High-strength rubidium/cesium special-effect adsorbent as well as preparation method and application thereof

A high-strength, adsorbent technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problem of high brittleness of silica gel, poor binding force of gel carrier, low connection strength, etc. problems, achieve excellent chemical stability, excellent acid resistance, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

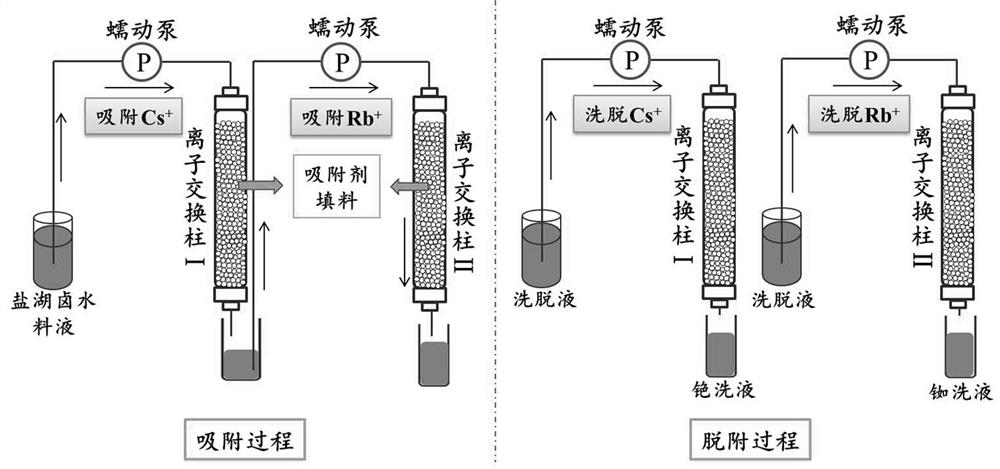

Image

Examples

Embodiment 1

[0030] Dissolve 3-aminopropyltriethoxysilane in 95% ethanol solvent and stir to obtain a transparent solution, add ammonium phosphomolybdate to the solution and perform mechanical stirring for 4 h, then filter to obtain amino-modified ammonium phosphomolybdate, Wherein the mass ratio of 3-aminopropyltriethoxysilane, ammonium phosphomolybdate, and 95% ethanol is 1: 10: 50.

[0031] Add bisphenol A epoxy resin into dibutyl phthalate and stir to obtain a viscous solution with a viscosity of 0.2 Pa s. Add amino-modified ammonium phosphomolybdate to the solution and continue stirring for 0.5 h, then Add aliphatic polyamine cross-linking agent and stir for 30 min, then stand still to get epoxy resin gel / amino-modified ammonium phosphomolybdate composite high-strength rubidium and cesium special-effect adsorbent, in which bisphenol A epoxy resin, amino-modified The mass ratio of ammonium phosphomolybdate and aliphatic polyamine crosslinking agent is 1:2:0.03.

[0032] The compressiv...

Embodiment 2

[0038] Diethylenetriaminopropyltrimethoxysilane was dissolved in 95% ethanol solvent and stirred to obtain a transparent solution, ammonium phosphomolybdate was added to the solution, mechanically stirred for 2 h, and then filtered to obtain amino-modified ammonium phosphomolybdate , wherein the mass ratio of diethylenetriaminopropyltrimethoxysilane, ammonium phosphomolybdate, and 95% ethanol is 1: 15: 100.

[0039]Add bisphenol F epoxy resin into dibutyl phthalate and stir to obtain a viscous solution with a viscosity of 1.5 Pa s. Add amino-modified ammonium phosphomolybdate to the solution and continue stirring for 1 h, then Add polyamide polyamine cross-linking agent and stir for 20 min, then stand still to obtain high-strength rubidium and cesium special-effect adsorbent compounded by epoxy resin gel / amino-modified ammonium phosphomolybdate, in which bisphenol F epoxy resin, amino-modified The mass ratio of ammonium phosphomolybdate and polyamide polyamine crosslinking age...

Embodiment 3

[0042] Dissolve N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane in 95% ethanol solvent and stir to obtain a transparent solution, add ammonium phosphotungstate to the solution, stir mechanically for 1 h, and then filter Obtain amino-modified ammonium phosphotungstate, wherein the mass ratio of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, ammonium phosphotungstate, and 95% ethanol is 1: 15: 100.

[0043] Add bisphenol S-type epoxy resin into acetone and stir to obtain a viscous solution with a viscosity of 4 Pa s. Add amino-modified ammonium phosphotungstate to the solution and continue stirring for 1 h, then add alicyclic polyamine exchange The mixture was stirred for 20 min, and left to stand to obtain a high-strength rubidium and cesium special-effect adsorbent composited by epoxy resin gel / amino-modified ammonium phosphotungstate, in which bisphenol S-type epoxy resin, amino-modified ammonium phosphotungstate, The mass ratio of the cycloaliphatic polyamine crosslinking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com