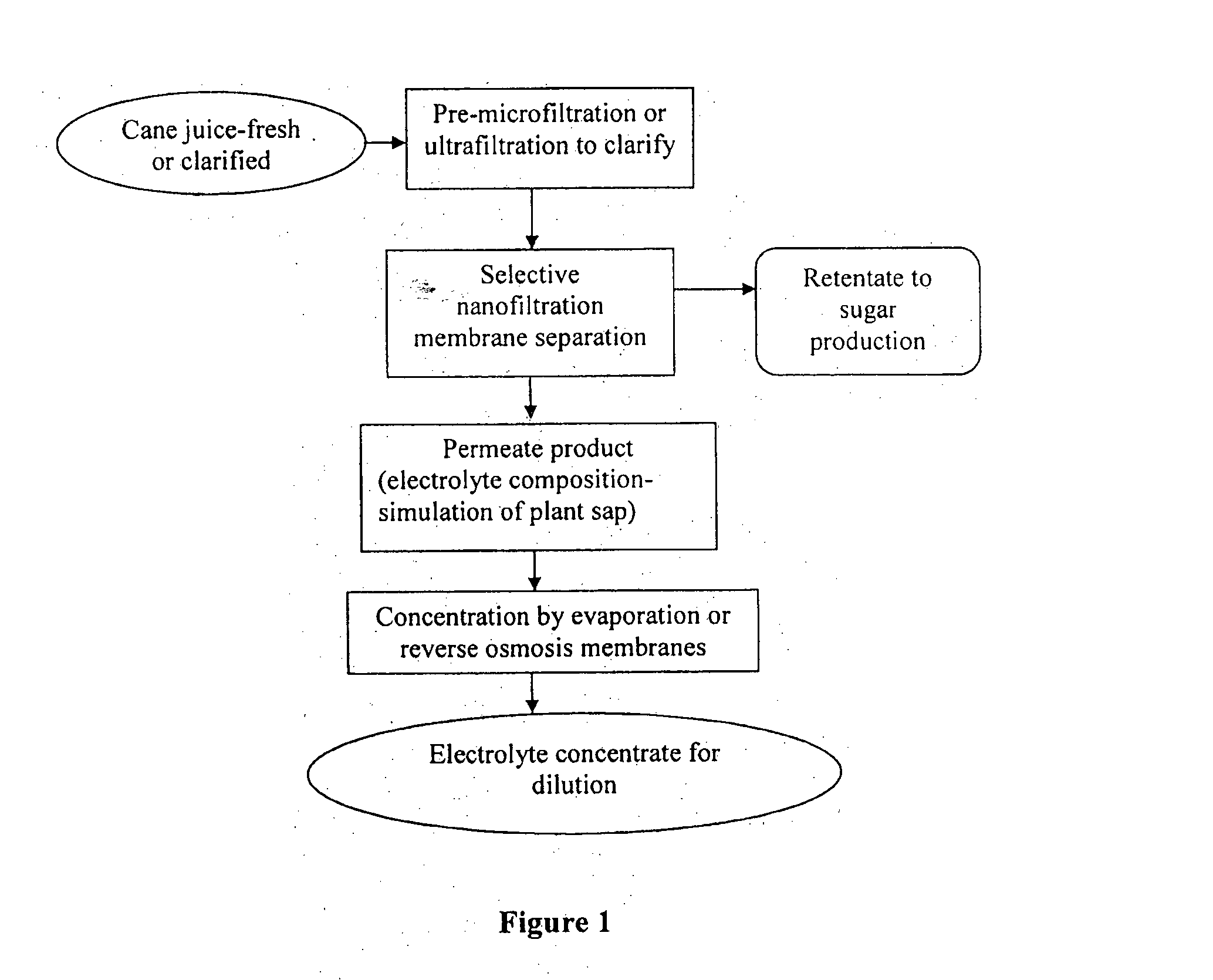

Plant-based electrolyte compositions

InactiveUS20130052298A1Low contentMinimise and avoid problemFood ingredient as antioxidantProtein composition from eggsPlant basedSweet sorghum

This invention relates, inter alia, to various plant-based electrolyte compositions, methods of preparing them and methods of using them. One embodiment concerns a plant-based electrolyte composition comprising a plant-derived electrolyte content high in potassium relative to sodium, and a plant-derived carbohydrate content less than about 6% weight / volume. Another embodiment concerns a method for re-hydrating an individual or preventing dehydration or over-hydration of an individual or for preventing or treating potassium deficiency in an individual, by administering to the individual a plant-based electrolyte composition. The electrolyte compositions can be prepared from sugarcane juice, sugar beet juice, sweet sorghum juice, palm syrup, maple sap, vegetable juice or fruit juice.

Owner:THE STATE OF QUEENSLAND ACTING THROUGH THE DEPT OF AGRI FISHERIES & FORESTRY +1

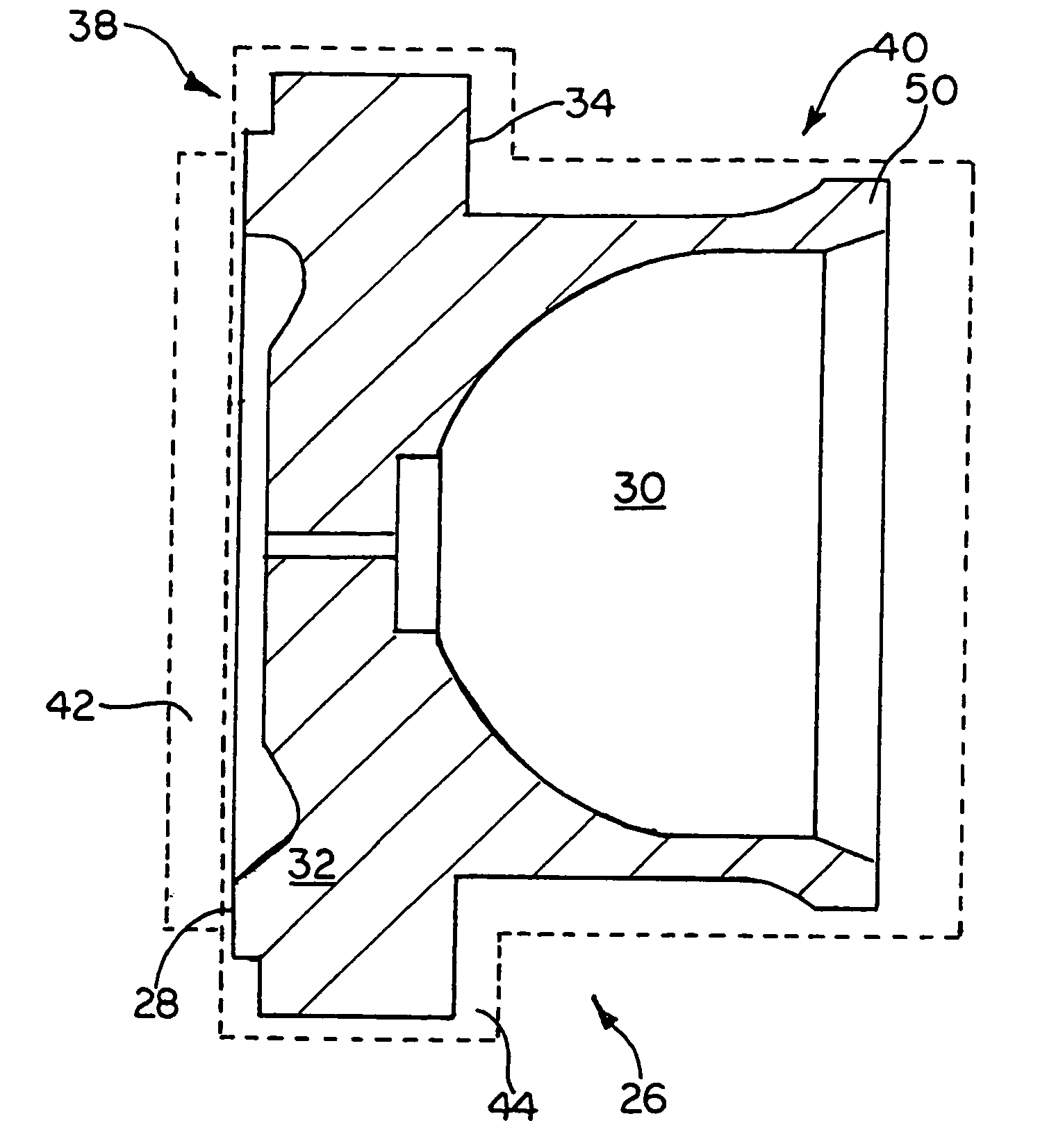

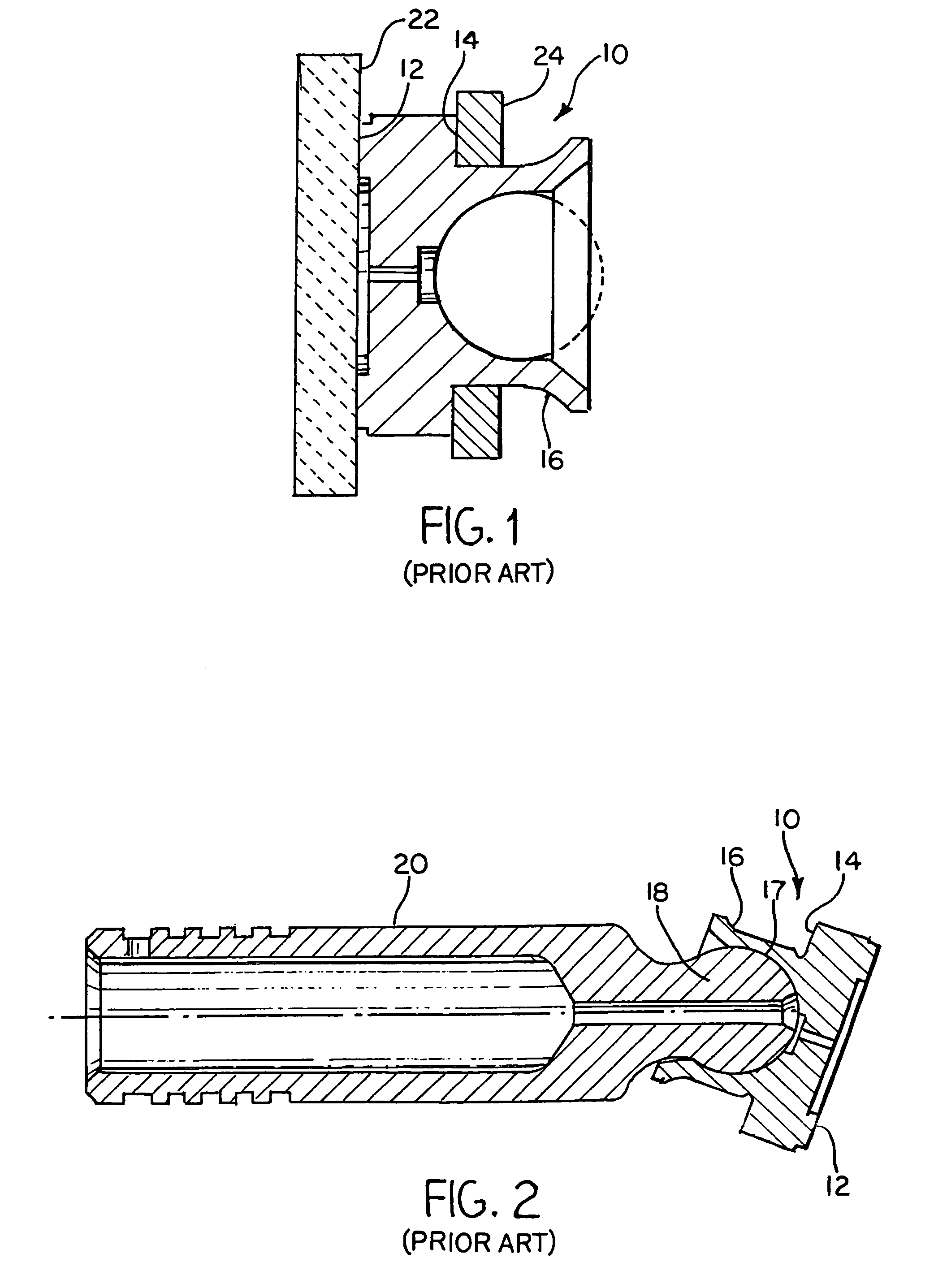

Selectively cold worked hydraulic motor/pump shoe

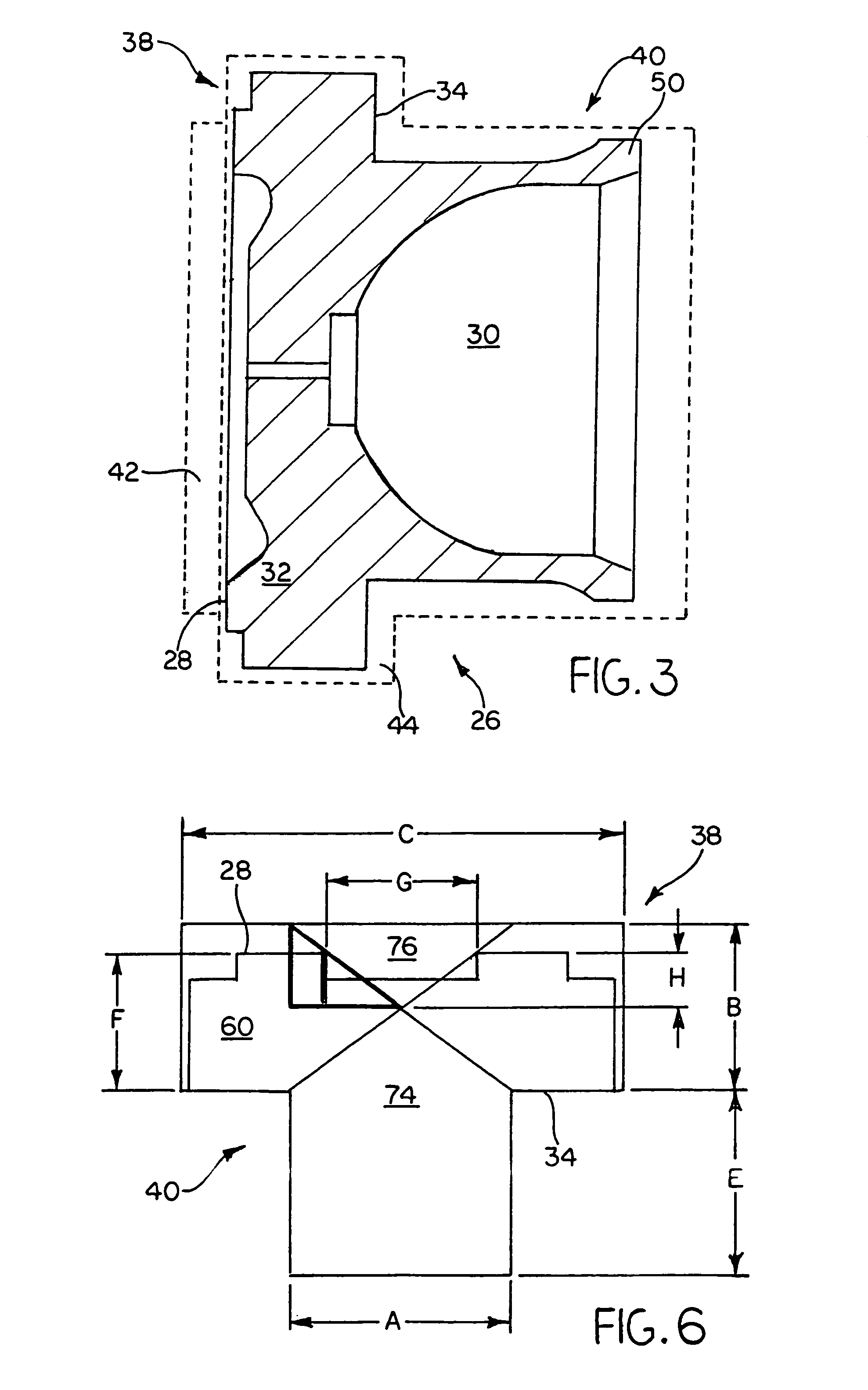

InactiveUS7025182B2Reduce fracturesSimplifying grindingPositive displacement pump componentsBraking membersWear resistantEngineering

A method of manufacturing a wear resistant shoe (26) includes upsetting (46) one end portion (38) of cylindrical member to work harden that portion to a substantial depth, machining (48) the cylindrical member portion to finished dimensions and surface hardening (56) a face (28 or 34) of the machined cylindrical member portion. The cylindrical member may comprise rod stock of a diameter less than the greatest diameter of the finished shoe and be upset or swaged to axially reduce and radially increase the dimensions of the one end portion. A hollow region (30) is formed in an opposite rod stock end portion and the periphery (50) of the hollow region is crimped about a rounded end (18) of the piston (20). The cold work done during the swaging or forming process provides a foundation for hardened faces comprising balance (28) and auxiliary balance (34) lands, forms a crude shape of the shoe, and imparts work hardening and wear property improvements. The harder metal surface provides a foundation for subsequent surface hardening such as coating with TiN. The crimping process used to join the shoe to the piston imparts cold work to the skirt region of the shoe and enhances the wear resistance of the shoe. The cold heading step (46) may be omitted if a hardened rod stock is used, but the skirt should be annealed (66) prior to crimping to the piston.

Owner:HONEYWELL INT INC

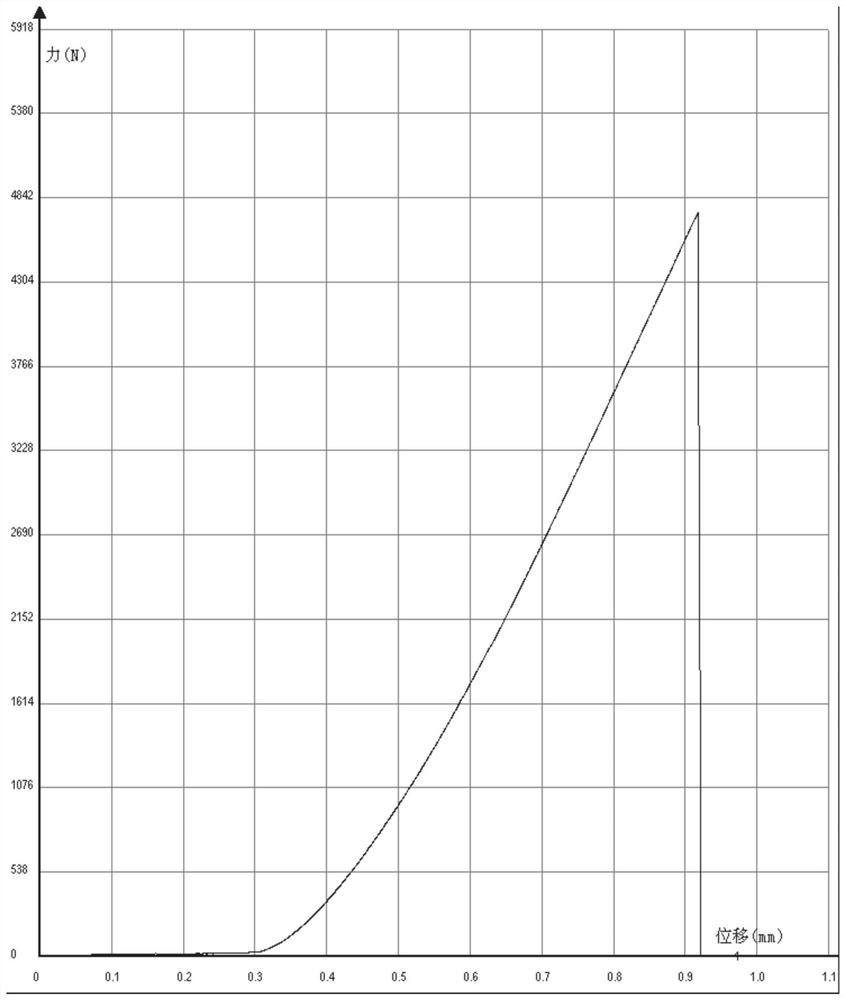

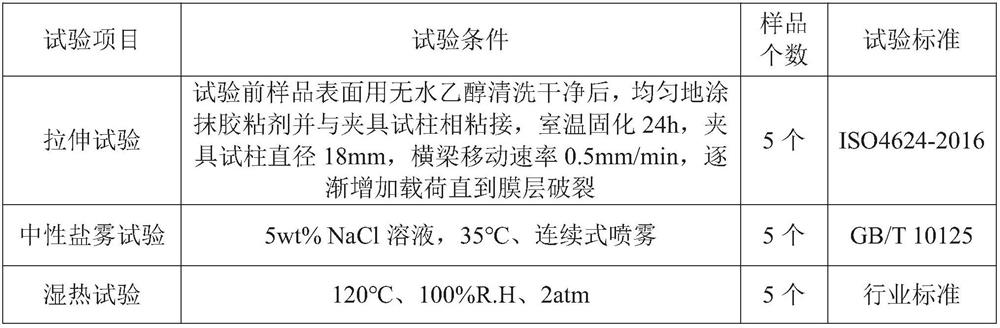

Surface strengthening treatment method of neodymium-iron-boron permanent magnet and application of surface strengthening treatment method

ActiveCN112975580AThe process of surface strengthening treatment technology is simpleEasy to operateMetallic material coating processesCleaning using liquidsMetallurgyAlkaline etching

The invention discloses a surface strengthening treatment method of a neodymium-iron-boron permanent magnet and an application of the surface strengthening treatment method. The surface strengthening treatment method comprises the following steps that the surface of the neodymium-iron-boron permanent magnet is polished and roughened; then the obtained neodymium-iron-boron permanent magnet is placed in an alkaline solution to be subjected to ultrasonic etching treatment; then the obtained neodymium-iron-boron permanent magnet is placed in acetone to be subjected to whole-surface treatment; then the obtained neodymium-iron-boron permanent magnet is placed in deionized water to be subjected to ultrasonic cleaning treatment; and finally, the obtained neodymium-iron-boron permanent magnet is dried. The invention further discloses a preparation method of the neodymium-iron-boron permanent magnet surface coating. According to the method, the surface of the magnet is sequentially strengthened through the technical processes of polishing, roughening, alkaline etching, acetone surface finishing, ultrasonic cleaning and vacuum drying, so that the binding force between the surface of the neodymium-iron-boron permanent magnet and a coating is remarkably enhanced, the temperature and humidity resistance and the neutral salt mist resistance of the coating are improved, and meanwhile, the surface treatment method is simple in process and easy to operate.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Oxygen-consuming electrode and method for its production

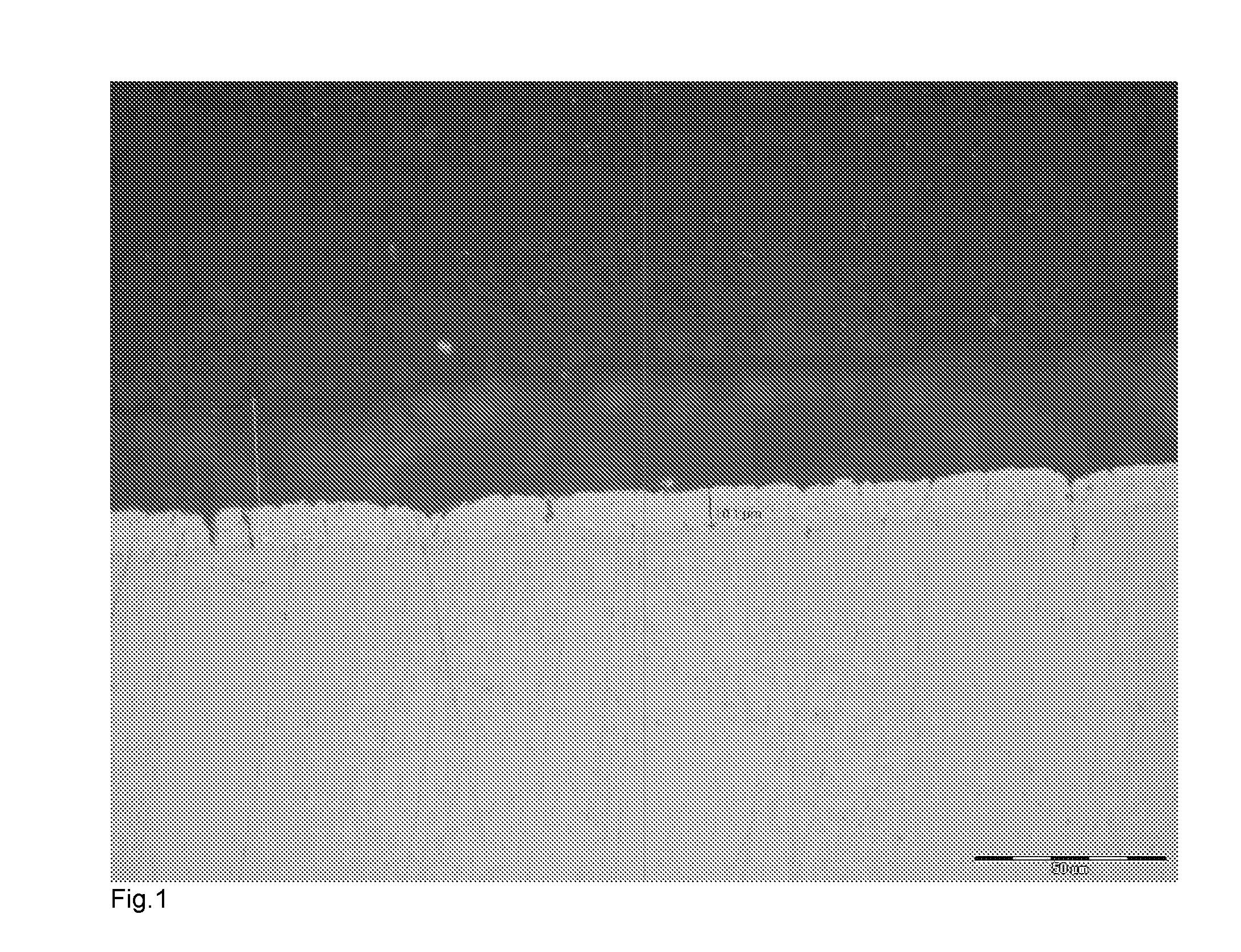

InactiveCN105132940AAdhesivelyConsistent and strong adhesionAlkaline accumulator electrodesElectrode shape/formsPtru catalystElectrolysis

An oxygen-consuming electrode is provided, in particular for use in the chlor-alkali electrolysis, a new type of catalyst described coating as well as an electrolysis apparatus. It is a manufacturing process for the oxygen-consuming electrode, and their use in the chlor-alkali electrolysis or fuel cell technology will be further described. At least the oxygen-consuming electrode comprises a current collector and a gas diffusion layer with a catalytically active component, wherein the gas diffusion layer as at least one porous sheet is formed of a fluorinated polymer, in the introduced fine crystalline metallic catalyst particles as catalytically active component and electrically conductively connected via a first intermediate metallic layer with the current collector.

Owner:BAYER MATERIALSCIENCE AG

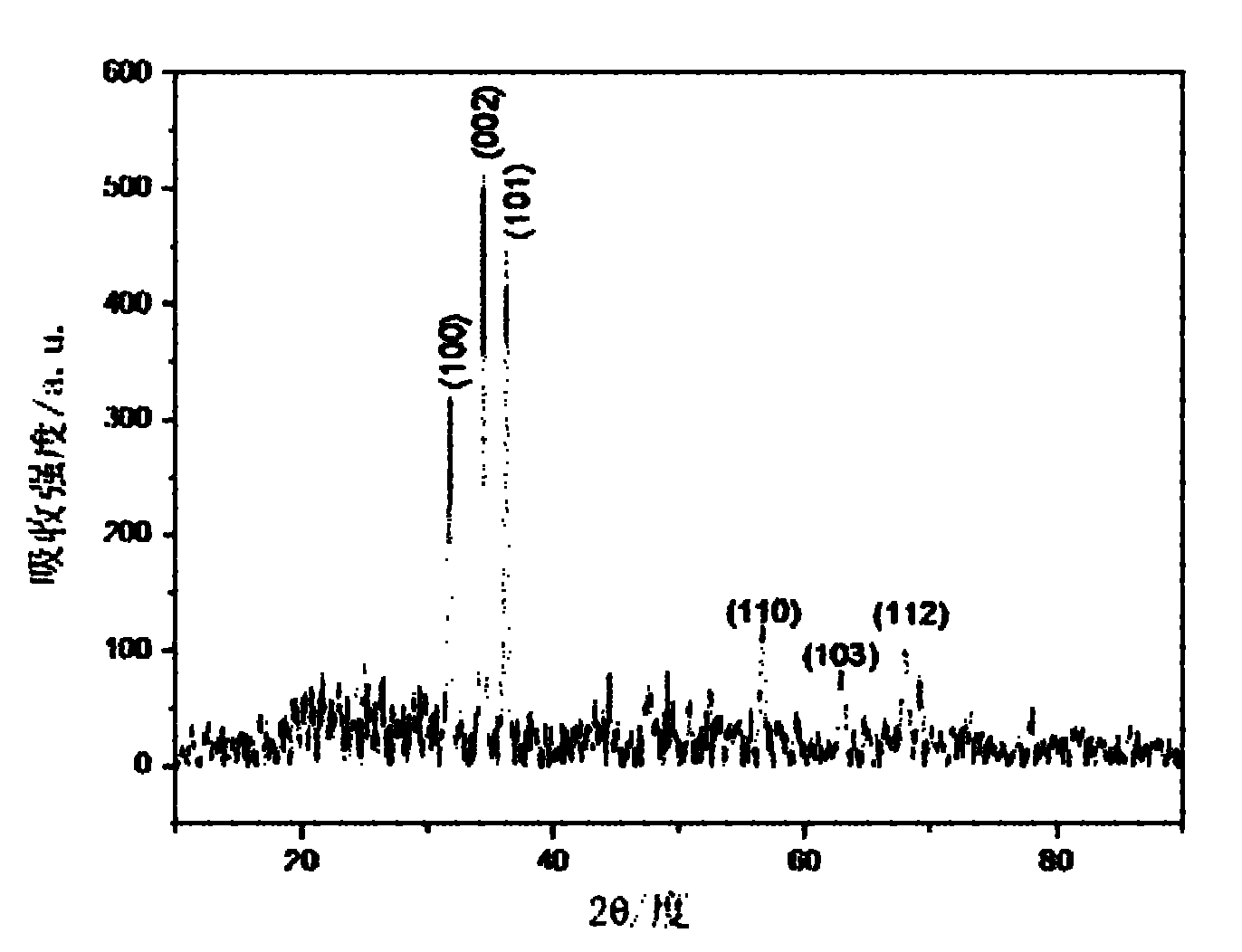

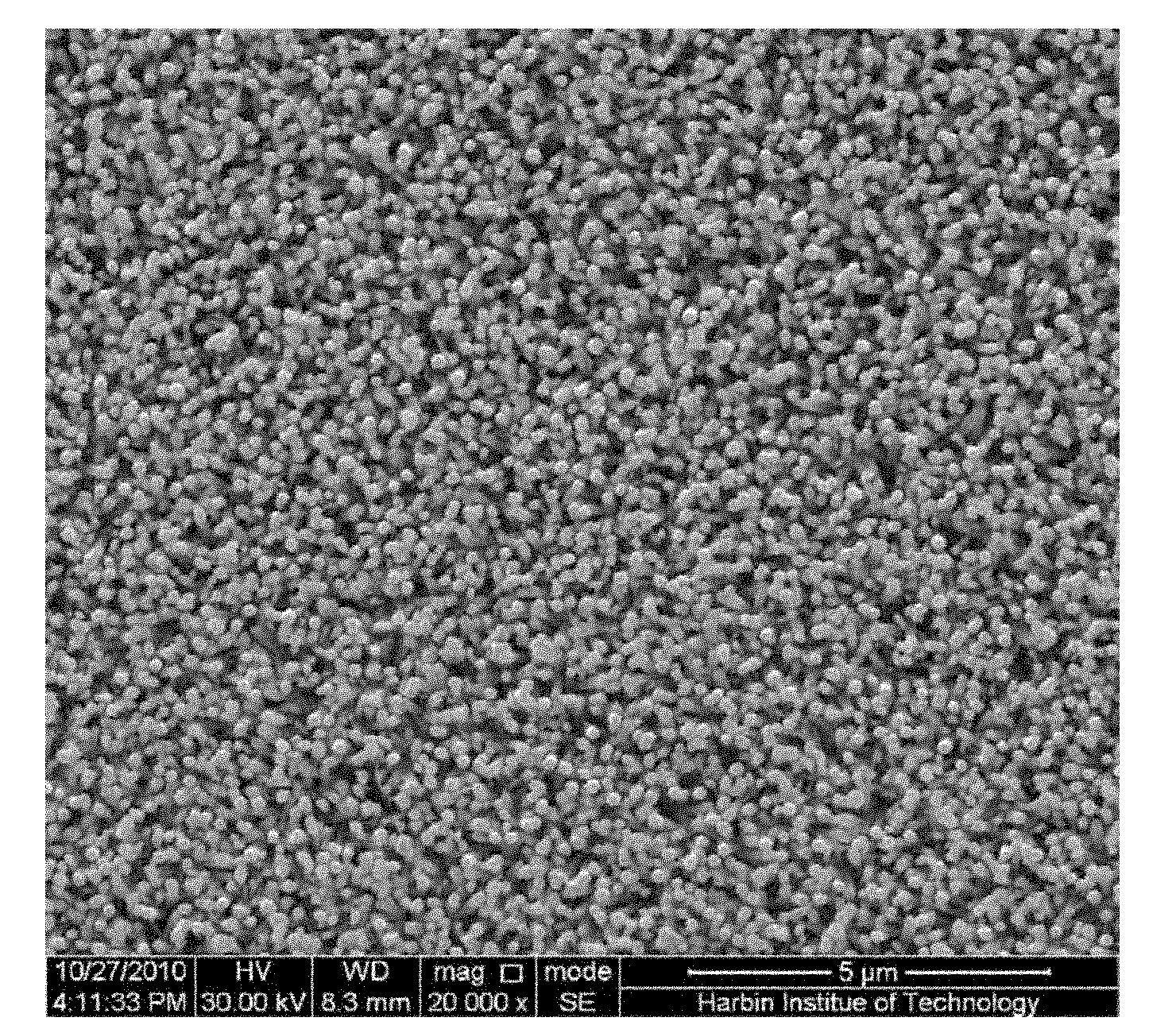

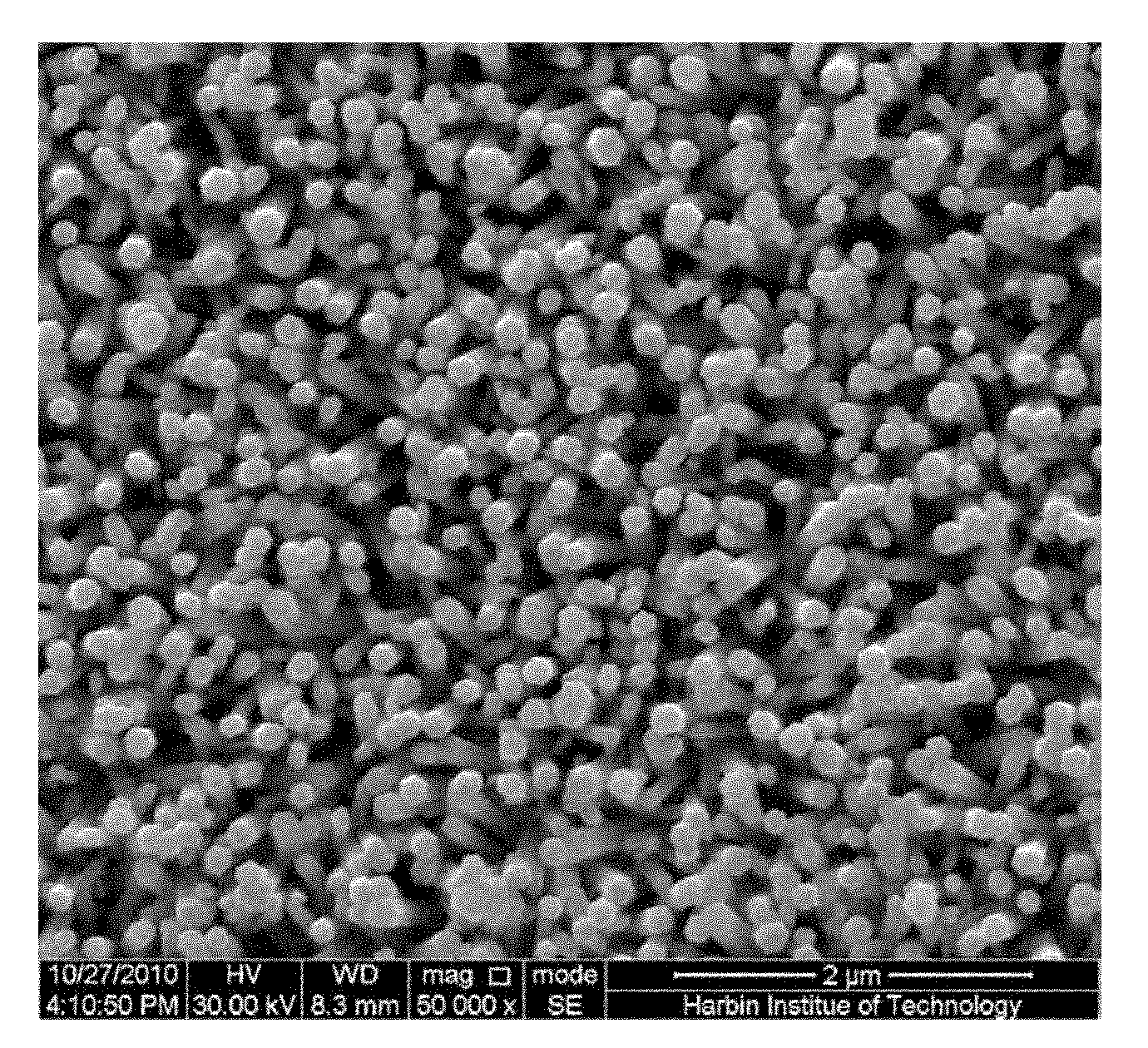

Method for preparing uniform-diameter zinc oxide nanorods on LB (Langmuir-Blodgett) zinc oxide seed film

InactiveCN102080260AArranged in orderGood basePolycrystalline material growthFrom normal temperature solutionsHigh energyZinc Acetate Dihydrate

The invention relates to a method for preparing zinc oxide nanorods, in particular to a method for preparing uniform-diameter zinc oxide nanorods on an LB (Langmuir-Blodgett) zinc oxide seed film. The invention aims to solve the problems of high energy consumption and complex operation in the existing method for preparing uniform-diameter zinc oxide nanorods by using a zinc oxide film as the substrate, the problem that the zinc oxide film structure can not be easily controlled by manpower, and the problem of unstable shape and dimensions of the prepared zinc oxide nanorods. The method comprises the following steps: 1. treating a quartz substrate; 2. preparing a spreading liquid; 3. preparing a zinc acetate solution; 4. preparing a zinc oxide seed film; 5. preparing a growth liquid; and 6. preparing zinc oxide nanorods. The zinc oxide nanorods prepared by the method provided by the invention have the advantages of high purity, no impure phase and uniform diameter (140-180nm). The invention is applicable to the field of nano materials.

Owner:HARBIN INST OF TECH

Override-based, predictive speed capping

ActiveUS20160176050A1Good baseGuaranteed uptimeProgramme controlProgramme-controlled manipulatorEngineeringManipulator

A method for controlling a manipulator, with the method being particularly suitable for the respecting of predetermined monitoring limits. The method operates by initiating a halting movement or a speed capping based on an identified actual override trend, and is thus suitable, in particular, for path movements by means of spline interpolation.

Owner:KUKA ROBOTER

Process and Apparatus for Sealing Wellhead Leaks Underwater or On Land

InactiveUS20130272792A1Good baseFlutter can be mostly eliminatedConstructionsLiquid flow controllersOcean bottomTerrain

The sealing of underwater and above ground leaks of materials such as petroleum, mud, gas and finely divided solids from wellheads, pipelines and other natural or man-made works is accomplished by placing over the leak a heaviest duty, leak-proof, weighted curtain whose shape and size allow the curtain to be filled in place with cement or other heavy materials, thus effectively sealing the outflow of the materials.The curtain can optionally be fitted with one or more redirection valves to drain off and capture the materials under pressure, for example to transport oil, during and even after the sealing process, from a seabed wellhead leak to a surface ship. An optional second, larger curtain fitted with through-channels with stopcocks can be placed over the first curtain, and the lower valves and through-channels can be connected to continue the transport of materials.Preparation of the sealing sight is minimal, ideally consisting of forming a continuous circular path to more carefully mate the curtain's peripheral-weights with the ground or seabed terrain. If a wellpipe or other obstacle might damage the curtain, or vice versa, the wellpipe would be modified, and / or an optional self-expanding support attached to the curtain underside can protect the curtain during its cement-filling weighting process.

Owner:CORDELL STEVE

Alloy coated workpieces

ActiveUS20150203951A1Lower Level RequirementsLevel of corrosion protectionPretreated surfacesSolid state diffusion coatingPowder mixtureZinc alloys

A process for providing a corrosion resistant coating on uncoated ferrous components, involving mechanical plating, using as a coating medium a zinc metal-containing powder, such as zinc or zinc alloy powder, or a powder mixture of zinc or zinc alloy and at least one other metal, so as to build up a firmly adherent coating of the coating medium over exposed surfaces of the components, heating the components with the firmly adherent coating to produce solid-solid diffusion to form an Fe / Zn intermetallic over the surfaces, at least in a base layer of the coating built up by the plating, and cooling the components

Owner:KWIK COAT AUST

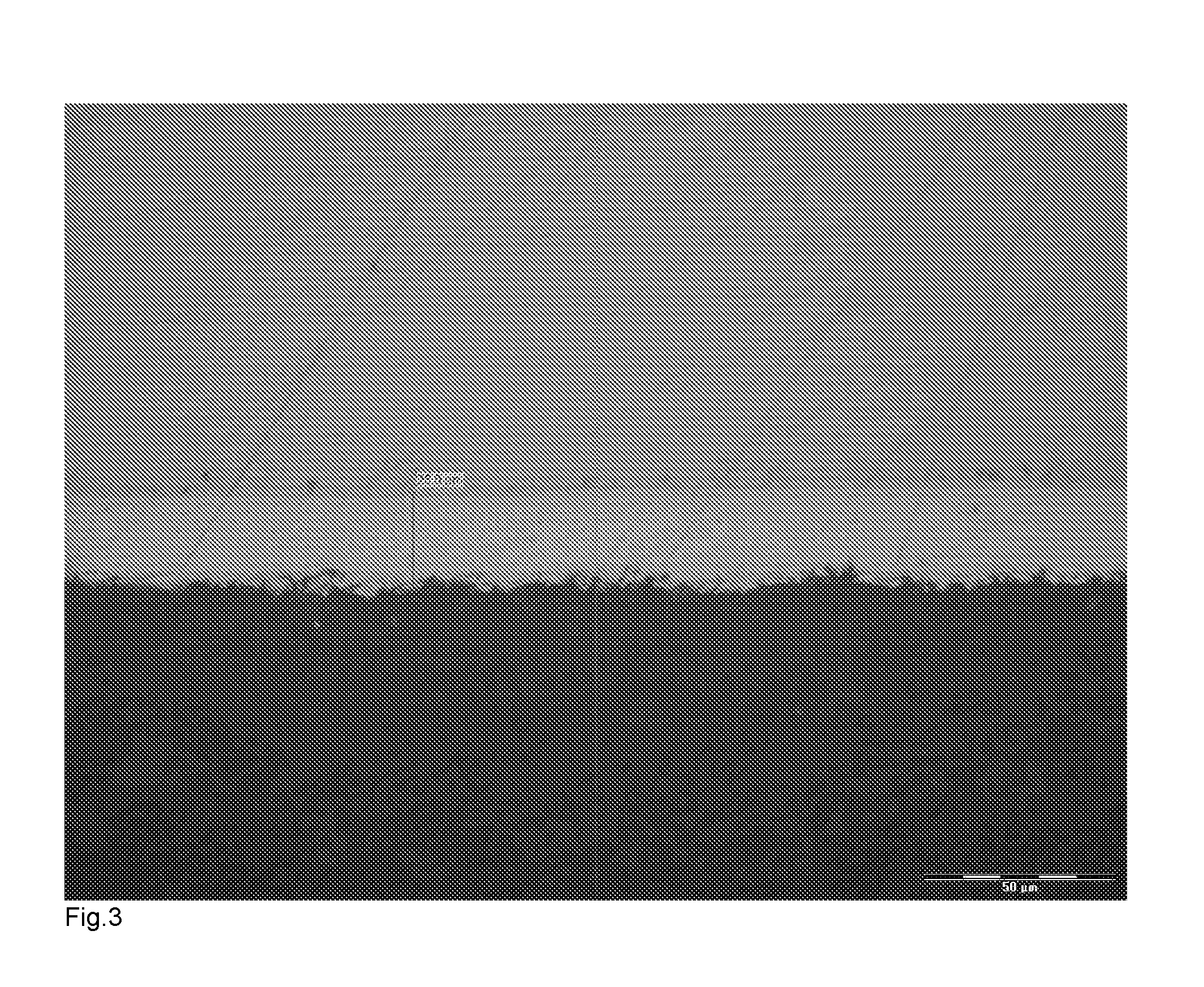

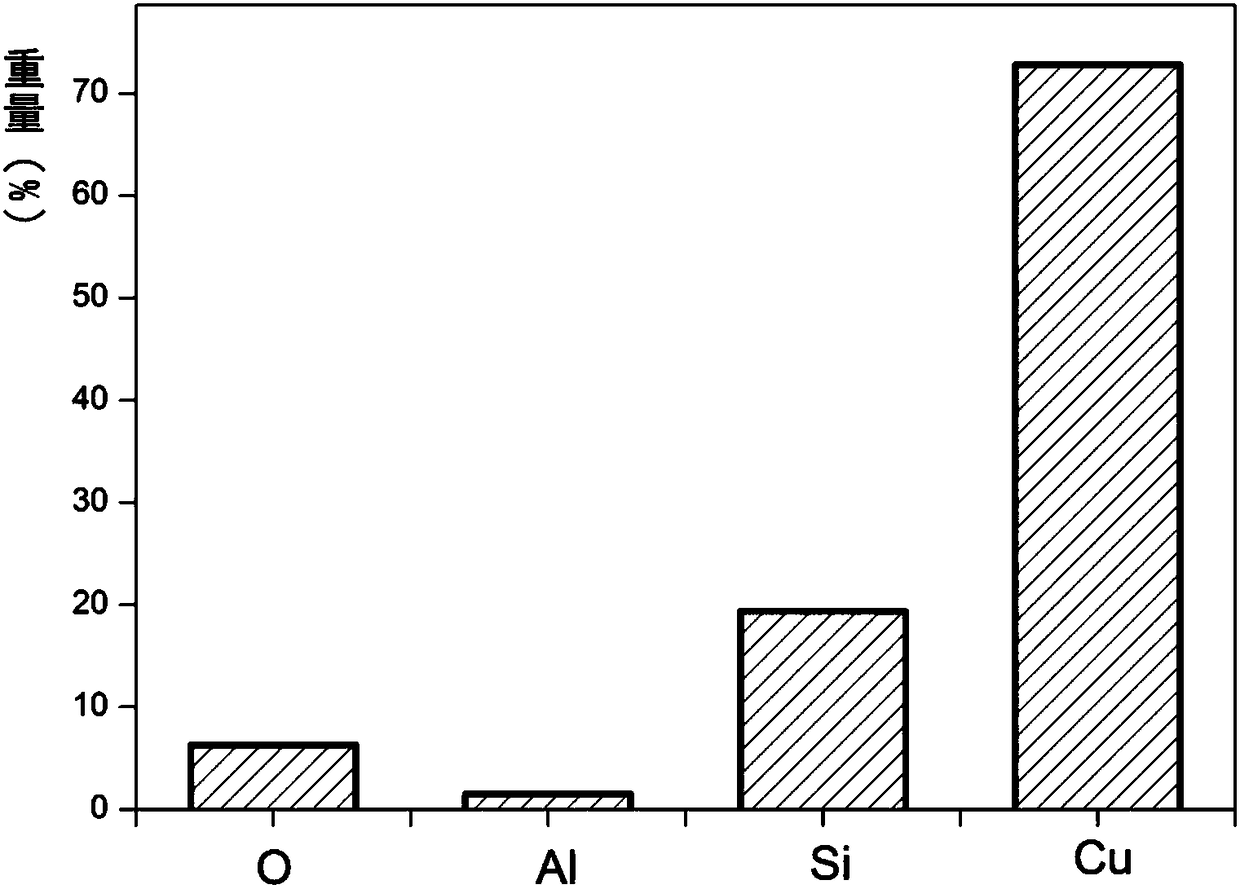

Method for electroless deposition of copper on aluminum oxide film

InactiveCN108531895AGood baseSimple methodLiquid/solution decomposition chemical coatingCopper coatingRoom temperature

The invention discloses a method for electroless deposition of copper on an aluminum oxide film. The method includes steps: soaking an aluminum oxide film in ammonium chloropalladate ((NH4)2PdCl4) aqueous solution for 15min-17min; taking out, and completely rinsing with deionized water; soaking the aluminum oxide film in Cu electroless deposition solution for 10min-13min, taking out, rinsing withdeionized water and blowing to dry, so that electroless deposition of copper on the aluminum oxide film is completed. By the method for electroless deposition of copper on the aluminum oxide film, problems of high cost and process complexity in an existing copper deposition preparation process are solved; reaction is carried out at the room temperature, simplicity in operation, short time, recyclability of raw materials and environmental friendliness are realized, and applicability of a copper coating is improved.

Owner:XIAN UNIV OF TECH

A method for assembling nano-gold cubes to form dimer structures using DNA origami templates based on surface-enhanced Raman effects

ActiveCN110057806BEfficient assemblyExact Space AddressabilityRaman scatteringFermentationDimerPhotonics

Owner:NANJING UNIV OF POSTS & TELECOMM

Filter by example

ActiveUS8631025B2Good baseEasy to FeedbackDigital data processing detailsMedical imagesData miningData science

Owner:KONINK PHILIPS ELECTRONICS NV

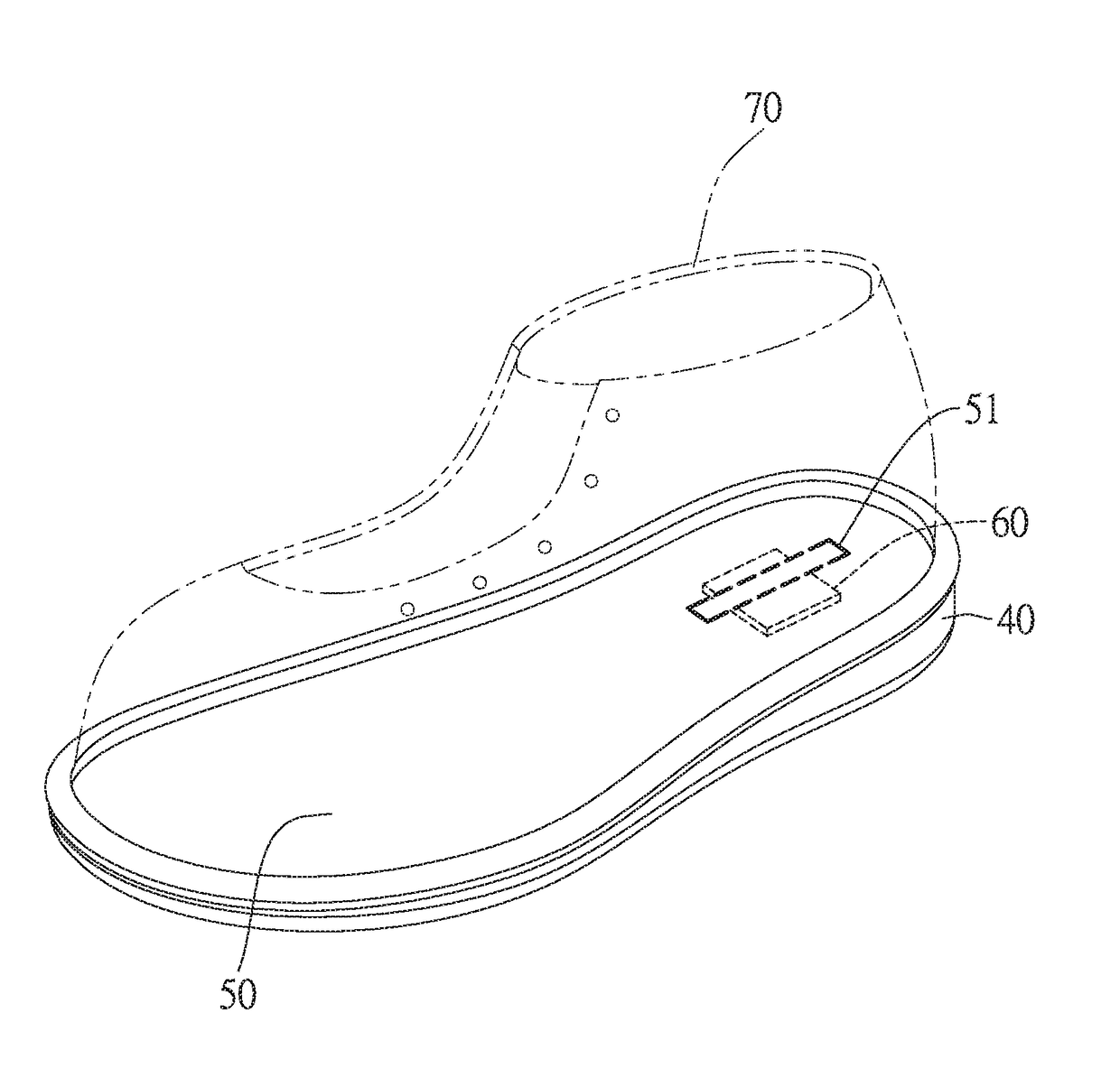

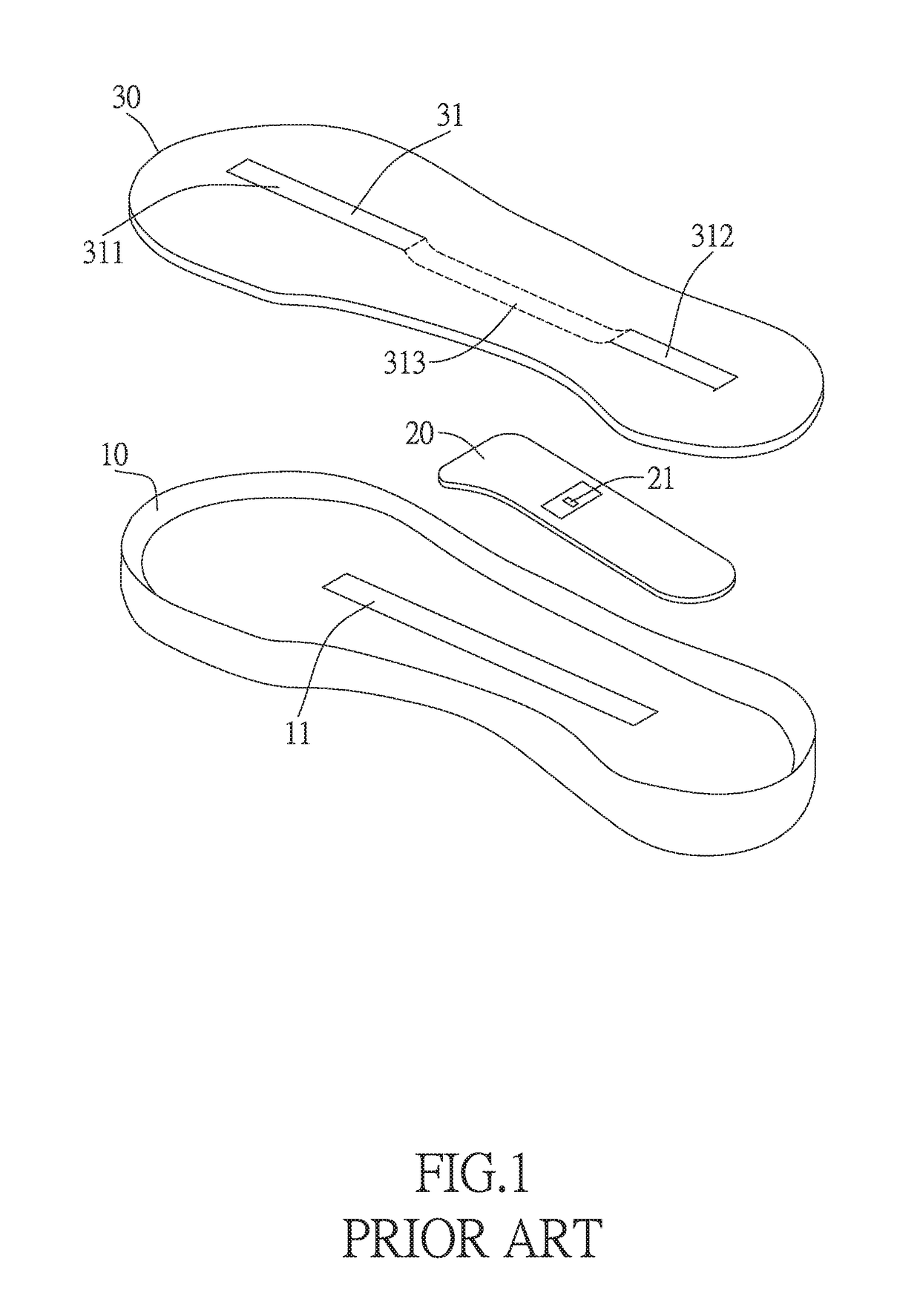

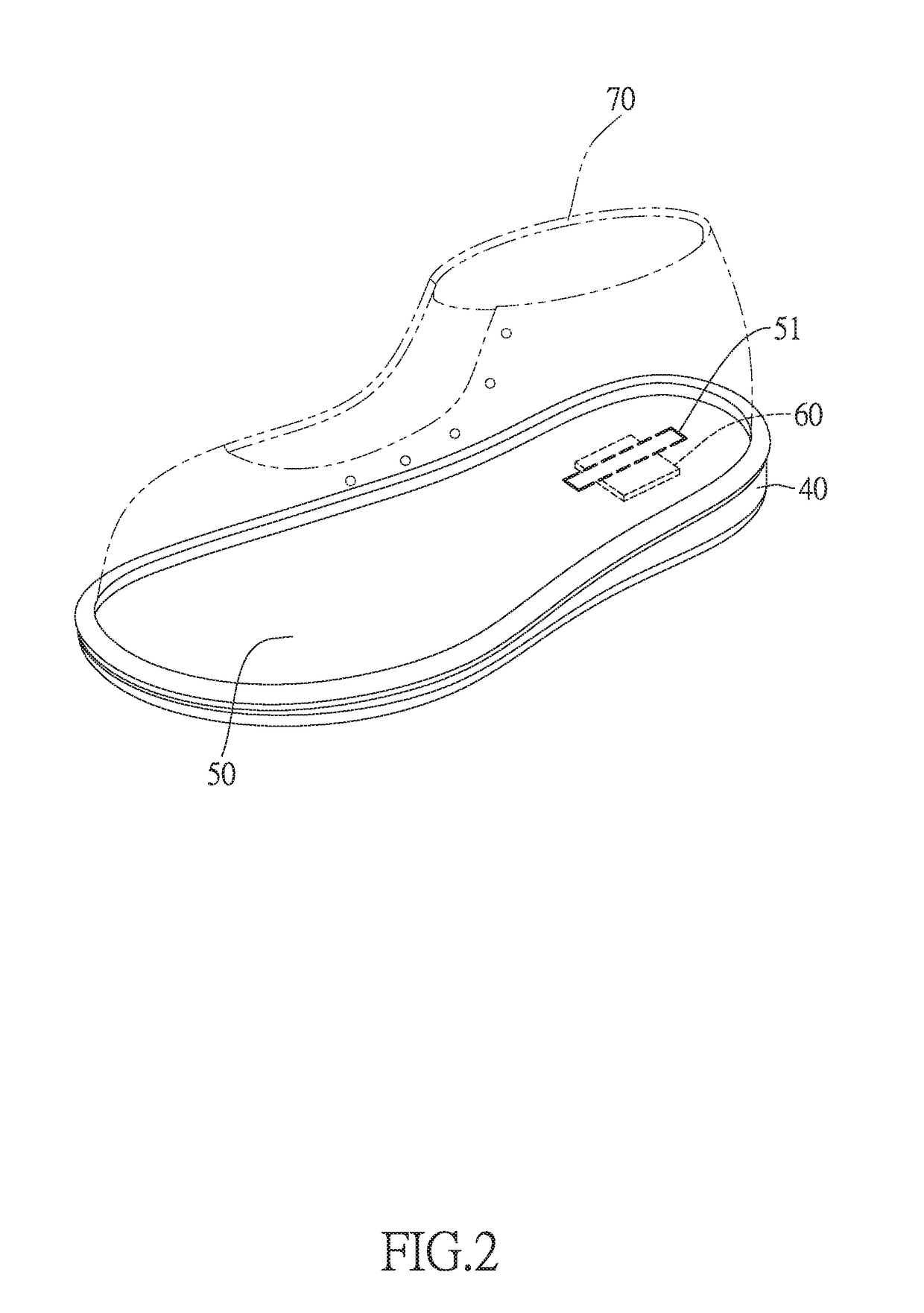

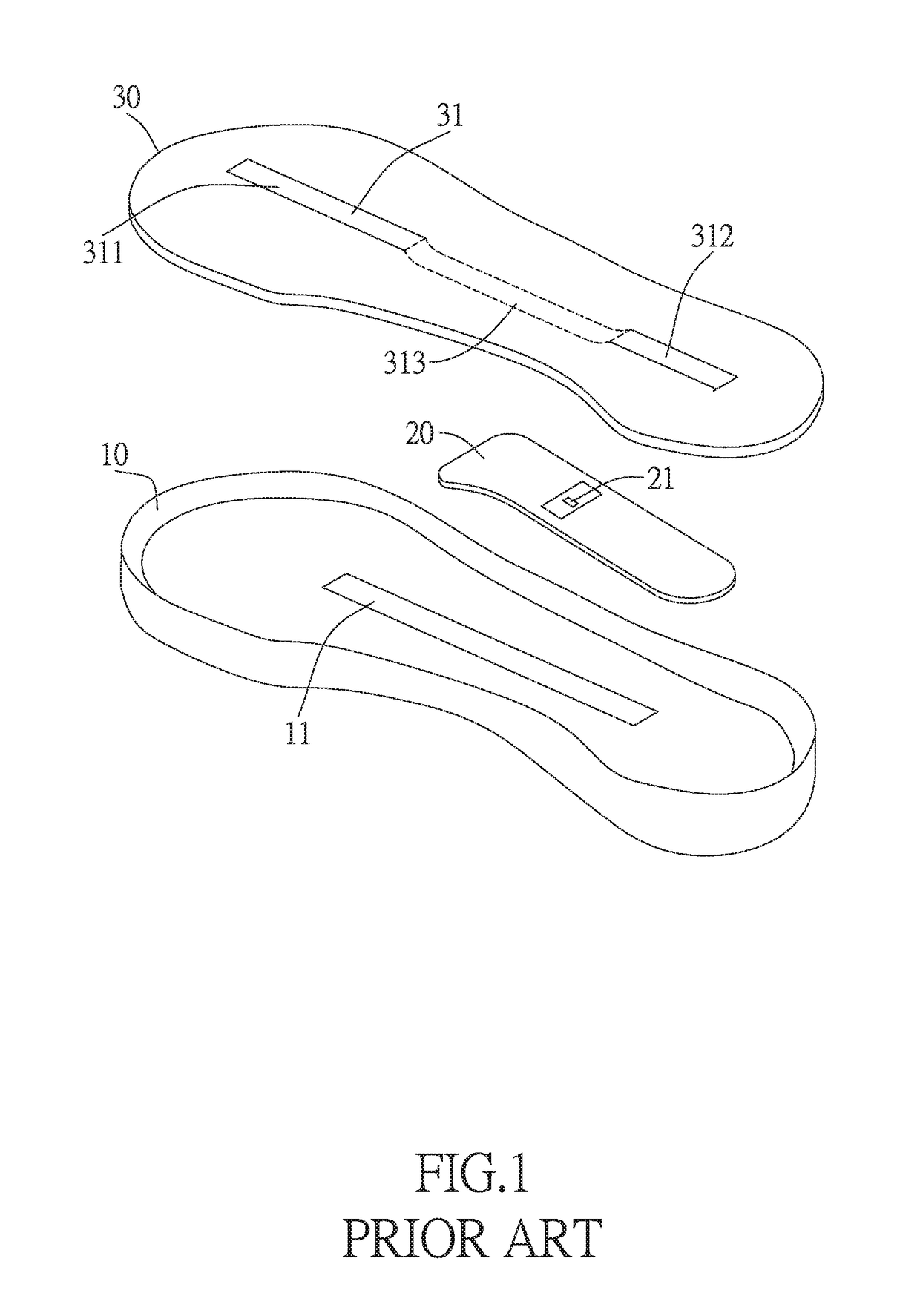

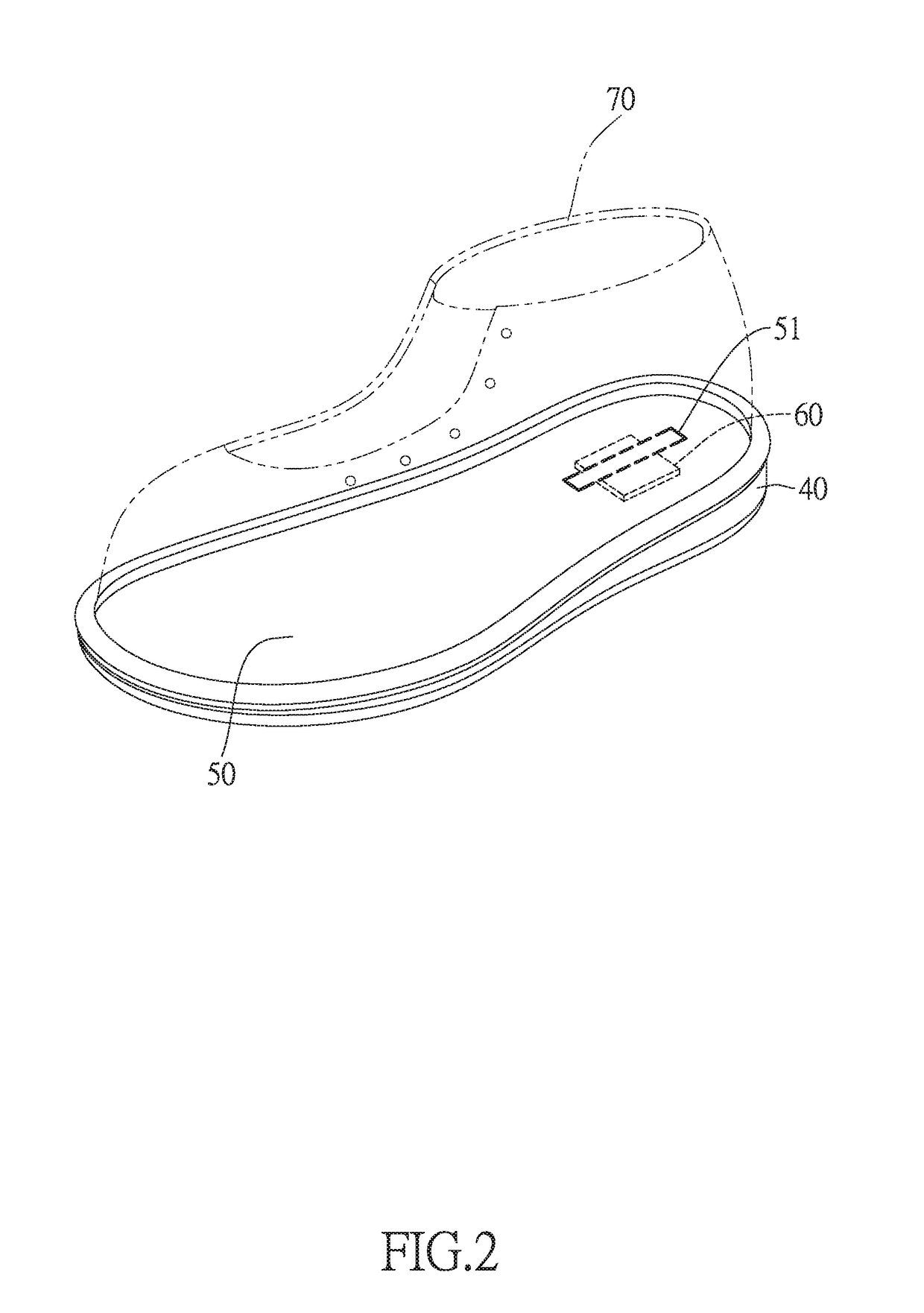

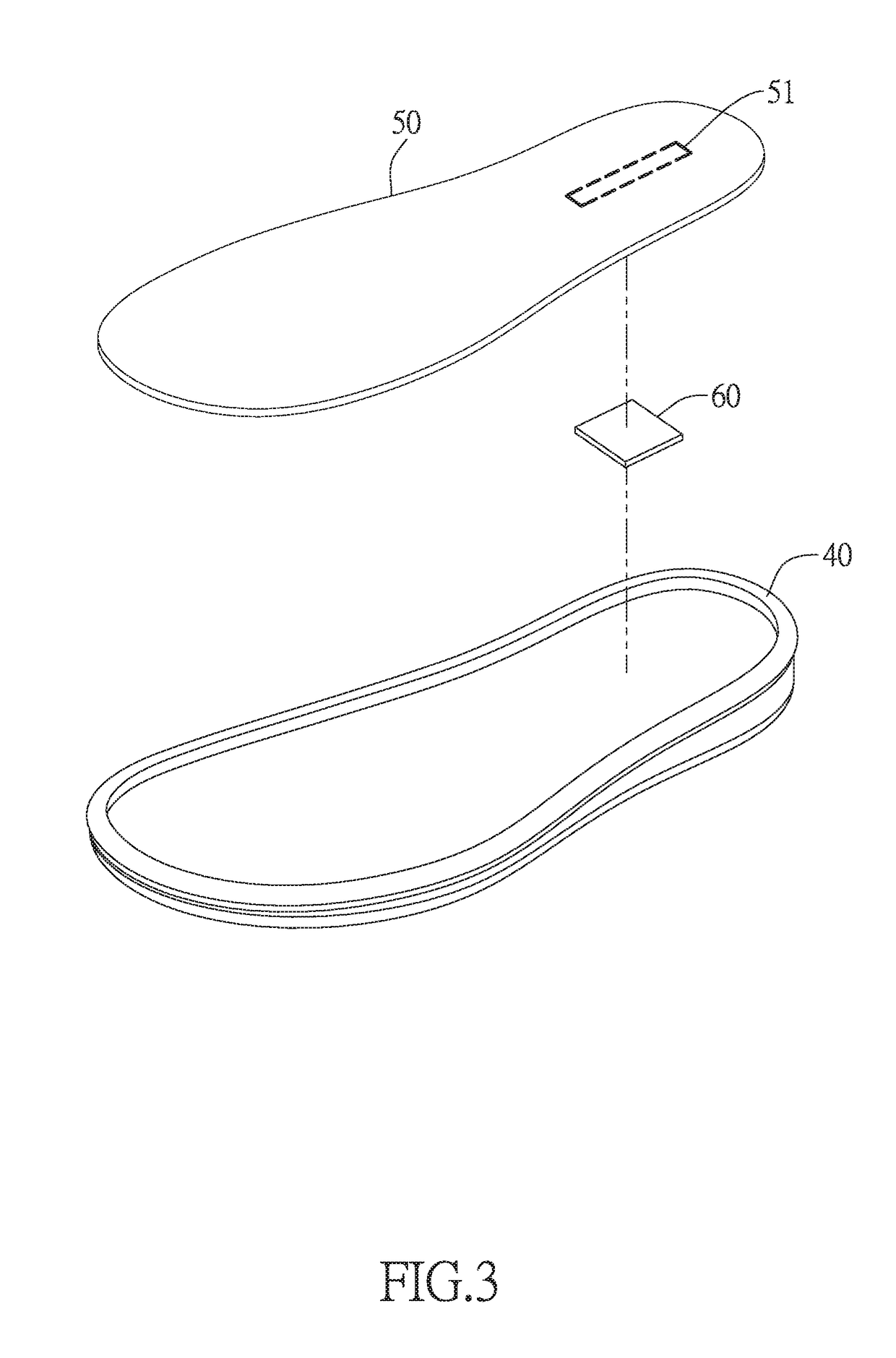

Antistatic shoe

An antistatic shoe includes an outsole having a conducting portion that is made of a conducting material and an insole that has a conducting portion mad of a conducting material. An antistatic unit is sewn to the conducting portion of the insole from below so as to be located between the outsole and the insole. An upper is mounted on the outsole and the insole. Electric connection between the components allows static electricity from a human body to be transmitted to a resistor in the antistatic unit, so that static electricity that would otherwise accumulate in the human body can be stably removed by the resistor and sent to the ground. This eliminates the risk of a transient electrostatic discharge that may disadvantageously damage adjacent electronic devices or generate sparks.

Owner:NEW PROCESS CORK

Alloy coated workpieces

ActiveUS9885103B2Good baseExtended durationSolid state diffusion coatingPressure inorganic powder coatingPowder mixtureZinc metal

A process for providing a corrosion resistant coating on uncoated ferrous components, involving mechanical plating, using as a coating medium a zinc metal-containing powder, such as zinc or zinc alloy powder, or a powder mixture of zinc or zinc alloy and at least one other metal, so as to build up a firmly adherent coating of the coating medium over exposed surfaces of the components, heating the components with the firmly adherent coating to produce solid-solid diffusion to form an Fe / Zn intermetallic over the surfaces, at least in a base layer of the coating built up by the plating, and cooling the components.

Owner:KWIK COAT AUST

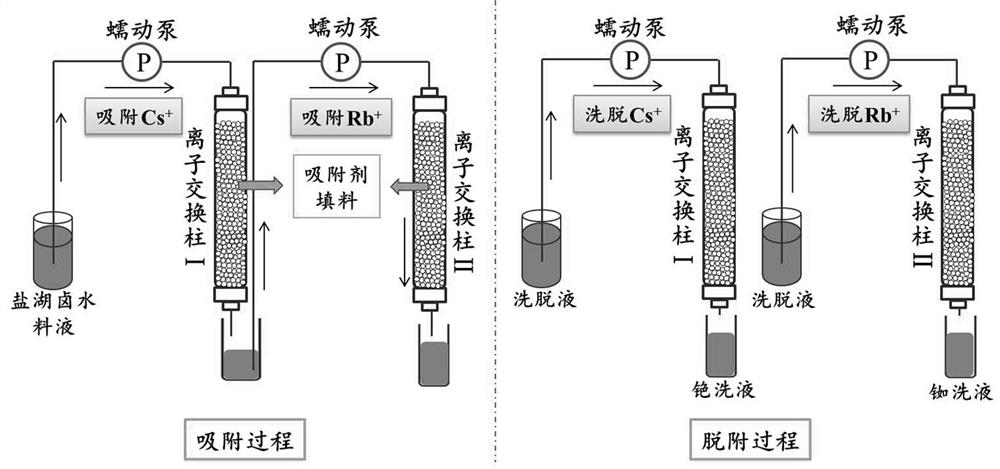

High-strength rubidium/cesium special-effect adsorbent as well as preparation method and application thereof

ActiveCN114259997AStrong cohesionTight molecular structureOther chemical processesWater contaminantsEpoxyHeteropoly acid

The invention discloses a high-strength rubidium / cesium special-effect adsorbent as well as a preparation method and application thereof. Epoxy resin gel is taken as a carrier, and amino modified heteropolyacid salt is taken as an adsorption effective component. The preparation method comprises the following steps: (1) dissolving amino silane in a 95% ethanol solvent, stirring to obtain a transparent solution, adding heteropolyacid salt into the solution, mechanically stirring for 1-4 hours, and filtering to obtain amino modified heteropolyacid salt; and (2) adding epoxy resin into the non-active diluent, stirring to obtain a viscous solution, adding the amino modified heteropolyacid salt prepared in the step (1) into the solution, continuously stirring, adding the polyamine cross-linking agent, stirring, and standing to obtain the high-strength rubidium / cesium special-effect adsorbent. The high-strength rubidium / cesium special-effect adsorbent has excellent chemical stability and acid, alkali and salt resistance, is high in rubidium and cesium selectivity and large in adsorption capacity, and is suitable for large-scale dynamic extraction of rubidium and cesium from salt lake brine.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Antistatic shoe

An antistatic shoe includes an outsole having a conducting portion that is made of a conducting material and an insole that has a conducting portion mad of a conducting material. An antistatic unit is sewn to the conducting portion of the insole from below so as to be located between the outsole and the insole. An upper is mounted on the outsole and the insole. Electric connection between the components allows static electricity from a human body to be transmitted to a resistor in the antistatic unit, so that static electricity that would otherwise accumulate in the human body can be stably removed by the resistor and sent to the ground. This eliminates the risk of a transient electrostatic discharge that may disadvantageously damage adjacent electronic devices or generate sparks.

Owner:NEW PROCESS CORK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com