Local chemical-plating technique for aluminum radiator bores

A local chemical and heat sink technology, applied in hot-dip plating process, liquid chemical plating, heat exchanger shell, etc., can solve the problems of high cost of aluminum heat sink and high cost of nickel-phosphorus alloy, and save nickel resources , easy to achieve, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

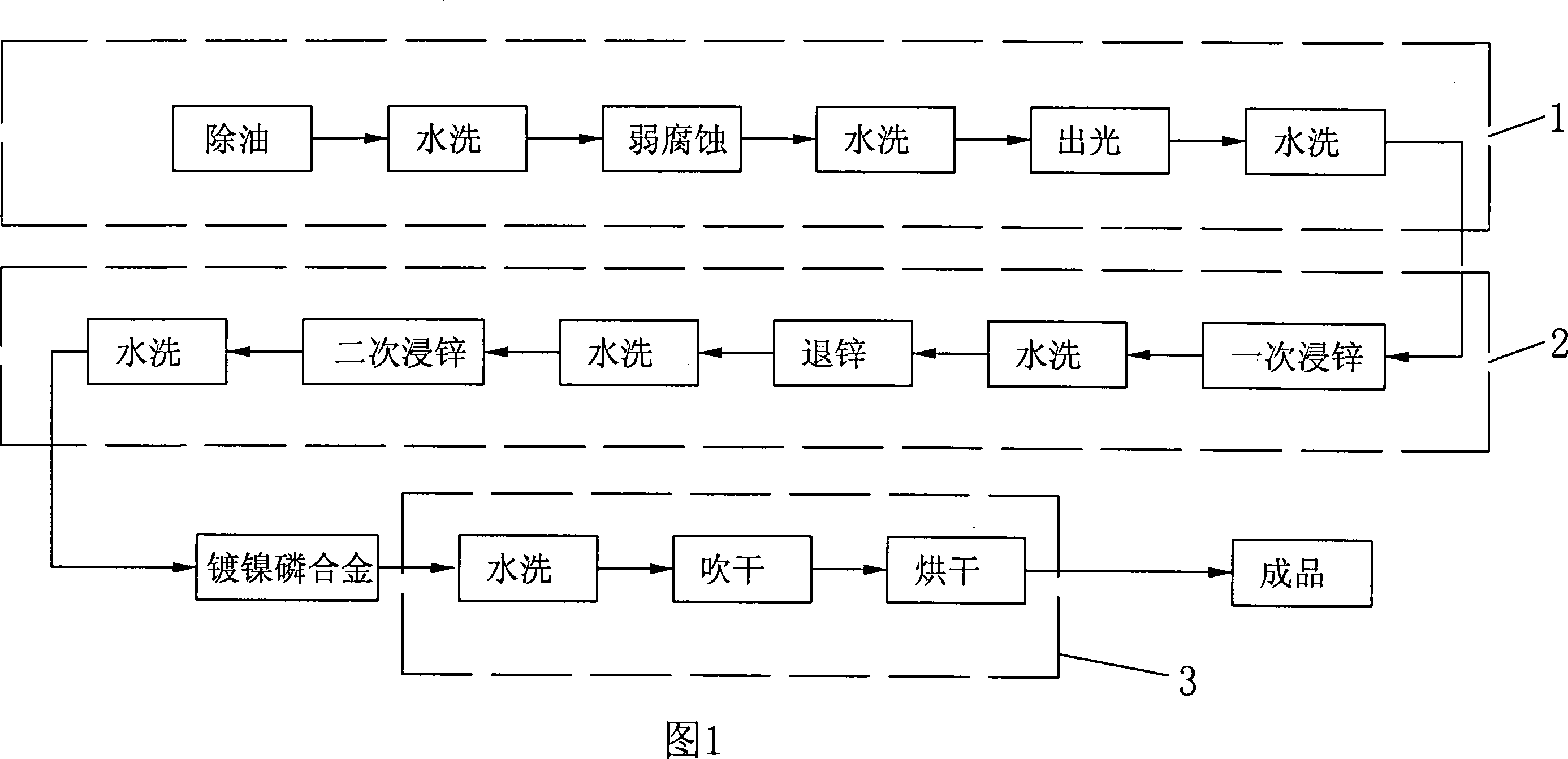

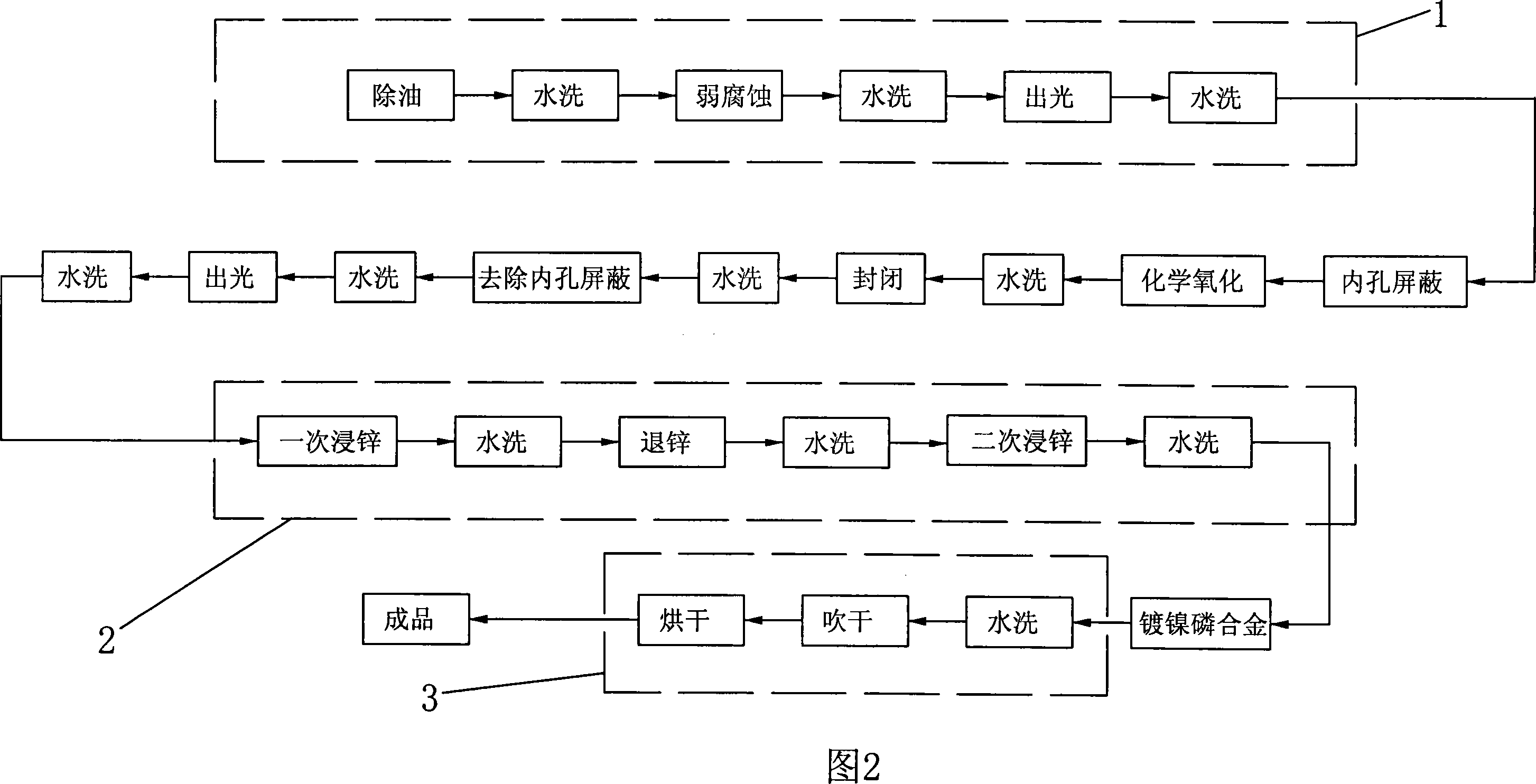

[0047] For further revealing the present invention, below in conjunction with embodiment is described, shown in accompanying drawing 2, it comprises the following steps:

[0048] The first step is to pre-treat the aluminum radiator, which is to degrease, wash, weakly corrode (weakly corrode it with lye), wash, light (pickling), and wash the aluminum radiator in sequence. Each process in the process is the same as the current existing process;

[0049] Step 2, shielding the inner hole, take a rubber tube that is longer than the length of the inner hole and smaller in diameter than the inner hole, one end of the rubber tube is closed, the other end of the rubber tube is connected to the inflator, and then the rubber tube is inserted Into the inner hole of the aluminum radiator, and then inflate the rubber tube through the air compressor, which is to connect the inflator to the air compressor, and then inflate the rubber tube through the inflator, the rubber tube expands and stic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com