Oxygen-consuming electrode and method for its production

A depolarization and electrode technology, applied in the direction of electrodes, battery electrodes, alkaline battery electrodes, etc., to achieve the effect of low ohmic voltage drop and small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

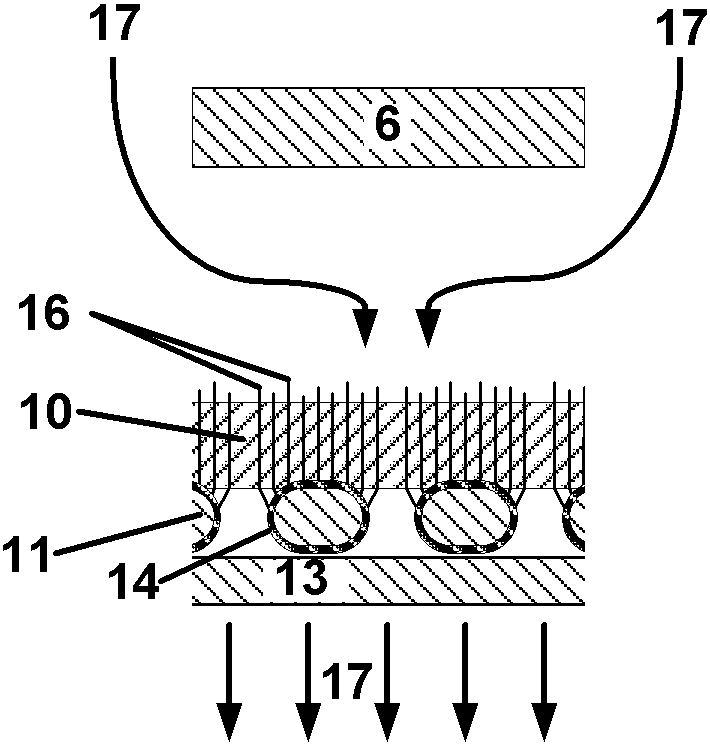

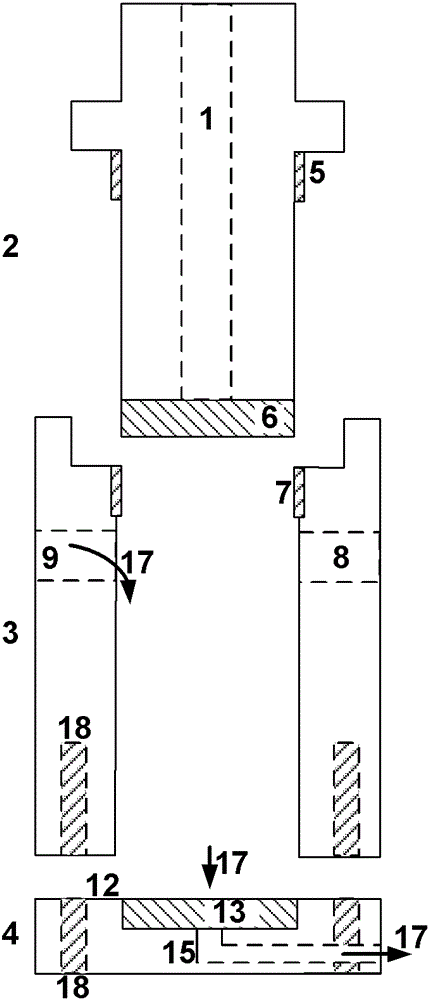

[0080] The starting material is nickel catenary (mesh size 500 μm, wire thickness 150 μm; thickness after rolling 120 μm) and 4 layers 70 μm thick and porosity 85% to 90% as current collector 1 which has been flattened 10 of three-dimensional expanded PTFE membranes.

[0081] First, the nickel mesh 1 was activated in 25% by weight sulfuric acid for 1 minute, and then washed away with water. Subsequently, the nickel mesh was clamped in the figure 1 Between the base 4 and the housing 3 of the manufacturing unit (2, 3, 4) shown in, there is a 10cm 2 ?? (36 mm in diameter) geometric electrode area in a sheet free of frit 13 and sealed in the process by flat silicone seals (not shown) each in The mesh has a thickness of 1 mm above and below. Introduce silver cyanide solution (36g / lAgCN, 60g / lKCN, 45g / lKCN 2 CO 3 ) until the silver anode 6 is immersed in said solution at the anode support 2. Close entrances and exits. The cathode contacts are formed with the mesh 1 by four ti...

Embodiment 2

[0089] Electrodes were prepared analogously to Example 1. However, from silver nitrate solutions with different compositions (0.1MAgNO 3 , 0.06MH 3 PO 4 ) and generate catalytically active silver structures by different configurations of current versus time. Deposition was achieved by 25 consecutive cycles of this protocol: 5 current pulses with a length of 60 ms and a waiting time between pulses of 1 s by applying a voltage of 60 V (producing a current of approximately 25 A), followed in each case by Deposition at 10A for 1s.

[0090] When the above current density is 4.0kA / m 2 The electrode attained a potential of -200 mV vs. NHE when operated as an oxygen depolarized cathode in a half-cell under conditions of . Silver content is about 350g / m 2 electrode area.

Embodiment 3

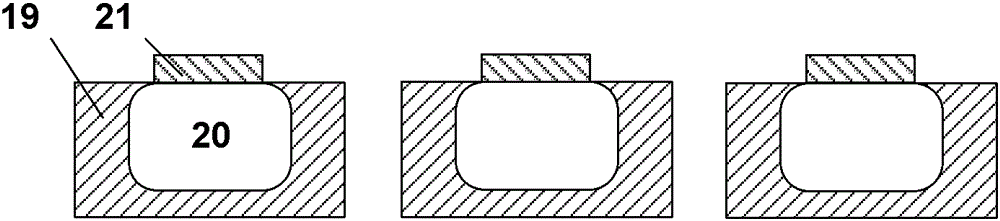

[0092] The catenary used for electrode manufacture was a titanium mesh 20 (mesh size 500 μm, wire thickness 150 μm) that had been flattened. The latter was masked on one side by an adhesive film and coated with a 2-pack solder resist 19 (PetersSD2444NB-M). The film was peeled off and excess resist was removed from the web using compressed air. After curing, remove resist residues on uncoated surfaces again with fine sandpaper (see image 3 ). The mesh was clamped in the fabrication unit as described in Example 1 for the silver-coated mesh (ie, no porous PTFE membrane). On a clean surface, a silver mesh 21 with a thickness of about 40 μm is made of silver cyanide solution (105g / lAgCN, 113g / lKCN, 60g / lK 2 CO 3 , 30g / lKOH) deposited at 0.5A for 300s. At the end of electrode fabrication, it is used in oxygen depolarized cathodes as a catenary that can be peeled from the titanium mesh since it does not adhere strongly to it. However, at the beginning it remained on the titani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com