Pad design for electrochemical mechanical polishing

a technology of mechanical polishing and plating pads, applied in the direction of electrolysis processes, electrolysis components, lapping tools, etc., can solve the problems of excessive conditioning, non-planar feature side of the substrate, and needing planarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The words and phrases used in the present invention should be given their ordinary and customary meaning in the art by one skilled in the art unless otherwise further defined. The embodiments described herein may relate to removing material from a substrate, but may be equally effective for electroplating a substrate by adjusting the polarity of an electrical source. Common reference numerals may be used in the Figures, where possible, to denote similar elements depicted in the Figures.

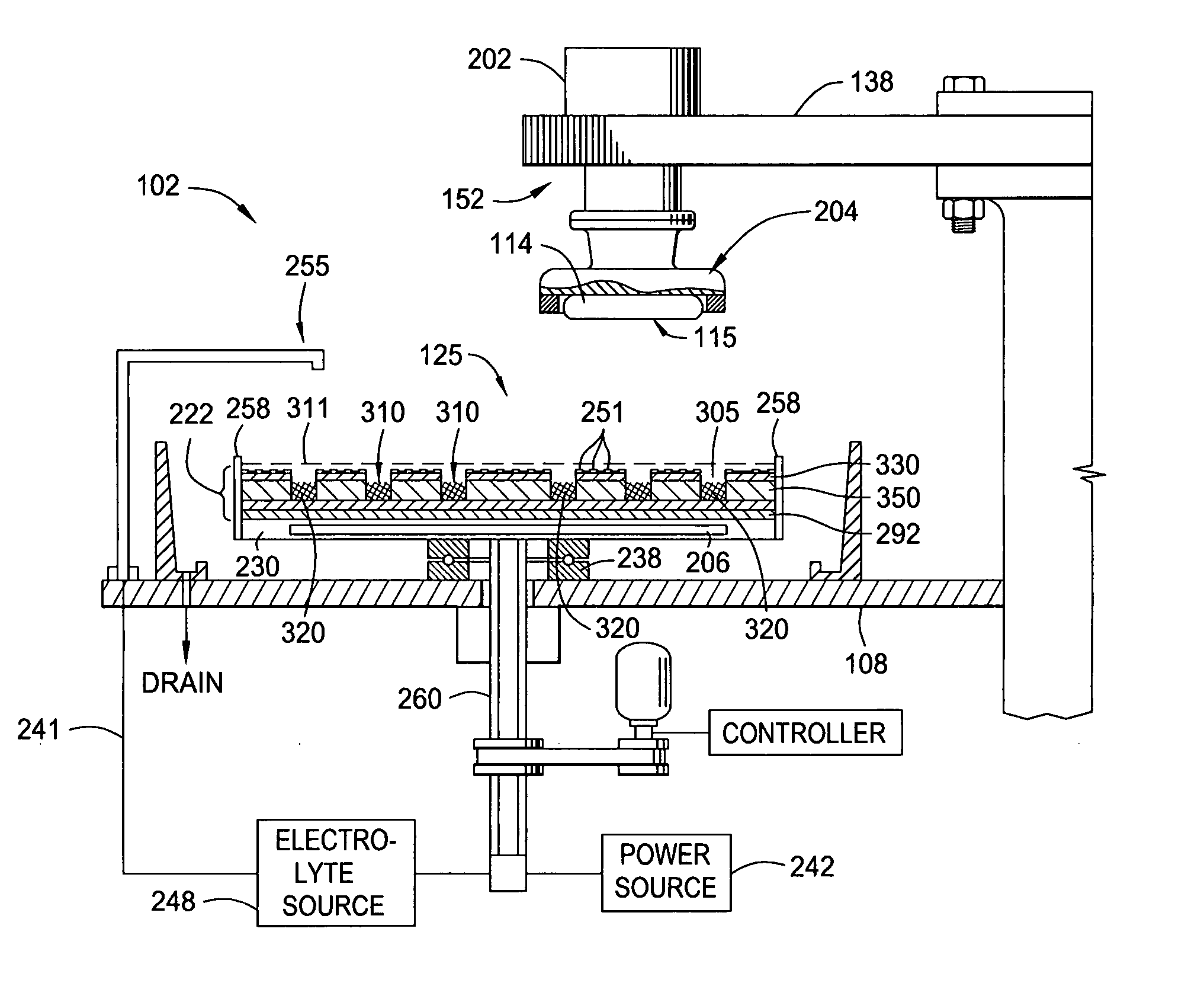

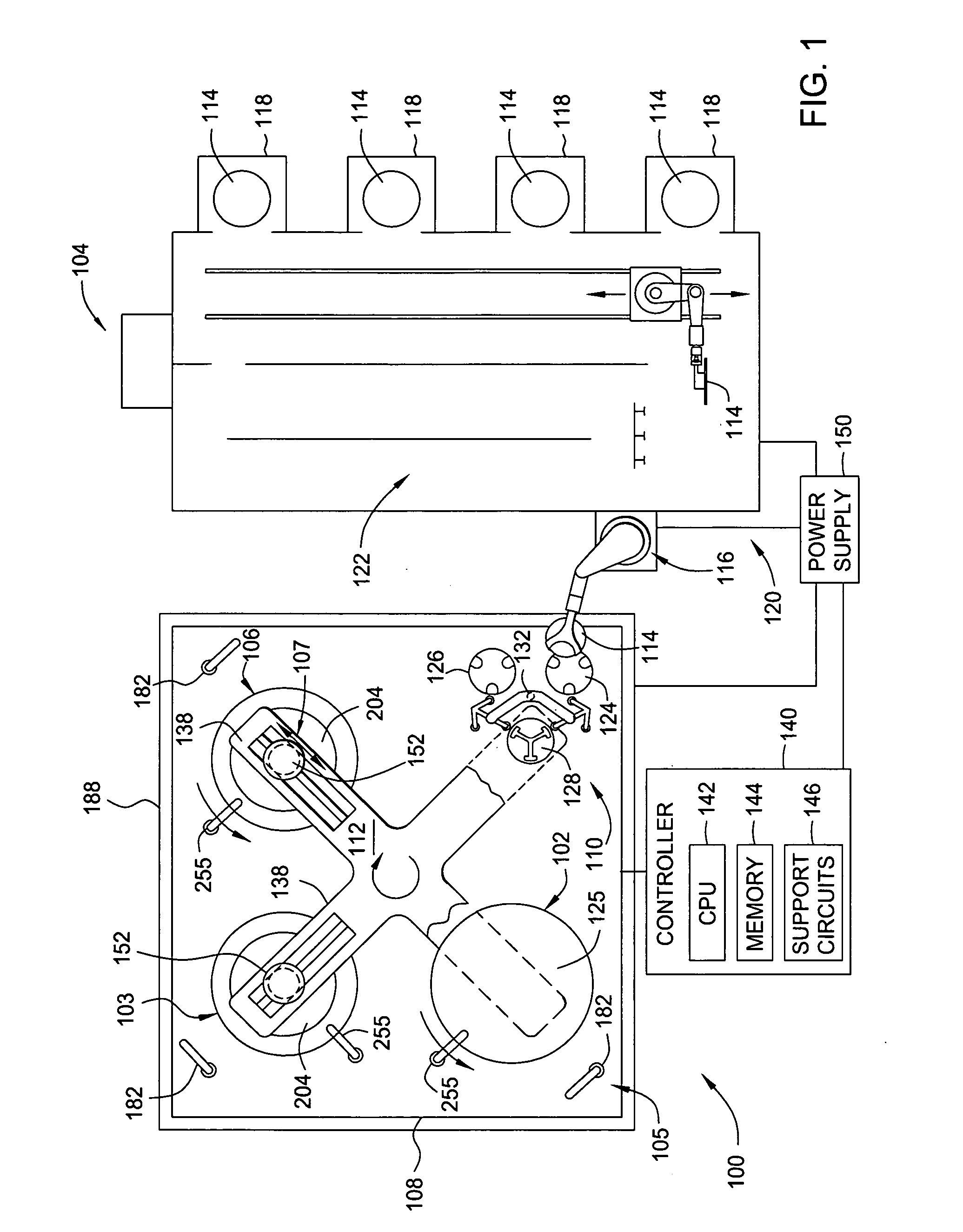

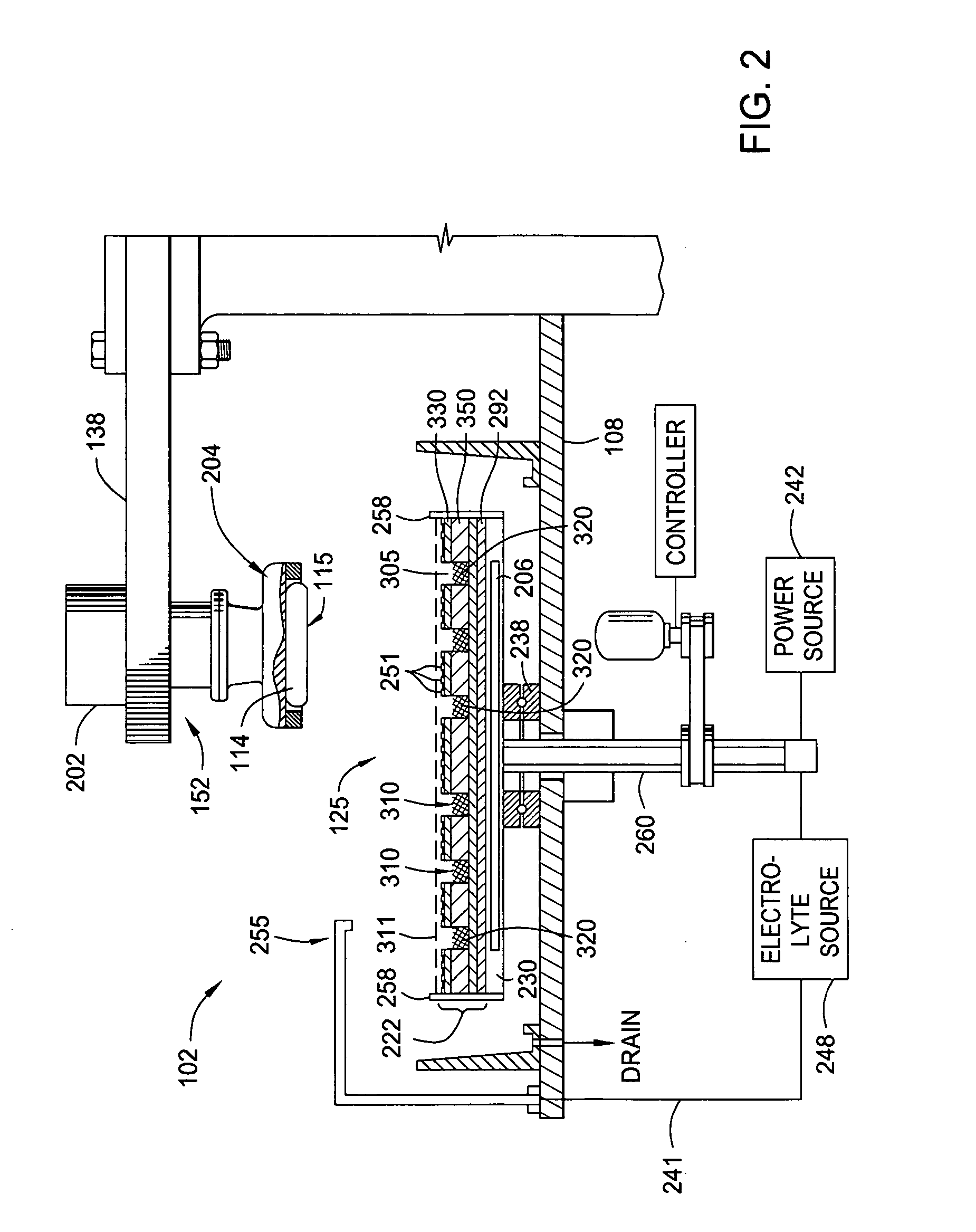

[0028]FIG. 1 is a plan view a processing system 100 having a planarizing module 105 that is suitable for electrochemical mechanical polishing and chemical mechanical polishing. The planarizing module 105 includes at least a first electrochemical mechanical planarization (ECMP) station 102, and optionally, at least one conventional chemical mechanical planarization (CMP) station 106 disposed in an environmentally controlled enclosure 188. An example of a processing system 100 that may be adapte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conductive | aaaaa | aaaaa |

| pressure sensitive | aaaaa | aaaaa |

| thermal sensitive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com