Surface strengthening treatment method of neodymium-iron-boron permanent magnet and application of surface strengthening treatment method

A technology of surface strengthening and treatment method, applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc. and other problems, to achieve the effect of improving the surface state, good temperature and humidity resistance, and prolonging the time of neutral salt spray corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Another aspect of the embodiments of the present invention also provides a method for preparing a surface coating of an NdFeB permanent magnet, which includes:

[0049] Using the aforementioned surface strengthening treatment method to carry out surface strengthening treatment on the NdFeB permanent magnet;

[0050] And, applying a coating liquid to the surface of the NdFeB permanent magnet, so as to form a protective coating on the surface of the NdFeB permanent magnet.

[0051] In some more specific embodiments, the protective coating includes a ZnAl coating, but is not limited thereto.

[0052] In some more specific embodiments, the coating liquid includes inorganic metal powder, but is not limited thereto.

[0053] Further, the inorganic metal powder is nanoscale inorganic metal powder.

[0054] Further, the inorganic metal powder includes any one or a combination of two or more of alumina, manganese oxide, titanium dioxide, and cerium oxide, but is not limited th...

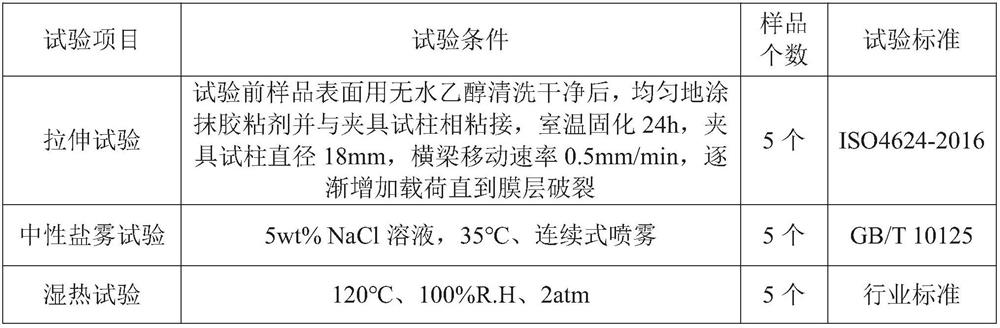

Embodiment 1

[0079] 1. Wire cutting process Φ15mm×10mm, 26mm×20mm×7mm (length×width×height) and 5mm×10mm×10mm (r inner × r outer × h) three kinds of NdFeB permanent magnets, and on the cylindrical grinding machine Polishing and cleaning;

[0080] 2. Surface strengthening treatment of NdFeB permanent magnets:

[0081] (1) The magnet after wire cutting is mechanically polished on a grinding machine;

[0082] (2) Place the NdFeB permanent magnet in the self-contained dust-removing sandblasting machine for surface roughening, the particle size of the quartz sand is 1mm, the air pressure is 0.5MPa, and the sandblasting time for one side is 3min;

[0083] (3) Etching the NdFeB permanent magnet obtained in step (2) in a strong alkaline solution, the solution composition: sodium hydroxide (industrial grade) 10g / L, trisodium phosphate (industrial grade) 45g / L, The rest is deionized water, the pH value is 11, the temperature is 80°C, the ultrasonic frequency is 60kHz, and the treatment time is 40m...

Embodiment 2

[0098] 1. Two specifications of NdFeB permanent magnets of Φ15mm×10mm and 26mm×20mm×7mm (length×width×height) are processed by wire cutting, and polished and cleaned on the cylindrical grinder;

[0099] 2. Surface strengthening treatment of NdFeB permanent magnets:

[0100] (1) The magnet after wire cutting is mechanically polished on a grinding machine;

[0101] (2) Place the NdFeB permanent magnet in the self-contained dust-removing sandblasting machine for surface roughening, the particle size of the quartz sand is 2mm, the air pressure is 0.5MPa, and the sandblasting time for one side is 3min;

[0102] (3) Etching the NdFeB permanent magnet obtained in step (2) in a strong alkaline solution, the solution composition: sodium hydroxide (industrial grade) 25g / L, trisodium phosphate (industrial grade) 50g / L, The rest is deionized water, the pH value is 13, the temperature is 100°C, the ultrasonic frequency is 60kHz, and the treatment time is 30min;

[0103] (4) Then immerse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com