Patents

Literature

40 results about "Mechanical plating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanical plating, also known as peen plating, mechanical deposition, or impact plating, is a plating process that imparts the coating by cold welding fine metal particles to a workpiece. Mechanical galvanization is the same process, but applies to coatings that are thicker than 0.001 in (0.025 mm). It is commonly used to overcome hydrogen embrittlement problems. Commonly plated workpieces include nails, screws, nuts, washers, stampings, springs, clips, and sintered iron components.

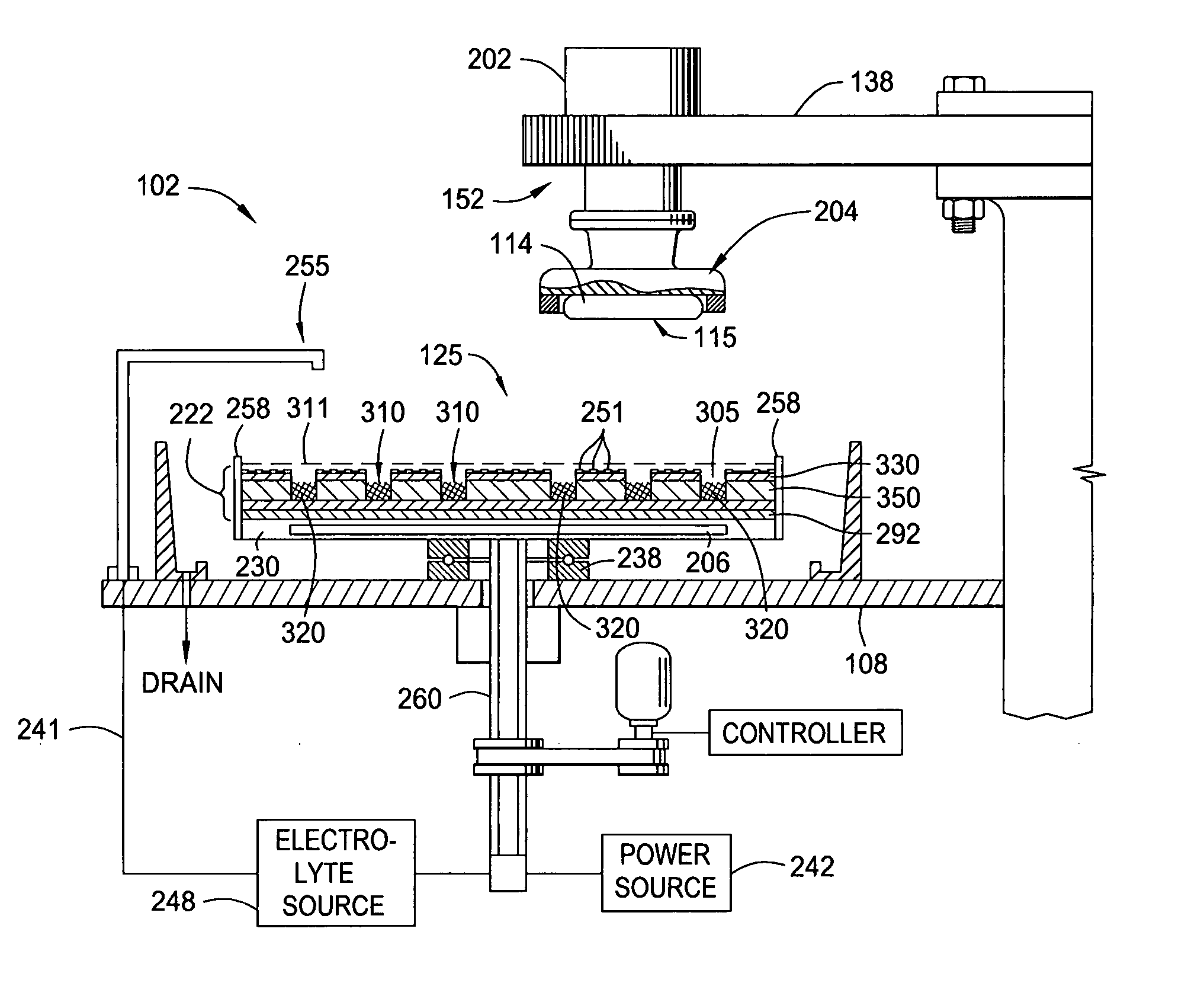

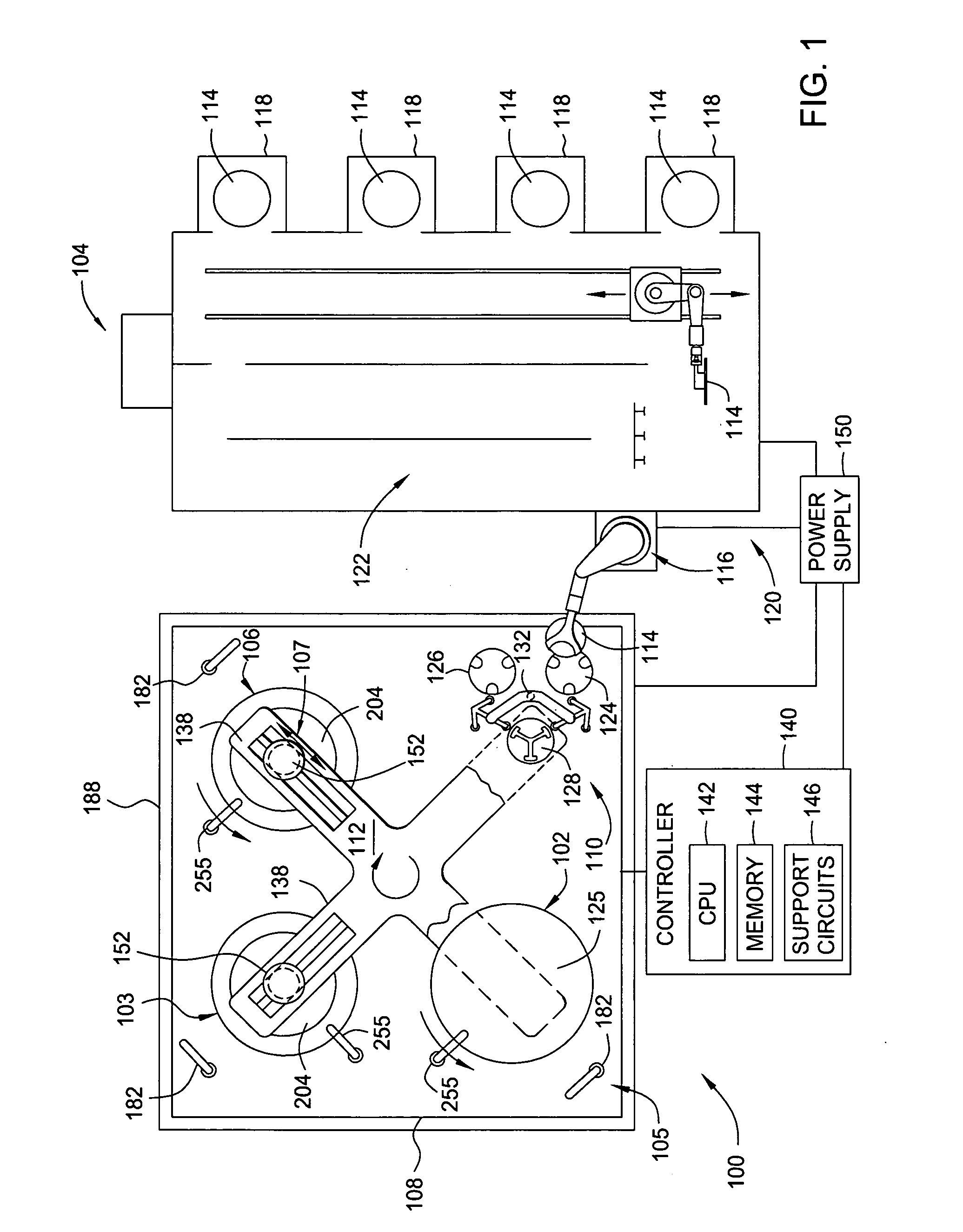

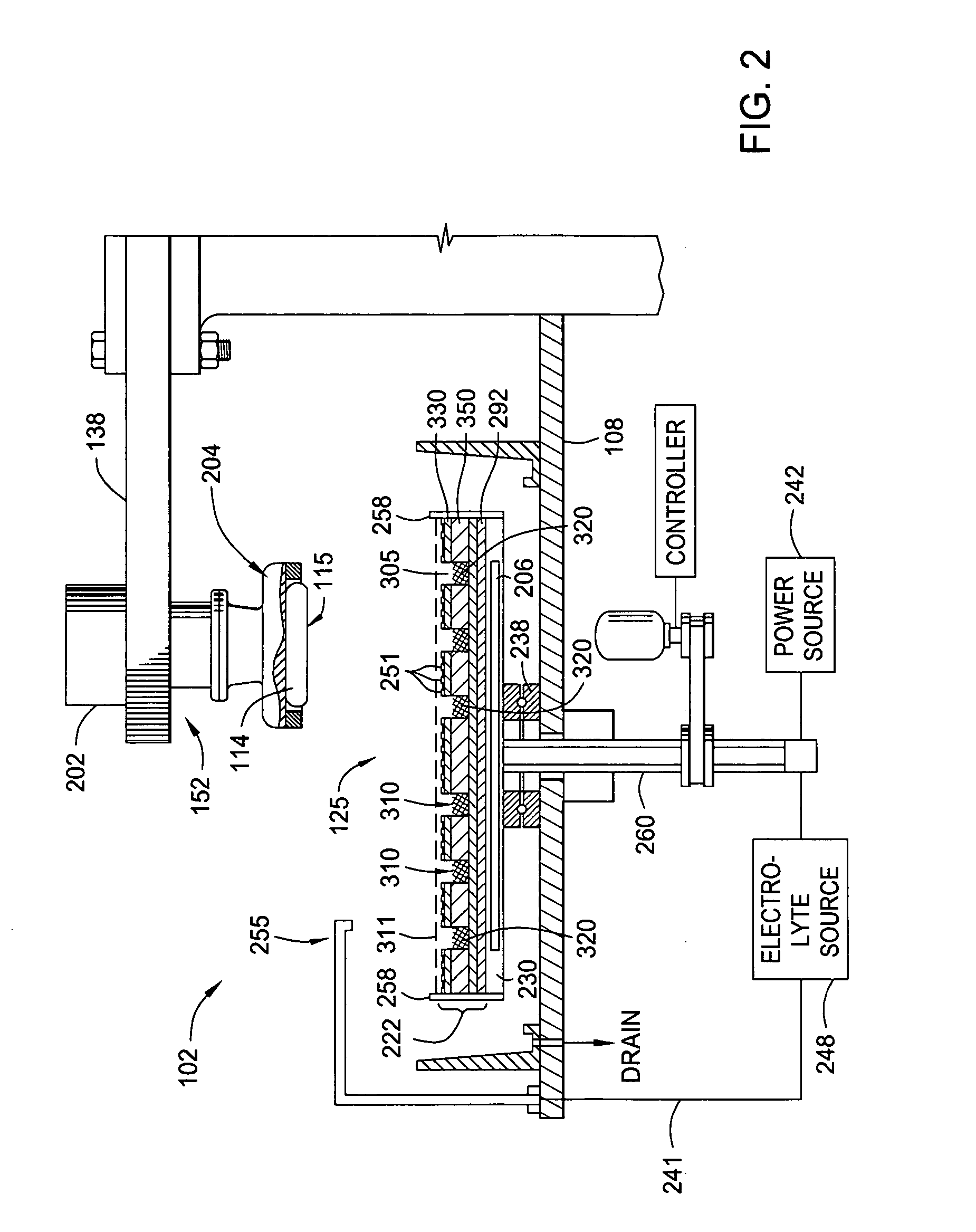

Pad design for electrochemical mechanical polishing

InactiveUS20060070872A1Electrolysis componentsSemiconductor/solid-state device manufacturingEngineeringCentrifugal force

A method and apparatus for processing a substrate by electrochemical mechanical planarization and electrochemical mechanical plating is disclosed. Included are various embodiments of a processing pad article comprising an open cell foam subpad that is adapted to retain an electrolyte while encountering centrifugal motion, and simultaneously provide electrical and / or abrasive contact to a feature side of a substrate. Also disclosed is a platen capable of holding an electrolyte during processing at a desired RPM, then releasing the electrolyte centrifugally at a higher RPM. The release is actuated by an operator or by centrifugal force.

Owner:APPLIED MATERIALS INC

Sedimentation accelerating agent and application used for coating mechanically plated with copper and copper alloy

ActiveCN105112904APowdering speed is fastUniform colorMetallic material coating processesCopper coatingBalance water

The invention discloses a sedimentation accelerating agent and application used for a coating mechanically plated with copper and copper alloy and belongs to the technical field of surface plating. The sedimentation accelerating agent is prepared from 0.5%-1% of diatomite, 1%-2% of sodium gluconate, 0.5%-1% of triethanolamine, 35%-45% of stannous salt, 1%-3% of ammonium dihydrogen phosphate, 5%-10% of OP-10, 1%-1.5% of inorganic acid and the balance water according to a certain adding sequence. The sedimentation accelerating agent is applied to mechanical plating method through which a copper coating or a copper alloy coating is formed on the surface of a steel product, and the adding amount of the sedimentation accelerating agent is 1 / 3-1 / 2 the adding mass of copper powder or copper alloy powder. By adopting the sedimentation accelerating agent in the mechanical plating technique of the steel product, the copper powder or the copper alloy powder can subside on the surface of the steel product rapidly, and the copper coating and the copper alloy coating which are smooth in surface and uniform in color can be obtained.

Owner:KUNMING UNIV OF SCI & TECH

Processing for forming Zn-Sn alloy layer through mechanical plating and Sn reduction disposition

InactiveCN102409334AGood removal effectReduce bond strengthPressure inorganic powder coatingFerrous saltsPhosphoric acid

The invention provides a process for forming a Zn-Sn alloy layer through mechanical plating and Sn reduction disposition. The process comprises the steps of workpiece pretreatment before plating, establishment of a base layer on the surface of the workpiece, and alloyed plating thickening. A compound surfactant is used to change the characteristic of a plating solution, thus an environment in which continuous deposition of metal Zn powder on the surface of a plated part can be ensured, adsorption deposition plays a main role, and reduction carrying deposition plays an auxiliary role can be formed; a reduction deposition activator prepared by mixing a stannous salt, a ferrous salt, an ammonium salt, phosphoric acid and water is used for supplying Si element for the Zn-Sn plating layer through mechanical plating. The plating is smooth, bright, good in uniformity and high in compactness. As no metal Sn powder is adopted, carrying deposition of crude and large particles can be avoided, the reduced Sn atoms are preferentially adsorbed on the Zn powder and Zn powder alga-gobbets while the size of the Sn atoms is far less than that of the Zn powder and Zn powder alga-gobbets, under the same movement and impact conditions, the layer formation conditions of the plating are changed toward the direction favor of compaction and leveling, the utilization rate of non-ferrous metal is beneficial to being improved, and the production cost is lowered.

Owner:KUNMING UNIV OF SCI & TECH

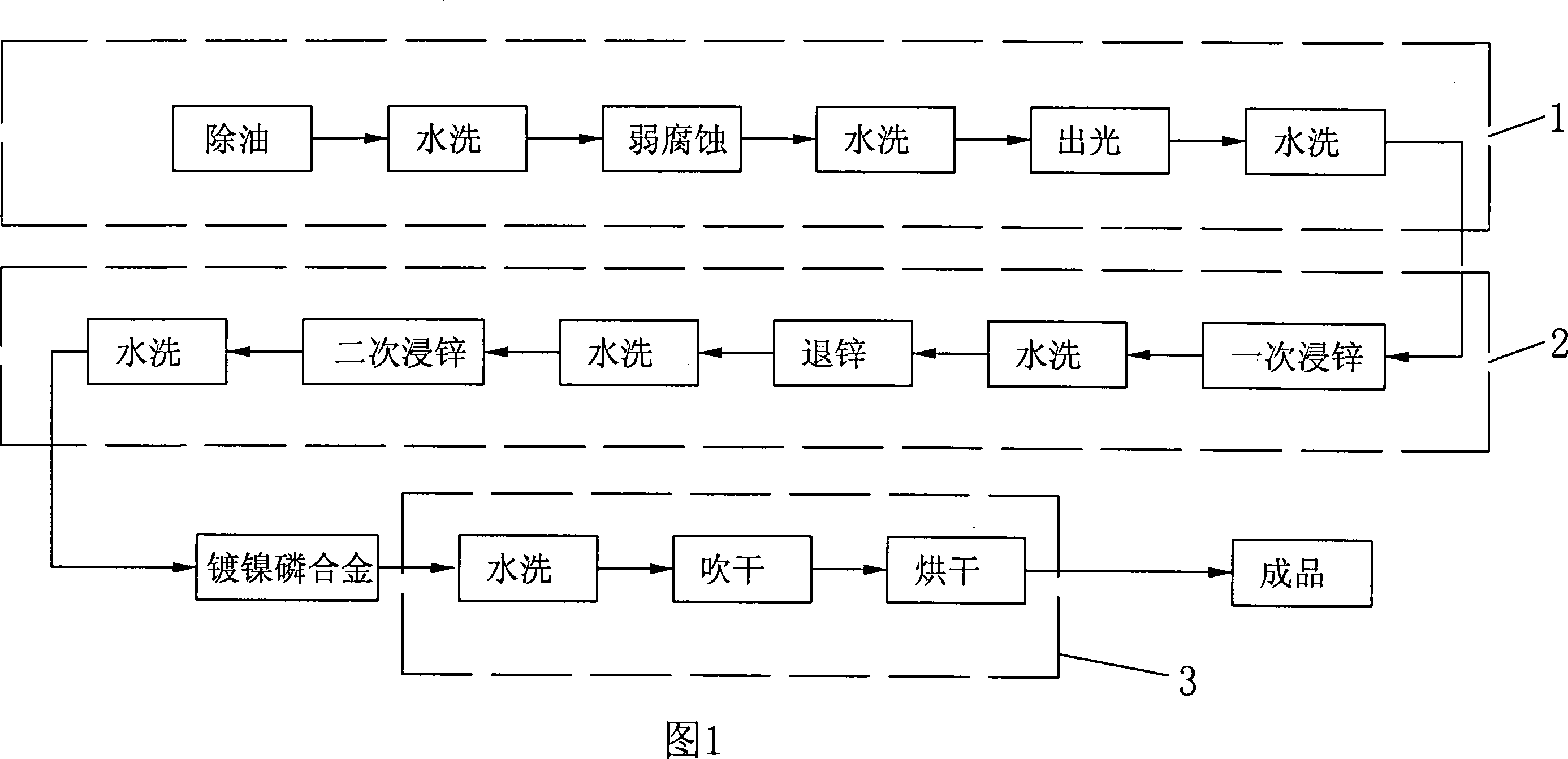

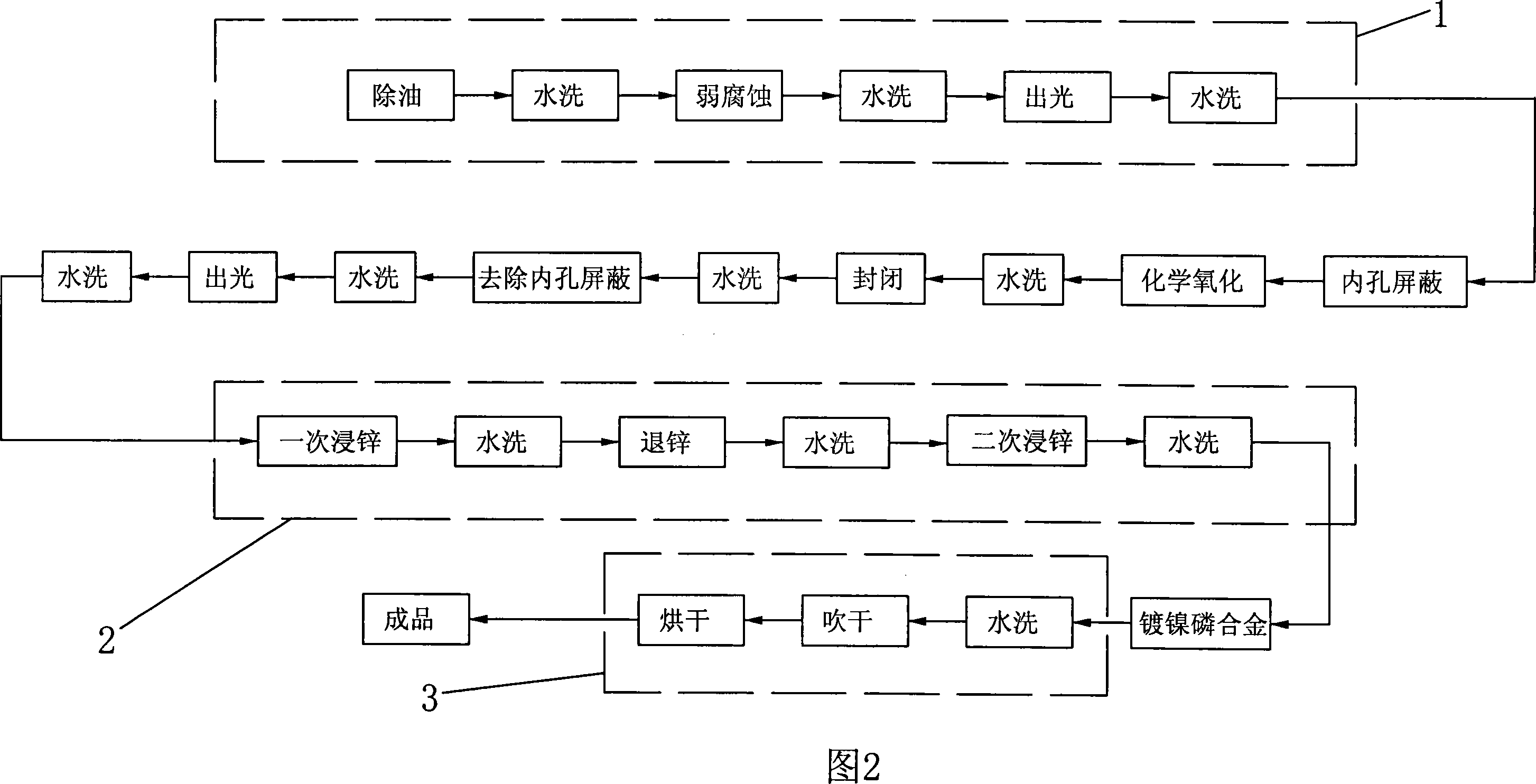

Local chemical-plating technique for aluminum radiator bores

InactiveCN101082126ALow costSaving Nickel ResourcesHot-dipping/immersion processesLiquid/solution decomposition chemical coatingSolderabilityZinc

The present invention relates to chemical plating technology, and is especially local chemical plating process for holes of aluminum radiator. The local chemical plating process includes: shielding the holes of aluminum radiator, oxidizing chemically in a chemical oxidizing bath to form oxide film in the un-shielded parts of the aluminum radiator, and closed chemical plating to deposit zinc layer and coat Ni-P alloy layer in the walls of the holes without oxide film. The present invention has simple technological process, capacity of forming weldable Ni-P alloy layer only in the holes, saving in nickel source and capacity of lowering radiator producing cost.

Owner:TWD METAL PRODN

Process of mechanical copper plating and mechanical copper alloy plating

ActiveCN105112988APotential stabilityProcess stabilityElectrolysis componentsDual effectPolyethylene glycol

The invention discloses a process of mechanical copper plating and mechanical copper alloy plating and belongs to the technical field of surface plating of a steel product. The process of mechanical copper plating and mechanical copper alloy plating comprises the steps of adjusting the pH value of a plating solution by means of universal mechanical plating equipment, then adding copper powder or copper alloy powder and a sedimentation accelerating agent into the plating solution, and finally a cooper coating or a copper alloy coating is prepared on the surface of the steel product along with the rotation of a plating cylinder of the mechanical plating equipment. The sedimentation accelerating agent adopted by the process is composed of diatomite, sodium gluconate, triethanolamine, stannous salt, ammonium dihydrogen phosphate, polyethylene glycol, OP-10, inorganic acid and a defined amount of water. By adopting the process of mechanical copper plating and mechanical copper alloy plating, the copper powder or the copper alloy powder can subside on the surface of the steel product rapidly, the process is simple, the operation is convenient, and the dual-effect of corrosion prevention and decoration of the steel product can be achieved.

Owner:KUNMING UNIV OF SCI & TECH

Deposition activator for mechanical plating of Zn-Sn alloy

InactiveCN102409335AReduced Plating Process CostsMeets high tin plating requirementsLiquid/solution decomposition chemical coatingPressure inorganic powder coatingFerrous saltsPhosphoric acid

The invention provides a deposition activator for mechanical plating of a Zn-Sn alloy and a preparation method thereof, and belongs to the technical field of surface plating of steel materials. The technical scheme adopted by the invention is as follows: the deposition activator comprises the following components in percentage by mass: 13-55% of stannous salt, 11-45% of ferrous salt, 5-30% of ammonium salt and 10-50% of phosphoric acid. By adopting the deposition activator in the invention, Sn and Zn powder can be subjected to codeposition on the surface of a steel workpiece to form a Zn-Sn alloy plating through reduction deposition, and plating of a Sn-enriched plating with no Sn powder addition and low cost can be realized.

Owner:KUNMING UNIV OF SCI & TECH

Promoter for mechanical plating of copper and copper alloy and use method of promoter

The invention discloses a promoter for mechanical plating of copper and copper alloy, and belongs to the technical field of steel product surface copper plating. The promoter is composed of 0.5%-2% of diatomite, 1%-2% of sodium gluconate, 0.5%-1% of triethanolamine, 1%-3% of ammonium chloride, 78%-83% of tin salt, 5%-8% of ammonium dihydrogen phosphate, 0.5%-2% of boric acid and 5%-10% of polyethylene glycol; all the substances are mixed to form powder, and in use, 40% of the powder promoter, 2%-5% of OP-10, 5%-10% of phosphoric acid and the balance water are prepared to form an aqueous solution according to a certain adding sequence. The promoter is used for forming copper or copper alloy plating on the surface of a steel product through a mechanical plating method, and in the plating process, the usage amount (the unit is milliliter) of the promoter aqueous solution is 8-10 times the surface area (the unit is square meter) of a steel product to be plated. Through the promoter, rapid deposition of copper or copper alloy powder on the surface of the steel product can be achieved, and the copper or copper alloy plating which is smooth in surface and even in color is obtained.

Owner:KUNMING UNIV OF SCI & TECH

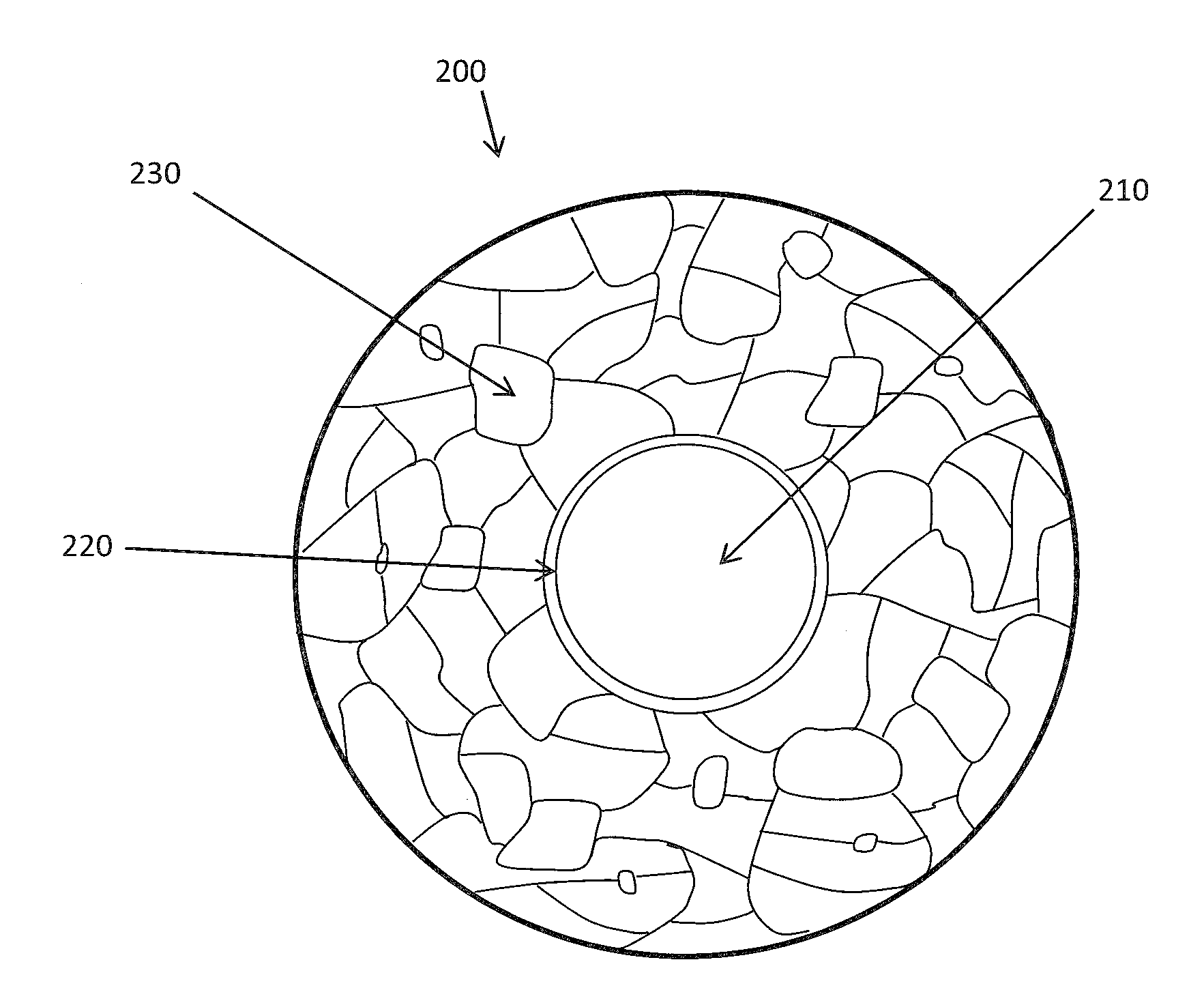

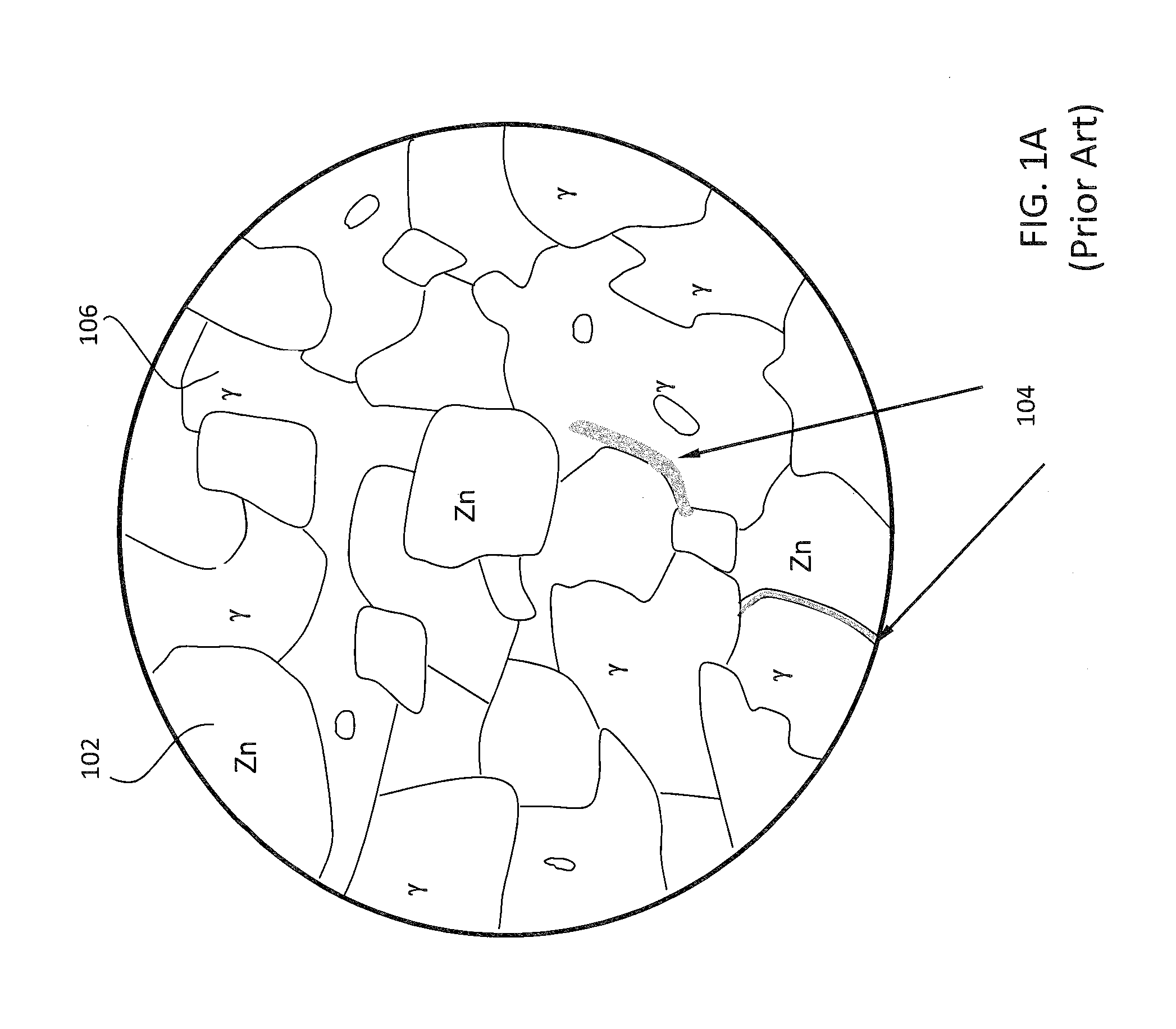

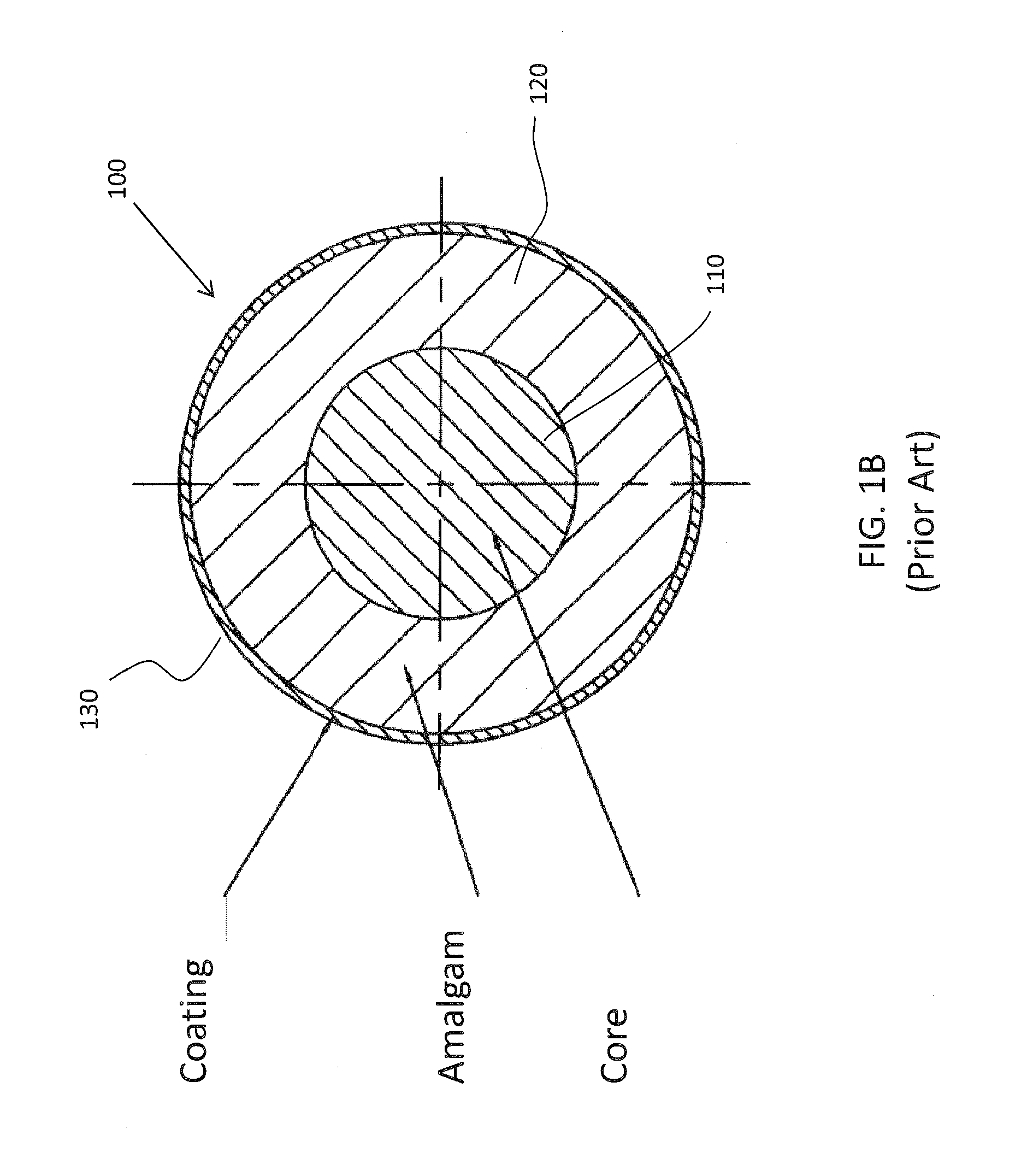

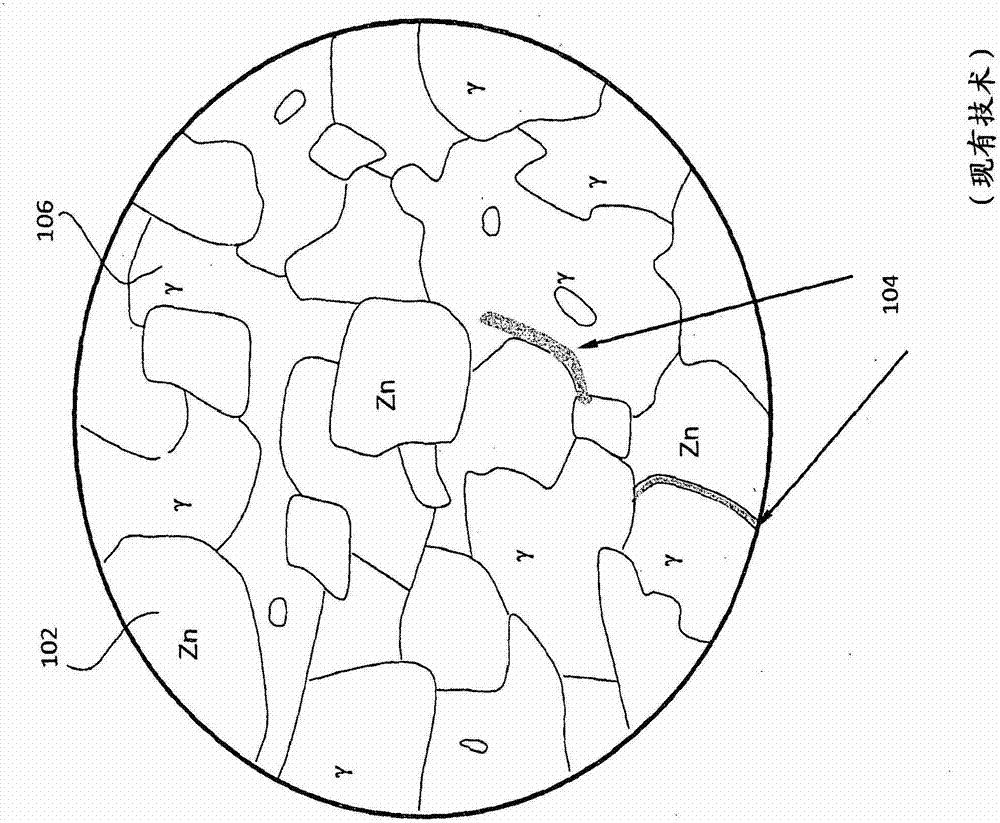

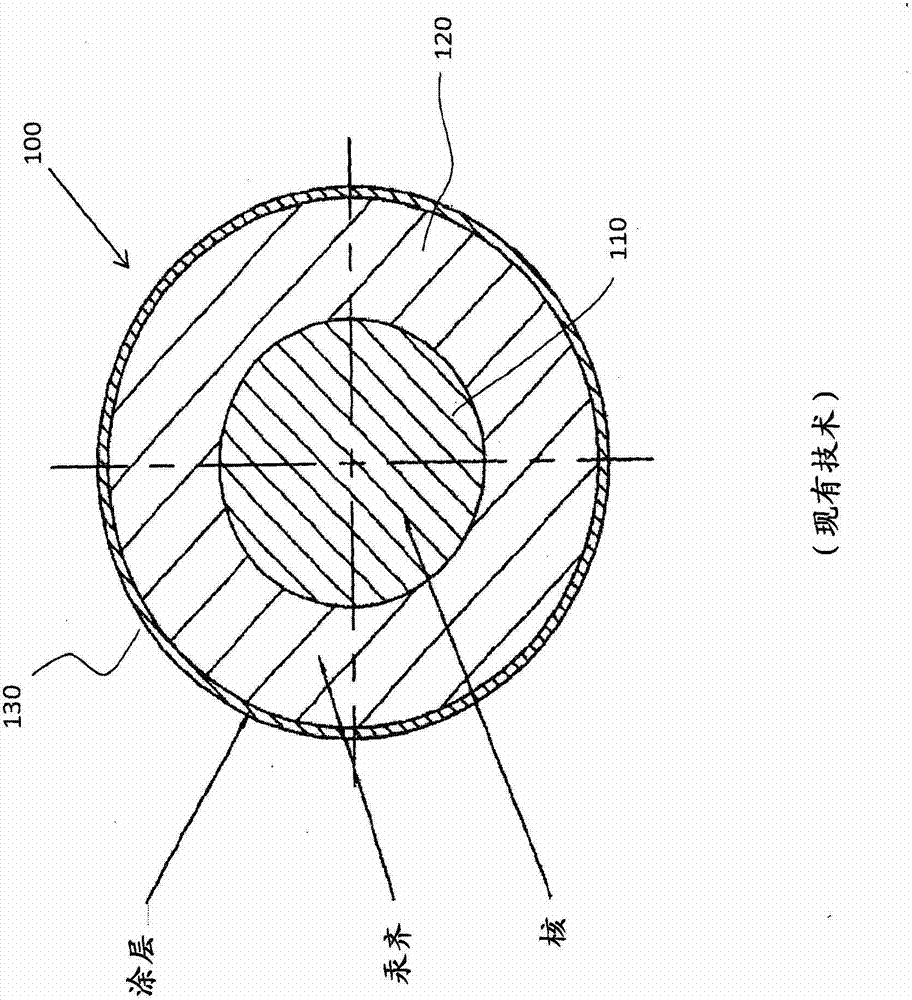

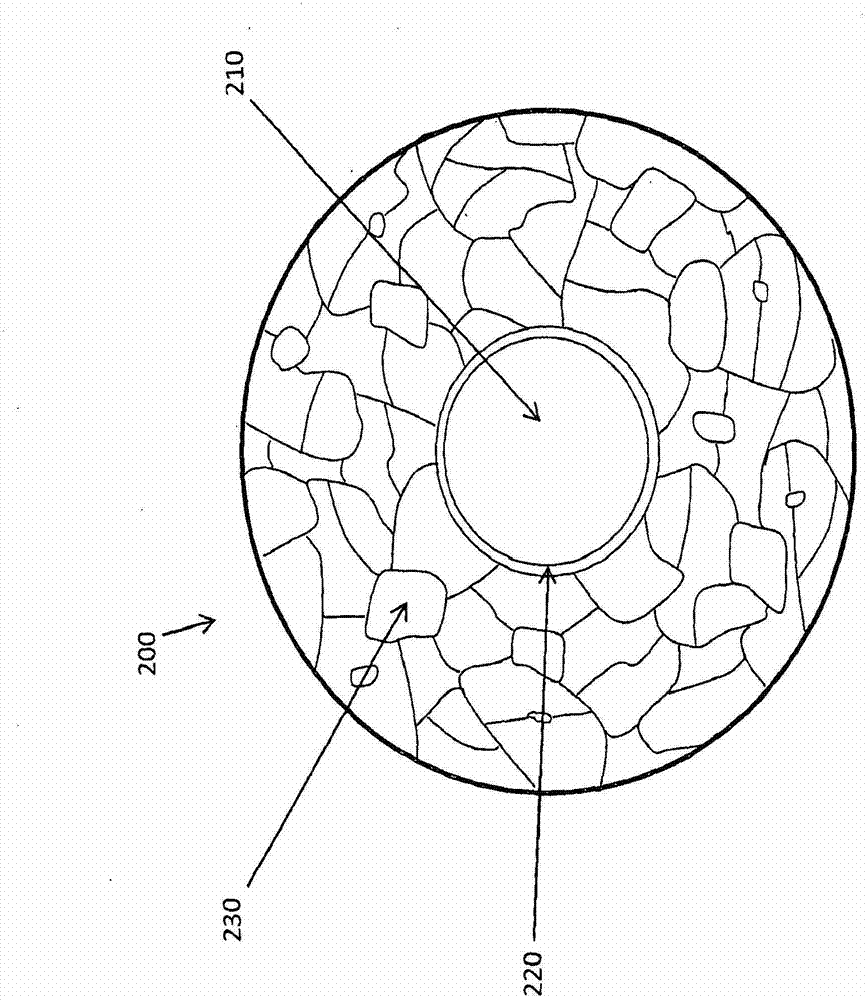

Mechanically plated pellets and method of manufacture

Mechanical plating provides a new technique of manufacturing of certain materials containing multiple elements, including amalgams, and novel pellets containing multiple materials. Some embodiments provide new and versatile materials for dosing mercury, metals or other inorganic compounds into lamps. Some embodiments include materials comprising layers of metals or compounds built up on a substrate. One embodiment is a layer of zinc amalgam applied to a glass sphere. Also disclosed is an improved method of manufacture for such particles that will speed production, increase yields, lower costs and reduce exposure to mercury in the workplace.

Owner:ADVANCED LIGHTING TECH

Shot material for mechanical plating, and high corrosion resistant coating using same

InactiveUS20060263622A1Improve corrosion resistanceImprove coating uniformityAbrasion apparatusThin material handlingZincImpurity

Shot material for mechanical plating is provided, comprising steel core particles clad with an alloy comprising 1 to 5% by weight of aluminum, 3 to 15% by weight of magnesium, preferably 5 to 15% by weight of magnesium, and the balance of zinc and unavoidable impurities. The alloy may contain a total of 1% by weight of impurities. An Fe—Zn alloy layer may be provided between the alloy cladding and the steel core. The shot material may contain 3 to 80% by weight of iron. The preferable average diameter of the shot particles is 100 to 600 μm.

Owner:DOWA TEPPUN INDS +1

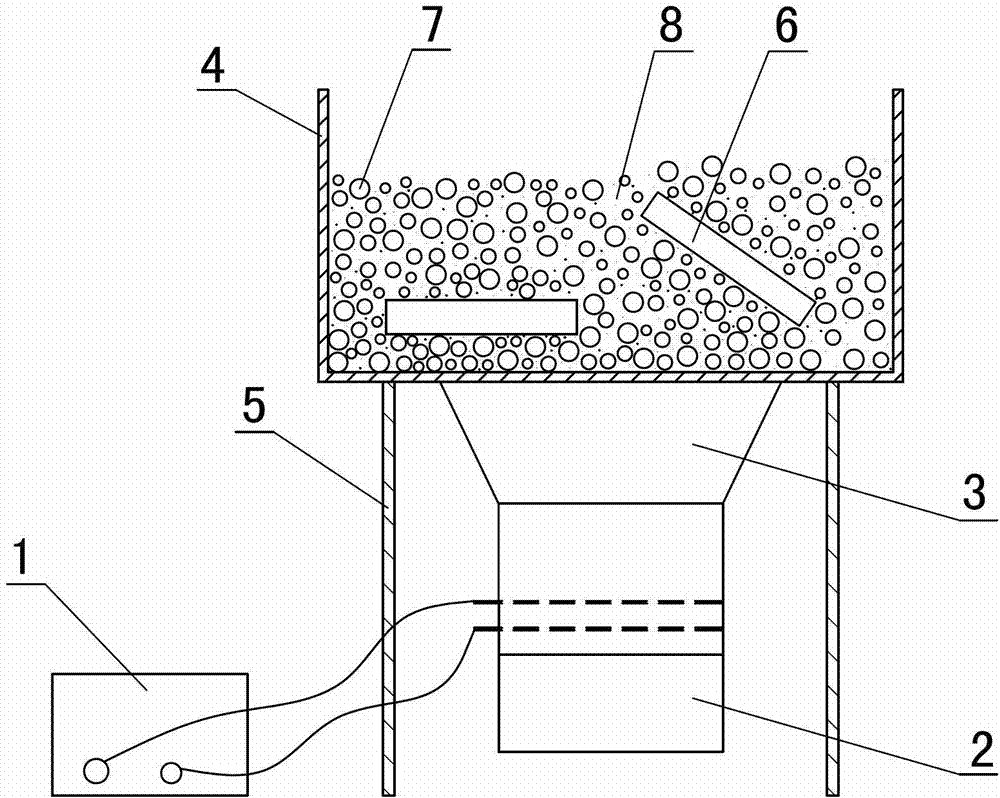

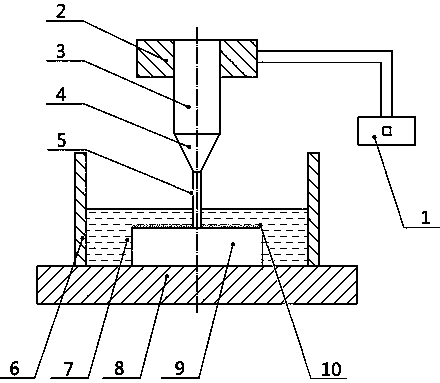

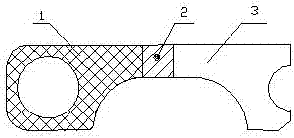

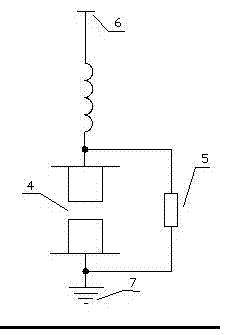

Wet-process ultrasonic mechanical plating device

InactiveCN103205745AChange vibration intensityImprove uniformityPressure inorganic powder coatingWork performanceUltrasonic vibration

The invention provides a wet-process ultrasonic mechanical plating device. The wet-process ultrasonic mechanical plating device comprises an ultrasonic generator, an ultrasonic transducer, an amplitude-change pole, a vibrating slot and a bracket; the wet-process ultrasonic mechanical plating device is characterized in that the vibrating slot is fixedly arranged on the bracket, wherein the bottom of the vibrating slot is fixedly connected with the ultrasonic transducer by the amplitude-change pole; and a wiring end of the ultrasonic transducer is connected with a power supply output end of the ultrasonic generator. According to the wet-process ultrasonic mechanical plating device, the ultrasonic vibrating system is adopted to replace the conventional roller type rotation for driving glass beads to vibrate at a higher frequency, so that the metal powder is collided and twisted to the surface of a workpiece, and therefore, the plating layer is flat, smooth, good in uniformity and high in compactness. Meanwhile, an open type vibrating slot is adopted by the device for carrying out mechanical plating on the components with larger dimensions, so that the working performances are excellent.

Owner:SHANDONG UNIV OF TECH

Shot material for mechanical plating, and high corrosion resistant coating using the same

ActiveCN1869283AImprove corrosion resistanceReduced corrosion resistanceAbrasion apparatusThin material handlingAlloyCorrosion resistant

Shot material for mechanical plating is provided, comprising steel core particles clad with an alloy comprising 1 to 5% by weight of aluminum, 3 to 15% by weight of magnesium, preferably 5 to 15% by weight of magnesium, and the balance of zinc and unavoidable impurities. The alloy may contain a total of 1% by weight of impurities. An Fe-Zn alloy layer may be provided between the alloy cladding and the steel core. The shot material may contain 3 to 80% by weight of iron. The preferable average diameter of the shot particles is 100 to 600 mum.

Owner:DOWA ELECTRONICS MATERIALS CO LTD +1

Mechanically plated pellets and method of manufacture

Mechanical plating provides a new technique of manufacturing of certain materials containing multiple elements, including amalgams, and novel pellets containing multiple materials. Some embodiments provide new and versatile materials for dosing mercury, metals or other inorganic compounds into lamps. Some embodiments include materials comprising layers of metals or compounds built up on a substrate. One embodiment is a layer of zinc amalgam applied to a glass sphere. Also disclosed is an improved method of manufacture for such particles that will speed production, increase yields, lower costs and reduce exposure to mercury in the workplace.

Owner:ADVANCED LIGHTING TECH

Additive for copper deposition in mechanical zinc-copper plating process

The invention discloses an additive for copper deposition in a mechanical zinc-copper plating process, and belongs to the technical field of surface treatment for metal fittings. The additive is prepared from, by mass, 2%-3% of copper sulfate, 0.6%-1% of ascorbic acid, 1%-2% of sodium bentonite, 15%-18% of stannous mono-sulphate, 1%-2% of OP-10, 3%-5% of sulfuric acid, 2%-4% of polyethylene glycol 600 and the balance water. The additive for copper deposition in the mechanical zinc-copper plating process is used in a mechanical plating method for forming a zinc-copper composite plating layer on the surface of a steel product. In the using process, a traditional mechanical zinc plating method is adopted at first for plating the surface of the steel product with a zinc layer with the preset thickness, then, the additive is adopted in an assisted mode for plating the surface of the zinc plating layer with a copper layer, and finally the zinc-copper composite plating layer with excellent corrosion resistance and the beautiful appearance can be obtained on the surface of the steel product.

Owner:KUNMING UNIV OF SCI & TECH

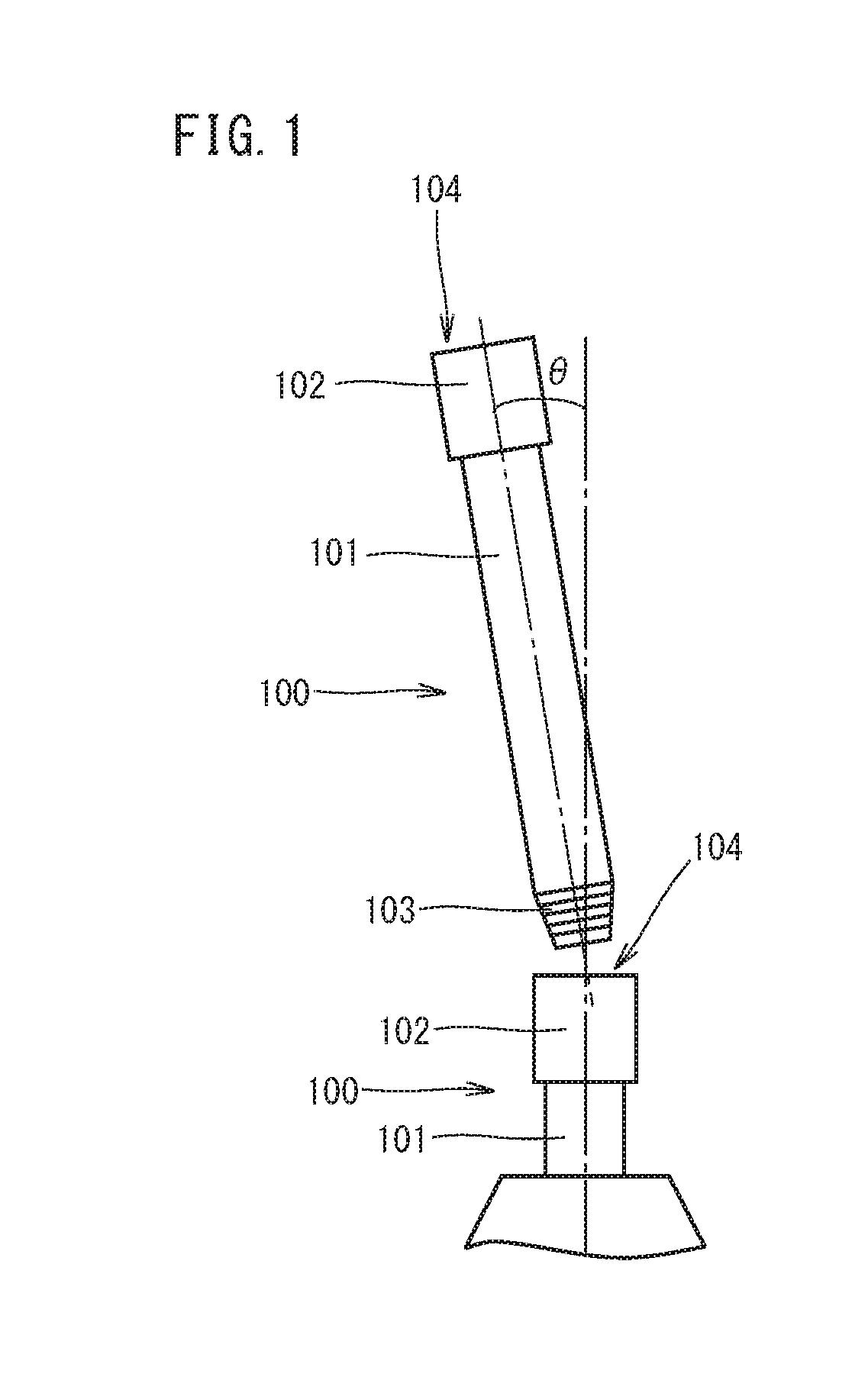

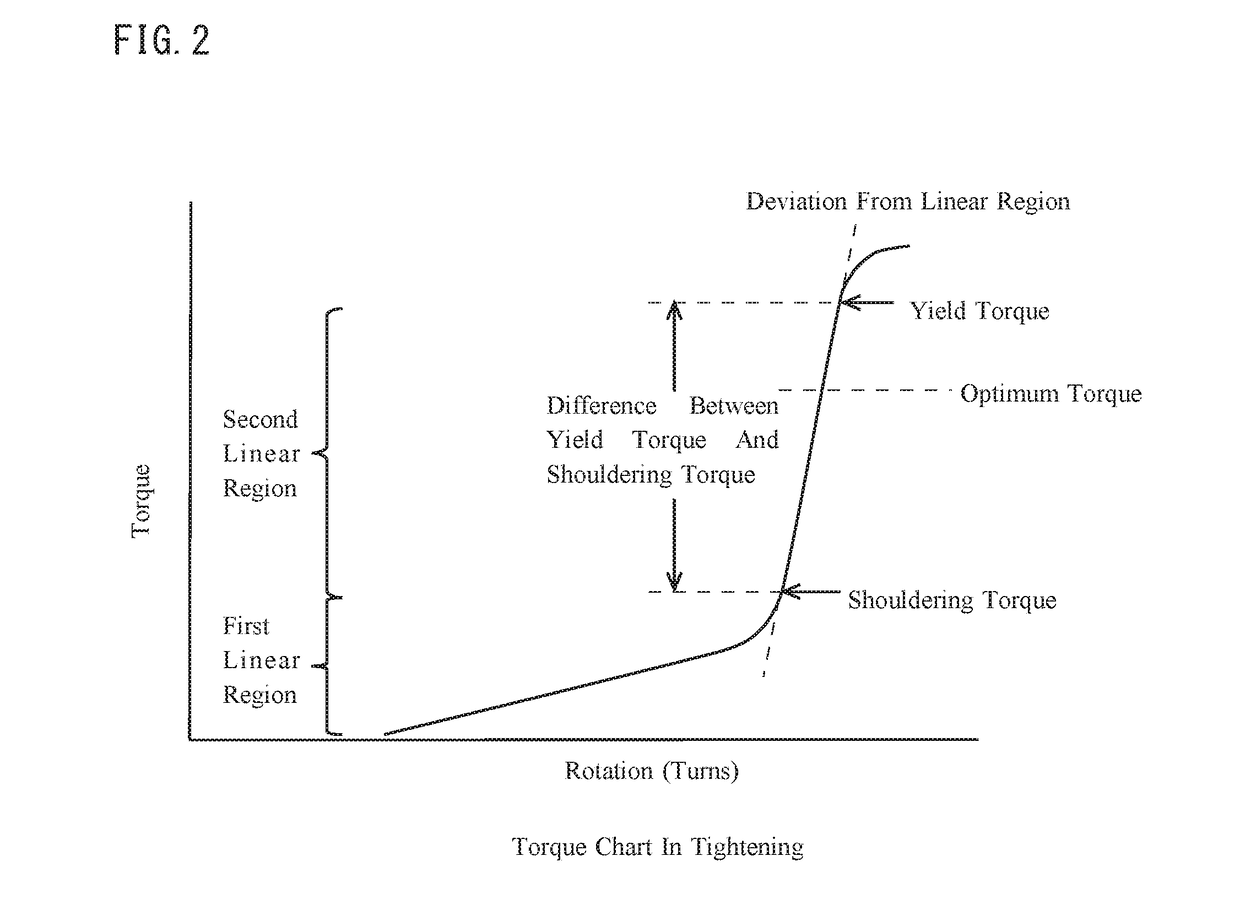

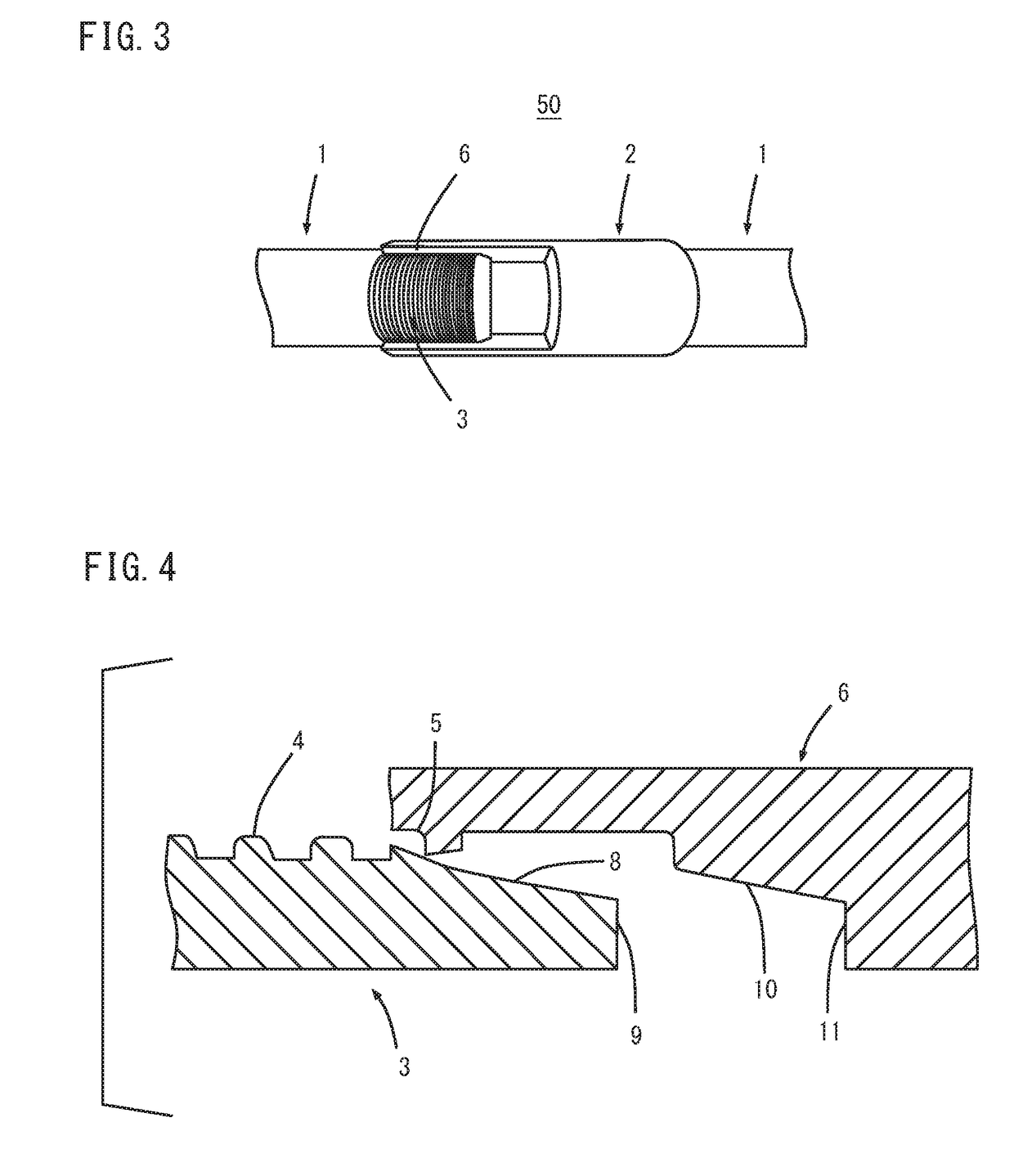

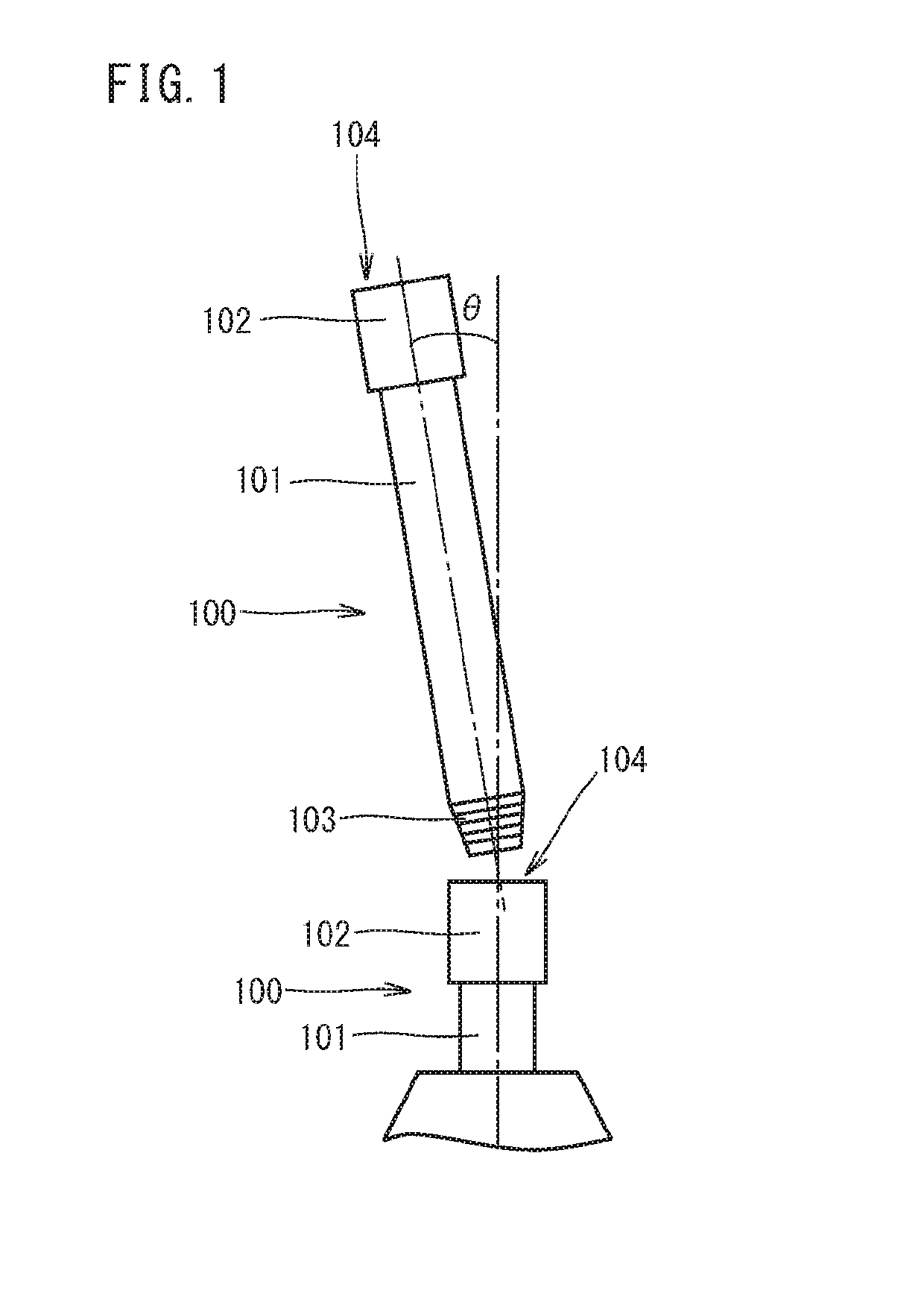

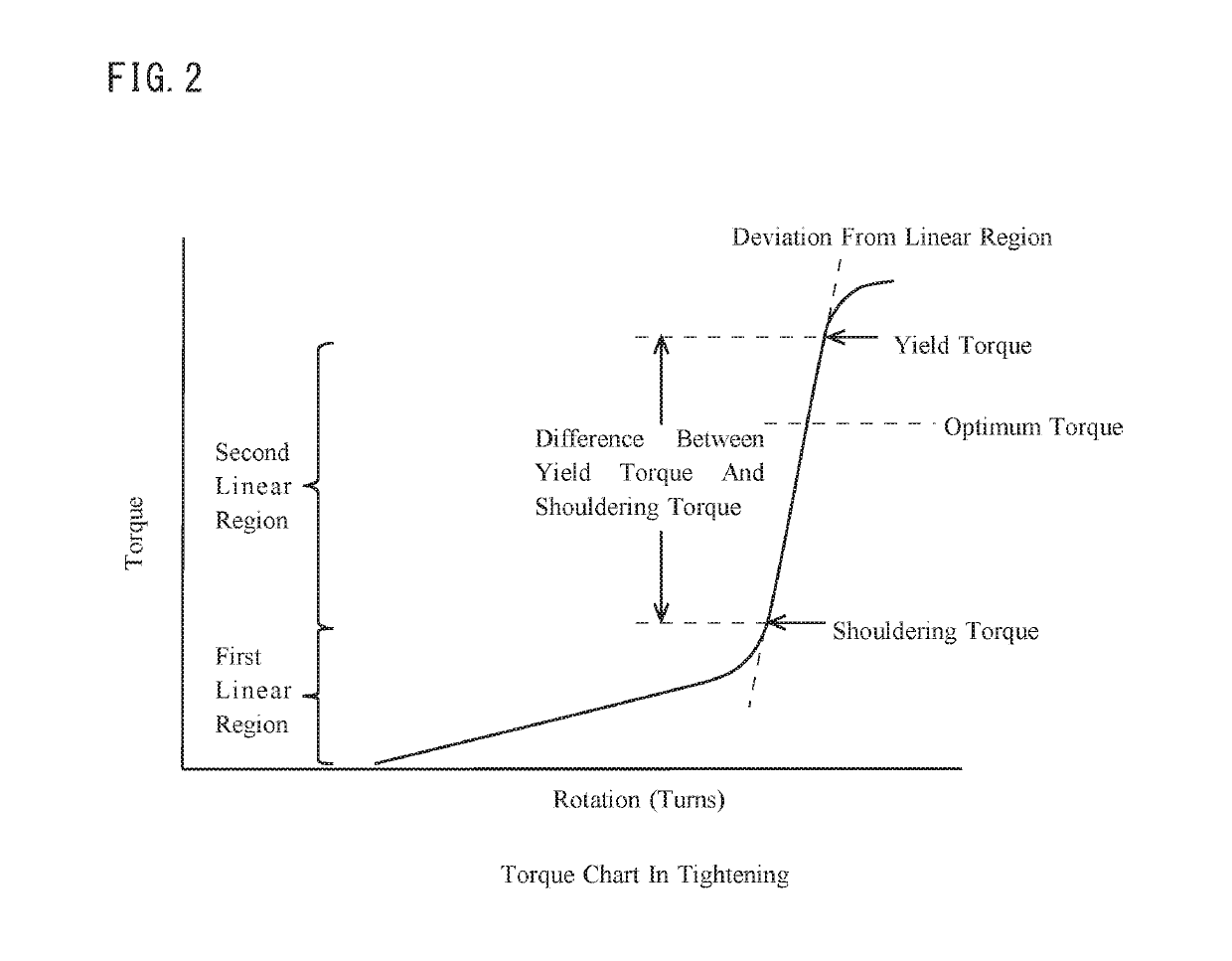

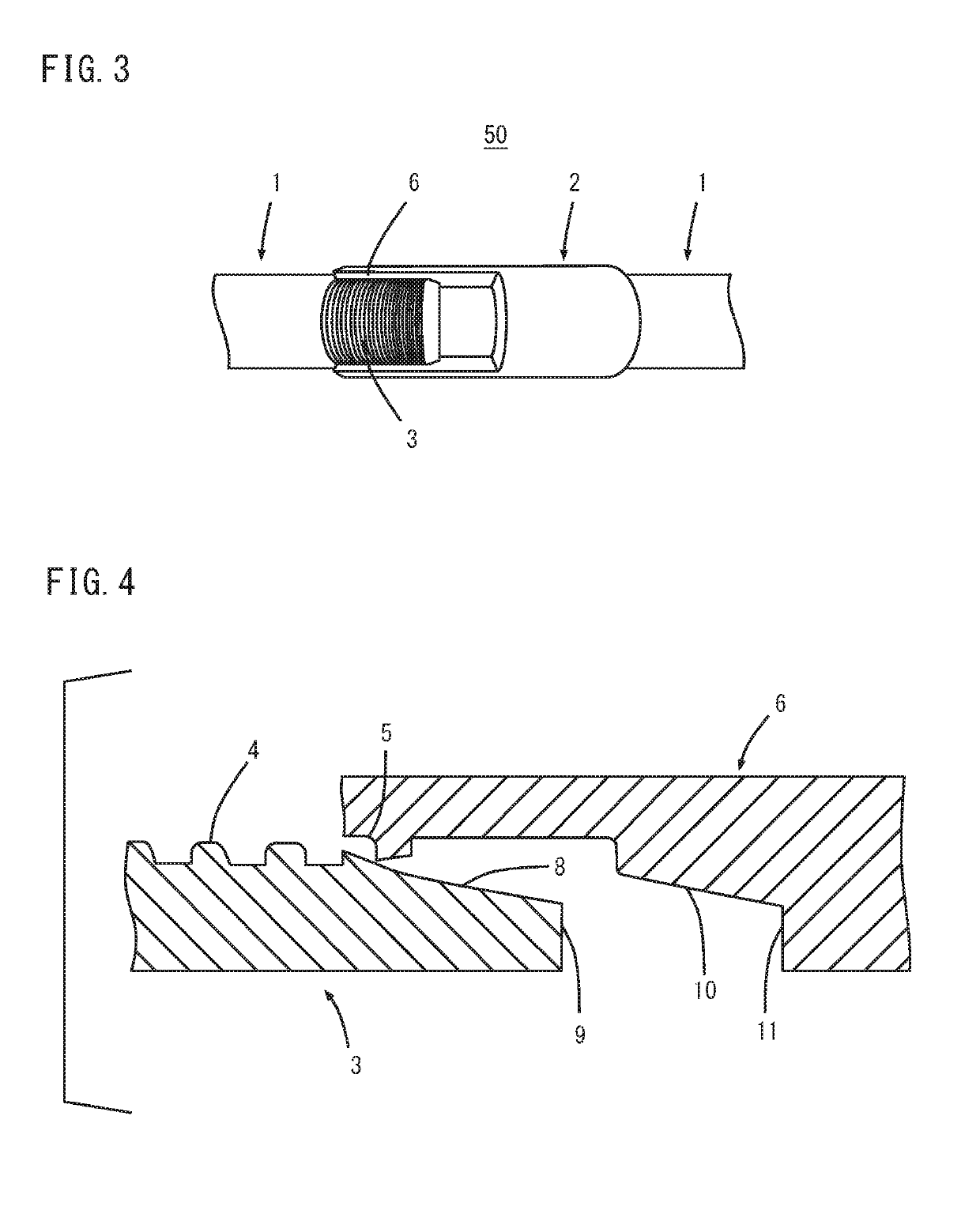

Threaded Connection for Pipe or Tube and Method for Producing the Threaded Connection for Pipe or Tube

The present invention has an objective to provide a threaded connection for pipe or tube including a pin and a box, having excellent galling resistance, torque property, and anticorrosion property, and still having an excellent adhesiveness with a lubricating coating even when being repeatedly exposed to high temperature and very low temperature, and to provide a method for producing the threaded connection for pipe or tube. The threaded connection for pipe or tube according to the present embodiment includes a pin (3) and a box (6). The pin (3) and the box (6) have contact surfaces including a thread portions (4) and (5) and unthreaded metal contact portions (8) and (10), respectively. The threaded connection for pipe or tube comprises an electroplating layer consisting of a Zn—Ni alloy, a mechanical plating layer consisting of Zn or a Zn alloy, and a lubricating coating, on the contact surface of at least one of the pin (3) and the box (6), in this order from a contact surface side.

Owner:VALLOUREC OIL & GAS FRANCE SAS

Numerical control ultrasonic mechanical plating device

The invention discloses a numerical control ultrasonic mechanical plating device. The device comprises an ultrasonic generator, an ultrasonic transducer, an ultrasonic amplitude variation rod, a numerical control platform, a firing pin, a material groove and a fixing device; and the device is characterized in that the material groove is formed in the numerical control platform, a workpiece is placed in the material groove, the upper part of the workpiece is a firing pin, the firing pin is connected to the ultrasonic amplitude variation rod, the ultrasonic amplitude variation rod is connected to the ultrasonic transducer, the ultrasonic transducer is installed on a gantry of the numerical control platform through a fixing device, and the wiring end of the ultrasonic transducer is connectedto the output end of the ultrasonic generator. According to the numerical control ultrasonic mechanical plating device, the numerical control platform is adopted to control the scanning path of the firing pin on the surface of the workpiece, and the metal powder is plated on the surface of the workpiece by the impact action of the firing pin; and parts with larger sizes can be subjected to mechanical plating treatment.

Owner:SHANDONG UNIV OF TECH

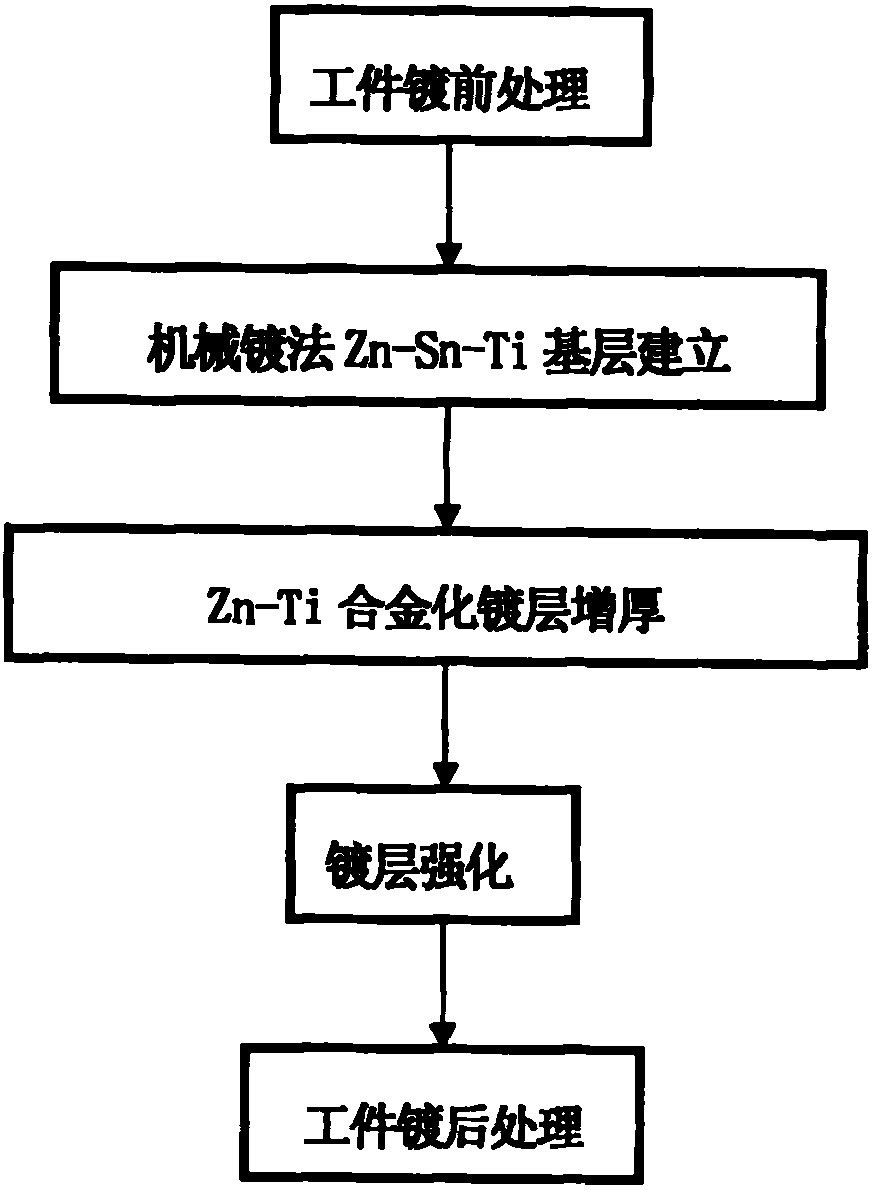

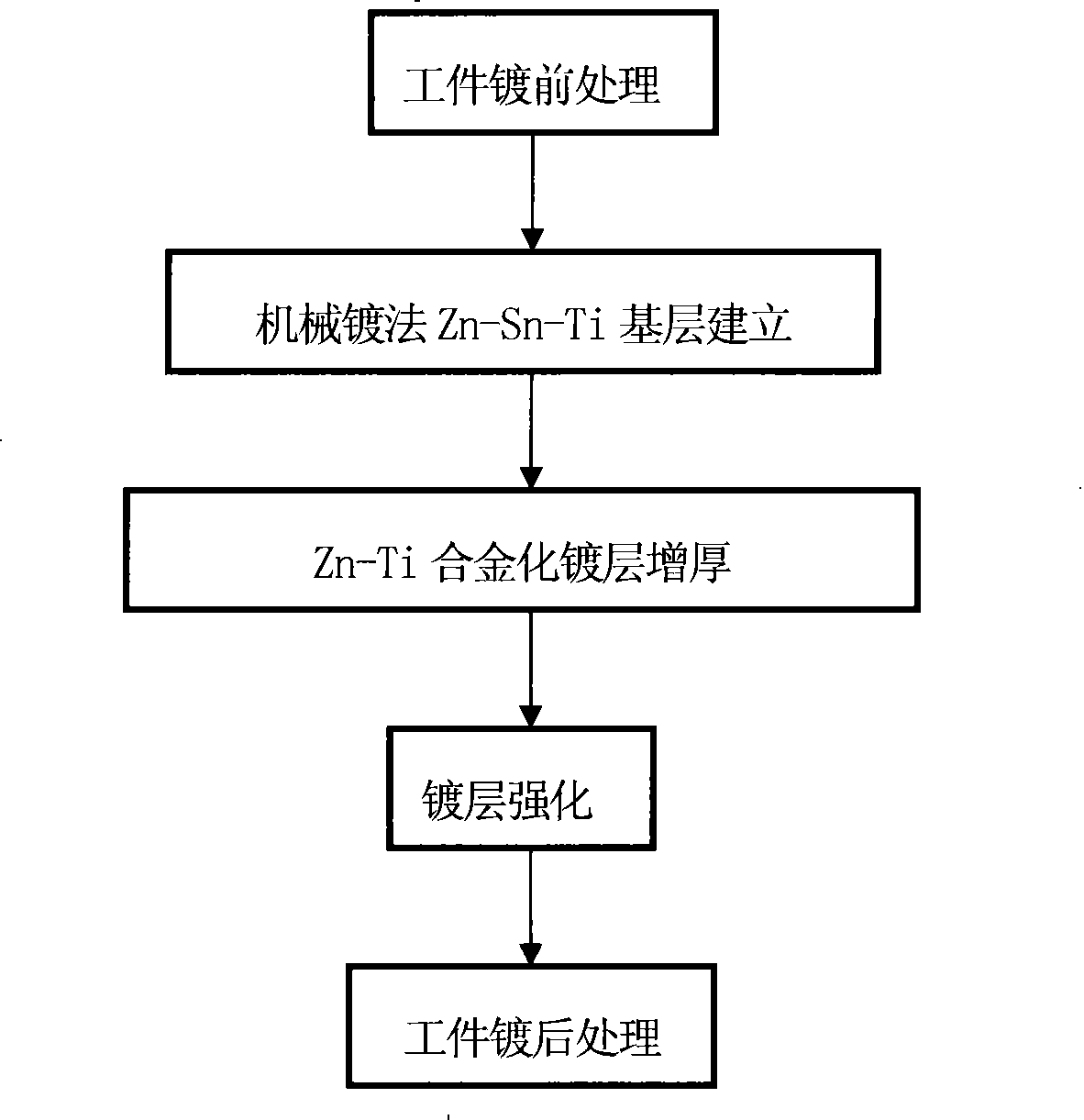

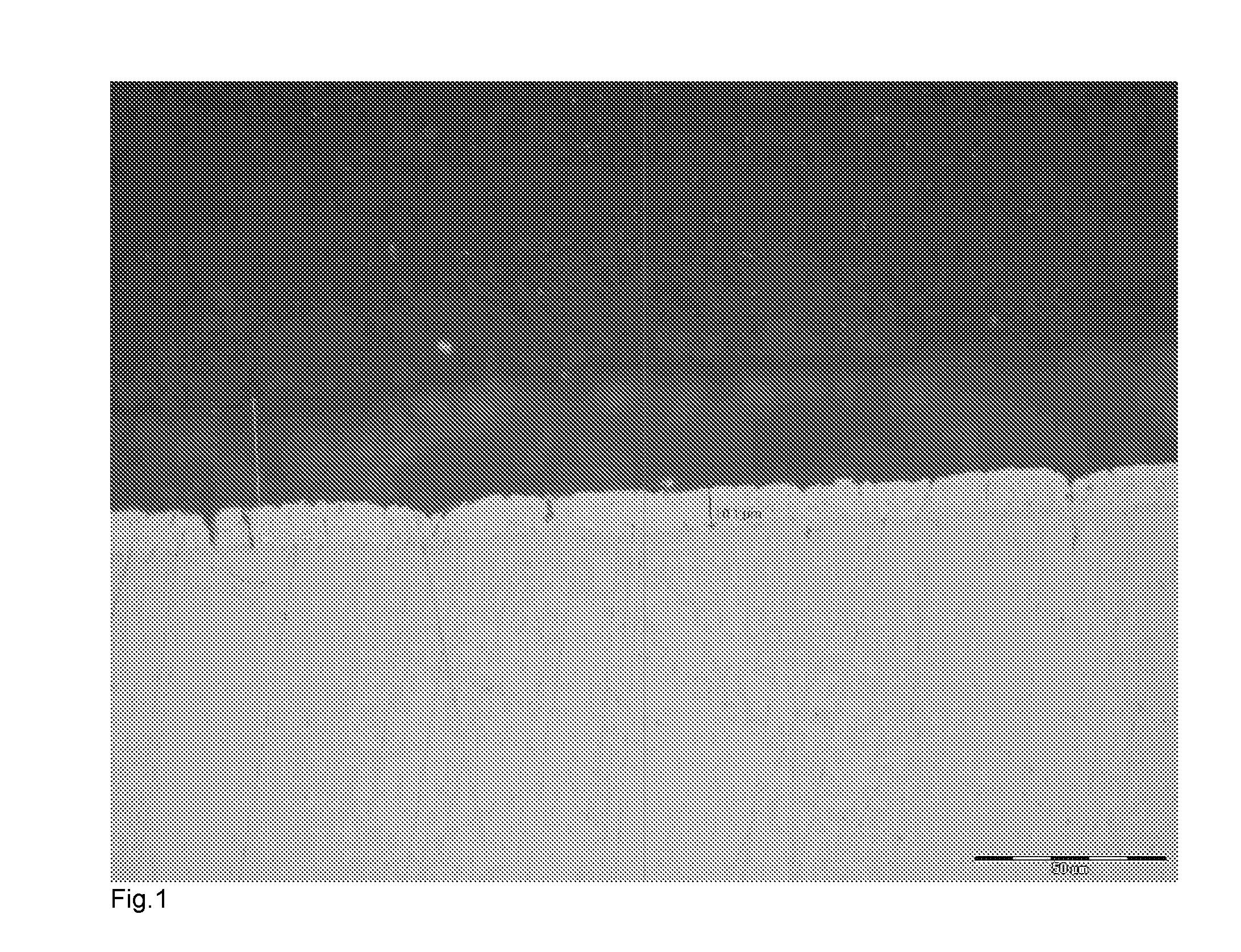

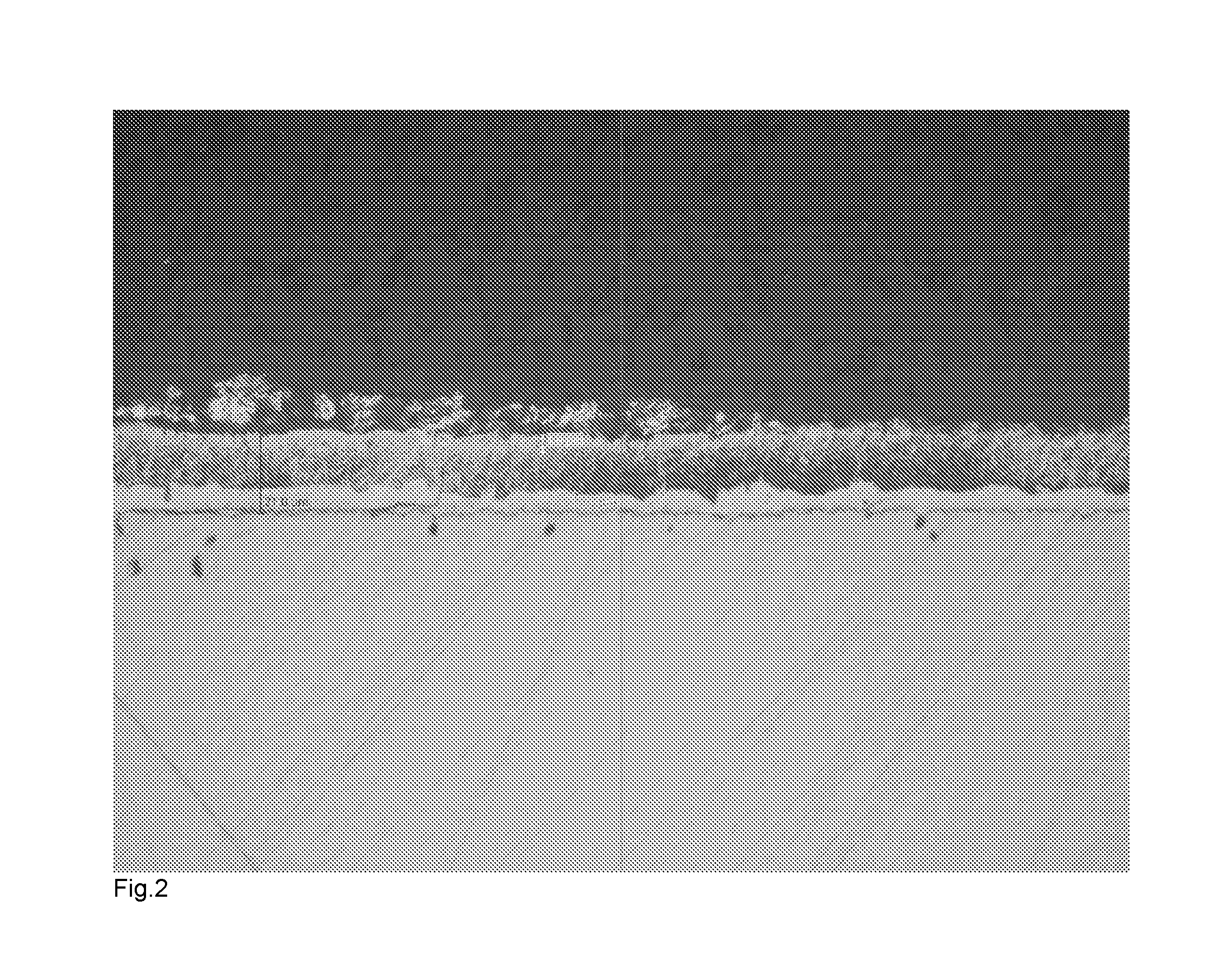

Zinc based titanium alloy coating process for mechanical plating

The invention puts forward a method for forming Zn-Ti alloy plating on the surface of a steel part by adding titanium salts in a mechanical plating process, belonging to the technical field of a surface plating process. The method comprises the following processes of treating a workpiece before plating, building a base layer, thickening alloyed plating, strengthening the plating, etc. After the workpiece is treated before plating at a normal temperature and pressure by use of a mechanical plating method, the workpiece is put into a plating cylinder having impact media and water; then zinc powder, stannous and inorganic titanium salt solution are added in, and the plating cylinder is rotated so as to form an alloy base layer on the surface of a steel matrix; surfactant, sedimentary activator, inorganic titanium salt water-soluble additive and zinc powder are added in for thickening the alloyed plating; and finally, water is added in and the plating cylinder is rotated, so as to strengthen the organization structure of the plating. As inorganic titanium salts are added in the mechanical plating process, under the action of plating solution and an impacting fluid state environment inthe plating cylinder, the titanium salts can improve the deposition characteristics of the metallic zinc powder and are partially reduced and precipitated, so as to increase the strength, hardness and corrosion resistance of the plating.

Owner:KUNMING UNIV OF SCI & TECH

Copper gold powder slurry for mechanical plating and preparation method thereof

The invention discloses copper gold powder slurry for mechanical plating and a preparation method thereof and belongs to the technical field of surface mechanical plating of small hardware. The copper gold powder slurry for mechanical plating is applied to surface mechanical copper plating of steel parts and plating treatment of copper alloys. The copper gold powder slurry is composed of the following materials of 20% of copper gold powder, 5-8% of oxalic acid, 0.5-2% of citric acid, 3-5% of sodium polyacrylate, 1-3% of polyethylene glycol and the balance water; the copper gold powder slurry prepared in certain adding order is used for surface mechanical copper plating of the steel parts and plating treatment of the copper alloys, and traditional powder-shaped copper gold powder is substituted for adding, so that flying and drifting of the copper gold powder in the adding process are avoided, and the operating environment is improved; and in addition, when the copper gold powder slurry is used, adding is convenient, and the current technological process of mechanical zinc-copper plating is not influenced.

Owner:KUNMING UNIV OF SCI & TECH

Alloy coated workpieces

ActiveUS20150203951A1Lower Level RequirementsLevel of corrosion protectionPretreated surfacesSolid state diffusion coatingPowder mixtureZinc alloys

A process for providing a corrosion resistant coating on uncoated ferrous components, involving mechanical plating, using as a coating medium a zinc metal-containing powder, such as zinc or zinc alloy powder, or a powder mixture of zinc or zinc alloy and at least one other metal, so as to build up a firmly adherent coating of the coating medium over exposed surfaces of the components, heating the components with the firmly adherent coating to produce solid-solid diffusion to form an Fe / Zn intermetallic over the surfaces, at least in a base layer of the coating built up by the plating, and cooling the components

Owner:KWIK COAT AUST

Threaded connection for pipe or tube and method for producing the threaded connection for pipe or tube

The present invention has an objective to provide a threaded connection for pipe or tube including a pin and a box, having excellent galling resistance, torque property, and anticorrosion property, and still having an excellent adhesiveness with a lubricating coating even when being repeatedly exposed to high temperature and very low temperature, and to provide a method for producing the threaded connection for pipe or tube. The threaded connection for pipe or tube according to the present embodiment includes a pin and a box. The pin and the box have contact surfaces including a thread portions and and unthreaded metal contact portions, respectively. The threaded connection for pipe or tube comprises an electroplating layer consisting of a Zn—Ni alloy, a mechanical plating layer consisting of Zn or a Zn alloy, and a lubricating coating, on the contact surface of at least one of the pin and the box, in this order from a contact surface side.

Owner:VALLOUREC OIL & GAS FRANCE SAS

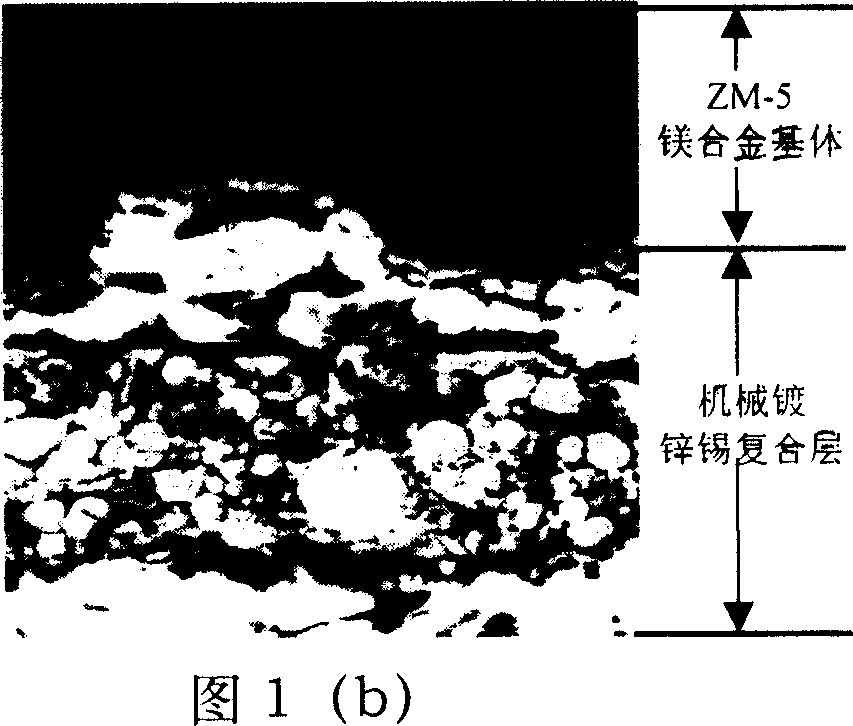

Technology adapted for magnesium alloy matrix surface mechanical zinc-and tin-plating composite coating

InactiveCN100347342COvercome the characteristics of easy to be corrodedNo pollutionPressure inorganic powder coatingTin platingDip-coating

The present invention discloses one kind of mechanical plating technological process to form composite coating on the surface of magnesium alloy base. The present invention includes pre-treatment process for magnesium alloy base, formulation of mechanical plating solution and mechanical plating process. The pre-treatment includes the steps of deoiling, etching, activating and zinc dip coating. The mechanical plating solution consists of base plating solution and dispersant, and the metal powder for the plating consists of zinc powder and tin powder of 200-300 mesh fineness and weight ratio of 0.2-5. The composite coating on the surface of magnesium alloy base is homogeneous, fine and well combined with the base material, and can raise the corrosion resistance of the magnesium alloy base obviously.

Owner:BEIHANG UNIV

A kind of copper-gold powder slurry for mechanical plating and preparation method thereof

The invention discloses copper gold powder slurry for mechanical plating and a preparation method thereof and belongs to the technical field of surface mechanical plating of small hardware. The copper gold powder slurry for mechanical plating is applied to surface mechanical copper plating of steel parts and plating treatment of copper alloys. The copper gold powder slurry is composed of the following materials of 20% of copper gold powder, 5-8% of oxalic acid, 0.5-2% of citric acid, 3-5% of sodium polyacrylate, 1-3% of polyethylene glycol and the balance water; the copper gold powder slurry prepared in certain adding order is used for surface mechanical copper plating of the steel parts and plating treatment of the copper alloys, and traditional powder-shaped copper gold powder is substituted for adding, so that flying and drifting of the copper gold powder in the adding process are avoided, and the operating environment is improved; and in addition, when the copper gold powder slurry is used, adding is convenient, and the current technological process of mechanical zinc-copper plating is not influenced.

Owner:KUNMING UNIV OF SCI & TECH

Mechanical horn plated resistance film insulation sheet

ActiveCN103618976BExtended service lifeSimple manufacturing processTransducer detailsElectrical resistance and conductanceArcing horns

The invention relates to a mechanical horn phenolic laminated cotton board plated resistance film insulation sheet. When the metal contact mechanical and electronic horn is working, a large arc will be generated in the air due to the on-off of the metal contact. The existence of such an arc will affect the conductivity of the metal contact and reduce its working reliability. Horn not working properly. The composition of the present invention includes: a carbon oil resistance film (1), an insulating sheet (3) is treated with via hole copper coating (2), and the carbon oil resistance film (1) is electrically connected on both sides, which is equivalent to connecting a resistor in parallel at both ends of the insulating sheet , Play the role of reducing arcing in the working process of the horn. The invention is applied to mechanical horns.

Owner:HARBIN GOODTIME ELECTRONICS

Preparation method of silver-coated copper composite powder with zinc intermediate layer

ActiveCN113000837APacked tightlyImprove antioxidant capacityTransportation and packagingMetal-working apparatusChemical platingOxidation resistant

The invention discloses a preparation method of silver-coated copper composite powder with a zinc intermediate layer. The preparation method comprises the following steps of: preparing Cu / Zn / Ag three-layer composite powder by using a method of combining mechanical plating and chemical plating, performing alkali washing and degreasing on Cu powder suspension, preparing a mechanical plating Zn material, performing mechanical plating Zn on Cu powder, washing, preparing chemical plating Ag liquid, performing chemical plating Ag on Cu / Zn powder, washing, and drying to obtain the silver-coated copper composite powder with zinc as the intermediate layer. According to the preparation method, the intermediate layer is added, so that the coating of silver on the outer layer and copper on the inner layer is more compact, and the oxidation resistance of silver-plated copper powder is further improved.

Owner:KUNMING UNIV OF SCI & TECH

Processing for forming Zn-Sn alloy layer through mechanical plating and Sn reduction disposition

InactiveCN102409334BImprove uniformityHigh densityPressure inorganic powder coatingFerrous saltsPhosphoric acid

The invention provides a process for forming a Zn-Sn alloy layer through mechanical plating and Sn reduction disposition. The process comprises the steps of workpiece pretreatment before plating, establishment of a base layer on the surface of the workpiece, and alloyed plating thickening. A compound surfactant is used to change the characteristic of a plating solution, thus an environment in which continuous deposition of metal Zn powder on the surface of a plated part can be ensured, adsorption deposition plays a main role, and reduction carrying deposition plays an auxiliary role can be formed; a reduction deposition activator prepared by mixing a stannous salt, a ferrous salt, an ammonium salt, phosphoric acid and water is used for supplying Si element for the Zn-Sn plating layer through mechanical plating. The plating is smooth, bright, good in uniformity and high in compactness. As no metal Sn powder is adopted, carrying deposition of crude and large particles can be avoided, the reduced Sn atoms are preferentially adsorbed on the Zn powder and Zn powder alga-gobbets while the size of the Sn atoms is far less than that of the Zn powder and Zn powder alga-gobbets, under the same movement and impact conditions, the layer formation conditions of the plating are changed toward the direction favor of compaction and leveling, the utilization rate of non-ferrous metal is beneficial to being improved, and the production cost is lowered.

Owner:KUNMING UNIV OF SCI & TECH

A kind of additive for zinc-copper composite mechanical plating

The invention discloses an addition agent for zinc-copper composite mechanical plating, and belongs to the technical field of hardware surface treatment. The addition agent comprises, by mass percent, 3% to 6% of copper sulfate, 1% to 2% of sodium citrate, 1% to 2% of sodium bentonite, 0.3% to 0.5% of salicylic acid, 6% to 10% of stannous chloride, 10% to 15% of citric acid, 10% to 13% of polyethylene glycol 1000 and the balance water. The addition agent is in a water solution state, and is convenient to use, during adding use, the agent can be directly weighed and used, further expansion is not needed, during use, the adding amount is related with the surface area of a product to be subject to steel plating, components of the addition agent are common raw materials, the raw material source and purchasing are convenient, by the adoption of the addition agent, a zinc-copper composite mechanical coating can be prepared on the surface of the steel product, and dual effects of surface protection and decoration can be obtained.

Owner:KUNMING UNIV OF SCI & TECH

A kind of accelerator for mechanical copper plating and copper alloy and using method thereof

The invention discloses a promoter for mechanical plating of copper and copper alloy, and belongs to the technical field of steel product surface copper plating. The promoter is composed of 0.5%-2% of diatomite, 1%-2% of sodium gluconate, 0.5%-1% of triethanolamine, 1%-3% of ammonium chloride, 78%-83% of tin salt, 5%-8% of ammonium dihydrogen phosphate, 0.5%-2% of boric acid and 5%-10% of polyethylene glycol; all the substances are mixed to form powder, and in use, 40% of the powder promoter, 2%-5% of OP-10, 5%-10% of phosphoric acid and the balance water are prepared to form an aqueous solution according to a certain adding sequence. The promoter is used for forming copper or copper alloy plating on the surface of a steel product through a mechanical plating method, and in the plating process, the usage amount (the unit is milliliter) of the promoter aqueous solution is 8-10 times the surface area (the unit is square meter) of a steel product to be plated. Through the promoter, rapid deposition of copper or copper alloy powder on the surface of the steel product can be achieved, and the copper or copper alloy plating which is smooth in surface and even in color is obtained.

Owner:KUNMING UNIV OF SCI & TECH

Alloy coated workpieces

ActiveUS9885103B2Good baseExtended durationSolid state diffusion coatingPressure inorganic powder coatingPowder mixtureZinc metal

A process for providing a corrosion resistant coating on uncoated ferrous components, involving mechanical plating, using as a coating medium a zinc metal-containing powder, such as zinc or zinc alloy powder, or a powder mixture of zinc or zinc alloy and at least one other metal, so as to build up a firmly adherent coating of the coating medium over exposed surfaces of the components, heating the components with the firmly adherent coating to produce solid-solid diffusion to form an Fe / Zn intermetallic over the surfaces, at least in a base layer of the coating built up by the plating, and cooling the components.

Owner:KWIK COAT AUST

A kind of additive for depositing copper in mechanical galvanizing-copper process

The invention discloses an additive for copper deposition in a mechanical zinc-copper plating process, and belongs to the technical field of surface treatment for metal fittings. The additive is prepared from, by mass, 2%-3% of copper sulfate, 0.6%-1% of ascorbic acid, 1%-2% of sodium bentonite, 15%-18% of stannous mono-sulphate, 1%-2% of OP-10, 3%-5% of sulfuric acid, 2%-4% of polyethylene glycol 600 and the balance water. The additive for copper deposition in the mechanical zinc-copper plating process is used in a mechanical plating method for forming a zinc-copper composite plating layer on the surface of a steel product. In the using process, a traditional mechanical zinc plating method is adopted at first for plating the surface of the steel product with a zinc layer with the preset thickness, then, the additive is adopted in an assisted mode for plating the surface of the zinc plating layer with a copper layer, and finally the zinc-copper composite plating layer with excellent corrosion resistance and the beautiful appearance can be obtained on the surface of the steel product.

Owner:KUNMING UNIV OF SCI & TECH

A kind of deposition accelerator and application for mechanical copper plating and copper alloy coating

ActiveCN105112904BPowdering speed is fastUniform colorMetallic material coating processesCopper coatingSodium gluconate

Owner:KUNMING UNIV OF SCI & TECH

A kind of mechanical copper plating and copper alloy process

ActiveCN105112988BProcess stabilityPotential stabilityElectrolysis componentsProcess equipmentPolyethylene glycol

The invention discloses a mechanical copper plating and copper alloy process, which belongs to the technical field of surface plating of iron and steel parts. The mechanical copper plating and copper alloy process of the present invention is by means of general mechanical plating equipment, by adjusting the pH value of plating solution, then adding copper powder or copper alloy powder and deposition accelerator in plating solution, along with the plating of mechanical plating equipment The drum is rotated to finally prepare a copper layer or a copper alloy layer on the surface of the steel part. The deposition accelerator used in the process of the present invention for copper plating consists of diatomaceous earth, sodium gluconate, triethanolamine, stannous salt, ammonium dihydrogen phosphate, polyethylene glycol, OP-10, phosphoric acid, and an appropriate amount of water. By adopting the mechanical copper plating and copper alloy process of the present invention, rapid deposition of copper or copper alloy powder on the surface of steel parts can be realized, the process is simple, the operation is convenient, and the double effect of anticorrosion and decoration of steel parts can be achieved.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com