Technology adapted for magnesium alloy matrix surface mechanical zinc-and tin-plating composite coating

A composite coating, mechanical galvanizing technology, applied in metal material coating process, pressure inorganic powder coating, coating and other directions, can solve the problems of poor corrosion resistance of magnesium and magnesium alloy materials, and achieve poor corrosion resistance, Easy-to-control, simple-to-equip effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

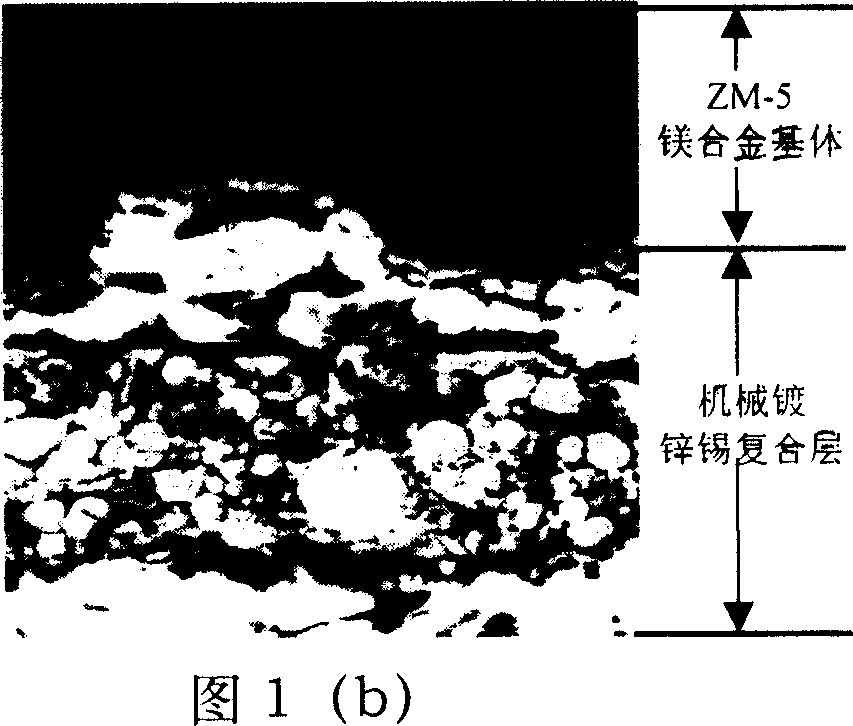

[0053] Embodiment 1 ZM-5 magnesium alloy mechanical galvanized tin composite coating

[0054] A, the ZM-5 magnesium alloy sample (4 samples, the total surface area is about 24cm 2 ) for pre-treatment, stand-by;

[0055] Oil removal is carried out in an aqueous solution composed of 10% sodium hydroxide and 5% sodium phosphate, the treatment temperature is room temperature, and the oil removal treatment time is 30s.

[0056] Etching is carried out in a dilute phosphoric acid solution with a concentration of 20%, the treatment temperature is room temperature, and the etching treatment time is 20s.

[0057] Activation Activation is carried out in an aqueous solution composed of 15% potassium pyrophosphate and 10% sodium carbonate, the treatment temperature is 80°C, and the activation treatment time is 20 minutes.

[0058] Zinc dipping is carried out in an aqueous solution composed of 50g / L zinc sulfate, 10g / L sodium carbonate, 6g / L sodium fluoride and 150g / L potassium pyrophosph...

Embodiment 2

[0066] Example 2 AZ91 magnesium alloy composite mechanical galvanized tin layer

[0067] A, the AZ91 magnesium alloy samples (4 samples, the total surface area is about 24cm 2 ) carry out the pretreatment of degreasing, etching, activation and galvanizing, stand-by; sample pretreatment is identical with embodiment 1.

[0068] B, preparation mechanical plating bath is identical with embodiment 1.

[0069] C, selecting the shock medium is the same as that in Example 1.

[0070] D. Add 4 AZ91 magnesium alloy samples, 50ml of mechanical plating solution, 50g of glass beads, and 6g of metal powder mixed uniformly with a mass ratio of 2:1 zinc powder and tin powder into the plating barrel. Adjust the rotation speed of the plating barrel to 90r / min, and start to implement mechanical plating.

[0071] Then add 2g of zinc-tin mixed powder every 15 minutes, repeat twice, and then carry out intensive impact for 15 minutes.

[0072] Finally, the AZ91 magnesium alloy sample was taken o...

Embodiment 3

[0074] Embodiment 3 MB60 magnesium alloy mechanical galvanized tin composite coating

[0075] A, the MB60 magnesium alloy samples (4 samples, the total surface area is about 24cm 2 ) to carry out the pre-treatment of degreasing, etching, activation and galvanizing, stand-by; the sample pre-treatment is the same as that of Example 1.

[0076] B, preparation basic plating solution is identical with embodiment 1.

[0077] C, selecting the shock medium is the same as that in Example 1.

[0078] D. Add 4 MB60 magnesium alloy samples, 50ml of basic plating solution, 50g of glass beads, and 6g of metal powder mixed uniformly with a mass ratio of 1:2 zinc powder and tin powder into the plating barrel. Adjust the rotational speed of the plating barrel to 90r / min, and begin to implement mechanical plating.

[0079] Then add 2g of zinc-tin mixed powder every 15 minutes, repeat twice, and then carry out intensive impact for 15 minutes.

[0080] Finally, the MB60 magnesium alloy sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com