Steel wire rope picking waste acid and high zinc and lead-containing sludge co-disposal system and process

A steel wire rope acid and sludge technology is applied in the co-processing system and process field of steel wire rope pickling waste acid and sludge containing high zinc and lead. The process is simple, the effect of preventing environmental pollution and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

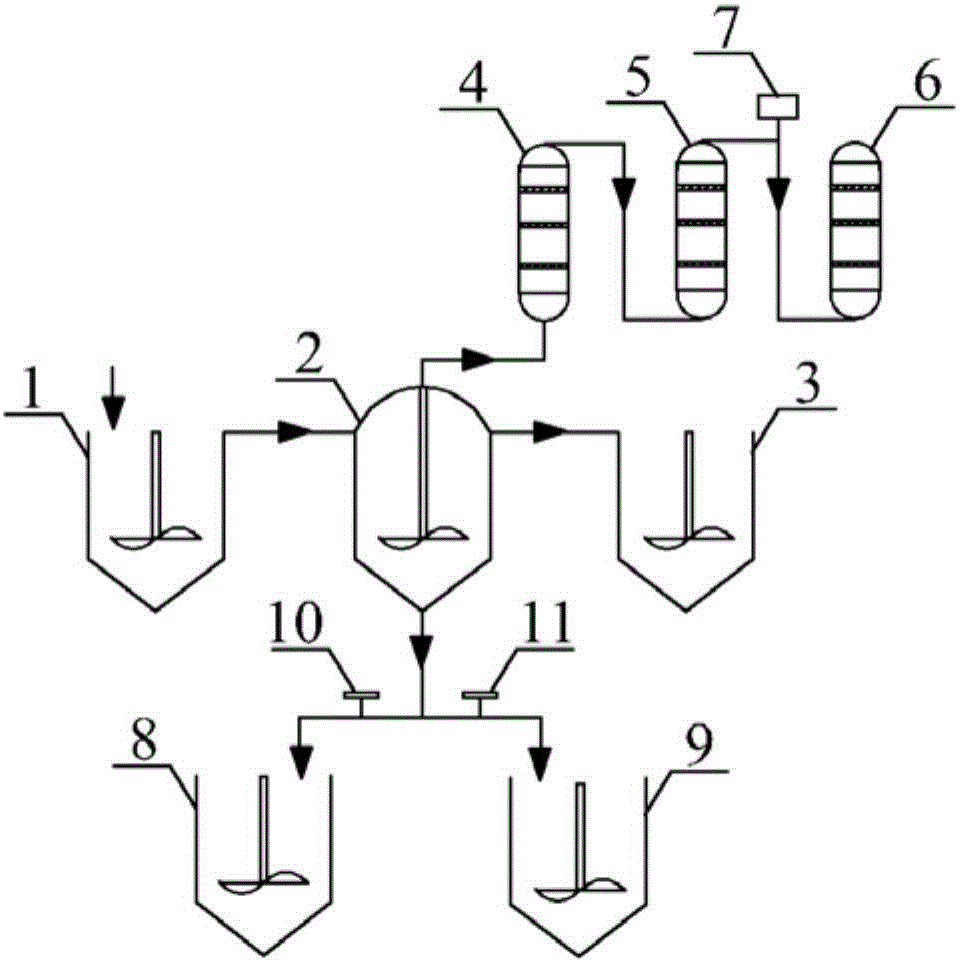

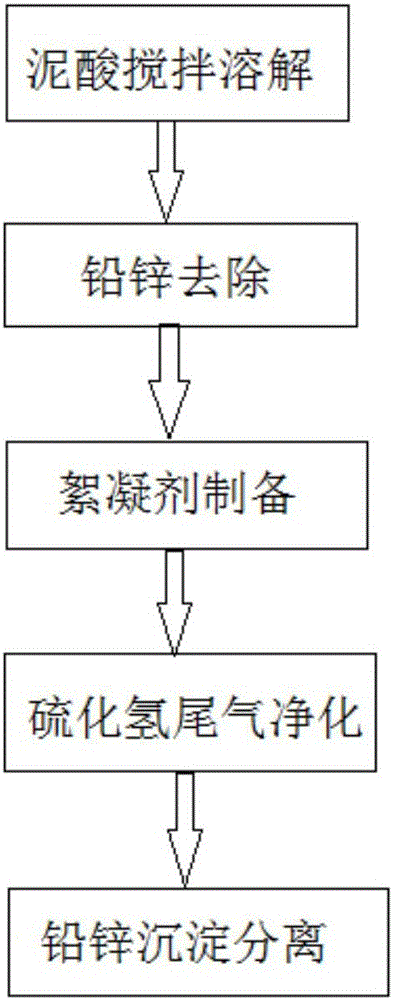

[0052] refer to figure 1 , figure 2 , add the sludge (moisture content 30%-75%) of the steel wire rope factory sludge into the mud acid stirring and dissolving device 1 after the plate and frame pressure filtration, and the dosage is: add to the mud acid stirring and dissolving device 1 1 / 3 of the volume, then add waste acid solution (H + The concentration is 13%, the lead content is 720mg / L, the zinc content is 4000mg / L), and the dosage is V (waste acid): V (sludge) = 3:1, that is, the volume is 9 cubic meters. After stirring for 2 hours and standing still for 3 hours, the supernatant was pumped into the lead and zinc removal device 2 using an acid-resistant lift pump. After testing, the lead content of the acid solution after dissolving the mud is 799mg / L, and the zinc content is 6940mg / L. Add 230kg of sodium sulfide solid to the lead and zinc removal device 2, stir and react for 30min, and pass the resulting lead and zinc precipitation mixture into the The lead-zinc pre...

Embodiment 2

[0059] refer to figure 1 , figure 2 1. Add the sludge (moisture content 40%-75%) of the steel wire rope factory sludge into the mud acid stirring and dissolving device 1 after the plate and frame pressure filtration, and the dosage is: add to the mud acid stirring and dissolving device 1 1 / 2 volume, then add waste acid solution (H + The concentration is 10%, the lead content is 4500mg / L, the zinc content is 5100mg / L), the dosage is V (waste acid): V (sludge) = 8: 1, that is, the volume is 24 cubic meters. After stirring and reacting for 4 hours and standing still for 5 hours, the supernatant was pumped into the lead and zinc removal device 2 using an acid-resistant lift pump. After testing, the lead content of the acid solution after dissolving the mud is 6500mg / L, and the zinc content is 7000mg / L. Add 1101kg of potassium sulfide solids to the lead-zinc removal device 2, stir and react for 60min, and pass the resulting lead-zinc precipitation mixture into the The lead-zinc...

Embodiment 3

[0066] refer to figure 1 , figure 2 1. Add the sludge (moisture content 40%-75%) of the steel wire rope factory sludge into the mud acid stirring and dissolving device 1 after the plate and frame pressure filtration, and the dosage is: add to the mud acid stirring and dissolving device 1 1 / 5 of the volume, then add waste acid solution (H + The concentration is 12%, the lead content is 3000mg / L, the zinc content is 4200mg / L), and the dosage is V (waste acid): V (sludge) = 10:1, that is, the volume is 30 cubic meters. After stirring and reacting for 1 hour and standing for 1 hour, the supernatant was pumped into the lead and zinc removal device 2 using an acid-resistant lift pump. Detect that the lead content of the acid solution after dissolving the mud is 5300mg / L, and the zinc content is 5600mg / L. Add 483.5kg of calcium sulfide solids to the lead-zinc removal device 2, stir and react for 30min, and pass the resulting lead-zinc precipitation mixture into the lead The zinc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com