Method for electroless deposition of copper on aluminum oxide film

A technology of electroless deposition and aluminum oxide, applied in the field of electroless deposition of copper on aluminum oxide film, can solve the problems of high cost, high pollution, complicated process, etc., and achieve the effect of simple method and good conductive effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

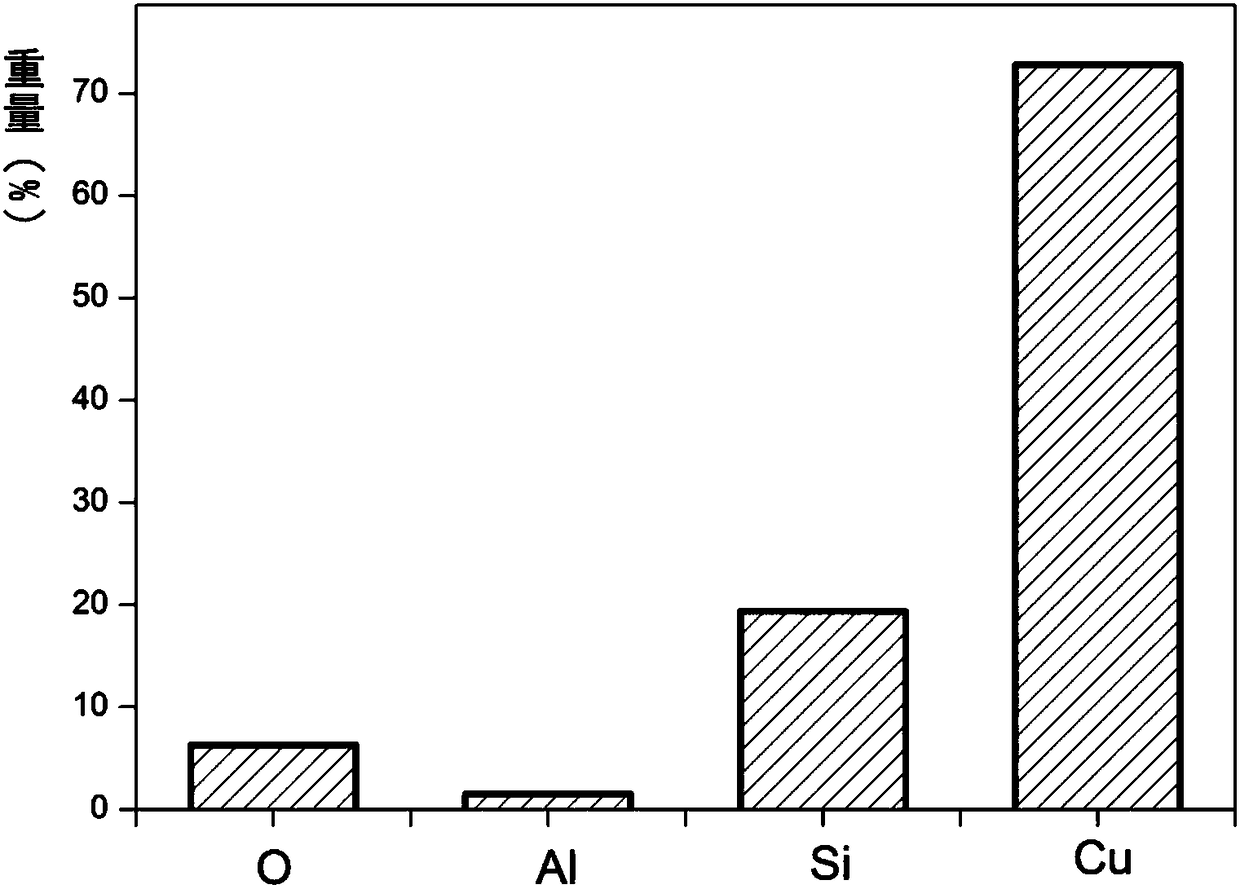

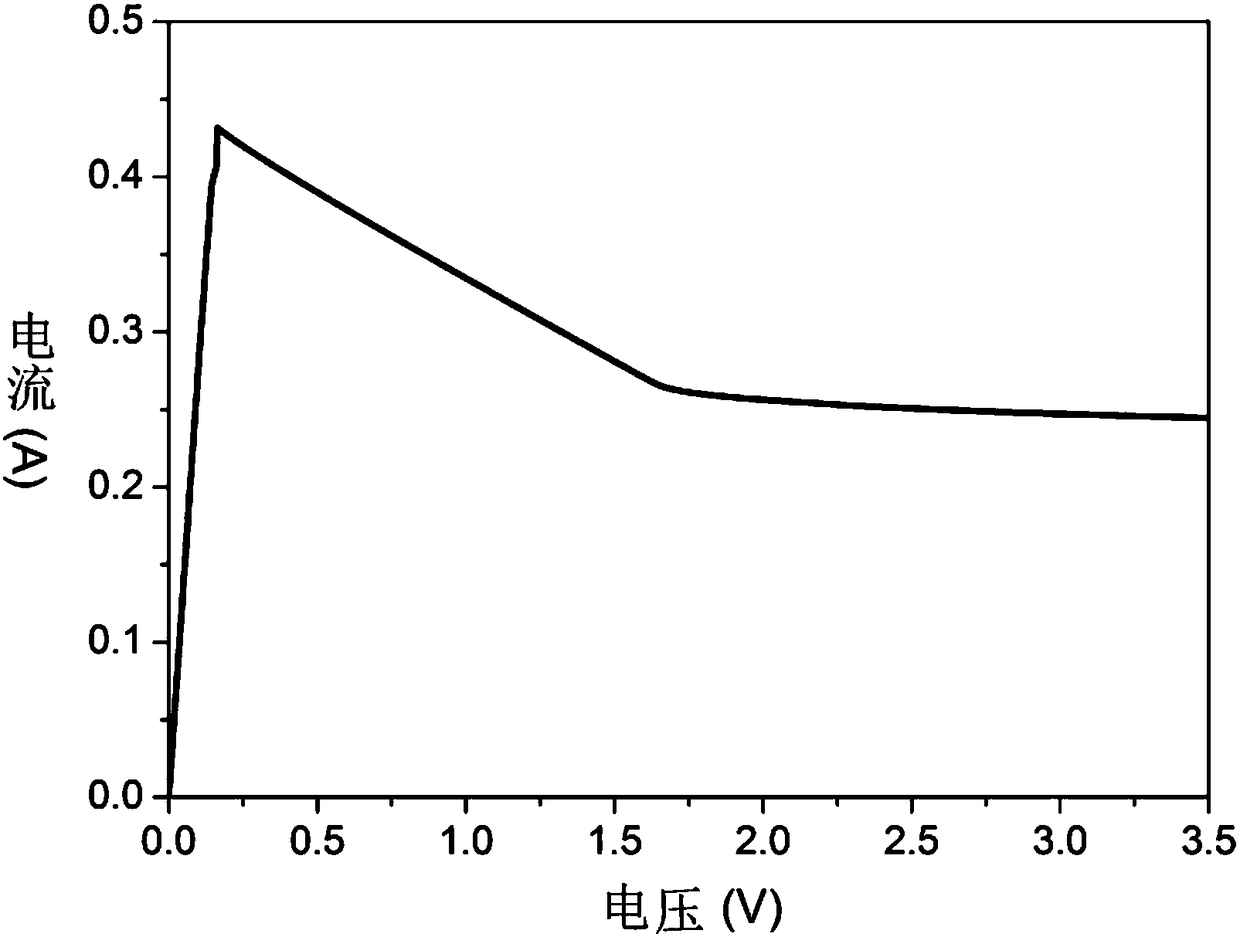

Image

Examples

Embodiment 1

[0031] A method for electrolessly depositing copper on an aluminum oxide film, the specific steps are as follows:

[0032] Step 1, under the dark condition, the aluminum oxide film is immersed in the ammonium chloropalladate ((NH4) that mass concentration is 6g / l 2 PdCl 4 ) after soaking in the aqueous solution for 17 minutes; take out the aluminum oxide film, clamp the aluminum oxide film with tweezers and constantly shake and rinse it in deionized water for 5 minutes, and set aside;

[0033] Step 2. Weigh sodium hydroxide, anhydrous copper sulfate and potassium tartrate according to the mass ratio of 1:1:2.3, mix well and add deionized water with 18% of the total mass of sodium hydroxide, anhydrous copper sulfate and potassium tartrate to make Dissolve fully, obtain solution A, stand-by;

[0034] Step 3, the solution A obtained in step 2 is mixed uniformly with the formaldehyde (HCHO) aqueous solution with a volume concentration of 9.5ml / l by a volume ratio of 1:1 to obtai...

Embodiment 2

[0037] A method for electrolessly depositing copper on an aluminum oxide film, the specific steps are as follows:

[0038] Step 1, under the dark condition, the aluminum oxide film is immersed in the ammonium chloropalladate ((NH4) that mass concentration is 6.2g / l 2 PdCl 4 ) after soaking in the aqueous solution for 16.8 minutes; take out the aluminum oxide film, clamp the aluminum oxide film with tweezers and continuously shake and rinse it in deionized water for 6 minutes, and set aside;

[0039] Step 2. Weigh sodium hydroxide, anhydrous copper sulfate and potassium tartrate according to the mass ratio of 1:1:2.4, mix well and add deionized water with 18.5% of the total mass of sodium hydroxide, anhydrous copper sulfate and potassium tartrate to make Dissolve fully, obtain solution A, stand-by;

[0040] Step 3. Mix the solution A obtained in step 2 with the formaldehyde (HCHO) aqueous solution with a volume concentration of 9.6ml / l by a volume ratio of 1:1 to obtain an el...

Embodiment 3

[0043] A method for electrolessly depositing copper on an aluminum oxide film, the specific steps are as follows:

[0044] Step 1, under the dark condition, the aluminum oxide film is immersed in the ammonium chloropalladate ((NH ) that mass concentration is 6.5g / l 2 PdCl 4 ) after soaking in the aqueous solution for 16.5min; take out the aluminum oxide film, clamp the aluminum oxide film with tweezers and continuously shake and rinse it in deionized water for 5min, and set aside;

[0045] Step 2. Weigh sodium hydroxide, anhydrous copper sulfate and potassium tartrate according to the mass ratio of 1:1:2.5, mix well and add deionized water with 18.8% of the total mass of sodium hydroxide, anhydrous copper sulfate and potassium tartrate to make Dissolve fully, obtain solution A, stand-by;

[0046] Step 3, the solution A obtained in step 2 is mixed uniformly with the formaldehyde (HCHO) aqueous solution of 10ml / l by the volume ratio of 1:1, obtains the electroless deposition s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com