Method for preparing uniform-diameter zinc oxide nanorods on LB (Langmuir-Blodgett) zinc oxide seed film

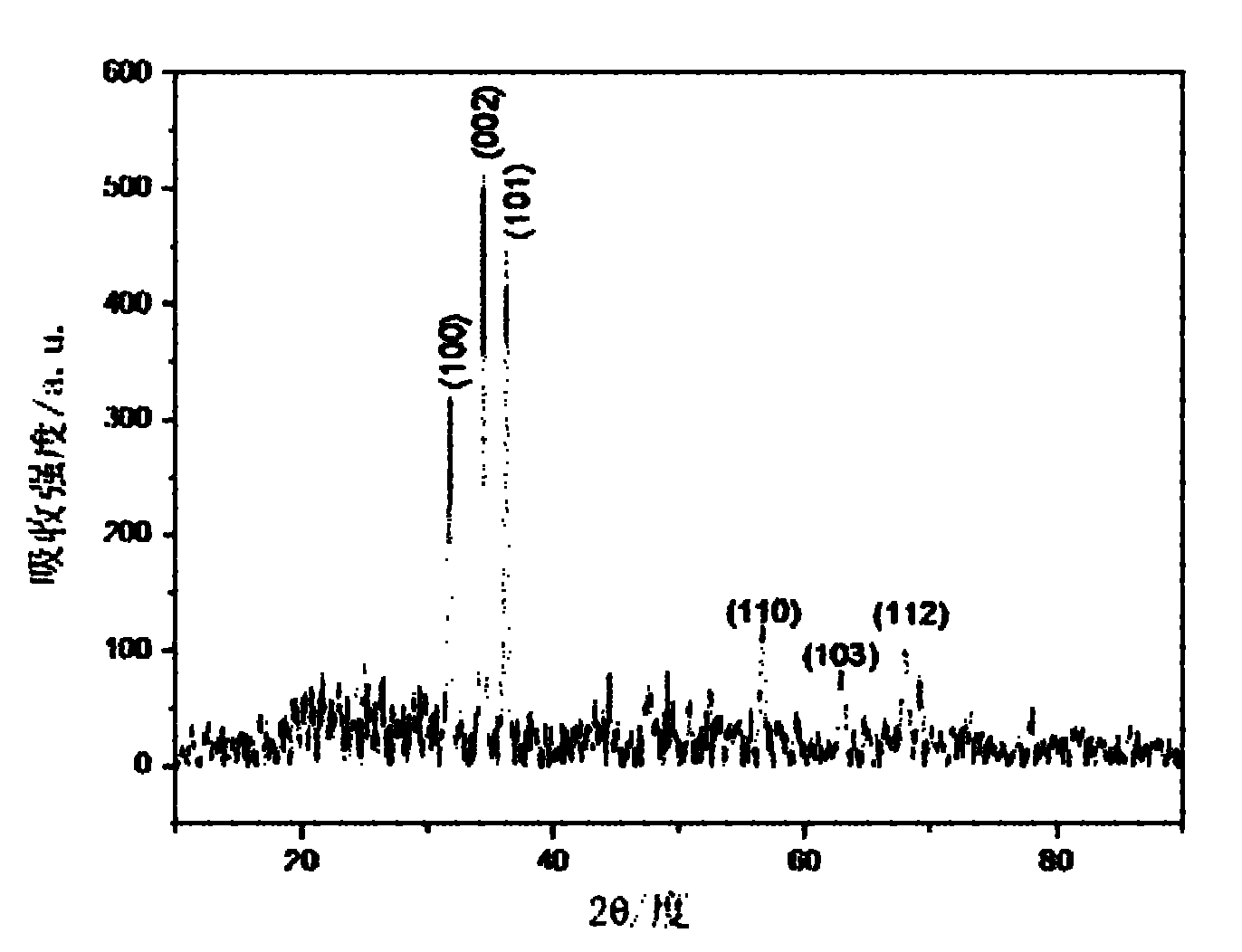

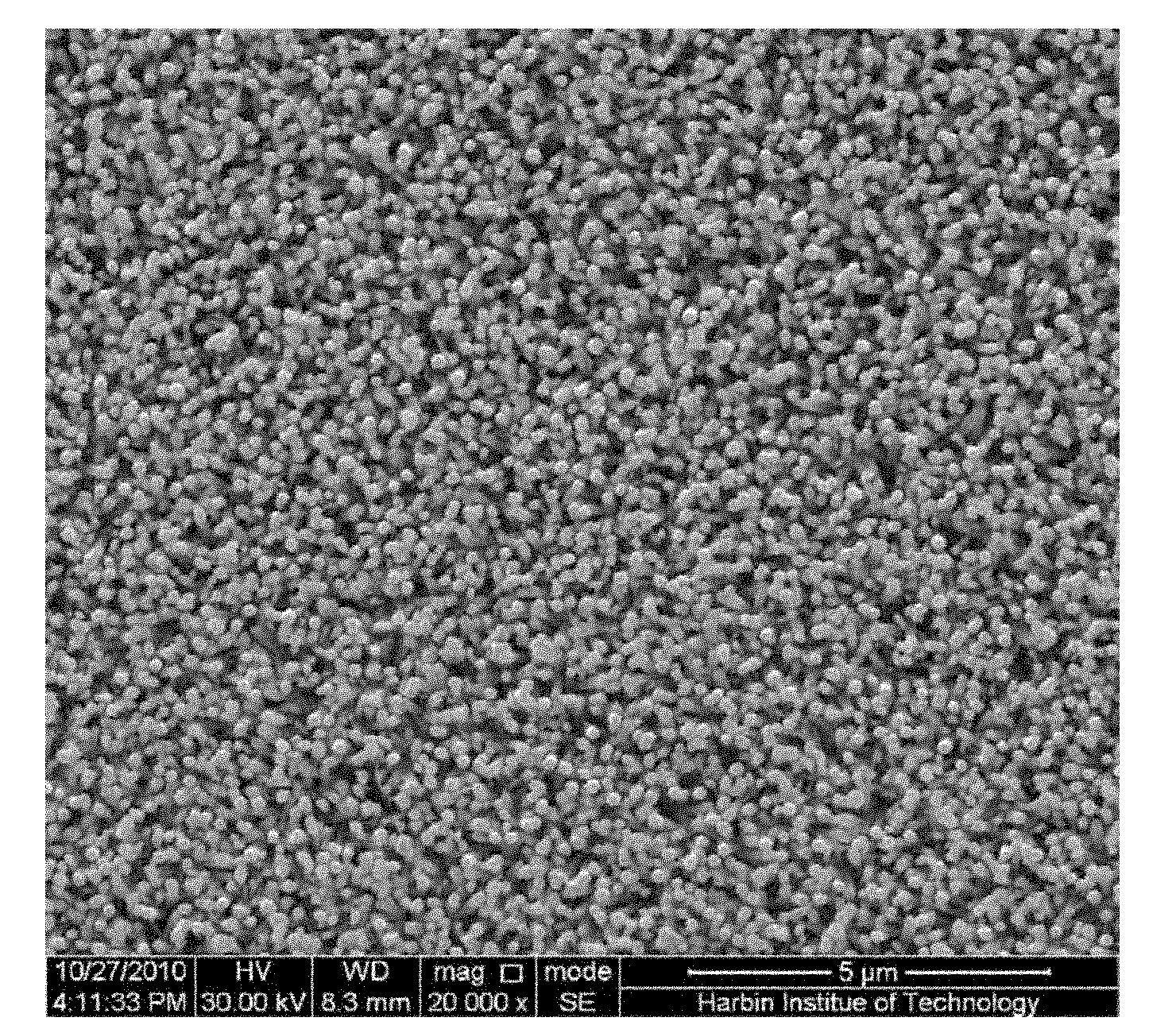

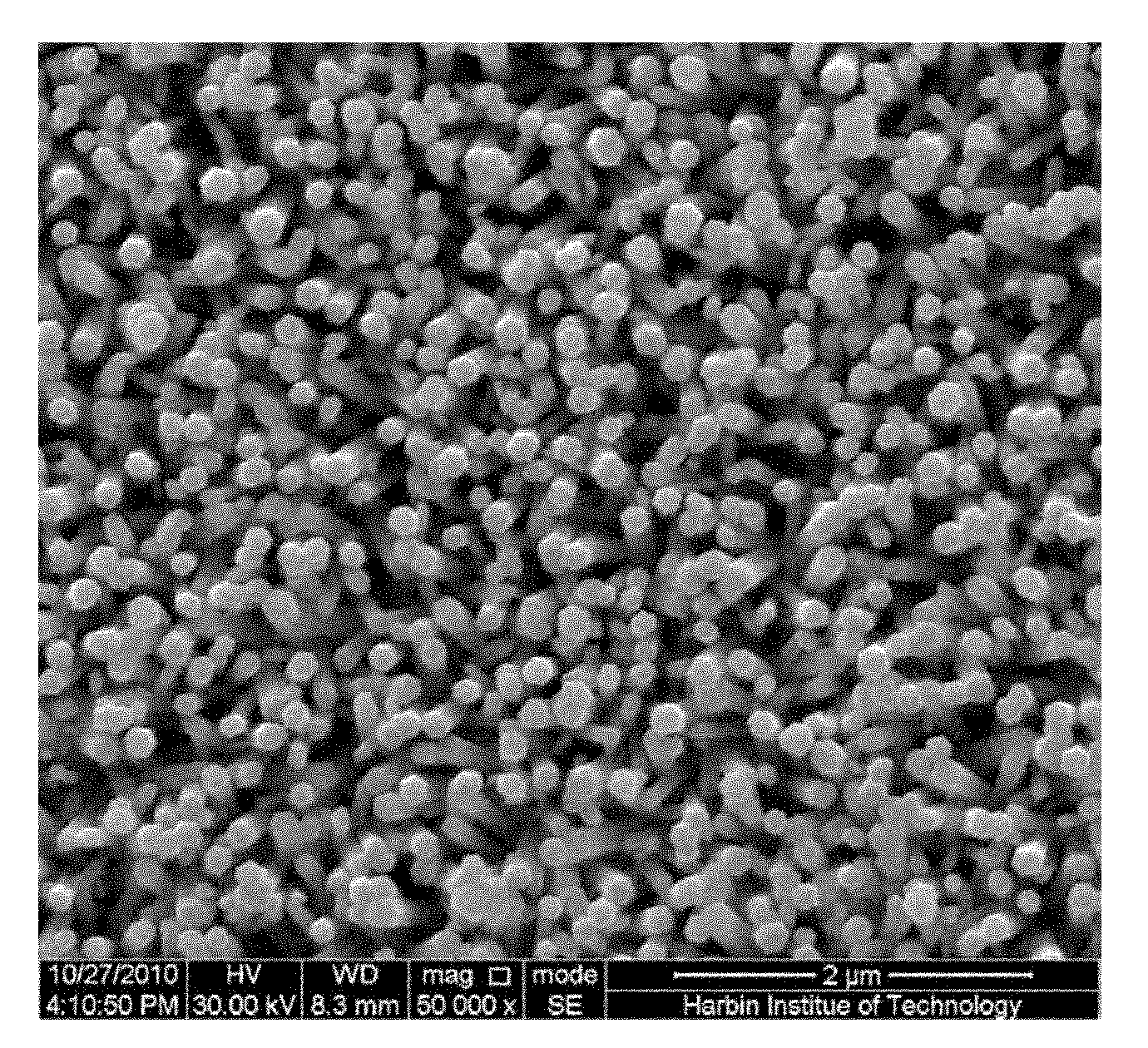

A zinc oxide nanorod, seed film technology, applied in zinc oxide/zinc hydroxide, chemical instruments and methods, single crystal growth and other directions, can solve the problem of zinc oxide nanorod shape, size instability, zinc oxide film structure is not easy to artificial Control, complex operation and other problems, to achieve the effect of easy operation, stable size and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Specific embodiment one: present embodiment prepares the method for the zinc oxide nanorod of uniform diameter on LB zinc oxide seed film, carries out according to the following steps: 1, the processing of quartz substrate: immerse quartz substrate in ethanol completely, with 40KHz Ultrasonic treatment for 10 to 15 minutes, then completely immerse the quartz substrate in acetone, use 40KHz ultrasonic treatment for 10 to 15 minutes, then wash the quartz substrate with ultrapure water for 3 to 5 times, and then completely immerse the quartz substrate in alkaline hydrogen peroxide In the solution, use 40KHz ultrasonic treatment for 10-20min, then completely immerse the quartz substrate in the acidic hydrogen peroxide solution, use 40KHz ultrasonic treatment for 10-20min, then wash the quartz substrate with ultrapure water for 3-5 times, and dry it to obtain Treated quartz substrate; 2. Preparation of spreading solution: Mix stearic acid and chloroform and stir with a magnet...

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment differs from Embodiment 1 in that: In step 1, the quartz substrate is completely immersed in ethanol, and treated with 40KHz ultrasonic waves for 12-14 minutes. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the quartz substrate is completely immersed in acetone, and treated with 40KHz ultrasonic waves for 12-14 minutes. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com