Mechanical horn plated resistance film insulation sheet

A technology of insulating sheet and resistive film, applied in the direction of electrical components, sensors, sensor parts, etc., can solve the problems of affecting the conductivity of metal contacts, reducing reliability, and the speaker not working normally, so as to simplify the manufacturing process and reduce the cost. , the effect of saving internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

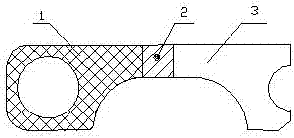

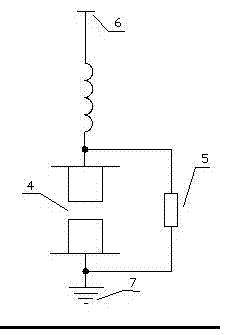

[0022] The insulating sheet of the mechanical horn plated with resistive film, its composition includes: carbon oil resistor: 1, the insulating sheet 3 is subjected to via hole 2 copper-clad treatment, and the carbon oil-coated resistive film realizes electrical connection on both sides, which is equivalent to connecting a resistor 5 in parallel at both ends of the insulating sheet, It plays the role of reducing arcing during the working process of the horn.

Embodiment 2

[0024] According to the mechanical horn insulation sheet plated resistance film described in embodiment 1, a resistor is connected in parallel at both ends of the metal contact of the mechanical electric horn to share the current value when part of the metal contact 4 is disconnected, so as to reduce contact arcing, Reduce the effect of metal contact ablation to improve the service life of mechanical and electronic horns.

Embodiment 3

[0026] According to the resistive film plating on the insulating sheet of the mechanical horn described in Embodiment 1, the insulating sheet and the arc-extinguishing resistor are integrated to simplify the process and reduce the cost to the greatest extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com