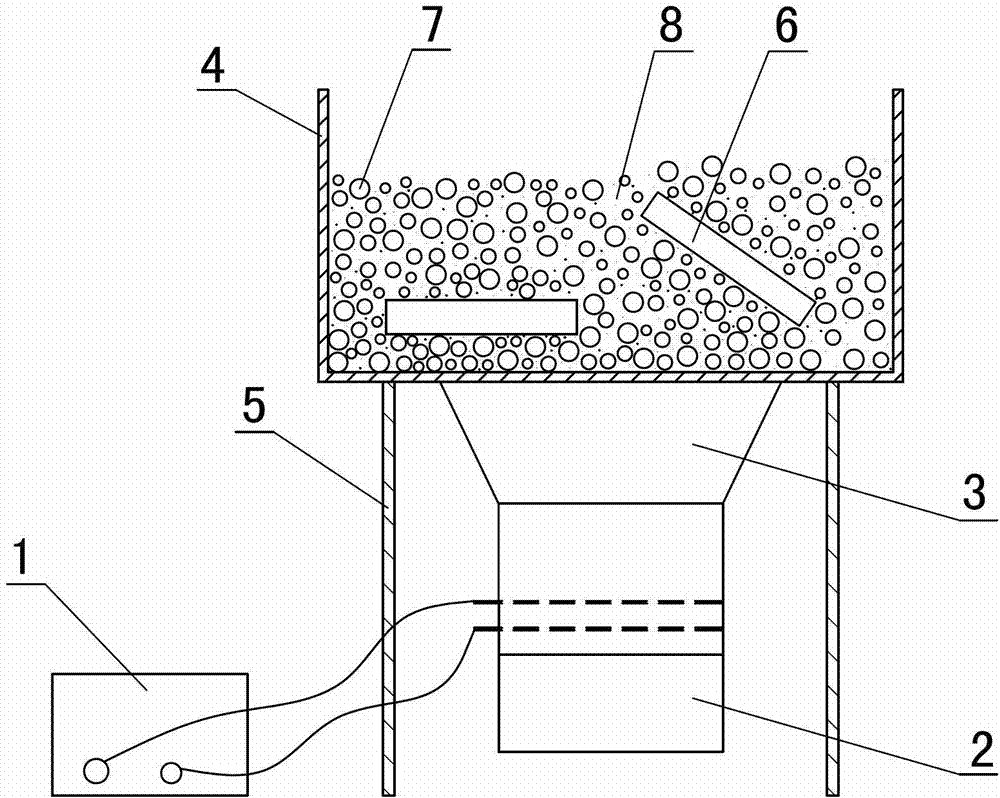

Wet-process ultrasonic mechanical plating device

A mechanical plating and ultrasonic technology, applied in the direction of pressure inorganic powder plating, etc., can solve the problems of high noise, limited workpiece size, complex transmission system, etc., and achieve the effect of high density, smooth coating and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] exist figure 1 In the shown embodiment: the vibration tank 4 adopts a stainless steel tank with an open upper end and an inner wall coated with epoxy paint, and is fixedly installed on the bracket 5. The bottom of the vibration tank 4 is glued to the ultrasonic transducer 2 via the horn 3. It is double fastened and connected with screws, the vibration frequency of the ultrasonic transducer 2 is 20KHz-50KHz, and its wiring terminal is connected to the power output end of the ultrasonic generator 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com